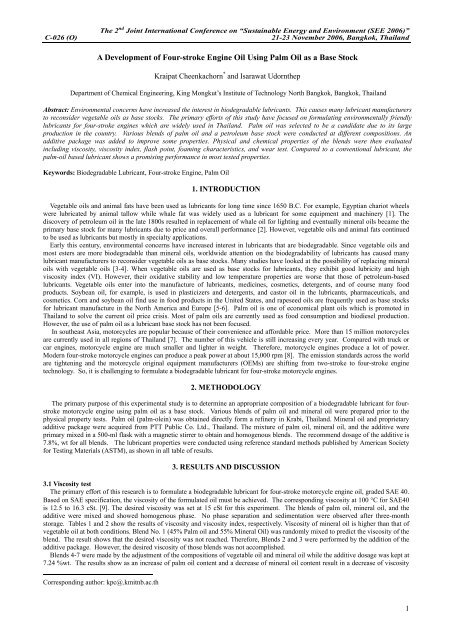

A Development of Four-stroke Engine Oil Using Palm Oil as a Base ...

A Development of Four-stroke Engine Oil Using Palm Oil as a Base ...

A Development of Four-stroke Engine Oil Using Palm Oil as a Base ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The 2 nd Joint International Conference on “Sustainable Energy and Environment (SEE 2006)”C-026 (O) 21-23 November 2006, Bangkok, ThailandA <strong>Development</strong> <strong>of</strong> <strong>Four</strong>-<strong>stroke</strong> <strong>Engine</strong> <strong>Oil</strong> <strong>Using</strong> <strong>Palm</strong> <strong>Oil</strong> <strong>as</strong> a B<strong>as</strong>e StockKraipat Cheenkachorn * and Isarawat UdornthepDepartment <strong>of</strong> Chemical <strong>Engine</strong>ering, King Mongkut’s Institute <strong>of</strong> Technology North Bangkok, Bangkok, ThailandAbstract: Environmental concerns have incre<strong>as</strong>ed the interest in biodegradable lubricants. This causes many lubricant manufacturersto reconsider vegetable oils <strong>as</strong> b<strong>as</strong>e stocks. The primary efforts <strong>of</strong> this study have focused on formulating environmentally friendlylubricants for four-<strong>stroke</strong> engines which are widely used in Thailand. <strong>Palm</strong> oil w<strong>as</strong> selected to be a candidate due to its largeproduction in the country. Various blends <strong>of</strong> palm oil and a petroleum b<strong>as</strong>e stock were conducted at different compositions. Anadditive package w<strong>as</strong> added to improve some properties. Physical and chemical properties <strong>of</strong> the blends were then evaluatedincluding viscosity, viscosity index, fl<strong>as</strong>h point, foaming characteristics, and wear test. Compared to a conventional lubricant, thepalm-oil b<strong>as</strong>ed lubricant shows a promising performance in most tested properties.Keywords: Biodegradable Lubricant, <strong>Four</strong>-<strong>stroke</strong> <strong>Engine</strong>, <strong>Palm</strong> <strong>Oil</strong>1. INTRODUCTIONVegetable oils and animal fats have been used <strong>as</strong> lubricants for long time since 1650 B.C. For example, Egyptian chariot wheelswere lubricated by animal tallow while whale fat w<strong>as</strong> widely used <strong>as</strong> a lubricant for some equipment and machinery [1]. Thediscovery <strong>of</strong> petroleum oil in the late 1800s resulted in replacement <strong>of</strong> whale oil for lighting and eventually mineral oils became theprimary b<strong>as</strong>e stock for many lubricants due to price and overall performance [2]. However, vegetable oils and animal fats continuedto be used <strong>as</strong> lubricants but mostly in specialty applications.Early this century, environmental concerns have incre<strong>as</strong>ed interest in lubricants that are biodegradable. Since vegetable oils andmost esters are more biodegradable than mineral oils, worldwide attention on the biodegradability <strong>of</strong> lubricants h<strong>as</strong> caused manylubricant manufacturers to reconsider vegetable oils <strong>as</strong> b<strong>as</strong>e stocks. Many studies have looked at the possibility <strong>of</strong> replacing mineraloils with vegetable oils [3-4]. When vegetable oils are used <strong>as</strong> b<strong>as</strong>e stocks for lubricants, they exhibit good lubricity and highviscosity index (VI). However, their oxidative stability and low temperature properties are worse that those <strong>of</strong> petroleum-b<strong>as</strong>edlubricants. Vegetable oils enter into the manufacture <strong>of</strong> lubricants, medicines, cosmetics, detergents, and <strong>of</strong> course many foodproducts. Soybean oil, for example, is used in pl<strong>as</strong>ticizers and detergents, and c<strong>as</strong>tor oil in the