Paper No: 200000 - International Conference of Agricultural ...

Paper No: 200000 - International Conference of Agricultural ...

Paper No: 200000 - International Conference of Agricultural ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

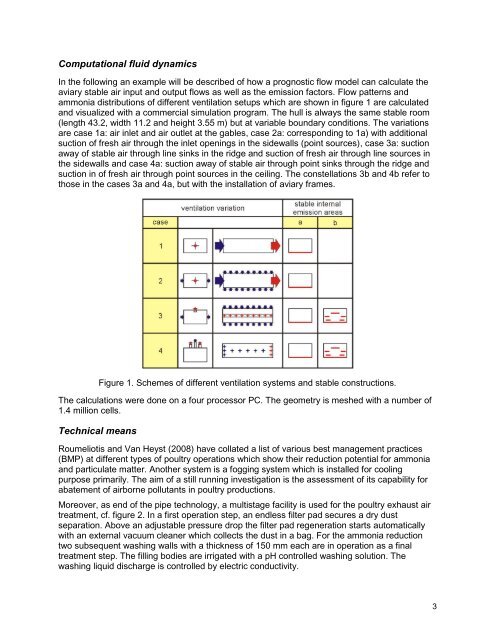

Computational fluid dynamicsIn the following an example will be described <strong>of</strong> how a prognostic flow model can calculate theaviary stable air input and output flows as well as the emission factors. Flow patterns andammonia distributions <strong>of</strong> different ventilation setups which are shown in figure 1 are calculatedand visualized with a commercial simulation program. The hull is always the same stable room(length 43.2, width 11.2 and height 3.55 m) but at variable boundary conditions. The variationsare case 1a: air inlet and air outlet at the gables, case 2a: corresponding to 1a) with additionalsuction <strong>of</strong> fresh air through the inlet openings in the sidewalls (point sources), case 3a: suctionaway <strong>of</strong> stable air through line sinks in the ridge and suction <strong>of</strong> fresh air through line sources inthe sidewalls and case 4a: suction away <strong>of</strong> stable air through point sinks through the ridge andsuction in <strong>of</strong> fresh air through point sources in the ceiling. The constellations 3b and 4b refer tothose in the cases 3a and 4a, but with the installation <strong>of</strong> aviary frames.Figure 1. Schemes <strong>of</strong> different ventilation systems and stable constructions.The calculations were done on a four processor PC. The geometry is meshed with a number <strong>of</strong>1.4 million cells.Technical meansRoumeliotis and Van Heyst (2008) have collated a list <strong>of</strong> various best management practices(BMP) at different types <strong>of</strong> poultry operations which show their reduction potential for ammoniaand particulate matter. Another system is a fogging system which is installed for coolingpurpose primarily. The aim <strong>of</strong> a still running investigation is the assessment <strong>of</strong> its capability forabatement <strong>of</strong> airborne pollutants in poultry productions.Moreover, as end <strong>of</strong> the pipe technology, a multistage facility is used for the poultry exhaust airtreatment, cf. figure 2. In a first operation step, an endless filter pad secures a dry dustseparation. Above an adjustable pressure drop the filter pad regeneration starts automaticallywith an external vacuum cleaner which collects the dust in a bag. For the ammonia reductiontwo subsequent washing walls with a thickness <strong>of</strong> 150 mm each are in operation as a finaltreatment step. The filling bodies are irrigated with a pH controlled washing solution. Thewashing liquid discharge is controlled by electric conductivity.3