Free Information - Tech Directions

Free Information - Tech Directions

Free Information - Tech Directions

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

free information free subscriptionSeptember 2008We make it easy for you to get what you need. This page can beused to request more information on products in this issue and tosubscribe or renew your subscription to techdirections. Simplyfax or mail this form to us or subscribe online. For links to suppliers, visit www.techdirections.com/buyersguide.html.Subscribe online: www.techdirections.com/html/subscription_request.htmFor more information from companies in this issue, simply check the appropriateboxes below, add your name and school address, and return this form.FREE INFORMATIONAdvertisersCompanyPage no.$ All Electronics Corp. ..............29$ Badger Graphic Sales, Inc. ..29$ The Cad Academy ...................2$ Chief Architect ...........................6$ M. L. Condon Co. ...................29$ Dassault Systemes .................32$ 80/20 Inc. .................................29$ Goodheart-WillcoxPublishers .................................19$ Kelvin ........................................29$ Leonard SafetyEquipment ................................33$ Olsen Safety Equipment .......29$ Satco Supply ............................29$ Seven CornersHardware, Inc. ...........................6$ Studica ......................................27$ <strong>Tech</strong> <strong>Directions</strong> Books &Media ..................................29, 31$ Test Equipment Depot ..........13$ Tormach ....................................25e-gallery$ All Electronics Corp. ..............23$ ETCAI Products ......................23$ Hobart Inst. of Welding<strong>Tech</strong>nology ...............................23$ Industrial Press........................23$ intelitek ......................................24$ jds Products .............................24$ Lab-Volt Systems ....................24$ Mastercam................................24$ NCCER ......................................24$ RealBooks ................................25$ Shopmaster ..............................25$ <strong>Tech</strong> <strong>Directions</strong> .......................25Product Central/<strong>Free</strong> for the Asking$ Adam Equipment ....................29$ Bernard WeldingEquipment ................................29$ Career SolutionsPublishing .................................27$ Ferguson Publishing. .............26$ Hearlihy .....................................28$ Lerner Publishing Group ......26$ Mastercam................................26$ Pitsco .........................................27$ Smith System ...........................27$ Software Kids ..........................26$ Wiha Tools ................................27$ Woodstock Int’l, Inc. ..............28FREE SUBSCRIPTIONTo be considered for a free subscription, fill out this section with your schooladdress, check the appropriate boxes below, and return this form.Your title: (check only one)(1) $ Administrator(2) $ Department Head/Chair(3) $ TeacherYour type of school:(check only one)(A) $ Fed./State/SchoolDistrict Headquarters(D) $ College/University(E) $ Community/Jr. College(F) $ Vocational/<strong>Tech</strong>nicalSchool(J) $ Sr. H.S. (9-12)(K) $ Jr.-Sr. H.S. (7-12, K-12)(L) $ Middle/Jr. H.S. (6-9, K-8)(M) $ Elementary (K-6)Check all subjects you teach orsupervise:(X) $ Aeronautics/Aviation(A) $ Agricultural <strong>Tech</strong>(5) $ Appliance Repair(I) $ Applied Math/English(B) $ Automotive (incl. AutoBody)(C) $ Bldg. Trades/Construction<strong>Tech</strong> (incl. HVAC&R)(F) $ CAD/Drafting/Design(V) $ Careers/<strong>Tech</strong>nical (incl.Vo-Ed, School-to-Work)(7) $ CNC/CAM/CIM/FMS(S) $ Communications(3) $ Computer <strong>Tech</strong>(L) $ Counseling &Assessment(G) $ Electricity(H) $ Electronics(1) $ Engineering/Pre-Engineering(K) $ Forge/Foundry(Y) $ History of <strong>Tech</strong>nology(J) $ Hydraulics/Pneumatics(E) $ <strong>Information</strong> <strong>Tech</strong>nology(M) $ Machine Shop(N) $ Manufacturing/Production(P) $ Metals(Q) $ Plastics(R) $ Power/Energy(incl. Diesel)(6) $ Robotics(8) $ Safety(D) $ Science/Applied Science(2) $ Small Engines(W) $ <strong>Tech</strong>nology Ed(4) $ <strong>Tech</strong> Prep(9) $ Transportation(T) $ Welding(U) $ WoodworkingThis card is from:(8) $ Personal copy(9) $ Pass-along copyPlease printName_______________________________________________________Title ___________________________ Phone No. ___________________(Opt.)School ______________________________________________________*School Address _____________________________________________City, State ___________________________________ Zip ____________E-mail ______________________________________________________$ I want to receive (or continue to receive) techdirections.$ I do not want to receive techdirections.$ I am retiring. Name of teacher filling your position:______________________________________________Subscribe online: www.techdirections.com/html/subscription_request.htmFAX: 734-975-2787Mail: <strong>Tech</strong> <strong>Directions</strong> RequestsP.O. Box 8623Ann Arbor, MI 48107-8623E-mail address information is for inhouse use only and will not be shared or sold! • Incomplete forms will not be processed. • Publisher reserves the right to determine free qualifications.*Your school address must be used to receive techdirections for free. If you wish to receive your magazine at home, please visit us at www.techdirections.com and click on subscribe for thepaid subscription form.www.techdirections.com REPLY/SUBSCRIBE 3

technically speakingSusanne Peckham susanne@techdirections.comI recently read a great article authored by thelieutenant governor of Massachusetts. As a guestcolumnist for The Metrowest Daily, Timothy Murray wroteto inform the public about the benefits and successesof his state’s technical schools, which he describes as“high schools where admission is competitive, wheremastery is the standard not just time spent in class,where community and business partnerships augmentschool budgets, and where students are prepared for thechallenges of the global economy.”Murray goes on to describe enrollment numbersthat attest to a growing interest in tech schools—forexample, 821 students applying for 400 spots at Worcester<strong>Tech</strong>nical High. In recent years, Massachusetts techschools have seen roughly twice as many applications asavailable openings. “Students and their families are votingwith their feet—beating a path to the vocational-technicalschool yards,” Murray says.According to school superintendents around thestate, parents and students are realizing that today’stech school model expands, rather than limits, students’career opportunities. Parents and students “see a highlystructured, disciplined, and safe environment that helpsstudents excel,” Murray writes.Having worked with and toured many tech schools,Murray has come to see them as “dynamic places, wherestudents are engaged and inspired. Learning is applied,not theoretical, helping students see the relevance oftheir course and project work to their future success.”He goes on to write: “Education experts say publicschools today must teach students 21st-century skills toprepare them to compete in aglobal economy. Beyond thebasic academics, 21st-centuryskills include the abilityto work in teams, to thinkcritically and solve problems,to use technology, and beable to communicate effectively. . . . These skills are mosteffectively taught through project-based learning, withclear accountability standards and opportunities forstudents to hone their leadership and communicationskills. That is the vocational model in Massachusetts.”Murray calls for expanding the availability oftechnical education so that “all qualified studentshave the opportunity to pursue their passion.” Afternoting progress in recent years with strengthening theacademic components of technical programs, he closesby writing: “Policy makers need to take note, however,that enhancing academics must not come at the expenseof student time spent developing their skills or trade.Academics are vital, but equally important is learninghow to work on a team, in a real-world environment, withtechnology relevant to today’s economy. . . . That’s thecore of the vocational experience, and it’s a lesson thevocational schools could teach some of our traditionalhigh schools.”A Prakken Publications MagazineDigital <strong>Tech</strong> <strong>Directions</strong> (ISSN 1940-3100) is published monthly,except June and July, by Prakken Publications, Inc., 832 PhoenixDrive, Ann Arbor, MI 48108. Executive, editorial, and advertisingoffices are at PO Box 8623, Ann Arbor, MI 48107-8623, telephone734-975-2800; fax 734-975-2787. Vol. 68, No. 2.Board of Directors Turalee A. Barlow, George F. Kennedy,Janice E. Knope , Susanne PeckhamPublisher George F. KennedyAssistant Publisher & Business Mgr. Turalee A. Barlow,tbarlow@techdirections.comManaging Editor Susanne Peckham, susanne@techdirections.comAssociate Editor Pam Moore, pam@techdirections.comArt, Design, and Production Manager Sharon K. MillerAdvertising Sales RepresentativesTonya L. White, 800-530-9673 x209, tonya@techdirections.comMatt Knope, 800-530-9673 x200, matt@techdirections.comRichard J. Alden, 603-899-3010, fax: 603-899-2343. rjalden@techdirections.comDavid A. Yetman, 603-878-4705;dyetman@techdirections.comSubscription Dept. Vanessa Revelli, vanessa@techdirections.com, 800-530-9673 x217EDITORIAL ADVISORY BOARDMichael Fitzgerald, <strong>Tech</strong>nology Education Specialist, Offi ce ofCareer and <strong>Tech</strong>nical Education, Indiana Dept. of Education,Indianapolis, INPaul Koontz, President, Denford Inc., Medina, OHEd Prevatt, School Specialist, National Center for ConstructionEducation and Research, Gainesville, FLJohn Roccanova, <strong>Tech</strong>nology Education, Webutuck Central School,Amenia, NYMark Schwendau, <strong>Tech</strong>nology Instructor, Kishwaukee College,Malta, ILKendall N. Starkweater, Executive Director,International <strong>Tech</strong>nologyEducation Association, Reston, VAPEER REVIEW BOARDGregory G. Belcher, Ph.D., Asst. Professor, <strong>Tech</strong>nical TeacherEducation, Pittsburg State University, KSDaniel M. Claiborne, Ph.D., Chair, Department of Industrial andEngineering <strong>Tech</strong>nology, Murray State University, KYSam Cotton, Ph.D., Asst. Professor, Ball State University, Muncie,INRonald F. Gonzales, Ph.D., ASE, Program Chair, <strong>Tech</strong>nology TeacherEducation Professor, Brigham Young University, UTClarke Homoly, Assoc. Professor, Dept. of Aviation, University ofCentral Missouri, WarrensburgRobert T. Howell, Ph.D., Asst. Professor, <strong>Tech</strong>nology Studies, FortHays State University, KSRobert D. Mordini, Ed.D., Asst. Professor, <strong>Tech</strong>nology Studies, FortHays State University, KSRichard Phillips, Ed.D., Division Chair, <strong>Tech</strong>nologies Division,Mountain Empire Community College, VAJoseph Scarcella, Ph.D., Professor of Education, California StateUniversity, San BernadinoMark S. Schwendau, M.S., <strong>Tech</strong>nology Instructor, KishwaukeeCollege, Malta, ILBert Siebold, Ph.D., Professor, Department of Industrial & Engineering<strong>Tech</strong>nology, Murray State University, KYChris Zirkle, Ph.D., Asst. Professor, College of Education, Ohio StateUniversity, Columbus, OHSubscriptions: individuals: $30 per year; $55 two years; Canadianand foreign: add $10 per year. Canadian GST #R126213487. Singlecopies $3. Group rate for students in teacher-training insti-tutionsavailable upon request.Periodicals postage paid at Ann Arbor, MI, and additional mailingoffi ces. Printed in U.S.A.POSTMASTER: Please send change of address information to <strong>Tech</strong><strong>Directions</strong>, PO Box 8623, Ann Arbor, MI 48107-8623.Manuscripts should be addressed to: Editor, <strong>Tech</strong> <strong>Directions</strong>, PO Box8623, Ann Arbor, MI 48107-8623. Manuscripts become propertyof <strong>Tech</strong> <strong>Directions</strong> upon letter of acceptance to author and signedcopyright release form. Payment made on publication. Electroniccopies of back issues available from ProQuest <strong>Information</strong> andLearning, www.il.proquest.com. Microform copies available fromNAPC, www.napubco.com©2008 by Prakken Publications, Inc.4 techdirections ◆ SEPTEMBER 2008