lubricants, pharmaceuticals, andcosmetics. Corn and soybean oil find use in food products in the United States, and rapeseed oils are frequently used <strong>as</strong> b<strong>as</strong>e stocksfor lubricant manufacture in the North America and Europe [5-6]. <strong>Palm</strong> oil is one <strong>of</strong> economical plant oils which is promoted inThailand to solve the current oil price crisis. Most <strong>of</strong> palm oils are currently used <strong>as</strong> food consumption and biodiesel production.However, the use <strong>of</strong> palm oil <strong>as</strong> a lubricant b<strong>as</strong>e stock h<strong>as</strong> not been focused.In southe<strong>as</strong>t Asia, motorcycles are popular because <strong>of</strong> their convenience and affordable price. More than 15 million motorcyclesare currently used in all regions <strong>of</strong> Thailand [7]. The number <strong>of</strong> this vehicle is still incre<strong>as</strong>ing every year. Compared with truck orcar engines, motorcycle engine are much smaller and lighter in weight. Therefore, motorcycle engines produce a lot <strong>of</strong> power.Modern four-<strong>stroke</strong> motorcycle engines can produce a peak power at about 15,000 rpm [8]. The emission standards across the worldare tightening and the motorcycle original equipment manufacturers (OEMs) are shifting from two-<strong>stroke</strong> to four-<strong>stroke</strong> enginetechnology. So, it is challenging to formulate a biodegradable lubricant for four-<strong>stroke</strong> motorcycle engines.2. METHODOLOGYThe primary purpose <strong>of</strong> this experimental study is to determine an appropriate composition <strong>of</strong> a biodegradable lubricant for four<strong>stroke</strong>motorcycle engine using palm oil <strong>as</strong> a b<strong>as</strong>e stock. Various blends <strong>of</strong> palm oil and mineral oil were prepared prior to thephysical property tests. <strong>Palm</strong> oil (palm-olein) w<strong>as</strong> obtained directly form a refinery in Krabi, Thailand. Mineral oil and proprietaryadditive package were acquired from PTT Public Co. Ltd., Thailand. The mixture <strong>of</strong> palm oil, mineral oil, and the additive wereprimary mixed in a 500-ml fl<strong>as</strong>k with a magnetic stirrer to obtain and homogenous blends. The recommend dosage <strong>of</strong> the additive is7.8%, wt for all blends. The lubricant properties were conducted using reference standard methods published by American Societyfor Testing Materials (ASTM), <strong>as</strong> shown in all table <strong>of</strong> results.3. RESULTS AND DISCUSSION3.1 Viscosity testThe primary effort <strong>of</strong> this research is to formulate a biodegradable lubricant for four-<strong>stroke</strong> motorcycle engine oil, graded SAE 40.B<strong>as</strong>ed on SAE specification, the viscosity <strong>of</strong> the formulated oil must be achieved. The corresponding viscosity at 100 °C for SAE40is 12.5 to 16.3 cSt. [9]. The desired viscosity w<strong>as</strong> set at 15 cSt for this experiment. The blends <strong>of</strong> palm oil, mineral oil, and theadditive were mixed and showed homogenous ph<strong>as</strong>e. No ph<strong>as</strong>e separation and sedimentation were observed after three-monthstorage. Tables 1 and 2 show the results <strong>of</strong> viscosity and viscosity index, respectively. Viscosity <strong>of</strong> mineral oil is higher than that <strong>of</strong>vegetable oil at both conditions. Blend No. 1 (45% <strong>Palm</strong> oil and 55% Mineral <strong>Oil</strong>) w<strong>as</strong> randomly mixed to predict the viscosity <strong>of</strong> theblend. The result shows that the desired viscosity w<strong>as</strong> not reached. Therefore, Blends 2 and 3 were performed by the addition <strong>of</strong> theadditive package. However, the desired viscosity <strong>of</strong> those blends w<strong>as</strong> not accomplished.Blends 4-7 were made by the adjustment <strong>of</strong> the compositions <strong>of</strong> vegetable oil and mineral oil while the additive dosage w<strong>as</strong> kept at7.24 %wt. The results show <strong>as</strong> an incre<strong>as</strong>e <strong>of</strong> palm oil content and a decre<strong>as</strong>e <strong>of</strong> mineral oil content result in a decre<strong>as</strong>e <strong>of</strong> viscosityCorresponding author: kpc@.kmitnb.ac.th1

