MF WR Series Windrowers Brochure - Hesston.com

MF WR Series Windrowers Brochure - Hesston.com

MF WR Series Windrowers Brochure - Hesston.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>WR</strong> <strong>Series</strong> SP <strong>Windrowers</strong> & SwathersThere’s hay.And now there’s<strong>Hesston</strong> Hay

Plug & Play AutoSteering The most advanced GPS steering available.Field speeds up to 16 mph.The all new<strong>WR</strong> <strong>Series</strong>.Cutting-edgeheader to tail.Electro-Hydraulic SteeringMore precision, quicker responseand adjustable steering sensitivity.FieldMax MonitorControls virtually every windrower function,using advanced operational software.Semi-Active Air Suspension SeatReads and adjusts to field conditions,reducing the transfer of vibrations.Independent Header FlotationFor unprecedented flexibility and control.

Cab SuspensionA better way to handle borders, pivots and the roughest field conditions.AGCO POWER EnginesOur 6.6 liter 220 HP powerhouse and revolutionaryQuadBoost 188 HP 4-cylinder engine or 137 HP4-cylinder engine.e3 Clean Air TechnologyThe <strong>com</strong>plete answer to Tier IVi <strong>com</strong>pliance.V-Cool SystemIncludes an auto-reverse fan that eliminatesthe need for rotary screen cleaners.Radial TiresFor better traction, moreflotation and a better ride.TwinMax Advanced ConditioningDouble crimping vs. crushing forfaster-drying and higher quality hay.GlideRider Rear Axle SuspensionOur new adjustment-free system that assuressmooth, stable operation with far less bounce.Low-Profile RazorBar Delivers a closer, faster, quality cut.

Wel<strong>com</strong>e to our new<strong>WR</strong> <strong>Series</strong> brochure.I am the frontier. And the dust bowl. And abundant waves of grain.Wel<strong>com</strong>e to the next generationof windrowers. And the nextgeneration of hay.More than just a new model, ourall new <strong>Hesston</strong> by Massey Ferguson ®<strong>WR</strong> <strong>Series</strong> represents an entirely newclass of self-propelled windrower.There’s no other windrower out therethat delivers quality hay faster or moreefficiently, with greater precision, lessfatigue, better fuel economy and loweroperating costs.I am six generations of farmers, looking forward to sunrise.And six generations, working into the night.The Spirit of the BrandI am the sun on your back. And the swagger in your step.I am your independence. I am hard work. And bountiful rewards.We like to call the end result <strong>Hesston</strong> Hay, because our new <strong>WR</strong> <strong>Series</strong> isthe only way you can produce it.A steadier hand. And a <strong>com</strong>fortable <strong>com</strong>panion.I am an easier ride on that rough row to hoe.

I am resolute. Resourceful. Inventive. And honest.I understand your dreams. And your realities.I am the next chore. The next crop. The next harvest. The next opportunity.I am your tractor. Your tool. Your edge.I am your strong right hand.I am Massey Ferguson.The heart of the farm. And the joy in the work.PAGE 3

Once a pioneer,always a pioneer.Over 160 years ago, Daniel Masseystarted it all. He was a family man,working man, businessman, inventor,tradesman, manager, entrepreneur andgenius. In other words, he was a farmer.For more than 50 years, we’ve shownthat same <strong>com</strong>mitment in the hayand forage business, too. Since 1955,<strong>Hesston</strong> has been the undisputedleader, with innovations like the firstself-propelled windrower, the firsthydrostatic windrower and the firstbig rectangular baler.Today, more than ever, we’re determinedto prove that the heart of theoriginal Massey Ferguson and <strong>Hesston</strong>brands still beats under the shiny newexteriors of every model we make.“Beauty in engineering is that which issimple, has no superfluous parts andwhich answers exactly its purpose.”192619471847Daniel Massey establishes what willbe<strong>com</strong>e Massey Ferguson – the sameyear Thomas Edison, Joseph Pulitzerand Jesse James were born.Harry Ferguson patents the 3-point hitchand changes tractor design forever.19551967Hydro-Static 600 – the firsthydrostatic drive windrower.<strong>Hesston</strong> introduces the<strong>Hesston</strong> introduces its Model 100–the first <strong>com</strong>mercially availableself-propelled windrower.–Harry FergusonNow part of the Massey Fergusonfamily, the <strong>Hesston</strong> ManufacturingCompany is founded.

