Waterjet Cleaning Of Steel Process Lines Without Damage To The ...

Waterjet Cleaning Of Steel Process Lines Without Damage To The ...

Waterjet Cleaning Of Steel Process Lines Without Damage To The ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

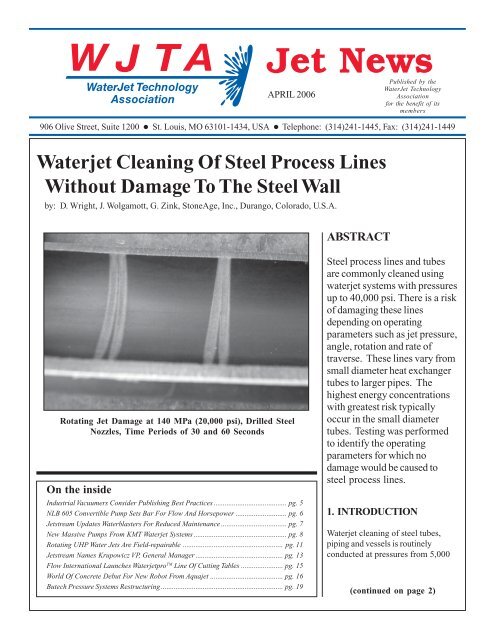

APRIL 2006Published by theWaterJet TechnologyAssociationfor the benefit of itsmembers906 Olive Street, Suite 1200 l St. Louis, MO 63101-1434, USA l Telephone: (314)241-1445, Fax: (314)241-1449<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong><strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong> <strong>Steel</strong> Wallby: D. Wright, J. Wolgamott, G. Zink, StoneAge, Inc., Durango, Colorado, U.S.A.ABSTRACTRotating Jet <strong>Damage</strong> at 140 MPa (20,000 psi), Drilled <strong>Steel</strong>Nozzles, Time Periods of 30 and 60 SecondsOn the insideIndustrial Vacuumers Consider Publishing Best Practices ........................................ pg. 5NLB 605 Convertible Pump Sets Bar For Flow And Horsepower ............................ pg. 6Jetstream Updates Waterblasters For Reduced Maintenance .................................... pg. 7New Massive Pumps From KMT <strong>Waterjet</strong> Systems ................................................... pg. 8Rotating UHP Water Jets Are Field-repairable ....................................................... pg. 11Jetstream Names Krupowicz VP, General Manager ................................................ pg. 13Flow International Launches <strong>Waterjet</strong>pro TM Line <strong>Of</strong> Cutting Tables ....................... pg. 15World <strong>Of</strong> Concrete Debut For New Robot From Aquajet ........................................ pg. 16Butech Pressure Systems Restructuring ................................................................... pg. 19<strong>Steel</strong> process lines and tubesare commonly cleaned usingwaterjet systems with pressuresup to 40,000 psi. <strong>The</strong>re is a riskof damaging these linesdepending on operatingparameters such as jet pressure,angle, rotation and rate oftraverse. <strong>The</strong>se lines vary fromsmall diameter heat exchangertubes to larger pipes. <strong>The</strong>highest energy concentrationswith greatest risk typicallyoccur in the small diametertubes. Testing was performedto identify the operatingparameters for which nodamage would be caused tosteel process lines.1. INTRODUCTION<strong>Waterjet</strong> cleaning of steel tubes,piping and vessels is routinelyconducted at pressures from 5,000(continued on page 2)

<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong> <strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong> <strong>Steel</strong> Wall, from page 1to 40,000 psi. <strong>The</strong> concerns byplant operators have beendamage by high pressurewaterjets and mechanical wearcaused by the rubbing of thenozzle against the wall of thetube. Another sometimesoverlooked failure mode of pipingand tubing is due to corrosionrelated to the plant process, inboth carbon steel and stainlesssteel materials. <strong>The</strong>re have beeninstances of blame placed onwaterblast contractors for damagethat was actually due to corrosion,because the waterjet cleaningremoved the material from thecorrosion pits and cracks that hadbeen keeping the tubes from leakingthrough these tiny pits and cracks. Acorrosion damaged stainless steel tubeis shown in Figures 1 and 2. <strong>The</strong>pitting caused by corrosion hasFigure 1. Pitting Caused by Corrosion inStainless <strong>Steel</strong> Tuberelatively sharp edges. A waterjetattacks steel through the process ofcavitation erosion by water dropletimpact, which looks much moresmooth and rounded (see Figures 4, 6,9, 12, 14 and 15). <strong>The</strong> purpose of thistesting was to determine operatingFigure 2. Detail of Corrosion Pits inStainless <strong>Steel</strong> Tubeparameters which will not result inwaterjet damage to the tubes, and toillustrate what the damage caused bywaterjet action looks like.(continued on page 4)for all of your water blasting needs!Industrial <strong>Cleaning</strong>TOOLS• Rotary Gun - 4 or 8 Nozzles• Aqua-Spider - Wall/hull cleaner• Mini-Scrubber - Hand held cleaner• RHD - Rotating pipe cleanerFEATURES• 40,000 psi• 200 gpm• 1000 hp• Vacuum attachmentsSurface PreparationVacuum SystemsFor surface preparation and industrial cleaning applications, contactAQUA-DYNE regarding the most innovative Water Energy products.(713) 864-6929 • www.aqua-dyne.com • info@aqua-dyne.comPage 2 WJTA on the web: www.wjta.org April 2006