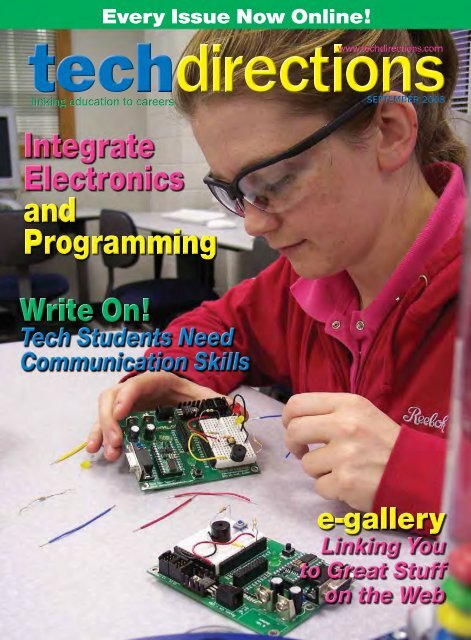

contentsSeptember 2008Vol. 68, No. 2ELECTRONICS12Easy-to-Implement Project Integrates Basic Electronicsand Computer ProgrammingBy Richard Johnson and Ray ShackelfordComputer programming and basic electronics are oftenconsidered two separate entities and consequently often taughtas completely separate subjects. But here, using a BASIC Stampdevelopment board, students fabricate digital circuits, then usePBASIC to write program code that will control the circuits thatthey have built.COMMUNICATION17Not Just for English Classes—Writing SkillsEssential in <strong>Tech</strong> Ed TodayBy Peter WorleyA survey of educators from a variety offields indicates that writing belongs in allcourses and that all teachers need to takeresponsibility for including some sort ofwriting project in their classes.CAREER DIRECTIONS20Fluid Power <strong>Tech</strong>nician By Pam MooreEverything students need to know aboutcareers for fluid power technicians—wages, responsibilities, skills needed,career advancement possibilities, andmore.INFORMATION TECHNOLOGY22High <strong>Tech</strong> High School Wins School Web Siteof the MonthSPECIAL FEATURE23page 12e-galleryMake classroom and lab purchases easier by referringto <strong>Tech</strong> <strong>Directions</strong>’ gallery of leading companiesavailable on the Web.COLUMNS4 <strong>Tech</strong>nically SpeakingSusanne Peckham7 Direct from WashingtonAnne C. Lewis8 The Report Susanne Peckham9 Mastering ComputersReid Goldsborough10 <strong>Tech</strong>nology’s PastDennis Karwatka11 <strong>Tech</strong>nology TodayAlan Pierce26 Product Central28 <strong>Free</strong> for the Asking30 More than Funpage 22About the cover: A student fabricates a digital circuit that will eventually becontrolled by student-written PBASIC program code. (See page 12.) Photocourtesy of Richard Johnson and Ray Shackelford. Cover design by SharonK. Miller.www.techdirections.com CONTENTS 5

New this month attechdirections.comProject of the MonthKatapultosHeads up! This technology project increasesmath, science, and technology correlations withinthe classroom while giving students a fun way tocollect and apply measurement data. This monthonly, price reduced to $4.95. Save $2!www.techdirections.com/proj_katapult.htmlNew ProjectBasic Electronics and Computer Programming ProjectStudents build simple electronics projects using a BASIC Stamp developmentboard and then write program code to control the circuits they have built.Includes four student projects, culminating in a door bell circuit. (Requirespurchase of development board.) www.techdirections.com/projectsE.htmlProductof the MonthExploring Solar EnergySeriesEasy-to-understand booksexplain solar energy and providestep-by-step activitiesthat apply solar energy principles.This month only, buyboth for $19.95, $9.95 off thelist price! www.techdirections.com/solar.html6 techdirections ◆ SEPTEMBER 2008

direct from washingtonNew CTE ReportDespite fears about career andtechnical education (CTE) beingsqueezed out of the high school curriculum,overall student participationdid not change measurably between1990 and 2005. What changes thathave occurred probably dealt morewith the quality and focus than withenrollment, areas not covered in anew statistical report on vocationaleducation from the National Centerfor Education Statistics (NCES).In New York City, for example,Mayor Michael Bloomberg has announcedthat the city may open upto four new career schools, presumablyto make an end run around traditionalvocational schools that havea poor academic record. The mayorsaid earlier this year that “college isnot for everyone, but education is,”and his takeover of the city’s publicschool system has jolted business asusual in the nation’s largest schoolsystem, putting much more emphasison accountability for studentprogress. The city has 21 vocationalschools, but almost half (47 percent)are ranked C or less on student progressreports. Many of the newly createdsmall schools in New York Cityhave a career focus, and altogetherthe district offers more than 280vocational programs in regular orseparate schools.The NCES report gives a nationalpicture of the CTE status. About 88percent of public high schools offeredoccupational programs, withhalf of them having access to anarea CTE school for courses. In the15-year period studied, the averagenumber of total CTE creditsand occupational credits earned bypublic high school graduates didnot change. They totaled about fourcredits for CTE and three credits foroccupational courses. In contrast,the number of credential-seekingundergraduates majoring in careerfields increased by about one-halfwww.techdirections.comAnne C. Lewisanneclewis@earthlink.netmillion students, although theirproportion of the overall enrollmentdecreased.For the rest of this item, visitwww.techdirections.com/w091.html.Plans for Educationfrom Politicians and OthersThe link between education andthe economy barely goes past rhetoricin the two presidential campaigncamps. While both candidates saythey will invest in education to keepthe economy moving, they almost ignoreworkforce quality or workforceadaptation issues.Only Sen. John McCain, theRepublican candidate, mentionsthe role of community colleges inworkforce development. Sen. BarackObama, the Democratic candidate,calls for expanding alternative pathsto high school graduation that includeapprenticeships and environmentalcorps, and he emphasizesimprovements in math and scienceteaching.Left out of their individual platformsis any mention of improvementsor changes to the WorkforceInvestment Act or an emphasis oncareer pathways that respond tochanging needs of the workforce.Some ideas for a national focus atleast came from two outside groupsthat joined forces to push a policystatement through the AFL-CIO executivecouncil. The American Federationof Teachers and the InternationalAssociation of Machinists andAerospace Workers (IAM) developeda policy statement, adopted by theAFL-CIO, for training the next generationof skilled workers. Its majorpoints include:• Encouraging skill developmentand education in high-need sectorssuch as infrastructure, defense, greentechnologies, aerospace, renewableenergy, education, and health carethrough state and federal financialaid programs.• Supporting new high-tech educationand training institutes in eachstate to help set the standard of 21stcenturyexcellence and innovation inworkforce development.For the rest of this item, visitwww.techdirections.com/w092.html.Expanding WorkforceDevelopment PartnershipsA year ago, major foundations inthe United States, joined by businesses,government, and nonprofit agencies,met to launch the National Fundfor Workforce Solutions, pledging toraise $50 million to expand promisingworkforce development partnershipsin different communities. The backboneof the initiative will be intermediaryorganizations that will organizeregional funding cooperatives.The idea is built on the experiencesof several foundations involved inworkforce development for a decadeor more. These include the Annie E.Casey Foundation and its Jobs Initiativein six cities, the Boston Foundation,and the Ford and RockefellerFoundations.As described in a brief historyof this initiative, these foundationscalled together 75 leaders in theworkforce development field in 2005to discuss the issues and make recommendationson how to create localcollaborations. Out of that meetingcame new efforts in Baltimore,San Francisco, Austin, Pennsylvania,Rhode Island, and New York City.The U.S. Department of Laborand other foundations have joinedthe initiative, and over the next fiveyears the National Fund will support30 to 40 existing and new fundingpartnerships in local communities.For the rest of this item, visitwww.techdirections.com/w093.html.Editor’s note: Due to rising paperand postage costs, we’ve placedportions of this column on our website. We welcome your reactions.Anne Lewis, one of the country’smost respected writers on educationpolicy, works in the Washington, DC,area.WASHINGTON 7