1974TABLE OF OPPORTUNITIESIntroduction p. 6Technology p. 8<strong>Hesston</strong> by Massey Ferguson introduces the 16-footRazorBar cutter, featuring the lowest profile in the2009industry for a closer, faster, cleaner cut.The inaugural <strong>Hesston</strong> belt buckle is issued –the first of the famous series still coveted bycollectors today.Engines p. 14e3 p. 161978Ride & Comfort p. 18Header Lift & Tilt p. 20Massey Ferguson leads theway in clean air technology withits visionary e3 SCR system.<strong>Hesston</strong> introduces the first2011large square baler.Our new <strong>WR</strong> <strong>Series</strong> introduceselectronically controlled hydraulics,operated by a virtual <strong>com</strong>puter terminal,allowing precision control of windrowerfunctions and the incorporation of featuresunheard of in previous windrowers.Advanced Conditioning p. 22Disc Header p. 24Sickle Headers p. 26Draper Headers p. 28Service & Support p. 302008Specifications p. 32PAGE 5

Designed by the sharpest minds in the hay business. Farmers.It’s no exaggeration to say the <strong>WR</strong> <strong>Series</strong> is the most important advance in <strong>Hesston</strong> technologyin 30 years, featuring more than a dozen proprietary features developed in response to directinput from working hay producers.For instance, we’ve be<strong>com</strong>e the first in the industryto operate all hydraulic, engine and drive functionsby means of an onboard virtual <strong>com</strong>puter terminal,utilizing hydraulic technology that provides a levelof precision previously unheard of – while actuallymaking the controls easier to use.The all new <strong>WR</strong> <strong>Series</strong>. Yet another benchmark fromthe <strong>com</strong>pany that introduced the first SP windrowerback in 1955. And nothing less than a new standardthat will redefine windrowing for years to <strong>com</strong>e.<strong>Hesston</strong> ExclusiveFPONew to QRC scanning?See page 30 for directions.

MODEL ENgine rated hp Headers THE PERFECT FIT<strong>WR</strong>9770 AGCO Power 6.6L 220DiscDraperAugerThis top-end model <strong>com</strong>petes in a new class of 200+ HPwindrowers, with the muscle to operate in heavy crop conditionslike winter forage, wet silage hay, and hilly or rough terrain.Our new 6.6-liter AGCO POWER Tier 4i engine uses fourvalves per cylinder to enhance airflow and increase horsepowerfor high-capacity mowing operations.<strong>WR</strong>9770<strong>WR</strong>9760AGCO POWER 4.9L Quad-Boost 188DiscDraperAugerOur new 4-cylinder windrower, this model is designed to performjust as well as, if not better than, most 6-cylinder windrowers. Byincreasing boost pressure, our new 4.9-liter QuadBoost enginegenerates more than enough power to run a 9196 model 16-footdisc header, equipped with an advanced conditioning system.<strong>WR</strong>9760<strong>WR</strong>9740 AGCO POWER 4.9L 137DraperAugerBuilt for the producer who wants to operate an auger or draperheader, this model features the same 4.9-liter AGCO POWERengine, but without QuadBoost technology. It still provides morethan enough horsepower to operate those headers, even inadverse conditions.<strong>WR</strong>9740<strong>WR</strong>9735 AGCO POWER 4.9L 137DraperAugerThis narrow cab swather model is primarily designed for wheatand canola, and for use with draper and auger headers onlyseveral months of the year. It <strong>com</strong>es with the same frame, engineand <strong>com</strong>ponents as the <strong>WR</strong>9740.<strong>WR</strong>9735<strong>WR</strong>9725 Cummins 3.3L 100DraperAugerAnother narrow cab model, designed for wheat and canola, thisis our smallest swather and is only available with the smaller cab.It’s equipped with a Cummins Tier 4i 100 HP engine that’s highlyefficient to operate.<strong>WR</strong>9725IntroductionSee <strong>com</strong>plete specs on page 32.PAGE 7