<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong> <strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong> <strong>Steel</strong> Wall, from page 22. TESTINGFigure 3. Rotating Nozzle TestArrangementTests were performed using a singlefixed jet and multiple rotating jets;Figure 3 illustrates the typical testarrangement for multiple rotating jets.<strong>The</strong> standoff distances used would betypical of tube and small pipe cleaningbut considered relatively close for pipesizes larger than six inches unlessprovisions were made to place the jetscloser to the pipe wall. For testsperformed at and below 140 MPa(20,000 psi), two types of nozzle wereused, one being drilled steel of poorquality, and the second high qualitystainless steel nozzles with flowstraighteners. Tests performed at 250MPa (36,000 psi) used good qualitysapphire nozzles. <strong>The</strong> tube sampleson which the tests were conductedconsisted of new 304 stainless steeland 1018 DOM carbon steel, both1.88 in. inside diameter. <strong>The</strong> amountand type of damage was found to bequite similar in the stainless steel andthe carbon steel, so most of the testingwas done in the 1018 carbon steel toallow for better visual contrast. <strong>The</strong>damage was quantified and comparedin terms of depth of material removal.3. RESULTS3.1 Stationary Jets<strong>The</strong> first of these tests used a poorquality drilled steel nozzle orifice,Figure 4. <strong>Damage</strong> to Carbon <strong>Steel</strong>Tubing, at 140 MPa (20,000 psi) withStationary Drilled <strong>Steel</strong> Nozzle, for TimePeriods of 10, 30 and 60 Secondstypical of small tube cleaning nozzleswithout replaceable inserts. An orificesize of 1.07 mm (.042 in.) was drilledat 90° in the head and tested with thejet perpendicular to the tube wall, at astandoff distance of 9.6 mm (.38 in.)Tests were run on both carbon steeland stainless steel for periods of 10, 30and 60 seconds at pressures of 70, 105(continued on page 10)Page 4 WJTA on the web: www.wjta.org April 2006

Industrial Vacuumers Consider Publishing Best Practices“From a contractor’s standpoint,you can hardly offer waterjetservice and not offer vacuum truckservice and vice versa,” says PatDebusk of Debusk Industrial Servicesand a board member of the WaterJetTechnology Association (WJTA). “Buteven though both types of equipmentwork the same job, their operatorsface different hazards.”Clearly, both waterjet and vacuumtruck operators need safety training.High-pressure presents an obviousdanger to operators and the peoplearound waterjet equipment. Highpoweredvacuums are also potentiallydangerous, and some combinationvacuum units use high-pressure wateras well. Vacuum operators often workin confined areas and trenches, andmust cope with electrical cables,pressurized pipes, and potentiallyhazardous structures.Twenty-one years ago, the newlyformed WJTA addressed safe andefficient waterjet use with its guide,Recommended Practices for the Useof Manually Operated HighPressure Water Jetting Equipment.This collection of best operatingpractices quickly became theindustry’s safety bible.A need appears to exist. AlthoughOSHA does not specifically regulateportable equipment, managers andsupervisors must comply with relevantOSHA regulations. Larger companiesoften have specialists who monitorsafety requirements and managetraining and compliance. This is oftenmore difficult for smaller firms.Adopting a single, generic set ofoperating guidelines and personnelclassifications would benefit bothsmaller and larger companies.Advantages(continued on page 17)<strong>To</strong> start with, managers would find iteasier to tell whether their safetyGuidelinesNow WJTA has begun exploringwhether it should create a similar setof guidelines for vacuum truckoperators.“Our waterjet handbook is not atraining manual, but a set of tried andproven practices developed by peoplethroughout the industry, says WTJAAssociation Manager Ken Carroll.“Many of the vacuum companies havereally good safety programs that wecould pull together into a single guide.”April 2006 WJTA on the web: www.wjta.org Page 5

NLB 605 Convertible Pump Sets Bar For Flow And Horsepower<strong>The</strong> 605 Series water jet pumpunits from NLB Corp. offerhigher horsepower and flow than anyother convertible pump — up to 600hp and 143 gpm (447 kw and 541lpm). A simple conversion kit letsusers operate at any of five pressuresto suit their applications: 6,000, 8,000,10,000, 15,000, or 20,000 psi (414 to1,400 bar).Since the conversion can becompleted with just six parts (and nomanifold change), operating efficiencyis high and maintenance is easy. <strong>The</strong>NLB 605 has many wear-reducingfeatures, including a slow-runningtriplex plunger pump and hard-coatedvalves and plungers. Corrosion-resistant stainless steel isused throughout the pump,instead of carbon steel.Minimum flow is 34 gpm(129 lpm).<strong>The</strong> NLB 605 Seriesunits all feature an internalgear pac instead of atraditional external drive.Other important featuresinclude a heavy-duty polychainsystem with belt guard andwater pressure-actuated throttlecontrol to adjust output to operatordemand.NLB Corp. manufactures a full lineof quality waterjetting systems andNLB 605 Series water jet pump unitaccessories for contractor andindustrial uses. <strong>The</strong>se include surfacepreparation, paint removal, tank andtube cleaning, concretehydrodemolition, concrete and pipecutting, and more. For moreinformation, visit www.nlbcorp.com.Page 6 WJTA on the web: www.wjta.org April 2006