the news reportMastercam Announces“Innovator of the Future”WinnerCNC Software, developer ofMastercam CAD/CAM software, hasannounced the winner of its Innovatorof the Future competition forthe 2007-2008 school year: BernieSievers, an advanced manufacturingstudent at Vincennes (IN) University.The competition aims to introducestudents to real-world manufacturingby asking them to produce a specificpart, to be judged by a representativeof the manufacturing industry.The 2007-2008 competition requiredstudents to design and cut asteering wheel. Students also had tosubmit a written description of thepart, explain the inspiration for thedesign, and list materials used.The judge was Boyd Coddington,known by many people from thepopular TLC show American HotRod. As it turns out, Bernie Sieversis a racecar enthusiast. His steeringwheel featured holes along bothtop and bottom that Coddington feltadded sleek racing styling.The runner-up was Kenyoj Burrell,a student at Eastern Arizona College,in Thatcher. His design integratedesthetics and ergonomics in hissteering wheel. Alex Beranek andJordan Hinkson, students at KenmoreMiddle School, Arlington, VA, took anhonorable mention with their biohazardsymbol steering wheel.Tiger Woods LearningCenter EmbracesEngineering ChallengesIf the Tiger Woods Learning Center(TWLC) is an accurate barometer,high school students’ interest inengineering is on the rise.Student in Orange, Los Angeles,and Riverside, CA, counties apply toparticipate in activities at the TWLC,including Synergistic Suites for thosewho want to explore digital manufacturing,multimedia, aerospace rock-Susanne Peckhamsusanne@techdirections.cometry, and engineering. TWLC focuseson career exploration in science,technology, engineering, and mathematics.Three hundred studentsparticipate each week.Participating students learnabout career possibilities and theimportance of teamwork. At the endof each session, students preparepresentations for their classmatesand parents, giving them a chance toshowcase the skills and techniquesthey’ve acquired at the center.Winners Announcedfor 2008 Adobe SchoolInnovation AwardsAdobe Systems Incorporated hasannounced the winners of the 2008Adobe School Innovation Awards.The awards program honors theinnovative work of high school studentsin the U.S. and Canada. Withthe theme “My Community—MyPlanet—My 21st Century,” studentssubmitted more than 300 projectsin three categories: web design anddevelopment; film and video; andgraphic and print design.The best of the best award, for theoutstanding overall submission, wentto Macy Sarchet, Phillip David Mellon,and Dillian Neiman from Gregory-PortlandHigh School in Portland,TX, for “Seagrass—My Community.”Winning entries in the three categorieswere also recognized. In theGraphic and Print Design categorythe winner was Nicholas Callahan,Watauga High School, Boone, NC, for“Stop Pollution.” In the Web Designand Development category, the winnerswere Tony Guglielmi, JacobBowen, Kevin Matteson, Jon Wilber,and Sam Morgan, Pickerington (OH)High School North for “The Environmentand You.” In the Film and Videocategory, the winners were RichardYeager, Kourtney Bryant, Craig Austin,and Chris Deig from F. J. ReitzHigh School, Evansville, IN, for “1937:Evansville’s Great Flood.”Winning entries were recognizedat the National Education ComputingConference (NECC) in San Antonio,TX, in early July. They can be viewedat www.adobe.com/education/community/k12/gallery/swf/index.html.Winners were selected by a panelof industry judges based on theiroriginality and effectiveness in communicatingproject objectives.The best of the best winner, plusa chaperone, received a trip to SanAntonio to attend the awards breakfast.Category winners received a$1,500 cash prize, a copy of AdobeCreative Suite 3 Master Collection,and a Lenovo laptop from contestsponsor Lenovo.Adobe will continue the AdobeSchool Innovation Award Program forthe 2008/2009 school year, reopeningthe competition this fall. Visit http://www.adobe.com/education/solutions/k12/awards/for information.South Dakota GrantsBoost CTE CurriculumThe South Dakota Department ofEducation is upping its support forcareer and technical education (CTE)by issuing a total of $1.5 million to37 schools and educational cooperativesto support 50 CTE projects duringthe 2008-2009 school year. Thefunded programs include a hands-oncurriculum in science, technology,engineering, and mathematics.The department had receivedmore than $3 million in requests forthe grants.EventsSept. 10-12. Spray Finishing Workshop.Owens Community College. Toledo,OH. www.owens.edu/workforce_cs/seminars.html.Oct. 13-17. Careers in ConstructionWeek. National Center for ConstructionEducation and Research. www.nccer.org.Oct. 15-17. Canadian Society for Trainingand Development. Toronto, ON.www.cstd.ca/conference/index.html.Oct 22-25. National Career PathwaysNetwork Conference. Cincinnati, OH.www.ncpn.info.Susanne Peckham is managing editorof <strong>Tech</strong> <strong>Directions</strong>.8 techdirections ◆ SEPTEMBER 2008

mastering computersIs Your Computer Keyboard Making You Sick?If you pay too much attention toall the TV commercials for antibacterialsoaps, wipes, lotions, and sprays,it can be difficult not to feel paranoidabout all the germs out therethat can get you. Now there’s a newthreat, or at least a newly publicizedthreat, to worry about.Your computer’s keyboard may beharboring the kinds of bugs that cancause a nasty case of food poisoning.This is according to new researchby the London-based consumergroup Which? (www.which.co.uk). Inswabbing 33 keyboards in its office,it found that 4 were home to enoughbacteria to be potential health hazards.One harbored 5 times moregerms than one of the office’s toiletseats and 150 times more than thelevel the group considers safe, akeyboard that was so badly contaminatedthat it had to be trashed.Most of the group’s keyboards,and by implication most keyboardsin use today, aren’t harboring harmfullevels of E.coli, staphylococcusaureus, and other nasties. But isyours—or are the ones in your classroomor lab?There’s no economical way to testall the keyboards out there, but thereare commonsense ways to preventbacterial contamination or eliminateit if it exists.“The main cause of a bug-infestedkeyboard is eating at your desk,”according to a report released by thegroup. Crumbs and spills can windup on and between the keys. “Thefood deposits encourage the growthof millions of bacteria, which canlead to stomach bugs.”Another cause of bacterial contaminationof keyboards is thoughtto be poor personal hygiene, such asneglecting to wash your hands aftergoing to the bathroom. Yet anotherculprit: dust, which can trap moistureand enable any bacteria that’salready on the keyboard to flourish.www.techdirections.comReid Goldsboroughreidgold@comcast.netOne potential cause of a keyboardthat can make someone sick, notmentioned by the report, is sharing itamong other many users—as is typicalin school settings—one of whommay have inadvertently coughed orsneezed onto it or into his hand. Ifthe user has a cold or flu, the virusescould wind up on other users’ hands.The way to deal with a dirtykeyboard, short of one fit to be destroyedas a result of bad bathroomhygiene, is to simply clean it. If youdon’t regularly clean yours, you’renot alone.In conjunction with testing its ownkeyboards, Which? conducted an onlinesurvey of 4,000 computer usersand found that 46 percent of respondentssaid they clean their keyboardless than once a month, 22 percentonce a month, and 29 percent morethan once a month.Cleaning a mildly dirty keyboardis easy. To get rid of crumbs and dustthat may have found their way betweenthe keys, unplug the keyboard,turn it upside down over a trash can,and gently shake. To remove anyremaining debris, spray between thekeys with a can of compressed air,vacuum between the keys using ahandheld vacuum cleaner, or wipebetween the keys with a computerbrush or small paintbrush.To rid the surface of keys of commongrease and grime, with the keyboardunplugged, gently wipe it offwith a cloth slightly dampened withwater followed by a wipe with a drycloth. To rid the keys of bacteria andviruses, gently rub the keyboard withan alcohol wipe.To help prevent the fading of theletters and other markings on thekeys, don’t rub too hard and avoidhousehold cleaning liquids. Accordingto Which?, alcohol-free wipes aregentler on your keyboard but aren’tas effective in ridding it of germs.Aside from ergonomic or specialtykeyboards, most computerkeyboards are relatively inexpensive,and replacing one if sticky liquid(soda, sweetened coffee) is accidentallyspilled is relatively painless.Some people have reported that placinga keyboard in a dishwasher sometimesworks in such cases, providedyou allow plenty of time for it to dryafterward. Others have reported thatkeyboards stop working after beingcleaned in this way.If you use a computer in a dirty ordusty environment, you could try asoft, flexible keyboard “skin,” availablefrom computer supply outletsand more easily cleaned than keyboards.Finally, don’t forget to keep yourmouse clean as well. With both balltypeand optical mice, cleaning aidsinclude a moistened cloth, a moistenedcotton swab, an alcohol wipe,and compressed air.Reid Goldsborough is a syndicatedcolumnist and author of the bookStraight Talk About the <strong>Information</strong>Superhighway.Calling AllInventors!Don’t let your studentsmiss the 2008-2009techdirectionsInventors Competition!RESCUEME!Get theminvolvedindevisingcreativeuses fordiscardedmilk cartons!For details, visit www.techdirections.com/contest.html or see page 22 of theAugust issue of techdirections.Deadline: January 30, 2009MASTERING COMPUTERS 9