More than technology. <strong>Hesston</strong>ology.Other manufacturers pride themselves on their technology. Brand afterbrand, year after year, they follow each other, struggling to play catch-up,with some “innovative” new feature.But the <strong>Hesston</strong> name has always been recognized as a leader, not afollower. And we have a philosophy about innovation that’s all our own.In short, if it doesn’t go beyond enhancing your speed, your <strong>com</strong>fort andyour efficiency – to actually improving the quality of your hay – it isn’tinnovation at all. It’s just embellishment.That’s why every technological advancement we’re now introducing withour <strong>WR</strong> <strong>Series</strong> windrowers is designed to do one thing – assure you ofreaping <strong>Hesston</strong> Hay. The highest quality, highest nutrient, highest valuehay possible.Another first in SP windrowers, from the brand that inventedthe category.We’ve said it before and we’ll say it again – our all new <strong>WR</strong> <strong>Series</strong> SP windrowersare absolutely the first in the industry to operate all hydraulic, engine and drivefunctions by means of an onboard virtual <strong>com</strong>puter terminal. Utilizing the mostrecent advances in electro-hydraulic technology, we’re now providing you with<strong>com</strong>puter controls that provide a higher level of precision than has ever beenavailable on a windrower.A multi-tasking monitor that’s years ahead.Consider our extraordinary new FieldMax monitor. It enables you to maximizeyour productivity in every way, on every acre of every field – every day. Virtually allfunctions of the Windrower are controlled from right here, offering you immediateaccess to features like a fuel economy monitor, performance monitor, headerflotation settings – even diagnostics and troubleshooting.The four main screens include a main work screen/dashboard, engine informationscreen, fuel economy meter and acre counter. We’ve made sure each one is easyto read, easy to understand and easy to navigate while you operate the windrower.The main dashboard is icon-based for no-nonsense readability. And a simple,yet <strong>com</strong>prehensive icon guide is attached to the console for easy reference.A wealth of useful information is displayed here, including:n Miles per hourn Header and engine RPMsn Fuel levelsn Diesel exhaust fluidn Coolant temperaturen Left/right flotationn Header tilt, header heightn Engine oil pressuren Header drive motor pressure(Acts as a pacer for optimum speed)AG Cam <strong>com</strong>patible

PAGE 9Technology

Innovative software that works harder, so you don’t have to.Mow all day – or even two – withoutrefueling. Another great feature ofthe <strong>WR</strong> <strong>Series</strong> is the convenienceof having the highest capacity fueltank in the business – 130 gallons.No other windrower holds more.Couple that with our e3 fuel-savingtechnology, and you can go for upto two full days in alfalfa.The software incorporated in our<strong>WR</strong> <strong>Series</strong> design is the latest, greatesttechnology available to take care of amultitude of windrower functions thatyou’d otherwise have to handle yourself,such as automatic header speed, coolingsystem, steering system and System 150 .For example, the automatic header speedcontrol allows the header to <strong>com</strong>municatedirectly with the windrower header drivepumps and the engine rpm. Other systemslike the V-Cool System are controlled bythe same software for optimum efficiency.Automatic header speed control.Obviously, as goes the header, so goesproductivity. And thanks to our windrowersoftware improvements andelectronic displacement pump controls,the response time of the automaticheader speed control has been reduced,making you more productive than ever. Itactually operates and adjusts the headerspeed independently of the engine speed.The benefits are obvious:n Head speed remains constant whenengine speed decreasesn Consistent cut and conditioningn Solid performance even on hills andwhen mowing thicker patches of cropLightweight and portable, System 150can even be moved from vehicle to vehicle.And you can transfer field informationusing a standard USB thumb drive.n Straight line drivingn Reduced operator fatiguen Center pivot circlesn ContoursReal time fuel data for realfuel efficiencies.GPS isn’t the only tactic to increaseyour fuel efficiency. Another great wayis by measuring fuel usage against theamount of work done – not just againstthe time you’ve spent doing it. And theFieldMax monitor digital fuel economymeter on these <strong>WR</strong> <strong>Series</strong> windrowersdoes just that. By monitoring acres pergallon and your operating speed, youcan make adjustments to maximizeyour fuel use. For example, in certainsituations, a field speed of 16 mphmight not be as fuel efficient as12.5 mph. When fuel prices are high,you can drive to maximize fueleconomy. When fuel prices are low,you can drive to maximize productivity.TechnologyPAGE 11<strong>Hesston</strong> Exclusive

Automatic precision. Automatic productivity.Once you’ve got the <strong>WR</strong> <strong>Series</strong> in the field, you’ll find everything aboutit is designed to make every pass more profitable. But the provenperformance of our System 150 positioning technology is a key factorin maximizing your return on investment. Whether your goal is toreduce skips and overlaps or to work at faster speeds, you can achieveit, thanks to the most sophisticated positioning system available.More specifically, System 150 technology allows you to use the fullwidth of your header, which means greater efficiency and fuel economy.Its hands-free steering reduces operator fatigue and enhances your<strong>com</strong>fort. You’ll also be working at faster speeds, so you’ll cover moreacres per hour. And pass-to-pass accuracy can be maximized from+/- ten inches down to +/- a single inch, depending on the correctionsignals you choose.The world’s most advancedhands-free* steering.Hands down.It only makes sense that the nextgeneration of windrower would makethe most of the next generation ofhands-free steering technology. Andthe <strong>WR</strong> <strong>Series</strong> does – with System150 Precision AutoSteering.Field speeds of up to 16 mph –with extreme accuracy, especiallyfor a windrower. The aggressive lineacquisition and on-line performanceof System 150 is second to none. Andeasy-to-use features like boundaryand area cut mapping allow you morecontrol over everything from planningyour swath patterns to identifyingareas of overlap.Just Plug & Play – because all <strong>WR</strong><strong>Series</strong> windrowers are pre-wired toaccept System 150 AutoSteering.And System 150 <strong>com</strong>municates directlywith our electro-hydraulic steering, soit eliminates the need for additionalsteering hardware. The response timeis drastically reduced for a much higherdegree of steering accuracy.Easy to operate – when System150 is “on,” the GPS signal replacesthe signal from the steering wheel.If the steering wheel is moved by hand,the windrower automatically goes backto manual steering ** .Stable 21 mph road transport.Thanks to the increased precision andaccuracy of our electro-hydraulic steeringand Electronic Displacement Control,our 21 mph travel speed offers bettercontrol, quicker response and morestability. Optional on the 4.9 liter models.* Please refer to the operator’s manual for proper operation of System 150 Precision AutoSteering Systemwith the <strong>WR</strong> <strong>Series</strong> <strong>Windrowers</strong>.**Operators can easily engage the System 150 AutoSteering by pressing a button on the back of theFNR handle.