New Massive Pumps From KMT <strong>Waterjet</strong> SystemsKMT <strong>Waterjet</strong> Systems, a manufacturer ofextreme-pressure waterjet equipment, hasintroduced new massive pumps for waterjet cutting: theSL-V 150 hp and the SL-V 200hp. <strong>The</strong>se are the latestadditions to the Streamline TM series of intensifiers,providing more pump sizes to better accommodatespecific applications.three intensifiers. <strong>To</strong>tal maximum output at any timeis 4gpm for the 200hp model and 3gpm for the150hp machine.l Easier to Maintain – Thread-together cylinderdesign for ease of access to components, seals, andparts.l Biggest Attenuator Capacity – Up to 1.5 gallons formore consistent pressure signal and smoother cuts.KMT <strong>Waterjet</strong> delivers extreme-pressure waterjetsystems which have great reliability and ease of use atpressures up to 60,000 psi and provides high levels ofcustomer service.Designed for customers who need more horsepowerbut who do not want to increase the number of pumps,the new massive pumps eliminate the need to haveseveral smaller pumps driving large numbers of cuttingheads. <strong>The</strong>se new pumps produce water under extremepressure using just two intensifiers, leaving room for abackup (redundant) intensifier. <strong>The</strong> net benefit is loweroperating costs.KMT <strong>Waterjet</strong> Systems is part of the KMT Groupwhich markets, develops and manufactures advancedproduction solutions for the engineering industry withinprecision grinding, sheet metal working, tube forming,and waterjet cutting. <strong>The</strong> KMT holding company,Karolin Machine <strong>To</strong>ol AB, is quoted on the “O” list ofthe Stockholm Stock Exchange.For more information, visit www.kmt-waterjet.com.<strong>The</strong> new pumps set a new industry standard for easeof operation by using the same, proven technology as thesmaller pumps along with the added benefits of: stackedintensifiers on the very front of the machines for easieraccess, electronic proportional control which automateschanging the pressure to any level desired, balancing andstroke control software, and doors with windows foreasy visual inspection.When compared to other pumps, the new massivepumps in 150hp and 200hp sizes produce more highpressure water at a lower cost per gallon.Additional features:l Redundant Option – Add an extra intensifier asbackup, for a total of three intensifiers, and moreassurance that at least 2gpm will be available.l Largest High Pressure Intensifiers – Output for justone intensifier is up to 2gpm, using any of up toPage 8 WJTA on the web: www.wjta.org April 2006

OUR HOURS OF OPERATION?ALL OF THEM.<strong>The</strong> 24/7 Support Program From Jetstream.Mechanical breakdowns can result in lost time, money and opportunities. Nobody understands that better than Jetstream.Thats why were the only company in the industry that provides replacement parts, accessories and technical supportaround the clock. In this industry, you cant afford to be down. With our after-hours parts shipment and professional advice,we can have you up and running in no time. No matter what time that may be. <strong>The</strong> Jetstream 24/7 Support Program.If your equipment goes down, well be up. You can count on it.For more information, contact a Jetstream representative at 800.231.8192,or visit us at www.waterblast.com.©2005 Federal Signal Corporation, listed on the NYSE by the symbol FSS.

<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong> <strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong> <strong>Steel</strong> Wall, from page 4and 140 MPa (10,000, 15,000, and 20,000 psi). Figure 4shows the damage created at 140 MPa (20,000 psi) with adrilled jet in carbon steel; the carbon steel results aregraphed in Figure 5. Figure 6 is a photograph of thedamage created at 140 MPa (20,000 psi) in stainless steel;the stainless steel results are plotted in Figure 7. Note thatthere is very little difference in results between the twomaterials. At 70 and 105 MPa (10,000 and 15,000 psi), nodamage was caused at the 10 second exposure, while slightdamage occurred at 140 MPa (20,000 psi). <strong>The</strong> damagecaused at 70 MPa (10,000 psi) can only be felt as surfaceroughness rather than depth; after exposure for 120seconds the damage did not increase.<strong>The</strong> next series of stationary jet tests used a high qualitysteel nozzle with a flow straightener and an orifice diameterof .97 mm (.038 in.), exiting from a nozzle head at 90° tothe tube wall. Due to the nature of the cavitationmechanism by which the waterjet damages the tube wall,this more coherent jet did not produce any damage up to orincluding 140 MPa (20,000 psi) after 60 seconds when thestandoff distance was 9.6 mm (.38 in.) from the tube wall.Cavitation and damage did occur when this nozzle wastested with increasing standoff distance at 105 MPa(15,000 psi) for 30 seconds at each point. <strong>The</strong>se resultsare shown in Figure 8.<strong>The</strong> final series of stationary jet tests, conducted at 250MPa (36,000 psi), used a sapphire nozzle insert, diameter.61mm (.024 in.), tested at 80° to the surface of the tubewall. Results showed that allowing a nozzle operating atthis pressure to stop rotating or traversing can result insignificant damage to the tube wall. Figure 9 shows thetest sample used and the resulting damage. <strong>The</strong>se resultsare plotted in Figure 10, along with the results at 140 MPa(20,000 psi) from the drilled jet tests for comparison.3.2 Rotating JetsUse of rotation as a means of keeping the jet moving overthe surface can greatly reduce or eliminate damage to steeltubes and pipes. Figure 11 illustrates the great differencebetween rotating and stationary jet damage; a stationary jetat 140 MPa (20,000 psi) can cause more damage thanrotating jets at 250 MPa (36,000 psi).<strong>Damage</strong> by rotating jets will still be incurred if the tool isleft rotating in the same place; the amount of time to causedamage is dependent on the pressure. At 70 MPa (10,000psi) a head rotating 500 rpm with three drilled steel jets of.84 mm (.033 in.) diameter (30 kW) at 85° in the samepath, at a standoff distance of 9.6 mm (.38 in.), did notcause any damage after 4 minutes in the same location,Figure 5. Stationary Drilled <strong>Steel</strong> Nozzle <strong>Damage</strong> to1018 Carbon <strong>Steel</strong> Tube WallFigure 6. <strong>Damage</strong> to Stainless <strong>Steel</strong> at 140 MPa(20,000 psi) with Drilled <strong>Steel</strong> Nozzle, for TimePeriods of 10, 30 and 60 SecondsFigure 7. Stationary Drilled <strong>Steel</strong> Nozzle <strong>Damage</strong> to304 Stainless <strong>Steel</strong> Tube Wall(continued on page 11)Page 10 WJTA on the web: www.wjta.org April 2006