technology’s pastThomas Midgley and High-Octane GasolineIn the early part of the 20thcentury, Henry Ford’s inexpensive,popular Model Tautomobile putAmerica on wheels.But technologistswondered if therewas enough gasolineto support a rapidlyexpanding market.Thomas Midgley’s1921 development ofthe tetra-ethyl-lead(TEL) additivehelped refiners getmore energy from abarrel of crude oil.Midgley was bornin 1889 in BeaverFalls, PA. His fatherwas a businessmanwho invented a detachable tire rim.His mother also had a technicalbackground. Her father invented sawblades with removable teeth. As ahigh school baseball player, Midgleyresearched methods for throwing animproved curve ball.In 1911, Midgley graduated fromCornell University with a degree inmechanical engineering. Probablyinfluenced by his parents, he plannedto become a professional inventor.Midgley had a couple of employersbefore going to work for Charles Kettering(1876 –1958) in 1916. Ketteringinvented the self-starter in 1911 andestablished the Dayton EngineeringLaboratory Company to focus on automotiveresearch. One of Midgley’searly assignments was to analyzeengine knock.Engine knock is undesirable combustionthat damages engines andreduces automobile performance.Today, we would say that it’s relatedto the octane value of gasoline. Butin 1916, no one knew what causedengine knock. Midgley inventedsome ingenious equipment for anexperimental single-cylinder engine.Thomas Midgley in the early1940sDennis Karwatkad.karwat@morehead-st.eduHe replaced part of the cylinderwith transparent quartz so that hecould photographthe combustionprocess. This wasthe first step ina long journey ofresearching gasolineadditives.Over a five-yearperiod, Midgleyand his co-workerstested 33,000different chemicalcompounds. Successfinally cameLibrary of Congressin 1921 when theyprepared and testedthe first quantityof tetra-ethyl-lead.They found that TELeliminated engine knock when justone ounce of the liquid was addedto 10 gallons ofgasoline. Commonlycalled“ethyl gasoline,”the resultingmix first went onsale in Dayton in1923. Ketteringestimated thattwo gallons ofgasoline withTEL provided asmuch energy asthree gallons withoutTEL. Thismeant that overthe next 25 yearsTEL would savea billion barrelsof oil.Midgley’sinnovation alsoushered in theage of the highcompressionengine. In the late1920s, engines had compressionratios of about 4:1. TEL allowed highercompression ratios, which resuledMidgley’s test engine resembledthis 1929 variable-compressionlaboratory engine.in more power. Ethyl gasoline letmanufacturers make more powerfulengines for automobiles, airplanes,and all other applications in whichgasoline engines were used. The firstthree finishers in the 1924 Indianapolis500 race used ethyl gasoline.Midgley went on to develop syntheticrubber and refrigerants. Heserved as president of the AmericanChemical Society, received manyawards, and accumulated over 250patents. A pleasant, likeable person,he sponsored the education of17 engineering students in the late1930s. After retiring from laboratorywork, in 1940 Midgley became vicepresident of Ohio State University’sresearch foundation. Midgley contractedpolio, and complicationsfrom the disease caused his death in1944.We now know that lead in gasolineis an environmental hazard.Only lead-free gasoline can be usedin modern automobiles. No onewas aware of the seriousness of theproblems caused by lead until longafter Midgley’s death. But in its day,not only did TEL extend gasolinesupplies, it helped win World War II.Britain’s Air Chief LordArthur Tedder stated,“Three factors contributedto . . . victory: theskill and bravery of thepilots, the Rolls-RoyceMerlin engine, and theavailability of suitable[high octane] fuel.”ReferencesBernstein, Mark. (2002,Spring). Thomas Midgleyand the law of unintendedconsequences.American Heritage ofInvention and <strong>Tech</strong>nology,pp. 38–46.Kettering, Charles F.(1982). Kettering digest.Reflections Press.National cyclopedia ofAmerican biography,Vol. XXXIV. Ann Arbor,MI: University Microfilms.Dennis Karwatka is professoremeritus, Department of Industrial andEngineering <strong>Tech</strong>nology, Morehead(KY) State University.10 techdirections ◆ SEPTEMBER 2008

technology todayAlan Piercepierceaj@optonline.netRe-Recording the Past or Present into New Digital FormatsPhoto 1Communication technologiescontinue to evolve, and this evolution—whenit turns revolutionary—kills older technologies that onceperformed the same task. To preventequipment obsolescence from destroyingmemories stored in old film,someone in your family probablyhad old home movie films convertedinto VCR tapes. Since the VCR is nowbeing replaced by DVD players, gameconsoles, and digital video recorders(DVRs), your movies that were oncesaved as video tapes will soon needupdating into a digital format.Many of the technology pressconferences that I attend are chockfullof products designed to convertold media recordings into new digitalfiles and formats. This column looksat some of the devices specificallydesigned to transfer old or new recordingsinto digital formats that canbe archived, listened to, or viewedusing the latest technology.Do you have a large, yet almostforgotten record collection? If you doand want to convert each record intoan MP3 file, check out Audio-<strong>Tech</strong>nica’snew record turntable (Photo1). Vinyl-record conversion projectsonce required the expertise of thetechno elite. Audio-<strong>Tech</strong>nica hasnow automated vinyl-record rippinginto a simple plug, play, and transferprocess.Photo 2You just plug the Audio-<strong>Tech</strong>nicaAT-LP2D-USB stereo turntable intoyour computer, load the includedsoftware, and let your computer converteach vinyl record fromanalog music into a digitalfile. It will take you only afew minutes to chop thisfile into individually namedsongs and save them as MP3files to your computer’smusic library. You can alsouse the included software toclean up the noise found onold records or keep the backgroundsound for its nostalgic value.Pinnacle’s new Dazzle DVD Recorder(Photo 2) does for old andnew video recordings what Audio-<strong>Tech</strong>nica does for old vinyl records.It allows you to transfer videosfrom any video source, withanalog outputs, directly intoDVDs without the need touse complex, time-consumingvideo-editing software. It isthe perfect hardware-softwarecombination for convertingold VCR tapes or new videocamera recordings into DVDs.Dazzle uses your computer butperforms this process on thefly without ever copying youroriginal or converted files toyour computer’s hard drive.My old video camera records onsmall DV tapes. To turn these tapesinto DVDs was a major process. Iwould first run the video through thecamera to record its contents to mycomputer hard drive. Next, I wouldPhoto 3use video-editing software to convertthe file into a movie. Finally, I wouldleave my computer running mostof the night, converting my movieframe by frame into a formatted DVD.Dazzle performs a 1:1 conversion inreal time removing all of the abovehassle. It took 1 hour and 7-1/2 minutesto convert an analog video intoa finished formatted DVD. The onlydrawback: some voice-video synchronizationerrors may occur.What can you do to transfer oldor new video files without acomputer? Pinnacle’s VideoTransfer Press & Go is asmall (2-1/2" ✕ 4-3/4" ✕ 3/4")block with a click wheel atits center (Photo 3). To useit, simply plug in the videosource at one end and the videooutput at the other end. Turn onthe unit by pressing one edge of theclick wheel and click this location tochange and set the video quality ofyour final product. Pressing the oppositeedge of the click wheel startsand stops the process recording.When you stop a recording, it takessome time before the recording lightchanges from red to blue. During thistime, the unit finishes its 1:1 conversionand finalizes encoding the filefor playback.Recalling the Facts1. How does advancing technologyaffect the playability of oldermusic and video recordings?2. Do you think that CDs and DVDswill still be in use 10 years from now?Why?Alan Pierce, Ed.D., CSIT, is a technologyeducation consultant. Visitwww.technologytoday.us for pastcolumns and teacher resources.www.techdirections.comTECHNOLOGY TODAY 11