The 2 nd Joint International Conference on “Sustainable Energy and Environment (SEE 2006)”C-026 (O) 21-23 November 2006, Bangkok, Thailand<strong>of</strong> the blends. The opposite trend w<strong>as</strong> observed for Blends No. 7-10. This is due to the fact that viscosity <strong>of</strong> mineral oil is quitehigher than that <strong>of</strong> vegetable oil.Looking at the viscosity index which shows the effect <strong>of</strong> temperature change on the viscosity <strong>of</strong> the oil, palm oil shows higherviscosity index than mineral oil. This is attributed to the fact that the molecular weight <strong>of</strong> palm oil is more consistent than that <strong>of</strong>mineral oil. The molecular interaction <strong>of</strong> vegetable oil also results in oil that h<strong>as</strong> higher viscosity index. <strong>Oil</strong> with high viscosity indexcan resist excessive thickening when the engine is cold. This results in a better engine starting and promoting prompt lubricationcirculation [10]. It also prevents an excessive thinning when the engine is hot and thus provide full lubrication to protect the rubbingsurfaces. Therefore, vegetable oil can provide this advantage when used <strong>as</strong> a b<strong>as</strong>e stock for lubricantsBlendsNo.Table 1 Viscosity <strong>of</strong> various blends (ASTM D445)Compositions (wt%)Viscosity at 100 C° (cSt)% <strong>Palm</strong> oil % Mineral oil % Additive1 45.00 55.00 0 8.082 41.74 51.02 7.24 8.743 40.91 50.00 9.09 11.094 55.66 37.11 7.24 16.065 60.30 32.47 7.24 14.716 64.94 27.40 7.24 12.787 57.90 34.30 7.80 13.608 52.90 39.30 7.80 14.459 50.60 41.60 7.80 15.0010 41.20 51.00 7.80 16.80Table 2 Viscosity (ASTM D445) and Viscosity Index (ASTM D2270) <strong>of</strong> selected blendsBlends Viscosity at 100° C (cSt) Viscosity at 40° C (cSt) ViscosityIndex100% <strong>Palm</strong> oil 8.65 42.66 187.00100% Mineral <strong>Oil</strong> 32.51 503.40 96.15Blend No. 9 15.04 111.60 140.00Commercial <strong>Oil</strong> 15.00 151.6 99.003.2 Fl<strong>as</strong>h pointAfter the blends <strong>of</strong> palm oil and mineral oil were made and the desired viscosity w<strong>as</strong> reached, Blend No. 9 w<strong>as</strong> selected for furtherproperty tests. Table 3 shows the results <strong>of</strong> fl<strong>as</strong>h point <strong>of</strong> different oils. The fl<strong>as</strong>h point property <strong>of</strong> palm oil and mineral oil isinsignificantly different. As expected, vegetable oil shows high fl<strong>as</strong>h point because <strong>of</strong> the strong interaction among molecules.Selected Blend No. 9 shows unexpectedly lower fl<strong>as</strong>h point than that <strong>of</strong> palm oil and mineral oil. This is possible due to the presence<strong>of</strong> the additive package. However, fl<strong>as</strong>h point <strong>of</strong> Blend No. 9 is higher than commercial oil. High fl<strong>as</strong>h point is a desirable propertyfor lubricants which leads to the safe transportation and handling processesTable 3 Fl<strong>as</strong>h point <strong>of</strong> selected blends (ASTM D92)Blends Fl<strong>as</strong>h Points (° C)100% <strong>Palm</strong> oil 304100% Mineral <strong>Oil</strong> 302Blend No. 9 278Commercial <strong>Oil</strong> 2563.3 Evaporative lossEvaporative loss is one <strong>of</strong> main properties to be considered