<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong><strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong><strong>Steel</strong> Wall, from page 10Figure 8. Effect of Standoff Distance with a StationaryHigh Quality <strong>Steel</strong> Nozzle With a Flow Straightenerat 105 MPa (15,000 psi)Rotating UHP Water Jets AreField-repairableNLB Corp. has introduced two ultra-high pressure(UHP) waterjet accessories that improveperformance and can be repaired in the field in under fiveminutes. <strong>The</strong> Viper 40, the first self-rotating head tooperate at pressures up to 40,000 psi (2,800 bar), easilyattaches to astandard NLBNCG40-286lance. Thisnew lance issimpler thanair-drivenUHP lancesand eliminatesthe expense ofan air source.<strong>The</strong> Viper40 has around stainlesssteel bodywith recessednozzle inserts,to reduce damage from nozzle strikes. Its combination ofrotating UHP action and a wide spray path make itexceptionally effective in a wide range of product removalapplications. Unlike previous SPIN-NOZZLE ® heads,which must be returned to the factory for repairs, the Viper40 can be repaired in the field in less than five minutes.Figure 9. <strong>Damage</strong> at 250 MPa (36,000 psi), Time Periodsof 10, 30 and 60 Seconds<strong>The</strong> NCG40-286 lance is also field-repairable, thanks toa unique quick-change cartridge seal that can be replacedin just 60 seconds. This lightweight lance features apatented trigger design (Patent No. 5,636,789) that allowsthe operator to dump pressure instantly. Other operatorfriendlyfeatures include easy trigger actuation andadjustable shoulder stock and handgrip.For more information, visit www.nlbcorp.com.Figure 10. Stationary Sapphire and Drilled Nozzle<strong>Damage</strong> to 1018 Carbon <strong>Steel</strong> Tube(continued on page 14)<strong>The</strong> Jet News is published by the WaterJet TechnologyAssociation (WJTA) and is a benefit of membership inthe Association.©2006 Jet News. All rights reserved. Reproduction inany form forbidden without express permission.April 2006 WJTA on the web: www.wjta.org Page 11

GT/WaterBlast TechnologiesMark Gillispie2400 Campbell Road, Bldg DHouston TX 77080Phone: (713)935-9856Fax: (713)935-9858Prepcon, Inc.Dominic HueyDave RuckerMichael O’Malley6737 Dogwood RoadBaltimore, MD 21207-4121Telephone: (410)265-6722Fax: (443) 200-1010Putzmeister AmericaUwe Erich ZimmermannGregory LauxCharles Johnson1733 90th StreetSturtevant, WI 53177Telephone: (262)884-6296CorporateWJTA Welcomes New MembersShell Global Solutions Int’lWim BondGert List NielsenBadhuisweg 3Amsterdam, 031-CMNetherlandsPhone: [31](20)6302029Fax: [31](20)6302235Corporate AlternateAlejandro VegaBefesa TLIAvda. Ingenieros Marcos Seguinnave 2. Pol. Ind. Las Salinasde Levante11500 Puerto de Santa MariaCadizSpainPhone: [34](956)543776Fax: [34](956)543681Corporate IndividualClinton BirdVeolia Environmental ServicesIndustrial Services806 Hoods Creek PikeAshland, KY 41101Telephone: (606) 329-1306Fax: (606)325-8475Larry ColliganVeolia Environmental ServicesIndustrial ServicesP.O. Drawer KGroves, TX 77619Telephone: (409)963-0151Fax: (409)983-7374Gerald HoffmanVeolia Environmental ServicesIndustrial ServicesP.O. Box 1099Rockdale, TX 76567Telephone: (512)446-6758Fax: (512)446-4901Debbie MartinVeolia Environmental ServicesIndustrial Services2000 North Highway 146LaPorte, TX 77571Phone: (713)307-2151Fax: (713)307-7644Randy MillarVeolia Environmental ServicesIndustrial Services3410 South Service RoadBurlington, ON L7N-3T2CanadaTelephone: (905)633-7172Fax: (905)633-7720Ken MitchellVeolia Environmental ServicesIndustrial Services511 E. Channel RoadBenicia, CA 94510Telephone: (707)748-3715Fax: (707)748-1681Veolia Environmental Services IndustrialServices formerly ONYX Industrial Services Inc.(continued on page 18)Page 12 WJTA on the web: www.wjta.org April 2006