Adjustable steering that’s as easy asone, two, three.Because our all new <strong>WR</strong> <strong>Series</strong> <strong>Windrowers</strong>utilize electro-hydraulic steering through ourElectronic Displacement Control (EDC), you’llenjoy more precision and quicker response time.Not to mention your new windrower will beeasier to drive, with more control, at fasteroperating speeds. But that’s not all, because thesemachines even allow you to adjust the steeringto your personal preference. It’s tunable at threelevels in terms of:n Steering resistance (friction)n Steering sensitivity (steering wheel movement)n Multi-position steering column“ I don’t want to adjust to mywindrower steering. I want itto adjust to me”– Farmer / Nebraska2,000 acres in hayTechnologyPAGE 13

Cooling fan technologythat’ll blow you away.Our high-performance cooling fan,part of our new V-Cool System,goes far beyond ordinary rotaryvacuum screen cleaners. Becauseit’s hydraulically driven, it can runat variable speeds, allowing it tomatch the cooling needs of theengine. Again, because it’s hydraulic,it can auto-reverse to clean out theradiators and fan screen. And that’sjust what it does at 15-minuteintervals. The fan reverses uponheader shutdown. The reverse fanalso senses the cooling performanceand adjusts the fan speed or increasesthe reversing cycle. When you tallyup all the advantages, you’ll be a fanof this fan too:n Fan speed is independent ofengine speedn Adjusts to conditionsn Saves fuel by operating atlower rpm when extra coolingisn’t neededn Reduces risk of waterpump failure due toless load on thepump bearings

AGCO POWER engines that clearly live up to their name.After all, isn’t POWER what enginesare all about? Their sole purpose is todeliver the POWER to do what youneed – hour after hour, day after day,year after year. Rest assured, theAGCO POWER engines in our new<strong>WR</strong> <strong>Series</strong> windrowers do more thandeliver the goods.n 6.6 liter / 220 HPn 4.9 liter / 188 HP QuadBoostn 4.9 liter / 137 HPOur six-cylinder AGCOPOWERhouse.You might say reliability is built intoour 6.6-liter engine’s DNA – alongwith durability, strength, longevity andoutstanding fuel economy. Manufacturedat our own SISU diesel plant in Nokia,Finland, these engines are backed byover 65 years of innovation and provenperformance.Four valves per cylinder – providea better fuel/air mixture, optimum<strong>com</strong>bustion and a reduction inthermal loads.A four-cylinder engine that thinksit’s a six.No one else in the industry offersanything like our 4.9-liter QuadBoostengine. Because this 4-cylinder powerplant features higher power density, itgenerates significantly more horsepower,not to mention excellent torque andfuel savings. And you thought only a6-cylinder engine could perform this well.Higher power density simply meansour new QuadBoost engineprovides more power from thesame engine volume.Features <strong>com</strong>mon to all.n Cross flow cylinder headsn Mid-cylinder liner supportn Turbo-chargedn Air to air intercooledn Common rail fuel injectionn Fracture split connecting rodsn Balanced rotating assemblyThe best way yet to dealwith Tier 4i.When it <strong>com</strong>es to <strong>com</strong>plying with EPATier 4i standards, we’ve been way aheadof our <strong>com</strong>petitors in proving that SCRemission technology is the only way togo. In tandem with the EEM4 system,our updated e3 clean air technologymeans these AGCO POWER dieselengines will run better, stay cooler andlast longer. Read on. We’d love to bringyou up to speed.“ If you haven’t got an engineyou can count on for thepower, the reliability and thefuel efficiency you need, therest doesn’t matter.”– Farmer / California5,000 acres in alfalfaCommon rail fuel injection –delivers improved fuel application withprecision metering.New full-authority ElectronicEngine Management.Working in perfect unison with theelectronic fuel injection system toprovide quick and precise response tothrottle movement, our EEM4 systemcontinually adjusts fuel injection inrelation to engine speed and load tomaximize power.Balanced rotating assembly –a feature normally found only in highperformanceracing engines, this ensuressmooth running dependability.<strong>Hesston</strong> ExclusiveEnginesPAGE 15