for choosing the lubricant b<strong>as</strong>e stock. Since lubricant is exposed to <strong>as</strong>evere condition, it may lose some light weight molecules when it is boiling and the heavy weight molecules are left behind. Thisleads to an incre<strong>as</strong>e in lubricant viscosity and thus, makes the oil more difficult to circulate through a lubricating system. Table 4demonstrates that Blend No. 9 shows lower evaporative loss than commercial oil since the sizes <strong>of</strong> molecules are consistent. One <strong>of</strong>the benefits <strong>of</strong> using vegetable oil <strong>as</strong> a b<strong>as</strong>e stock for lubricant is low volatility loss which results in lower oil consumption. Lowvolatility lubricants also have the potential for a positive impact on the environment [11].Table 4 Evaporative Loss <strong>of</strong> selected blends (ASTM D5800-B)BlendsEvaporative Loss (% wt)100% <strong>Palm</strong> oil N/A100% Mineral <strong>Oil</strong> N/ABlend No. 9 2.64Commercial <strong>Oil</strong> 3.072

The 2 nd Joint International Conference on “Sustainable Energy and Environment (SEE 2006)”C-026 (O) 21-23 November 2006, Bangkok, Thailand3.4 Sulfate <strong>as</strong>hTable 5 shows percent <strong>of</strong> sulfate <strong>as</strong>h <strong>of</strong> selected blends. Sulfate <strong>as</strong>h is a product from the combustion <strong>of</strong> sulfur present in fuels andlubricants. Pure palm oil shows extremely low sulfate <strong>as</strong>h. However, Blend No. 9 shows higher sulfate <strong>as</strong>h than commercial oil.This is due to the present <strong>of</strong> additive package which contains sulfur which leads to a high sulfate <strong>as</strong>h. The result agrees with theprevious study by Colclough [12] which demonstrated that the main additives used in automotive lubricants are zincdithiophosphates (ZDDP). ZDDP can lead to catalytic converter poisoning. Higher sulfate <strong>as</strong>h oil can contribute to an incre<strong>as</strong>eparticulate matter <strong>of</strong> the exhaust g<strong>as</strong> emission. The previous study demonstrated that sulfate may originate from both fuel and oil [13].The general contents <strong>of</strong> sulfur in fuel and oil are 500 and 5000 ppm, respectively. The consumption ratio <strong>of</strong> oil to fuel to oil is1000:1. When a sulfur balance is applied to the engine fuel and oil, it w<strong>as</strong> found that 99% <strong>of</strong> sulfate <strong>as</strong>h originated from the fuel andonly 1% originated from the oil [14].Table 5 Sulfate Ash <strong>of</strong> selected blends (ASTM D874)BlendsSulfate Ash (% wt)100% <strong>Palm</strong> oil 0.007100% Mineral <strong>Oil</strong> N/ABlend No. 9 1.10Commercial <strong>Oil</strong> 0.993.5 Foaming characteristicsFoaming characteristics <strong>of</strong> selected blends were shown in Table 6. Foaming in the lubricant is caused by the presence <strong>of</strong> water inthe b<strong>as</strong>e oil or some chemicals. The results show that Blend No. 9 shows relatively higher foaming characteristics than commercialoil for all sequence. This is attributed to the fact that the antifoam agent in this additive package did not perform well with vegetableoil. The new additive package is recommended to be investigated. As a result, the use <strong>of</strong> this formulated blend in such applicationsthat incur foaming should be avoided since foaming incre<strong>as</strong>es oxidation and reduces the oil flow to the bearing [10].BlendsTable 6 Foaming Characteristics <strong>of</strong> selected blends (ASTM D892)Foaming Characteristics (mL/mL)Sequence I Sequence II Sequence III100% <strong>Palm</strong> oil 210/0 N/A/0 60/0100% Mineral <strong>Oil</strong> N/A N/A N/ABlend No.9 490/310 300/N/A 190/10Commercial <strong>Oil</strong> 20/5 240/0 10/03.6 Wear scarTable 7 shows wear diameter <strong>of</strong> selected