A Peer-Reviewed ArticleEasy-to-Implement ProjectIntegrates Basic Electronicsand Computer ProgrammingBy Richard Johnson and Ray Shackelfordrjohnson@bsu.edu; rshackelford@bsu.eduTHE activities described inthis article give studentsexcellent experience withboth computer programmingand basic electronics.During the activities, studentswill work in small groups, using aBASIC Stamp development board tofabricate digital circuits and PBASICto write program code that will controlthe circuits they have built. Theactivity helps bridge the gap betweenprogramming and building electroniccircuits that control other devices.IntroductionComputer programming and basicelectronics are often considered twoseparate entities and consequentlyoften taught as completely separatesubjects. In the 1940s and 1950s,computer programming focused onmathematical formulas using theFORTRAN computer language andbusiness information processingusing the COBOL computer language.As computer-controlled hardwareevolved, it was generally limited tomachines directly connected to computerslike printers, storage devices,and display devices.Likewise, early electronic deviceslike radios, televisions, and furnacethermostats were often manuallycontrolled by a person turning adial to change the channel or temperature.However, in the past 10to 20 years designers have startedRichard Johnson is an assistantprofessor and Ray Shackelford is aprofessor, Department of <strong>Tech</strong>nology,Ball State University, Muncie, IN.to include programmablecomponentsor circuits in many oftoday’s electronicsdevices. Today, programmableelectronicdevices include coffeepots, video recorders,microwave ovens,garage door openers,HVAC thermostats, andtelephones.In the industrialsector, the process ofdeveloping electronicdevices and computerprogrammablecontrols is often combinedinto one designproblem. Recently,more people are writing computerprograms of some type. But, few ofthe programs they write have beendeveloped to directly control a pieceof hardware or other electronic device.Designing a computer program tosolve even a simple problem can bean exciting and challenging experience.Beginning programmers commonlymake the mistake of “jumping”into the problem by immediatelywriting computer code. This usuallyproves a big mistake. Designers anddevelopers of computer code mustclearly define and analyze the problembefore attempting to solve it.Good programmers start by analyzingthe problem and considering themost obvious and most significantactions that they need to take orhave occur. They then consider eachof these “big” actions by breakingthem down into smaller and moredetailed actions.After breaking the problem intosmaller, very simple actions, programmersbegin writing the programcode necessary to solve theidentified problems. This approachof breaking the problem down intosuccessively smaller actions is commonlycalled the top-down analysismethod.In an industrial environment, goodprogrammers write programs so thatothers can easily understand them.They include lots of comments intheir work and avoid tricky or obscureprogram coding techniques.Think of it this way: others shouldunderstand a good computer programwith little to no explanation.In a real-world setting, a goodcomputer program is just that—goodcode! The power of a microcontroller12 techdirections ◆ SEPTEMBER 2008

program lies in its ability to be linkedto another device or electronic circuitto control or analyze data fromthat device. Like the design of acomputer program, building an electroniccircuit to solve a problem canalso be very interesting and satisfying.Design of an electronic circuitor device requires the designer tounderstand the problem to be solvedand the hardware needed for a particularsolution. The designer mustthen visualize how the computerprogram, electronic circuit, anddevice to be controlled will functionas a unit. This process includes adetailed analysis of the circuit hardwareneeded, an understanding ofhow the hardware will be connected(wired together), knowledge of howthe hardware should react when theprogram runs, and, of course, thecost of the hardware, time, and laborneeded to produce it.The computer used in many oftoday’s smaller electronic devices isa small, thumb-size device called amicrocontroller. One of the simplestand commonly used programmablecontrollers used for educationalpurposes is the BASICStamp microcontrollerproduced and distributedby Parallax, Inc. (The BASICStamp gets its name fromits small, postage stampsize.) Because of the easeof programming it, the BA-SIC Stamp allows everyonefrom students to engineersto quickly program a microcontrollerusing powerful input/outputcommands andto make compatible connectionsto other electronic devices.(See Photo 1.) Wheninterfaced with peripheral devices,the microcontroller becomes a powerfultool for solving both simple andadvanced programming and industrialcontrol problems.To facilitate introducing theuse of microcontrollers like BASICStamp into the curriculum, Parallaxcreated a free resource calledParallax’s Stamps in Class. Stampsin Class and tutorials address theneeds of secondary students andsupport learning experiences rangingfrom beginning analog devicesPhoto 1to advanced robotics and industrialprocess control.BASIC Stamp is generally usedwith a development board, eitherinserted on a Board of Educationor integrated directly onto a BASICStamp HomeWork Board (Photo 1).BASIC Stamp, a development board,and PC software in combinationform the foundation for BASIC Stampmicrocontroller applications. BASICStamp Editor is PC software usedto create programs with the PBASIClanguage, a special version of thewww.techdirections.com ELECTRONICS 13

Material/EquipmentQty.Description1 Board of Education with Basic Stamp 2 moduleor HomeWork Board from Parallax, Inc. (Serial or USB versions)1 Power supply: 9 V battery or 9V/300mA wall transformer2 LEDs, T1 3/4 with diffused lens (different colors if possible),Panasonic part #LN21RPHL or #LN31GPHL or equivalent2 470 Ω resistors, 1/8 W (color bands: yellow, violet, brown)commonly used BASIC computerlanguage. It has several commandsadded for hardware control functionsand a series of very thorough andeasy-to-follow support documentationand manuals. Don’t be fooled bythe name BASIC—this computer languageis very powerful and includesover 200 commands!The ChallengeUsing identified materials, studentswill work cooperatively insmall groups to program a microcontrollerand build electronic circuitsdesigned to analyze, test, and performprescribed functions.ObjectivesUpon the completion of this designbrief, students will be able to:1. Analyze and determine the necessaryparts/materials to fabricateidentified electronic circuits.2. Work cooperatively to performall required processes and activities.3. Effectively use math, science,and technological principles andtechniques to solve identified problems.4. Design and produce requiredcomputer codes and electronic circuitsto stated criteria.5. Effectively locate, assess, anddiscuss information.6. Determine and communicatehow computer code and electronicsensory devices and controls impacteveryday life, and provide examplesof current technological applications.Requirements/Limitations1. Students will work cooperativelyin groups of two or three.2. Students will write computerprograms for a microcontroller andbuild an electronic circuit which willthen interact with and control a lightemittingdiode (LED).3. Students will have three classperiods to complete all of the activities.4. Students may use only thematerials and equipment listed orsupplied by the teacher.Getting Startedwith PBASIC: How to Usethe BASIC Stamp EditorFollow the instructions below tocreate the first PBASIC microcontrollerprogram. To complete thistask, your group will need to successfully:1. Connect the BASIC Stamp to theprogramming PC.2. Load and use BASIC StampEditor.3. Write a demonstration programto determine what 6 ✕ 7 is.Refer to the Web and Print Resourcesfor detailed information andsample commands required to successfullycomplete these activities.Procedure1. Review all instructions andgather the required materials.2. Be sure that the most currentversion of BASIC Stamp Editor isinstalled on your programming computer.3. Connect the Board of Educationor HomeWork Board to the PC usinga serial or USB cable.4. Using a 9 V battery or walltransformer, connect power to theBoard of Education or HomeWorkBoard.5. Open the BASIC Stamp Editorprogram.6. Select “Run” and then “Identify”from the Editor Menu Bar and verifythat the board is communicatingwith the PC. Confirm the “Yes” messagein the Loopback and Echo boxes(See Fig. 1.)7. From the Editor Menu Bar, select“Directive,” then “Stamp,” then“BS2,” and click the “OK” button.8. Next, from the Editor Menu Barselect “Directive,” then “PBASIC,”then “Version 2.5,” and click the “OK”button. Note: Steps 7 and 8 insertcommands that tell the Editor whichmodel BASIC Stamp is being usedand what version of PBASIC is beingused.9. In the program area of BASICWeb Resourceswww.parallax.com—provides basic information on microcontrollers, developmentboards, and programming tools and referenceswww.iguanalabs.com/breadboard.htm and www.kpsec.freeuk.com/breadb.htm—provide helpful information on breadboards and their functionswww.answers.com/microcontroller—useful descriptions of microcontrollersand their functionswww.basicx.com—detailed information on microcontrollers from BasicXhttp://electronics.howstuffworks.com/led.htm—basic information on LEDswww.digikey.com and www.mouser.com—an extensive selection of electroniccomponentsPrint ResourcesEdwards, Scott. (2001). Programming and customizing the BASIC Stampcomputer (2nd ed.). New York: McGraw-Hill.Parallax, Inc. (2004). What’s a Microcontroller? Student guide. Rocklin,CA.Parallax, Inc. (2005). BASIC Stamp syntax and reference manual. Rocklin,CA. ISBN #1-928982-32-8.14 techdirections ◆ SEPTEMBER 2008