Compliance without <strong>com</strong>promise.Compliance without <strong>com</strong>promise.The e3 SCR clean air system on our Tier 4i engines is emission technologythat <strong>com</strong>plies with Finally, you. there's Because emission it offers technology the most that farmer-friendly <strong>com</strong>plies with you. approach Because ourtoward meeting <strong>MF</strong>8600 EPA standards <strong>Series</strong> tractors – without offer the making most trade-offs farmer-friendly in power, approach towardproductivity and meeting operating up<strong>com</strong>ing costs. EPA standards – without making trade-offs in power,productivity and operating costs.With e3, you With don’t e3 give you don't up a give thing. up a thing.n Optimized fuel <strong>com</strong>bustionn Un<strong>com</strong>promised horsepower and torquen Un<strong>com</strong>promised horsepower and torquen Significantly improved fuel economyn Significantly improved fuel economyn An easier, more efficient path to meeting EPA standards now and in the futuren An easier, more efficient path to meeting EPA standardsn Engines that n run With cooler e3 technology, engines run coolern And e3 technology adds nothing to the price of the tractor“ I know I have to meet EPAstandards. But I also need toknow I’m not underminingmy "I need windrower’s technology performancethat meetsand EPA fuel standards. efficiency.” But first it hasto meet mine."– Farmer / KansasFarmer on 3,000 acres in Nebraska2,700 acres in wheat and hay

Inhales emission. Exhales power.Start to finish, e3 is designed to helpyou meet up<strong>com</strong>ing emission standardswithout sacrificing your own. It providesyou with all the energy you need in theform of undiminished horsepower andtorque. And it’s a fact that SCR systemsget up to 10% better fuel economy thanengines using other emissiontechnology.As simple as it is effective.The key to e3 technology is that it staysout of the way of what the engine isbuilt to do – provide power. Because e3is a post-<strong>com</strong>bustion, after-treatmentprocess that takes place in the exhaustsystem, it never interferes with theengine itself. And there’s no need fora larger radiator. Believe it or not,the e3 process actually allows ourAGCO POWER diesel engines toperform better, run more efficiently,stay cooler and last longer.Cleaner air. Pure performance.e3 technology treats the downstreamexhaust with Diesel Exhaust Fluid(DEF), which breaks down intoharmless nitrogen and water. Thetechnology is simple, robust andreliable, consisting of very few parts.Main <strong>com</strong>ponents include a tank,an injection system and an SCRcatalyst chamber.Our AGCO POWER diesel engines are optimized for high performance, lowparticulate emissions and low fuel consumption.In the catalyst chamber, nitrogen oxides (NOx)are transformed into harmless nitrogen gas andwater vapor.The pump and injection system unit reacts tothe emissions output of the engine by continuouslyvarying the amount of DEF added to theexhaust stream – effectively maintaining controlof emissions released into the environment.Tank that holds Diesel Exhaust Fluid (DEF)e3PAGE 17