Jetstream Names Krupowicz VP, General ManagerJetstream of Houston, LLP ispleased to announce theappointment of Bill Krupowicz to vicepresident, general manager.Krupowicz replaces Ron Schmidt,who has been named vice president oftechnology development at the FederalSignal Environmental Products Group.Jetstream is a subsidiary of this group.In his new role, Krupowicz willassist Jetstream with current growthinitiatives as the company continues topursue a global leadership position inthe high-quality, high-pressurewaterblasting equipment industry.Krupowicz, who joined Federal Signalin 2000, was most recently vicepresident, general manager of LeachCompany, another subsidiary of theFederal Signal Environmental ProductsGroup.Jetstream manufactures industrialhigh-pressure waterblasting equipmentoperated at pressures up to 40,000 psifor a wide range of industrial cleaningand surface prep applications. Productofferings include a complete line ofskid- and trailer-mounted pump units,control guns, valves, hoses,replacement parts and nozzles.For more information, call 1-800/231-8192, or visit Jetstream online atwww.waterblast.com.“Bill brings a wealth of engineering,product management and internationalbusiness knowledge to Jetstream,”said Mark Weber, president, FederalSignal Environmental Products Group.“His experience is a great complementto Jetstream, which has significantrevenue growth opportunities in newdomestic applications and internationalmarkets.”Mark Your Calendar2007 WJTAAmerican <strong>Waterjet</strong>ConferenceAugust 18-22, 2007Marriott HoustonWestchase HotelHouston, TexasExperienced contractorscan tell you: the firstname in water jetsolutions is NLB.From immediateequipment needs to simplequestions, help is only a clickaway. NLB is the source for:• top-quality pumps andaccessories (to 40,000psi) for virtually any job• 1-man pump conversions• convenient rentals, parts and service• industry-leading R&D• on-line water jet tips and forumsFor a 24/7 link to the most productive water jet solutions,visit www.nlbcorp.com. Or speak with one of the NLB pros,toll-free, at 1-877-NLB-7988.www.nlbcorp.comNLB. <strong>The</strong> Contractor’s Choice.29830 Beck Road, Wixom, MI 48393MI: (248) 624-5555, TX: (281) 471-7761NJ: (856) 423-2211, LA: (225) 622-1666CA: (562) 490-3277e-mail: nlbmktg@nlbusa.comApril 2006 WJTA on the web: www.wjta.org Page 13

<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong> <strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong> <strong>Steel</strong> Wall, from page 11and only slight damage had occurred after 6 minutes. Withthe same conditions at 105 MPa (15,000 psi) and .79 mm(.031 in.) diameter jets (48 kW), no damage was causedafter 60 seconds, with slight damage after 120 seconds, andat 140 MPa (20,000 psi) with .79 mm (.031 in.) diameterjets (74 kW), slight damage was caused after 30 seconds.<strong>The</strong> damage produced at the latter condition is shown inFigure 12. <strong>The</strong> plotted results are shown in Figure 13 inaddition to those obtained from a rotating head at 250 MPa(36,000 psi) with three nozzles, .48 mm (.019 in.) diameter(62 kW) at 80° to the tube wall with 9.6 mm (.38 in.)standoff distance. At 250 MPa (36,000 psi), a smallamount of damage was caused after 10 seconds, and a fairamount was created after 60 seconds. Figures 14 and 15show the test sample used and the resulting damage.When operating at 250 MPa (36,000 psi), even withrotation, the tool should be kept moving along the tube.3.3 Jet Angle<strong>The</strong> effect of jet angle of impingement on the tube wallwas studied at 250 MPa (36,000 psi) with rotating jets todetermine if a shallow angle resulted in reduced damage.A single .61 mm (.024 in.) sapphire nozzle was used. At 10degrees, no damage occurred after 60 seconds ofexposure, but a small amount of damage did begin to occurat 20 degrees after 30 seconds, and after 10 seconds with a30 degree angle. <strong>The</strong>se results are shown in Figure 16.Figure 11. Rotating Jet <strong>Damage</strong> Compared to StationaryJet <strong>Damage</strong>Figure 12. Rotating Jet <strong>Damage</strong>at 140 MPa (20,000 psi), Drilled<strong>Steel</strong> Nozzles, Time Periods of 30and 60 Seconds Also pictured on thecover4.0 CONCLUSIONS<strong>Waterjet</strong> damage to steel tubing and pipe is quite dependenton the operating pressure, rotation or other motion of thejet, and the amount of time the jets are left in the sameplace. <strong>Damage</strong> is also dependent on the standoff distanceand somewhat dependent on the quality of the jet. <strong>The</strong>re isa fairly high risk of damage at 250 MPa (36,000 psi); thejets must be kept continuously rotating and traversing alongthe tube or pipe; if the rotation or linear motion stops for asmuch as 10 seconds, damage may be caused. <strong>The</strong>re is adecrease in risk when the pressure is lowered to 140 MPa(20,000 psi); however, a stationary jet is still likely to causedamage and the operator should not allow a rotating tool tobe left in the same place for 30 seconds or more. <strong>The</strong> riskdecreases considerably further at 105 MPa (15,000 psi);rotating jets require over a minute in the same location tobegin to create damage, while a stationary jet could cause asmall amount of damage after 30 seconds. Operatingpressures at or below 70 MPa (10,000 psi) are at veryslight risk of causing damage with any combination ofconditions.Figure 13. Rotating Jet <strong>Damage</strong> Drilled <strong>Steel</strong> andSapphire NozzlesFigure 14. Rotating Jet <strong>Damage</strong> at 250 MPa(36,000 psi), at Time Periods of 10, 30 and 60Seconds(continued on page 15)Page 14 WJTA on the web: www.wjta.org April 2006