Fig. 1—Loopback andecho functionsFig. 2—Sample firstprogramFig. 3—Partial debugwindowStamp Editor, type the followingmicrocontroller program commands(Fig. 2.):DEBUG “Hello, here is your message”,CRDEBUG “What is 6 x 7”, CRDEBUG “The answer is: ”DEBUG DEC 6 * 7END10. From the Menu Bar, select“Run” and then “Run” again. The programshould execute and display awindow with the messages from theprogram. If an error window appears,check the program code for errorsand make the necessary modifications.Then run the program againuntil it functions properly.Observe what the program isdoing. Carefully compare the PBASICcommands in Fig. 2 to the displaywindow in Fig. 3. The DEBUG commandis a convenient and simple wayto display information from a PBASICprogram. The first two DEBUG commandswill display the quoted messageand then move the cursor to thebeginning of the next display line inthe DEBUG window (the “CR” at theend of a line meansCarriage Return). Thethird DEBUG commanddisplays a messagebut does notmove the cursor to anew line (no “CR” atthe end of this line).The fourth DEBUGcommand works differently—itdisplaysa number that is theresult of a calculation,in this case the number42 (the product of6 times 7). The “DEC”(short for “decimal”) option convertsthe number to base 10, a normalformat for humans to use but notnecessarily for computers.Advanced study question: Whatwould be displayed in place of thenumber 42 if the “DEC” option ofthe Debug command was not used?Within your group, discuss why thischange took place.Circuit Fabricationand TestingFollow the instructions belowto fabricate two electronic circuits.Then write a microcontroller programto control the circuit’s LED. Tocomplete this task, your group willneed to successfully:1. Fabricate a circuit to test theLED to make sure it works.2. Write a microcontroller programto control the circuit’s LED.3. Modify the test circuit so thatthe microcontroller program controlsthe LED.Refer to the Web and Print Resourcesfor detailed information andsample commands required to successfullycomplete these activities.Procedure1. Review all instructions andgather the required materials.2. Disconnect all power to thedevelopment board.3. Fabricate the circuit shownin Fig. 4 by inserting one end of a470 Ω resistor into a Vdd (5 V) socketand the other end into a row on thebreadboard. Then insert the anodeside of the LED into the same rowthat the resistor is in and insert thecathode side of the LED into a Vsssocket. Note: An LED has a positiveside (anode or Vdd) and negativeside (cathode or Vss), and that thenegative side is flat or has a notch onit. The resistor in this circuit limitsthe current flowing to the LED, keepingit from burning out.4. Connect the power to the BASICStamp and confirm that the LED isemitting light. Disconnect the powerto the BASIC Stamp. Obtain a replacementLED if necessary.5. To control theLED with the microcontrollerprogram,modify the circuitin Fig. 4 by movingthe Vdd end of the470 Ω resistor to theP11 socket on theleft side of the breadboardarea. Connectthe power to theBASIC Stamp.6. From the EditorMenu Bar selectVddVss“Directive,” then “Stamp,” then “BS2,”and click the “OK” button. Next, fromthe Menu Bar select “Directive,” then“PBASIC,” then “Version 2.5,” andclick the “OK” button.7. In the program area of BASICStamp Editor type the following microcontrollerprogram commands(Fig. 5):DOHIGH 11PAUSE 500LOW 11PAUSE 500LOOP8. Run the program and observethe LED activity. The DO/LOOP com-+470 ΩLED–Fig. 4—LEDtesting circuitwww.techdirections.com ELECTRONICS 15

HIGH 12 command after the HIGH 11command and add a LOW 12 afterthe LOW 11 command. Also changethe value after both PAUSE commandsto 500. (See Fig. 7.)6. Run the program and confirmthat both LEDs blink on and off atthe same time.Advanced study question: Howcould the program be modified sothe LED’s blink alternately, similarto railroad crossing warning lights?Make the necessary changes andmand will direct the program torepeat the commands between the“DO” and the “LOOP” statements aslong as the circuit has power andthe components are functioningproperly. Note: An “infinite” loop isoften considered poor code for manycomputer programs. However, in microcontrollerprograms that controlhardware the practice is common.9. Edit the original program bychanging the value after the PAUSEstatements from 500 to 250. Run themodified program and observe thechange in LED activity and compareit to the outcomes based on theoriginal code.10. Next, change the value in thePAUSE statements to 2000 and runthe program. Observe the change inLED activity and compare to previouschanges. Within your group, discusswhy these changes took place.11. Change the valueafter both PAUSE statementsback to 500.12. Save the PBASICprogram. From the MenuBar, select “File,” then“Save,” and name theprogram “LEDprogram1.bs2”. The program andcircuit will be needed forthe next activity.Fig. 5—LED control programSequencing LEDOutput DevicesUse the saved microcontrollerprogram and electronic circuit fromCircuit Fabrication and Testing asa starting point for this activity. Tocomplete this task your group willFig. 6—Add asecond LED tothe circuit470 Ωneed to successfully:1. Add a secondLED to the previouslyconstructed circuit.2. Modify themicrocontroller programto control bothLEDs.Procedure1. Review all instructionsand gatherthe required materials.2. Disconnect allpower to the developmentboard.3. Add a second LED and 470 Ωresistor to the circuit, referring toStep 3 from Circuit Fabrication andTesting. (Also, see Fig. 6.) Connectthe power to the BASIC Stamp andconfirm that the second LED is emittinglight.Vss470 ΩLEDVddVssLEDDisconnectthe powerto the BASICStamp. Obtaina replacementLED if necessary.4. Modifythe circuit inFig. 6 by movingthe Vddend of the second 470 Ω resistor tothe P12 socket on the left side of thebreadboard area. Connect the powerto the BASIC Stamp.5. Modify the program saved inCircuit Fabrication and Testing tocontrol the second LED by adding aFig. 7—Modified program to control two LEDsthen within your group, discuss whythe circuit/program functioned as itdid.ReferencesDe Jong, M. (2002). Interfacing microcomputers:Back to the future.The Physics Teacher 40, 360-367.Dietz, P. H. (2000). A pragmatic introductionto the art of electrical engineering.Hopkinton, MA.Ganssle, J. G. (2005, July). Turn a kidon to embedded systems. EmbeddedSystems Programming, 41-44.Hebel, M. (1999). Application of microcontrollersmanual. Carbondale,IL.An expanded version of this article,available for purchase, provides supplementaryinformation, ready-to-usestudent worksheets, and an additionalactivity: “Controlling Output Devicesand Sensors.” Please visit www.techdirections.com/projectsE.html.16 techdirections ◆ SEPTEMBER 2008

By Peter WorleyWORLEYPETER@aasd.k12.wi.usSCHOOL districts acrossthe nation have pursuedwriting across thecurriculum since theearly 1980s. But writingis something that many technologyeducators are just starting to implementin our classes. Some instructorshave shown a lot of apprehensionabout including writing in theircurriculum and daily assignments.also gotten some good advice onhow to incorporate writing into ourclasses. In this article, I share whatI’ve learned with others in the field.Table 1—Writing Across the Curriculum Survey:Communication Arts1. How do you feel about writing across the curriculum?2. Why do you feel writing is important in technology educationprograms?3. How do you think writing could be implemented in these classes?4. What should a teacher who does not teach writing expect fromtheir students?5. How should they, a non-communication arts teacher, grade theirwriting projects?sor to writing to learn (WTL) andwriting in the disciplines (WID). Thethree movements have continued togrow stronger throughout our educationalsystem. Romberger also states:“Writing across the curriculum acknowledgesthe differences in writingconventions across the disciplines,and believes students can best learnto write in their areas by practicingthose discipline-specific writingconventions.”The Surveys and ResultsI composed two surveys: one forthe Communication Arts departmentand one for the <strong>Tech</strong>nology Educationdepartment. I then surveyedthree teachers from each department.Please refer to Tables 1and 2.From my own perspective, as atechnology education instructor Iused to avoid writing projects, feelingthat writing was something forthe English department to teach. Inow realize that my students needto learn how to communicate withmany different people in a variety ofAfter taking a writing course lastsummer, I’ve grown very aware ofhow important writing is in all subjectareas, including technology education.I’ve conducted some researchand surveys that I think can help toconvince more technology teachersthat writing across the curriculumis important to help all our studentssucceed now and in the future. I’vePeter Worley is an automotiveinstructor, Appleton (WI) East HighSchool.Table 2—Writing Across the Curriculum Survey:<strong>Tech</strong>nology Education1. Do you feel writing is important in your technology educationclasses?2. If so why?3. Do you include writing projects in all your classes?4. What technology education classes do you teach?5. What type of writing projects do you do in your class?Background on WritingAcross the Curriculum“Writing across the curriculum isa pedagogical movement that beganin the 1980s,” Julia Romberger writes.This movement was the predeces-ways—verbal, written, and throughdemonstration.One of my biggest fears was notknowing how I could grade writingwww.techdirections.com COMMUNICATION 17