Hardworking cab improvements to make your life easier.Everything about our new cab is designed to give hay producers all the featuresthey’ve told us they want and need. To increase efficiency and reduce fatigue,we’ve redesigned these cabs top to bottom – and in the process,we’ve delivered a substantially better ride.Upgrades include:n Optional semi-active airsuspension seatn A more convenient, intuitiveside consolen Better lightingn Optional automatic climate controln A brand new steering column, witha greater range of steering wheelpositions and adjustmentsOh, and there’s one more featureprofessional producers asked us toaddress that came through loudand clear.A cab so quiet you can hearjaws dropping.Seriously. The reduction in operatingnoise on the <strong>WR</strong> <strong>Series</strong> is so significantit’s stunning. Thanks to our quieterrunninge3 Tier IVi engines, quieterhydraulics, extra sound-deadeningmaterial and a thicker floor mat,it’s almost like working in an officeenvironment. Only with a muchbetter view.A seat so responsive itanticipates every move.Our optional deluxe semi-active airsuspension seat takes sensor readingsmore than 60 times per second. Thenit reacts to field conditions and adjuststhe seat suspension instantaneously,improving the ride and reducingbounce. Since the jarring forcesduring windrowing are predominantlyhorizontal, our seat also moves laterally,fore and aft and side-to-side, to helpreduce operator fatigue.It also actually keeps you cooler in thesummer and warms you up in the fall.And because most hay farmers tell usthey’d windrow as fast as they could –as long as they can stay sitting down,we’ve made sure our new seat helpsthem do exactly that. In fact, we’ve hadit specially customized so now the seatcushions conform along with leatherside cushions even more precisely tothe operator, almost like a seat in asports car – just to help you stay put.Bottom line, this industry-exclusiveseat is specifically built to enhanceyour <strong>com</strong>fort, health and productivity –not to mention your speed.Enhanced cab suspension.On the <strong>WR</strong>9770 and <strong>WR</strong>9760, weoffer an optional cab suspension systemthat incorporates dual air bags, an airreservoir and dual shock absorbers –especially <strong>com</strong>forting features whenharvesting rough fields with the highspeed9195 or 9196 RazorBar discheader. With pressure settings from15 to 35 psi, the suspension is similarto that of a tractor cab – a real pluswhen you’re operating on pivots,borders or conditions involving dips,ruts or ditches.GlideRider adjustment-free rearaxle suspension.This durable, maintenance-free system is<strong>com</strong>posed of a solid oscillating rear axlebeam attached to the frame by parallelmaintenance free link arms on both sidesand a lateral support arm underneath.Providing the suspension are two gasshocks and a spring in the center ofthe axle. This <strong>com</strong>pletely new approachmeans GlideRider transfers load tothe main frame, so bounce is reducedand your <strong>com</strong>fort level is increased –even at higher field speeds.

PAGE 19Ride & Comfort

Climb every mountain. Or at least every hill.Let’s be honest. Hydraulically driven equipment like windrowers,<strong>com</strong>bines and sprayers aren’t exactly known for their pulling power.Especially when it <strong>com</strong>es to climbing hills or working in muddyconditions. So we’ve significantly boosted the pump flow to givethe <strong>WR</strong> <strong>Series</strong> unmatched hill-climbing ability, with more torquein the field and increased transport speed.Three selectable ranges provide the hydraulic power you need,at the rate you want to run.n Range 1: 0 to 13 mph (operator adjustable)n Range 2: (Field) 0 to 16 mphn Range 3: (Transport) 0 to 21 mph“ It’s no secret farming hasits ups and downs. You justhave to know how to makethe most of them.”– Hay producer / Idaho1,500 acres in hay

Independent header flotation.Another <strong>WR</strong> <strong>Series</strong> innovation that’s having a major impact on productivityis our independent header flotation. By adjusting each lift arm independently,you can increase the lift pressure on one side only, making it easier to cutover irrigation borders and center pivot irrigation tracks as well as allowingfor a closer cut without gouging into the ground. You can also balancethe header from side to side without making mechanical adjustments.And a return-to-level cut feature allows you to go back to your previoussettings. The header can rotate on an angle because of the modular designof the cutter bed.n Eliminates the need for balance weightsn On-the-go adjustmentn Decreases overall machine weightn Reduces ground <strong>com</strong>pactionn No need to raise the header to adjust flotationPAGE 21Header Lift & Tilt

We call it TwinMax but it’s really one-of-a-kind.Is your header working as hard as you are? Unless you’re running our<strong>Hesston</strong> by Massey Ferguson TwinMax Advanced Conditioning System,probably not. TwinMax double crimps the stems, reducing drying time byup to days, while allowing the leaves to stay healthy and whole, retainingtheir vital nutrients.The result is <strong>Hesston</strong> Hay – a higher quality crop that earns you a higherprice on every bale.Crimp vs. crush.Competitive windrowers still featuresystems that condition your cropby crushing both the stems and theleaves to accelerate drying time.But damaging the leaves means lostnutrients, lesser quality hay andlower market value.The only thing we crush isthe <strong>com</strong>petition.Instead of using a single set ofconditioning rollers with no gapbetween them, TwinMax uses twosets of steel-on-steel conditioningrolls, finely tuned to maintain a rollgap for varying crop conditions. Thegap is sustained by hydraulic rolltension that provides constant rollpressure and easy adjustment. Thecrop feeds into the first set ofrollers, where stems are crimpedevery two to three inches whileleaves pass through unharmed. Itthen passes through the second set,where the stems are crimped againevery one to two inches. Theherringbone pattern on the rollscreates a broad, well-formed, levelwindrow that dries faster, moreevenly, and rakes together moreeasily for better baling.“ Premium hay is thedifference between makingmoney and not making money.That’s the bottom line.”– Hay producer / Western Canada8,000 acres in hay<strong>Hesston</strong> Exclusive