blends. The results show that wear scar diameter <strong>of</strong> palm oil is insignificantly differentfrom that <strong>of</strong> commercial oil. Compared to commercial oil, an addition <strong>of</strong> additive package in Blend No.9 significantly improves wearscar. Vegetable oil and its additive perform better wear property because the polar head in its structure is able to interact with polarson the metal surfaces. The antiwear additive also forms a protective layer on the metal parts. Therefore, a good lubricity and wearproperty is obtained.Table 7 Wear scar <strong>of</strong> selected blends (ASTM D4172)BlendsWear scar(mm)100% <strong>Palm</strong> oil 0.58100% Mineral <strong>Oil</strong> N/ABlend No. 10 0.34Commercial <strong>Oil</strong> 0.604. CONCLUSIONThe blends <strong>of</strong> palm oil, mineral oil, and the additive package were conducted to formulate biodegradable lubricant for four-<strong>stroke</strong>motorcycle engine. The selected blend consists <strong>of</strong> 50.60%(wt) palm oil, 41.60 %(wt) mineral oil, and 7.80(%) additive package.The formulated blend shows better properties than commercial oil in terms <strong>of</strong> viscosity index, fl<strong>as</strong>h point, evaporative loss, and wearscar. However, foaming characteristics and sulfate <strong>as</strong>h are poorer because <strong>of</strong> the presence <strong>of</strong> improper additive. This primary showsthat palm oil h<strong>as</strong> a potential <strong>as</strong> a b<strong>as</strong>e stock for four-<strong>stroke</strong> motorcycle oil.5. ACKNOWLEDGMENTSThe authors gratefully acknowledge the contribution <strong>of</strong> the Department <strong>of</strong> Chemical <strong>Engine</strong>ering, King Mongkut’s Institute <strong>of</strong>Technology North Bangkok.3

The 2 nd Joint International Conference on “Sustainable Energy and Environment (SEE 2006)”C-026 (O) 21-23 November 2006, Bangkok, Thailand6. REFERENCES[1] Dowson, D., (1989) History <strong>of</strong> TribologyNon, Pr<strong>of</strong>essional <strong>Engine</strong>ering Publishing Ltd, London.[2] Dorinson, A. and Ludema, K.C. (1985) Mechanics and Chemistry in Lubrication Tribology Series 9, Amsterdam, TheNetherlands.[3] M<strong>as</strong>juki, H.H., Maleque, M.A.,Kubo, A., and Nonaka, T. (1999) <strong>Palm</strong> oil and mineral oil b<strong>as</strong>ed lubricants-their tribological andemission performance, Tribology International, 32, pp. 305-314.[4] Wan Nik, W.B., Ani, F.N., M<strong>as</strong>juki, H.H., Eng Giap, S.G. (2005), Rheology <strong>of</strong> bio-edible oils according to several rheologicalmodels and its potential <strong>as</strong> hydraulic fluid, Industrial Crops and Products, Article in Press.[5] Goyan, R. L., Melley, R.E., Wissner, P.A., and Ong, W.C. (1998) Biodegradable Lubricants, Lubrication <strong>Engine</strong>ering, 54, (7),pp. 10-17.[6] Fuks, I.G.., Yu, A., Evdokimov, A.A., and Luksa, A. (1992) Vegetable oils and animal fats <strong>as</strong> raw materials for manufacture <strong>of</strong>commercial, Chemistry and Technology <strong>of</strong> Fuels and <strong>Oil</strong>s, 4, pp. 203-237.[7] http//:www.dlt.go.th (2006).[8] http//:www.howstuffworks.com (2006).[9] Society <strong>of</strong> Automotive <strong>Engine</strong>ers (1995) SAE Fuel and Lubricants Standards, Warrendale, Pennsylvania, USA.[10] Mortier, R.M. and Orszulik, S.T. (1997) Chemistry and Technology <strong>of</strong> Lubricants, Chapman &Hall, Great Britain.[11] Rudnick, L.R. (2005) Synthetics, Mineral <strong>Oil</strong>s, and Bio-B<strong>as</strong>ed Lubricants, CRC/Taylor&Francis, Boca Roton.[12] Colclough, T (1987) Role <strong>of</strong> Additives and Transition Metals in Lubricating <strong>Oil</strong> Oxidation, Ind.Eng.Chem. Res., 26, pp. 1888-1895.[13] http//:www.osti.gov/fcvt/deer2005/plumley.pdf (2006).[14] http//:www.osd.gov/17.pdf (2006).4