projects, when I felt uninformedregarding proper writing techniques.One of my survey questions to thecommunication arts teachers askedhow a non-communication artsteacher should grade a writing assignment.Pauline Moran best stated theanswer: “Teachers in all areas needto set the specific expectations forthe assignments they design. Forsomething in the technology educationarea, for example, you might beless concerned with format and thelevel of polish on something studentswrite. You may be looking moreat the content. Don’t feel that youneed to have an elaborate rubric foreverything they write. Focus on theone or two things that you feel aremost important in that assignment.You can even grade on a complete/incompletebasis and leave it at that.Sometimes a simple check, checkThe consensus of the educators I surveyedwas that writing belongs in all courses andthat all teachers need to step up to the plateand take responsibility for including writingin their class.plus, or check minus on something isa way to give basic feedback withoutadding to your workload.”As a teacher without a writingbackground, I find this one of theeasier approaches to easing into thewriting and grading part of our curriculum.Over the past few years, INeed Tools?Need Supplies?Buy your classroom needsfromadvertisers!They make yourfree subscriptionpossible!have added a few writing projectsin my classes. The consensus of theeducators I surveyed was that writingbelongs in all courses and that allteachers need to step up to the plateand take responsibility for includingwriting in their class.Students and parents might askwhy students need to write in atechnology education class. AaronWegand gave a good response: “Writingis an important communicationskill that encompasses much morethan technology education—it is alife skill. Being able to communicateeffectively is as important, if notmore important, than understandingcontent. <strong>Tech</strong>nical writing is evenmore important within the scope oftechnology education. We, as teachersand students, must be able toconvey our thoughts using technicalterms to describe an operation orprocess. As a teacher and a student,writing—especially having the abilityto write in a technical format—givesyou an advantage. Being familiarwith terminology that is used withina specific industry allows you toread as well as write in a format thatothers in your field will be able tounderstand and learn from.” This isan extremely strong statement andfood for thought for all technologyeducators.Nick German also provided goodcomments: “Understanding how toeffectively relay thoughts takes onmany formats. Students in our classesneed to effectively and efficientlypresent their ideas to others orally,visually, and in written form. Faceto-faceinteraction (oral) is strengthenedwhen we better understand theproper organization of thoughts. ThisInterviewees/SurveyRespondersAppleton East High School<strong>Tech</strong>nology Education InstructorsNick GermanPhil ReisweberAaron WegandCommunications Arts InstructorsPauline MoranCorey OtisEric Ward18 techdirections ◆ SEPTEMBER 2008

organization is strengthened throughwriting. Visual presentations are becomingmore familiar today thanks tothe Internet and mobile devices. Weoften forget the responsibility thatgoes along with this instant medium.One of the great aspects of writing isthe time it takes to convey somethingthat is well thought out. As with oralcommunicating, writing also helps usorganize visual presentations, suchas demonstrations. In technology education,being able to relay thoughtsthrough written language is crucial tosuccess in writing and understandingmanuals, data sheets, designs, ideas,and thoughts.”Getting Writinginto <strong>Tech</strong>nology CoursesWhat type of writing projectscan a technology education teacheruse? I have my student’s researchnew technologies in the automotivearea, then write a paragraph or twodescribing the new technology, andthen explain how the new technologyimproves safety, drivability, orcomfort. Some technology educationinstructors have short-answer questionsfor their lab work and bookassignments.Aaron Wegand’s students have differentassignments depending on theclasses: “In Graphic Arts and ScreenPrinting, the students must, in onetyped page, explain the processesused and the terms to describetheir work that was done during theproject. Within the Advanced Photographyclass, students periodicallywrite articles as if they were a photojournalistand describe the actionsor scenarios from a picture that theyhad taken and printed.”Other forms of writing projectsthat we can incorporate into technologyeducation classes are portfolios,job descriptions, and step-by-stepprocedures, such as steps for doinga brake job or oil change. Studentscan also do career research papersand resume writing. They might alsopratice writing an accident report,since most jobs in the technologyfield deal with operating dangerousequipment.As an instructor of technologyeducation, what should technologyeducators expect from students’ writing?Corey Otis says: “They shouldexpect their best efforts. Theyshould expect proper use of punctuationand proper spelling. Theyshould expect proper use of grammar.All teachers need to reinforcethese skills. They should expect adecent effort—more than a sentencefragment—and they should expectfull ideas.” Eric Ward adds: “Clear,concise, organized writing that isspecific to the purpose and/or task athand.”Final ThoughtsOur students are exposed toamazing amounts of informationthrough many forms of media—theInternet, satellite and cable TV, cellphones, for example. All educatorsneed to teach proper ways to communicatethrough various media, andit all starts in writing of one form oranother.As technology instructors weneed to get away from old attitudestoward writing instruction andprepare our students for the real,contemporary world they are aboutto face. We can only do this by implementingall forms of learning—writingbeing one of the most importantin a technology-oriented society.We need to leave the mentalitythat writing is only for English classesbehind. We need to look to thefuture and see how important writingis to survival in our ever-changingworld. If we each do even the smallestamount of writing in our classes,we help to effectively prepare ourstudents for their future.Writing should not be like a foreignlanguage. It should be supportedin all curriculum areas. As instructorswho want to help our studentssucceed, we need to move far awayfrom the attitude that writing doesnot belong in the technology educationcurriculum.ReferenceRomberger, Julia. Writing acrossthe curriculum: An introduction.Downloaded from www.owl.english.purdue.edu/owl/resource/671/011www.techdirections.com COMMUNICATION 19

career directionsFLUID POWER TECHNICIANFluid power technicians, sometimes called hydraulic andpneumatic technicians, work with equipment that utilizes thepressure of a liquid or gas in a closed container to transmit,multiply, or control power. Working under the supervision of anengineer or engineering staff, they assemble, install, maintain, andtest fluid power equipment.Depending on their specialization, fluid power technicians maybe required to perform tasks as simple as replacing a hose on amachine in a factory, or as complex as fully dismantling, repairing,and reassembling a machine, worth hundreds of thousands ofdollars, on components that are so small that a magnifying glass isneeded to inspect it for signs of wear or maladjustment.About three-fourths of the factories in this country usehydraulic or pneumatic power systems. These fluid power systemsrun over half the machines and equipment used in industry. Theyare also important in transportation vehicles, such as in automatictransmissions, power brakes, and power steering. In addition, fluidpower is used for tasks as varied as opening supermarket doorsand raising and lowering the flaps on airplane wings.PersonalCharacteristics● Mechanical ability● Analytical mindset● Ability to work well in a team● Ability to communicate easily, bothorally and in writing● Enjoy learning how machines and otherequipment work● Extremely good at mathematics andscience● Willingness to keep up with changes inthe industry● Enjoy challenges and troubleshootingproblems$$$$WagesEarnings vary accordingto geographic location andindustry. Graduates of a two-yearprogram can expect to start outat approximately $17 to $20 perhour. An estimated average wagefor fluid power techs with someexperience is in the mid-$40,000s.Those who move intoadvanced positions, such as fluidpower specialist or consultantcan expect to earn considerablymore.Most workers in this fieldreceive a full benefits package,including vacation days, sickleave, medical and life insurance,and a retirement plan.The JobThere are two types of fluid power systems: hydraulic andpneumatic. Hydraulic systems use “wet” fluids, such as oil andwater. Pneumatic systems use “dry” fluids, such as pressurizedair or other gases.In their work, technician analyze blueprints and specifications,set up various machines; make precision parts; and use sensitivemeasuring instruments to ensure parts are exact. They may alsobe responsible for determining whether a piece of equipment isworking properly by connecting the unit to test equipment thatmeasures fluid pressure, flow rates, and power loss due to frictionor wear.<strong>Tech</strong>nicians might help engineers to design, test, and install afluid power system for a one-of-a-kind machine that is used to boltfenders on automobiles. Others in private industry may work onfluid power equipment used in such products as trucks, airplanes,and automatic doors.Hydraulic and pneumatic technicians work in factories,laboratories, and offices. Most are employed by private industry.A few work in independent research centers. Those workingin private industry are often on the maintenance or researchand development staffs of companies that use fluid power inmanufacturing. Hydraulic and pneumatic technicians may alsowork as service representatives. These technicians often travelfrom plant to plant to service machines.20 techdirections ◆ SEPTEMBER 2008