Flow International Launches <strong>Waterjet</strong>pro Line <strong>Of</strong> Cutting TablesFlow International Corporation(NASDAQ: FLOW) hasannounced the launch of its<strong>Waterjet</strong>PRO line of waterjetcutting tables.For less than the price of a usedwaterjet, <strong>Waterjet</strong>PRO offersaffordable tables that are dependable,fast and accurate and include suchfeatures as a jogging pendant andprogrammable Z-axis. <strong>Waterjet</strong>PROtables are made possible thanks toFlow’s new program, Powered byFlow, which enables machine toolproviders to integrate Flow’s ultrahighpressure(UHP) pump technology aspart of their existing product lines.Powered by Flow givescompanies looking to expand theircapabilities a consistent, reliablesource of ultrahigh-pressure. Inaddition, customers of thisprogram will receive the awardwinning, high quality serviceprovided by Flow including 24/7online parts ordering, trainedfield service engineers locatedaround the country, and superiortechnical support anddocumentation.“<strong>Waterjet</strong>PRO cutting tablesoffer companies previouslyunable to afford waterjet machines thebenefits of ultrahigh-pressure waterjettechnology, keeping them competitivein today’s manufacturingenvironment,” said Marjorie Millay,product manager, Flow International.Target markets for <strong>Waterjet</strong>PROtables include stone, tile anddecorative glass companies; small jobshops; sign shops; university and<strong>Waterjet</strong> <strong>Cleaning</strong> <strong>Of</strong> <strong>Steel</strong> <strong>Process</strong> <strong>Lines</strong><strong>Without</strong> <strong>Damage</strong> <strong>To</strong> <strong>The</strong> <strong>Steel</strong> Wall, from page 14technical colleges; R & D areas withinmanufacturing operations; companiesseeking economical methods forprototyping, producing small batchesand allowing suppliers to quicklydeliver product while setting up highcapacity cutting such as stamping ordie cutting; and anyone seeking a fast,flexible way to cut soft materials.For more information, visitwww.flowcorp.com.Figure 15.Detail of<strong>Damage</strong> by 250MPa (36,000psi), RotatingJet after 30SecondsFigure 16. Effect of Jet Impingement Angle at 250MPa (36,000 psi) with Single Rotating JetApril 2006 WJTA on the web: www.wjta.org Page 15

Safety Committee SolicitsComments OnImprovements <strong>To</strong>Recommended Practices<strong>The</strong> WJTA Safety Committeehereby solicits commentsregarding improvements to thepublication, Recommended Practicesfor the Use of Manually OperatedHigh Pressure <strong>Waterjet</strong>tingEquipment. While RecommendedPractices is reviewed periodically atthe biennial conferences of theWaterJet Technology Association, yourcomments and suggestions forimproving the publication are invitedand welcome anytime.Please address your comments andsuggestions to: Safety Committee, c/oWJTA, 906 Olive Street, Suite 1200,St. Louis, MO 63101-1434, fax:(314)241-1449, e-mail: wjta@wjta.org,web site: www.wjta.org.WJTA AdministrationChairman of the BoardJohn Wolgamott(970)259-2869Vice-PresidentPat DeBusk(281)842-8000Lydia M. Frenzel, Ph.D.(512)392-2210Mohamed Hashish, Ph.D.(253)850-3500Bill McClister(713)307-2142Andrew F. Conn, Ph.D.(410)532-3452Thomas J. Kim, Ph.D.(401)874-5991TreasurerLarry Loper(800)289-74472005-2007 DirectorsDavid Summers, Ph.D.(573)341-4314Emeritus MembersPresident/Jet News EditorGeorge A. Savanick, Ph.D.(952)432-7594SecretaryCraig Anderson(281)925-4501Hugh B. Miller, Ph.D.(520)621-4689Carl Olsen(253)872-2300Forrest Shook(248)624-5555Thomas J. Labus(262)245-9702Fun-Den Wang, Ph.D.(303)279-9415Association ManagersMark S. Birenbaum, Ph.D. l Kenneth C. Carroll(314)241-1445World <strong>Of</strong> Concrete Debut For NewRobot From AquajetNew robot from Aquajeteliminates the need for handtrimming and offers more stableoperation during vertical indexing.A new top-of-the-range HVD robotfrom hydrodemolition specialistAquajet made its debut at the recentWorld of Concrete Congress in LasVegas, Nevada.<strong>The</strong> new model features animproved front skirt and power head,offering increased versatility andeasier access up to the wall edge andinto corners. This eliminates the needfor final hand trimming any untreatedareas of up to 10 cm left by previousmodels against the wall edge.A new elevator hoist verticallypositions the cutting head. Itincorporates a sturdierconstruction to hold the headmore securely when indexingup to 6m freestanding height,ensuring more stable operationand eliminating any flexing andmovement.A stronger dual drive systemoffers increased hoist safety inthe event of a failure with thesecond unit automaticallystarting.<strong>The</strong> diesel-powered HVDrobot also features the provenhigh pressure lance controlsystem to provide enhancedsmooth and exact movement bythe highly efficient cutting head.A splashguard ensuresreduced splash by water anddebris.<strong>The</strong> simplified computercontrol system assists theoperator in avoiding mistakes inprogramming and the use of thehydrodemolition robot.<strong>The</strong> new unit is also shorter to offerincreased mobility.New US distributor<strong>The</strong> launch of the new robot atWorld of Concrete also marked thefirst appearance by the newlyappointed USA distributor, PutzmeisterAmerica Water Technology Division.For further information pleasecontact: Stefan Hilmersson, AquajetSystems AB, Brunnsvägen 15, SE-57015 Holsbybrunn, Sweden, Tel: int +46(0)383 508 01, Fax: int +46 (0)383 50730, email: aquajet@aquajet.se.IMPORTANT NOTICEREGARDING SPAMEmail addresses and other member contactinformation published in the WJTA MembershipDirectory is meant to encourage helpful, informativecommunication between members. <strong>The</strong> informationis not provided to circulate spam or junk mail.<strong>The</strong> WJTA leadership requests that members respectthe contact information of fellow members and not usethat information for the dissemination of spam or junkemail. Membership information is not meant to becirculated beyond the WJTA membership.Page 16 WJTA on the web: www.wjta.org April 2006

