ENVIRONMENTAL PRODUCT DECLARATION EczacıbaÅı ... - VitrA

ENVIRONMENTAL PRODUCT DECLARATION EczacıbaÅı ... - VitrA

ENVIRONMENTAL PRODUCT DECLARATION EczacıbaÅı ... - VitrA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.4 Cut-off criteriaCriteria for the exclusion of inputs and outputs (cutoffrules) in the LCA and information modules andany additional information are intended to supportan efficient calculation procedure.All inputs and outputs to a (unit) process are includedin the calculation, for which data were available.The applied cut – off criteria is 1 % of renewableand non-renewable primary energy usage and 1 %of the total mass input of that unit process in case ofinsufficient input data or data gaps for a unit process.The total of neglected input flows per module, e.g.per module A, B, C or D is a maximum of 5 % of energyusage and mass.3.5 Background dataBackground processes are taken from the publiclyavailable professional GaBi 4.4 databases as far asavailable (GaBi DOC 2010). Country and regionspecific data on energy sources including electricityand region specific data on raw materials such aslimestone and clay were taken from GaBi databases.3.6 Data qualityThe process data and the used background data(GaBi DOC 2010) are consistent. In addition, theorigin of the data is documented. Additional informationis gathered regarding the age of the data.The input and output data of the whole processplant was strongly emphasized. The supplied data(processes) were provided by Eczacıbaşı BuildingProducts Co. and checked for plausibility.Therefore, the data quality can be described asgood.The age of the data employed in this study is due to2010.3.7 Period under reviewThe period under review is defined as one year. Themonthly data is collected by the producer and is averagedto obtain the yearly data. As explained here,the average data for the year 2010 is utilized withinthis study.3.8 AllocationIn this study, allocation was avoided wherever possibleas required in FprEN 15804.Many different products are produced at the productionplant of Eczacıbaşı Building Products Co.located in Bozüyük, but as all products undergo thesame manufacturing process and as they are verysimilar in terms of material composition, all themanufactured products are classified as two productgroups: Vitreous china and fine fireclay. Each ofthese product groups are modeled separately,which means that in each model there is only onesingle product group As a result of this situation, co– product allocation becomes unnecessary as thereare no co – products existing.4 LCA: Scenarios and additional technical informationThe modules A4, A5, B1, B2, B3, B4, B5, referenceservice life, B6, B7 and C1 – C4 are not consideredand declared in this study.5 LCA: ResultsDESCRIPTION OF THE SYSTEM BOUNDARY (X = INCLUDED IN LCA; MND = MODULE NOT DECLARED)<strong>PRODUCT</strong> STAGE3.9 ComparabilityBasically, a comparison or an evaluation of EPD datais only possible if all the data sets to be comparedwere created according to FprEN 15804 and thebuilding context, respectively the product-specificcharacteristics of performance, are taken into account.CONSTRUC-TIONPROCESSSTAGEUSE STAGEEND OF LIFE STAGEBENEFITS ANDLOADSBEYOND THESYSTEMBOUNDARYSRaw material supplyTransportManufacturingTransportConstruction-installationprocessUseMaintenanceRepairReplacement 1)Refurbishment 1)Operational energy useOperational water useDe-constructiondemolitionTransportWaste processingDisposalReuse-Recovery-RecyclingpotentialA1 A2 A3 A4 A5 B1 B2 B3 B4 B5 B6 B7 C1 C2 C3 C4 DX X X MND MND MND MND MND MND MND MND MND MND MND MND MND MND6 Environmental Product Declaration Eczacıbaşı Building Products Co. – Vitreous China Ceramic Sanitaryware

RESULTS OF THE LCA - <strong>ENVIRONMENTAL</strong> IMPACT: 1 t Vitreous China Ceramic SanitarywareManufacturingParameter Unit A1 - A3Global warming potential [kg CO 2 -eq.] 1341Depletion potential of the stratospheric ozone layer [kg CFC11-eq.] 5.67E-05Acidification potential of land and water [kg SO 2 -eq.] 13.42Eutrophication potential [kg PO 4 3- - eq.] 0.57Formation potential of tropospheric ozone photochemical oxidants [kg Ethen eq.] 0.46Abiotic depletion potential for non fossil resources [kg Sb eq.] 9.31E-03Abiotic depletion potential for fossil resources [MJ] 18062RESULTS OF THE LCA - RESOURCE USE: 1 t Fine Vitreous China SanitarywareManufacturingParameter Unit A1 - A3Use of renewable primary energy excluding renewable primaryenergy resources used as raw materials[MJ] 3982Use of renewable primary energy resources used as raw materials[MJ] 0Total use of renewable primary energy resources [MJ] 3982Use of non renewable primary energy excluding non renewableprimary energy resources used as raw materials[MJ] 22604Use of non renewable primary energy resources used as rawmaterials[MJ] 0Total use of non renewable primary energy resources [MJ] 22604Use of secondary material [kg] 0Use of renewable secondary fuels [MJ] 0Use of non renewable secondary fuels [MJ] 0Use of net fresh water [m³] 19.3RESULTS OF THE LCA – OUTPUT FLOWS AND WASTE CATEGORIES: 1 t Vitreous China Ceramic SanitarywareManufacturingParameter Unit A1 - A3Hazardous waste disposed [kg] 0.52Non hazardous waste disposed [kg] 2711Radioactive waste disposed [kg] 0.34Components for re-use[kgMaterials for recycling[kg]Materials for energy recovery[kg]Exported energy per energy carrier [Type][MJ]Exported energy per energy carrier [Type][MJ]6 LCA: InterpretationThe non renewable energy resource use is veryhigh compared to the renewable energy resourceuse. This situation arises due to the use of naturalgas and electricity as energy source. Natural gas asa fossil fuel constitutes the major non renewableenergy source. Electricity also contributes to the nonrenewable resource usage because of the distributionof energy resources employed in generation ofthe power grid mix.There is no secondary material use in the manufacturingprocess of vitreous china ceramic sanitarywareproducts.The energy sources used in the production plant arenatural gas and electricity. There are no other additionalenergy resources used in the productionplant. Since in upstream processes no secondaryfuels are used, there is no input regarding renewableand non - renewable secondary fuels.The net fresh water use for vitreous china ceramicsanitaryware products is 19.4 m 3 per 1 t of product.Nearly the half of this water use arises due to preprocessesof the power grid mix. The other contributorsof this parameter are water utilized during manmanufacturingand the water usage for the pre –processes of the raw materials.Although radioactive compounds are not used in themanufacturing process itself, a small amount of radioactivewaste appears on the balance table. Thissmall amount arises due to the power grid mix andpre – processes of raw materials used in main manufacturingand packaging processes.All the impact categories except for ADPE and ODPare dominated either by natural gas utilization or thepower grid for vitreous china ceramic sanitarywareproducts.The environmental impact of the ADPE parameter ismainly generated because of the raw materials usedduring the main production process, the mouldingprocess and the packaging process such as zincoxide, gypsum and glue. Through the examinationof the ODP parameter it can be observed that theimpact generated in this category is sourced mainlyby polyurethane employed in the moulding process.Environmental Product Declaration Eczacıbaşı Building Products Co. – Vitreous China Ceramic Sanitaryware 7

