Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DIE FEEDING SYSTEM• Eliminate secondary operations• Reduce costs• Improve quality• Speed productionNEW!

PEMSERTER ® DIEFEEDING SYSTEMThe PEMSERTER <strong>die</strong> feed <strong>system</strong> will bring newdimensions to your stamping capabilities. Itincorporates the latest technologies to deliver theperformance that is needed to compete in the highlycompetitive stamping industry. It will eliminate thesecondary operations typically required for fastenerinsertion, thus reduce your overall labor costs, improvepart quality and dramatically improve the through put ofyour product.Precision track <strong>system</strong> properly orients fasteners.The benefits of using the <strong>die</strong> feed <strong>system</strong> are:• Increased productivity.• Increased quality.• Cost effective.• Reduced inventory/WIP.• Reduced manufacturing lead times.Recognizing the need for flexibility, the <strong>system</strong> can beconfigured to feed nuts, studs, and/or standoffs formultiple or single insertions, generally matching the rateof your stamping press.System can be configured for single or multiple insertions.As designed the <strong>system</strong> interfaces with the <strong>die</strong> and thepress with surprising ease. Through the use of multi pintwist lock connectors it is virtually plug and play. All thatis needed to operate the <strong>system</strong> is a standard 110Vreceptacle and shop air.Other advantages are that the standard tooling is inpress removable and can handle complex work piecesreaching into areas generally considered inaccessible.Additionally, if required special tooling can beengineered to fit your specific application.Uses standard 110V supply and shop air to operate. Adjustablecontrols are easily accessible through the keyed access door.During operation the operator is guided through theprocess by the touch screen operator interface and theon-line library of fault/help screens.The total <strong>system</strong> includes the <strong>die</strong> tooling, the fastener<strong>feeding</strong> <strong>system</strong>, the <strong>die</strong> sensing <strong>system</strong> and the supportyou need to make every project a success.© Copyright 2000 PEM Fastening Systems, a PennEngineering company. PEM and PEMSERTERare brand names and registered trademarks for fasteners and equipment manufacturedexclusively by PEM Fastening Systems.Touch screen for ease of set-up and operation.9/01

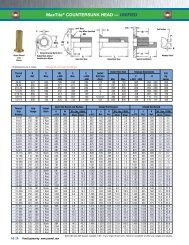

PUNCH ASSEMBLYDBCGATop ViewØESection A-APunch AssemblyShown CompressedØFAll dimensions are in inches.All dimensions are in millimeters.TypeThreadA B C D ØE ØF GLengthSize ± .05 ± .02 Max. ± .03 ± .01 ± .05 ± .01TypeThreadA B C D ØE ØF GLengthSize ± 1.3 ± 0.5 Max. ± 0.8 ± .25 ± 1.3 ± .25FH #4-40 .50 - 1.00 6.60 1.3 0.63 1.38 0.77 2.5 5.3FH #6-32 .50 - 1.25 6.60 1.3 0.63 1.38 0.77 2.5 5.3FH #8-32 .50 - 1.25 6.75 1.3 0.63 1.38 0.77 2.5 5.3FH #10-32 .50 - 1.25 6.75 1.3 0.63 1.38 0.77 2.5 5.3FH 1/4-20 .50 - 1.25 6.95 1.3 0.63 1.38 0.88 2.5 5.3HFH #10-32 .50 - 1.25 6.92 1.3 0.63 1.38 0.88 2.5 5.3HFH 1/4-20 .50 - 1.25 7.55 1.3 0.63 1.38 0.88 2.5 5.3FH M3 12 - 25 167.6 33 16 35 19.6 63.5 134.6FH M3.5 12 - 30 167.6 33 16 35 19.6 63.5 134.6FH M4 12 - 30 171.5 33 16 35 19.6 63.5 134.6FH M5 12 - 30 171.5 33 16 35 19.6 63.5 134.6FH M6 12 - 30 176.5 33 16 35 22.4 63.5 134.6HFH M5 12 - 30 175.8 33 16 35 22.4 63.5 134.6HFH M6 12 - 30 191.8 33 16 35 22.4 63.5 134.6ANVIL ASSEMBLY5/16-18 SHCS (4 Places)Top ViewØ 2”/50.8mmØ .75”/19.1mm2.5”/63.5mm1”/25.4mm2.625”/66.675mmSection A-A

CONFIGURATION WITH A STAMPING PRESSCUSTOM APPLICATIONSCustom designs such as the punch assembly shown below can be offered to meet theneeds of a specific customer application. Please call us for more information about yourrequirements. We will be happy to assist you to design the proper tool for your assembly.For more information call:1-800-523-5321VVisit us at our PEMNET SM Website:For the name of the Authorized PEM distributor nearest you, call one of thenumbers below or check our website.Specifications subject to change without notice.World Headquarters:5190 Old Easton RoadDanboro, PA 18916 USAE-mail: pem@pemnet.comTel: 215-766-8853 • Fax: 215-766-3634U.K. And Europe:Kirk Sandall Industrial EstateDoncaster, South Yorkshire • DN3 1QR, EnglandE-mail: arconix-uk@arconix.comTel: 01302 886961 • Fax: 01302 885341Asia/Pacific:Citipoint Industrial Complex152 Paya Lebar Road #03-06 • Singapore 409020E-mail: arconix-sing@arconix.comTel: 65 745 0660 • Fax: 65 745 2400