Industrial Vacuumers Consider Publishing Best Practices, from page 7procedures were the best way to meetOSHA and other regulations. “Whenwe issued our waterjet guidelines 21years ago, many companies thatthought they were in compliance reallywere not,” recalls Debusk.Third party recommendations alsoprovide greater credibility, says BillMcClister, Onyx Industrial ServicesVice President of Support Servicesand WJTA board member. “<strong>The</strong>WTJA is a disinterested third partyinvolved with technical education. Ithas nothing to gain from how it writesits recommendations,”he explains.This is especiallyimportant if a lawsuit arisesfrom a vacuum-relatedaccident. <strong>Without</strong> guidelinesthat define best practices,lawyers may challengecompanies to show that theytook all necessary safetyprecautions.Established, industry-wideguidelines provide abenchmark for industrialcleaning companies to showthey operate safely. “Ourguidelines have been cited incourt cases as evidence that acompany was followingrecommended practices,” saysCarroll.Even more importantly, saysMcClister, collaborating onbest practices gives the entireindustry a way to improve itsprocedures. “We’ve all mademistakes, we’ve all hadaccidents,” he explains. “Eachone is a black eye for theentire industry. By workingtogether, we can create acentral clearing house wherewe can learn from our individualmistakes and improve safety foreveryone.”Moving Forward<strong>The</strong> WJTA plans to bring togethervacuum equipment operators, endusers,and manufacturers in Chicagothis August to discuss potentialguideline development.“While we will go into the meetingwith an agenda, our real goal is tolisten to what the industry wants fromour organization,” says Carroll. “Mostindustrial cleaning companies we’vetalked with seem interested.”“If you’re a leader in this industry,you certainly want to be involved,”says Debusk. “This is a chance tostate your case and help make ourindustry safer and more efficient.”If you want to learn more, call KenCarroll, LeAnn Hampton, or MarkBirenbaum at WJTA at 314-241-1445or e-mail wjta@wjta.org.Reprinted by permission of Jetstream ofHouston, a subsidiary of Federal SignalCorporation’s Environmental Products Group.April 2006 WJTA on the web: www.wjta.org Page 17