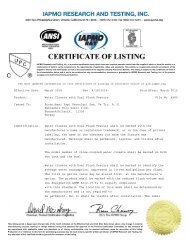

7 Requisite evidence7.1 Eluate analysisPb-Cd tests are conducted on ceramic plates (sinks)according to ISO 6486-2: 2000. The obtained testresults demonstrated that none of the samplesincluded Pb and Cd which states that the testresults for all samples were below the limit valuesset for Pb and Cd within the scope of ISO 6486-2:2000 The test is performed by Şişecam AnalyticalSupport Services Department – Glass ResearchCenter on 08.12.2010. The testing institution is accreditedby Türkak (Turkish Accreditation Institute).According to ISO 6486-2: 2000 all samples have tobe below the set limits as presented below in Table 3:Table 3. Limits for Pb and CdContainerPb CdUnittypelimit limitFlat mg/dm 2 0.8 0.07Small bowl mg/l 2 0.5Large bowl mg/l 1 0.258 ReferencesInstitut Bauen und Umwelt 2011Institut Bauen und Umwelt e.V., Königswinter (pub.):Generation of Environmental Product Declarations(EPDs); General principles for the EPD range of InstitutBauen und Umwelt e.V. (IBU), 2011-06www.bau-umwelt.dePCR 2011, Part AInstitut Bauen und Umwelt e.V., Königswinter (pub.):Product Category Rules for Construction Productsfrom the range of Environmental Product Declarationsof Institut Bauen und Umwelt (IBU), Part A:Calculation Rules for the Life Cycle Assessmentand Requirements on the Background Report. July2011www.bau-umwelt.dePCR 2011, Part BInstitut Bauen und Umwelt e.V., Königswinter (pub.):Product Category Rules for Construction Productsfrom the range of Environmental Product Declarationsof Institut Bauen und Umwelt (IBU), Part B:Requirements on the EPD for Sanitary Ceramics.November 2011www.bau-umwelt.deISO 14025DIN EN ISO 14025:2009-11: Environmental labelsand declarations — Type III environmental declarations— Principles and proceduresFprEN 15804FprEN 15804:2011-04: Sustainability of constructionworks — Environmental Product Declarations —Core rules for the product category of constructionproductsDIN EN 50001DIN EN 50001:2011-12 Energy management systems.Requirements with guidance for useISO 9001ISO 9001:2008 Quality management systems – RequirementsISO 14001ISO 14001:2004 Environmental management systems– Requirements with guidance for useISO 6486-2: 2000ISO 6486-2: 2000 Ceramic ware, glass-ceramicware and glass dinnerware in contact with food –Release of lead and cadmium -- Part 2: Permissiblelimits8 Environmental Product Declaration Eczacıbaşı Building Products Co. – Vitreous China Ceramic Sanitaryware

PublisherInstitut Bauen und Umwelt e.V. Tel. +49 (0)2223 2966 79- 0Rheinufer 108 Fax +49 (0)2223 2966 79- 053639 Königswinter E-mail info@bau-umwelt.comGermany Web www.bau-umwelt.comProgramme holderInstitut Bauen und Umwelt e.V. Tel. +49 (0)2223 2966 79- 0Rheinufer 108 Fax +49 (0)2223 2966 79- 053639 Königswinter E-mail info@bau-umwelt.comGermany Web www.bau-umwelt.comOwner of the DeclarationEczacıbaşı Building Products Co. Tel. +90 212 350 80 00Büyükdere Cad. Ali Kaya Sok. No:7 Fax: +90 212 350 85 58Levent Istanbul E-mail: vitraglobalinfo@eczacibasi.com.trTurkey Web www.vitra.com.trAuthor of the Life Cycle AssessmentPE INTERNATIONAL AG Tel. +90 212 244 6780Gümüşsuyu Mah. İsmet İnönü Cad. Fax: +90 212 244 6782Park Palas 23/7 Beyoğlu İstanbul E-mail: info@pe-international.comTurkey Web www.pe-international.com