TrainingHigh School• Mathematics• English• <strong>Tech</strong>nology education• Computer science• Drafting• Electronics• Physics• <strong>Tech</strong>nical or shop coursesPostsecondaryIn the past, you could become a fluidpower technician with only a high schooldiploma and some related technicalexperience. Today, however, most employersprefer to hire beginners who have somepostsecondary formal training in industrialtechnology, mechanics, or a related field inwhich fluid power is part of the curriculum.There are fewer than 25 trainingprograms that focus primarily on fluid powertechnology. Students in these programs takeclasses on very specialized topics, such asfluid power math, process and fabricationfundamentals, hydraulic components andaccessories, pneumatics components andcircuits, and advanced systems calculations.If it is not possible to attend a school withthis specialized training, training in a relatedfield, such as mechanical or electricaltechnology can provide adequate preparationfor employment.CertificationCertification is voluntary and offered throughthe Fluid Power Certification Board, administeredby the Fluid Power Society. Applicants must attendtwo or more days of classes and pass a threehour,written exam before receiving techniciancertification.Working ConditionsWorking conditions vary greatly depending ontype of job performed. Many technicians install,test, or repair equipment in factories and maywork alone or in pairs. Although their basic workweekis 35 to 40 hours, these technicians may berequired to work night or weekend shifts and overtimeon occasion. At times, they may be requiredto lift heavy parts and tools, handle greasy anddirty parts, and stand or lie in awkward positions.There is some danger of electric shocks, burns,and cuts. Those who work in laboratories or shopsare often part of a team that includes technicians,skilled workers, and engineers. Sometimes techniciansmust travel to inspect equipment in the field,and in many cases, they must deal with a widerange of customers and co-workers. Good communicationskills, both written and verbal, are crucial.Because fluid power techs often deal with avariety of problems and solutions, the work ischallenging and not repetitious. Many workers findtheir jobs highly enjoyable and satisfying.Employment OutlookBecause fluid power is used in somany different industries, the needfor technicians is growing rapidly.Currently, the demand for trainedworkers exceeds the supply. Inaddition, electrohydraulic and electropneumatictechnologies have opened up new markets, suchas active suspension on autos, and reestablishedolder markets, such as robotics. Therefore,the fluid power industry is expected to remainstrong through the next decade.Advancement OpportunitiesExperienced hydraulic and pneumatic technicians can becomesupervisors of maintenance crews in plants. They can also advance tocareers in sales, marketing, management, technical writing, or teaching.Where the Jobs Are● Aerospace industry● Construction industry● Agricultural industry● Machine tool and material handlingindustries● Fluid power also provides power forauxiliary systems on planes, ships, trains,and trucks.Professional AssociationsFluid Power Educational Foundationwww.fpef.orgInternational Fluid Power Societywww.ifps.orgNational Fluid Power Associationwww.nfpa.comwww.techdirections.com CAREER DIRECTIONS 21

High <strong>Tech</strong> High SchoolWins School Web Siteof the MonthTHE September Web Siteof the Month, www.hths.mcvsd.org, comes to usfrom the high school thatNewsweek magazine ranks7th in the nation: High <strong>Tech</strong> HighSchool (HTHS) in Lincroft, NJ. Accordingto Tanay Gavankar, the studentwho submitted the site: “Thissite was created from scratch (fromlayout design to all the coding) bystudents and is still currently maintainedsolely by students. It is W3Cvalidated and cross-browser compatible.With a clean and easy-to-navigatelayout, it is a stunning schoolweb site.” The staff of <strong>Tech</strong> <strong>Directions</strong>agrees.After selecting the site, we interviewedHTHS instructor Peter Borchardt,who teaches computer applicationsand digital electronics andadvises the students who createdand maintained the site. He told <strong>Tech</strong><strong>Directions</strong> that when the class of 2009started the school’s computer clubabout three years ago, it establishedas its first goal a complete redesignof the school’s web site. All membersof the club were assigned to workin groups or individually to make abasic template. Andrew Shum cameup with the current concept design.Using Shrum’s PhotoShop file, agroup of club members started codingthe new site. The team leaderswere Tanay Gavankar, Kevin Risden,and Joe Nugent.The beta of the site was first releasedin 2006. It was initially codedwith tables and was not XHTML orCSS standard compliant. During revisionsof the web site, students modifiedthe code design to comply withXHTML and CSS standards. Theyused Notepad, TextEdit, and AdobeDreamweaver Source Code editing(no WYSIWYG) to create the site.Students generate content forthe site from other students, teachers,administrators, and parents. Itincludes announcements of researchprizes, awards, and club achievements.As this issue of <strong>Tech</strong> <strong>Directions</strong>goes to press, featured on thesite are results ofthe most recentNew Jersey <strong>Tech</strong>nologyStudentsAssociationcompetition andHTHS students’first-place finishin Moody’s MegaMath Challenge.The site also hasa blog written bythe principal; analumni site withalumni news andblogs for eachclass; and accessto downloads ofthe school’s annualcalendar. Borchardtnoted thatstudents update the site as often asnecessary and at least once a week.When asked what problem-solvingstrategies students have usedin creating and maintaining the site,Borchardt replied, “The first problemwas to convert the layout to pure CSSfrom tables. This involved tediousrecoding and debugging of the code.Thankfully, server side includes areused (initially with SHTML, currentlywith PHP) to minimize the amountof work required to make site-widechanges.”None of the students involved increation of the site and its ongoingmaintenance have formal training inweb design. All knowledge of HTMLand CSS has been self-taught. Theyhave expanded the activities of theirextracurricular HTHS computer clubbeyond design and maintenance ofthe web site to include refurbishingPCs as a Microsoft Authorized Refurbisherand providing tech support tothe entire school.When asked how he and his studentsbenefit from having the site,Borchardt responded, “The web siteharbors a vast wealth of knowledge,ranging from basic announcementsand news to various downloadableforms for students and parents. Italso has background information onclubs, teachers, and so forth, for prospectiveand current students. ThePFA and Guidance each have theirrespective pages so that they can putwww.hths.mcvsd.orgwhatever information they desire onthe web. A resources page includesinformation on other sites to conductresearch and access the district-wide(MCVSD) Bulletin Board System.“Students working on this projectalso gain valuable work experiencedeveloping a standards-based website in groups, relying on each otherfor support and guidance. They learnhow to adhere to strict deadlines andethics that will further their academicand moral integrity in the long run.”Congratulations to the High <strong>Tech</strong>High School computer club for a jobwell done!22 techdirections ◆ SEPTEMBER 2008

e-galleryWelcome to techdirections’ portfolio of web sites from career/technical- and technology educationorientedmanufacturers and vendors. Check out these sites, where you’ll find descriptions and online orderinginformation on the products and services you need. Make classroom and departmental purchasing easier byreferring to these cutting-edge companies—and tell them techdirections sent you!Electronic Parts and Suppliesat Discount Priceswww.allelectronics.com is a unique source forlow-cost electronic parts and supplies. We stock awide array of products including components, smalldc motors,kits,magnets,tools,breadboardsand supplies.Wealso havea wide variety of industrial surplus, which includesmany unique one-of-a-kind items.Electricity and Electronics SoftwareComputer interaction makes learning electricityand electronicsexciting.Use withyour currenttextbooksand curriculum.Programsincludeactivitiesfor dc, ac, digital, diode, transistor, op amp, andpower supply circuits plus troubleshooting activitiesusing ohmmeters and voltmeters. Activities provideimmediate feedback and grading. Random variablevalues give variety to student learning experiences.Visit ETCAI Products at www.etcai.com for softwaredescriptions and to download free trial software.Call 800-308-0154 to request a free trial CD.Advanced Welding TrainingHobart Institute of Welding <strong>Tech</strong>nology’s staff of professionalsoffers youadvanced trainingin all major weldingprocesses. Servicesinclude skill-developmentcourses for thenew student, as wellas certifications andtechnical training forwelders looking toadvance their skills.Customized trainingfor your corporatewelding needs isavailable on- or off-site. A wide selection of world-class weldingtraining and educational materials are available for trainingor reference use. 1-800-332-9448, www.welding.org.<strong>Tech</strong>nical Books for Engineering, <strong>Tech</strong>nology,Manufacturing, and EducationThe Industrial Press web site is your source for Machinery’sHandbook and other technical references for CAD/CAM,CNC, Machine Shop/Tools, Metalworking, Maintenance, Math,Welding, and more. Look for the acclaimed Beginning and AdvancedAutoCAD 2009 Exercise Workbooks; CNC ProgrammingHandbook, 3rd Edition; Learning Mastercam Mill X2 Step byStep 2D; and <strong>Tech</strong>nicalShop Mathematics,3rd Edition. Formore information,visit www.industrialpress.com then navigateto AutoCAD, CAD/CAM/CIM, or CNC.www.techdirections.com E-GALLERY 23