PAGE 23Advanced Conditioning

Disc headers designed to make hay pay.If you’re determined to increase your acres per hour while achieving a closer, cleanercut, there’s no faster way to do it than by driving a 9195 or 9196 <strong>Hesston</strong> by MasseyFerguson disc header, with our industry-exclusive low-profile RazorBar cutterbar.The modular, heavy-duty spur gear design of the RazorBar means each gear assemblyand idler gear can be individually removed without taking the whole cutterbar apart.And there’s no need to split the gear modules for servicing. Easy to unbolt andreassemble, the idler gears and pins are removed through the top of the module,so there’s also no need to remove the rock guards for servicing. And each moduleis now sealed with O-rings instead of silicone.In the unlikely event a gear spindle breaks, it will be sheared off outside the cutterbedto prevent contamination of other gears. If a shaft is sheared, the <strong>com</strong>plete hubassembly can be quickly replaced. And because the RazorBar gears are designedto handle a higher load than <strong>com</strong>petitors’, a weak point or shear hub is simplyunnecessary.Our 13-foot and 16-foot RazorBar cutterbars feature a low-profile, spurgear cutterbed that’s thinner in design for closer cutting – so you can slicethrough lush alfalfa, tangled grass and tall Sudan with ease.Other features include:n Radura ® high-carbon steel knives ina choice of degrees and bevelsn Counter-rotating discs withincreased overlapn Sloping disc hub mounts for reduceddebris buildupn Ductile cast-iron module housings,machined for perfect alignment andmaximum durabilityn Infinitely variable disc speed, from1,000 to 2,500 rpm to matchcrop conditionsStandard or Advanced ConditioningWith a single set of steel-on-steel conditioner rolls, the 9195 RazorBar headercrimps stems every two to three inches. To speed drying time and further preserveleaf quality, our 9196 model features the new TwinMax Advanced ConditioningSystem, which “double crimps” the crop through a total of four conditioning rolls,resulting in a crimp approximately every inch. The herringbone pattern on eachmodel helps feed the crop evenly on both sides. And conditioner roll pressure ismaintained by a hydraulic roll tensioning system, allowing for consistent roll pressure,effective crimping and the best quality hay possible.Our improved, extendedturbulence reduction roll featuresbuilt-in side augers to producebetter windrows with fewer drivesand a better cut in light crop.Dual hydraulic motors, whichdrive the cutterbed from eachend, provide even torque loadacross the entire width of thecutterbar for increased reliability.Disc HeaderPAGE 25

The top of the heap in sickle bar headers.Leave it to the brand that invented the auger header to provide the smooth, clean cut you demand froma sickle/auger header. Available in 14-, 16- and 18-foot widths, the 9126 from <strong>Hesston</strong> by Massey Fergusonfeatures our trademark dual augers, along with a double sickle and a single pair of rubber-on-steel orsteel-on-steel conditioner rolls.Available in 14- and 16-foot cutting widths, the 9146 model boasts our exclusive TwinMax AdvancedConditioning System. All models feature hydraulic drive, hydraulic header flotation and hydraulic roll tensionfor easy adjustment and time-tested reliability.n Dual, counter-rotating augers – provide twoseparate “live” feeding elements, to ensureeven feeding across the full width of theconditioner rolls.n A half-swaybar dual sickle drive system uses acounter-balanced flywheel to reduce peak starting,stopping and cutting loads. The system alsoreduces vibration and side-to-side movement whiledriving the sickle at 1,840 strokes per minute.n Our hydraulic roll tensioning system maintainsconsistent conditioner roll pressure for effectivecrimping and the highest quality hay.n A standard header reverser on both of thesemodels allows the operator to back large objectsor slugs out of the header without leaving the seat.n Tine tubes are segmented between bulkheadspiders for quicker and easier tine replacement.Reel tine tubes also rotate on sealed ball bearingsfor longer life and less downtime.n Sickle sections are bolted to the sickle bar, ratherthan riveted, for quicker, easier field replacement.Unlike the <strong>com</strong>petition, we use a dual auger systemthat includes one floating auger – a sure fire methodto convey both light and heavy crops more gentlyand smoothly, consistently laying them in uniformwindrows with little or no adjustment.“ It’s all about the header. And whenyou’re running a <strong>Hesston</strong> header,you know you’re running the best.Unlike traditional conditioners, the TwinMaxSystem on our 9146 auger header features twopairs of independently controlled, steel-on-steelconditioner rolls for quicker drying, higher nutrientretention and simply better hay in every bale.– Farmer / Idaho2,000 acres in alfalfa