Conference Committee,2007 American <strong>Waterjet</strong>ConferenceRecommends and organizesthe Conference program andactivities.Pat DeBusk, Co-ChairmanBill McClister, Co-ChairmanCraig AndersonMohamed Hashish, Ph.D.Membership CommitteeRecommends policies toincrease membership inWJTA.Bill McClister, ChairmanPat DeBuskHugh B. Miller, Ph.D.Pete MitchellCarl OlsenNominating CommitteeOversees the nominationand election of boardmembers.Lydia Frenzel, Ph.D., ChairmanHugh B. Miller, Ph.D.Forrest ShookJohn WolgamottWJTA Committees(as of March 21, 2006)Following is a list of WJTA committees and the memberscurrently serving on those committees. All WJTA membersare invited to participate on committee or committees oftheir choice. Contact the WJTA office to volunteer for acommittee.Safety CommitteeRecommends changes tosafety manual.George A. Savanick, Ph.D.,ChairmanLydia Frenzel, Ph.D.Rick HeinJenny HoustonMarilee JardineKevin ObornForrest ShookDavid A. Summers, Ph.D.Gary <strong>To</strong>otheBob Turner<strong>Waterjet</strong> Short CourseProgram CommitteePlans and oversees theshort course programs heldin conjunction with thebiennial WJTA Conferences.Lydia Frenzel, Ph.D.Thomas Kim, Ph.D.Hugh B. Miller, Ph.D.David A. Summers, Ph.D.John Wolgamott<strong>To</strong> volunteer for any of these WJTA Committees,contact: WJTA Committees, 906 Olive Street, Suite 1200,St. Louis, MO 63101-1434, phone: (314) 241-1445, fax: (314) 241-1449, email: wjta@wjta.org, web site: www.wjta.org.1-800-964-92747000PSI24HP Honda Twin15,000 Hour GatesPoly Drive$4,499200 Models In Production - Free CatalogWJTA Welcomes New Members, from pg. 12Gary NotoVeolia Environmental ServicesIndustrial Services3018 N. Hwy 146Baytown, TX 77520Telephone: (713)307-2145Fax: (713)307-7260Bob TurnerVeolia Environmental ServicesIndustrial Services29906 North Legends Chase CircleSpring, TX 77386Telephone: (713)307-2127Fax: (713)307-7644IndividualPatrick AdamsAll State Technology, Inc.10 Lark LaneOak Ridge, NJ 07438Telephone: (973)697-8989Fax: (973)208-9542Sean BenoitPSC330 Walcot R.D.West Lake, LA 70669Telephone: (337) 882-1313Fax: (337) 8821314John DemakasDemakas Plumbing & Heating Inc.2370 Oakdale AvenueSan Francisco, CA 94124Telephone: 4152822121Fax: (415)282-2177Aaron M. GodfreyClean Harbors Environmental Ser.210 Forsyth RoadSalem, CT 06420Phone: (860)883-3015Fax: (860)585-1740Alan HillIntercleanPO Box 58087Greenmount, AucklandNew ZealandTelephone: [64](9)2737570Fax: [64](9)2737571Henry HsiehOHPrecision3, Lane 19, Pateh Rd.Hsinchu 300Taiwan, Republic of ChinaPhone: [886](3)5616277Fax: [886](3)5616381Mark G. MirePneumatic and Hydraulic Co., LLC105 Lafferty DriveBroussard, LA 70518Telephone: (800)762-8328Fax: (225)383-9818Jay C. Paro Jr.Certrifugal Services Inc.5595 Hwy 34 NorthRaleigh, IL 62977Phone: (618)268-4850Fax: (618)268-4573Pedro QuinonesCHCLP.O. Box 457<strong>To</strong>a Baja, PR 00951Phone: (787)794-1220Fax: (787)794-4831Sean RigneyArcadia Supply Inc.67 Erie BoulevardAlbany, NY 12204Richard W. SimsShamrock Septic ServiceP.O. Box 277Epworth, GA 3054Telephone: (706)492-2028Cameron StansberryJames Hardie BuildingProducts, Inc.17 Unytite DrivePeru, IL 61354Telephone: (815)220-3050Fax: (815)220-3097Keith SuttonMacLellan Integrated Services3120 Wall Street, Suite 100Lexington, KY 40513Phone: (859)219-5407Fax: (859)219-5438Nathan ThompsonPlumbing and Jetting, Ltd.79 Crib Street WareSG129HF United KingdomPhone: [44](08)000757540Fax: [44](08)00700416916Anton X. <strong>To</strong>mkoHydro Technical Serv., Inc.P.O. Box 305Elizabeth, PA 15037-0305Telephone: (412)384-9327Fax: (412)384-9350Luis <strong>To</strong>rresCAPP AGHilderserstrasse 16Schwallungen 98590 GermanyTelephone: [49]3684825810Fax: [49]3684825812Carl WikoffClearwater Plumbing Inc.409 N. Ft. Harrison AvenueClearwater, FL 33255Phone: (727)446-8355Fax: (727)461-2028Norton Williams368 Floral DriveWinter Garden, FL 34787Telephone: (407)970-2770Page 18 WJTA on the web: www.wjta.org April 2006

Butech PressureSystemsRestructuringButech Pressure Systems hasbeen a division of HaskelInternational, Inc. for several years.In November 2004, HaskelInternational, Inc., became a whollyowned subsidiary of Milton Roy, whois part of the United TechnologiesCorporation (UTC) family ofcompanies. UTC is one of the majorUS companies with worldwideoperations.<strong>The</strong> Butech Pressure Systemssales and engineering organizationwill remain in Erie, Pennsylvania, andit will continue to need parts andservices delivered there for theirwork.As of January 1, 2006, the ButechPressure Systems productsmanufacturing organization wasrestructured.<strong>The</strong> machine shop operationsremain in Erie with ownershiptransferred to the spin-off companyAdvanced Pressure Technologies,LLC. This new company will be runand staffed by current employees ofButech Pressure Systems.WaterArmorWater JetProtectionSafe at 40,000 psiTurtleSkin WaterArmor suitshave saved many operatorsfrom injuries on the job. Itspatented protective systemhas been tested to preventinjuries at flows as high as11 gpm at 20,000 psi or5.5 gpm at 40,000 psi.<strong>The</strong> assembly and tubingoperations will be transferred to theHaskel International plant inBurbank, California, with ownershipcontinuing under HaskelInternational, Inc.Advanced Pressure Technologies,LLC in Erie will continue as aprimary supplier of machined partsfor the Butech Pressure Systemsproduct line, under contact withHaskel International, Inc.TurtleSkin WaterArmor toe panelaccidentally swiped at 20,000 psi.Another TurtleSkin toe panel not only savedan operator from serious injury, it was easilyreplaced, saving the cost of an entire new suit.Winner of the 2005 WJTA Safety Awardturtleskin.com +1.603.878.1565April 2006 WJTA on the web: www.wjta.org Page 19

Count on our proven valves, fittings & tubingfor your waterjet cutting & blasting systemSafely delivering water at elevated pressures for cutting and cleaning applications demandsreliable operation from your valves, fittings and tubing. It demands Performance Under Pressure.For over 50 years, HiP has been focused on producing a complete line of the highestquality valves specifically designed for just such waterjet applications.We’re committed to providing our customers with the consistent quality andresponsive service that helped us earn ISO9001 certification. We stock an extensiveinventory of valves and accessories, allowing us to offer same day shipping ofmany products. For special orders, including custom manifolds, we have shortlead times and experienced engineering assistance.Before you spec high pressure valves, fittings or tubing, check out thecompany that Performs Under Pressure… HiP.HiP…Our Name is High Pressure<strong>To</strong> find out more, come see us online atwww.highpressure.comor call 1-800-289-7447CERTIFIEDHigh PressureEquipmentCompany