PAGE 27Sickle Headers

Draper headers built to cut a more impressive swath.A rubber-coated draper belt drive roller providespositive traction, less slippage, better belt trackingand less need for increased belt tension – whichmeans the draper head not only performs better inheavy or wet crop conditions, it also lasts longer.Turn any <strong>WR</strong> <strong>Series</strong> model into a high-capacity swatherby simply adding a <strong>Hesston</strong> 5200 <strong>Series</strong> draper header.Choose from five center-delivery header widths orthree double swath models. These shiftable draperheads let you position the swath at the center or tothe left and right side of the header for double swaths.A great fit with our all new <strong>WR</strong> <strong>Series</strong> <strong>WR</strong>9735 and<strong>WR</strong>9725 swathers.Our sickle drive planetary gear system.Because our sickle drive is a hydraulically drivenplanetary gear system, it stays in rotation at all times,so there are no peak starting and stopping loads. Thatmeans no matter how close you’re cutting, the 5200<strong>Series</strong> delivers smooth, clean performance in cereals,grass, forage or specialty crops. With fewer shafts, beltsand sheaves, it also demands far less maintenance.Our optional SCH sickle system.In previous systems, the knife in the cutterbar ofthe sickle was supported by a wear plate. But today’swider platforms and the demand for better cuttingperformance have led to excessive wear on theknifeback and the wear blades. Now, we’ve solved thatproblem, by utilizing the new SCH Roller Guide. Itrequires less power, reduces friction on the knifeheadand enhances overall cutting performance.“ At the end of the day, it just<strong>com</strong>es down to this – I needquality hay.”Heavy-duty, nylon-reinforced belts are driven by ahydraulic motor and are adjustable from the cab toany speed from 0 to 600 feet (0 - 183 m) per minute.5200 <strong>Series</strong> updates:n Optional Schumacher sickle systemn Electric reel fore/aft (standard)n Rubber-coated drive rollern Heavier reel mount motorn New sickle drive motor with heavier seals– Farmer / Colorado3500 acres in hayThe hydraulic reel drive is infinitely variable from 0to 60 rpm to precisely match reel speed to groundspeed and crop conditions.

PAGE 29Draper Headers

State-of-the-art serviceability.The efficient performance of the new <strong>WR</strong> <strong>Series</strong> doesn’t stop at downtime. We’vemade servicing your windrower faster and easier than ever.Radial tires.For improved traction, increased flotationand simply a better ride, we offer tworadial tire options on the <strong>WR</strong> <strong>Series</strong>:n Most service points are convenientlyaccessible from ground level.n Individual side shields offer easy access,as does the end cap for the radiator<strong>com</strong>partment.n Electric and hydraulic <strong>com</strong>ponents arelocated on the right side, so there’s noneed to crawl beneath the windrower.n Service diagnostics are readily providedby the FieldMax monitor.n Better <strong>com</strong>ponent access includes alower frame rail.Self-cleaning, maintenance-freecooling. How cool is that?Airflow for our new V-Cool Systemon the <strong>WR</strong> <strong>Series</strong> is provided by atemperature-activated, variable speedhydraulic fan. Operating automaticallythrough the windrower software, thissystem is so advanced, it actually cleansitself – reducing service time, optimizingefficiency and saving on fuel.23.1 x R26This turf tire is for use on pivots, bordersor other flat field conditions. The turfpattern makes a less aggressive footprintand helps reduce ground <strong>com</strong>paction.It’s also gentler on the crop, especiallyon short headland turns.620/75R26For hilly or rougher terrain, thisag tread tire <strong>com</strong>bines a deeplug pattern with radial tireflexibility to make it a greatsolution when additionaltraction is required whilestill maintaining a smoothtractor ride.“ When it’s time to cut, it’s timeto cut. You’ve got to stay up andrunning. So you’d better have amachine that works with you,not against you, when it <strong>com</strong>esto maintenance.”– Farmer / Saskatchewan1500 acres in canolaDownload a QR code scannerto your Smartphonen Open the application on your Smartphonen Point your phone’s camera at the code and scann The code will take you to one of our windrower videos

A great deal includes a great dealer.If you’re like most farmers, when you find your favorite piece of equipment, itbe<strong>com</strong>es almost like part of your family. And when you buy a <strong>Hesston</strong> by MasseyFerguson windrower, you instantly be<strong>com</strong>e part of ours. Our network of dealerswill advise and support you through the selection process, the buying process, andthrough operation and maintenance. Most importantly, your Massey Fergusondealer is continually focused on minimizing your downtime – especially duringcritical times of the year – via parts availability and well-trained, <strong>com</strong>petentmechanics. Because our dealers share your passion for farming, they’re happyto share their knowledge to keep you working happy.Even our warranty is high-performance.We’ll cover you for two years/2,000 hours on engines and for one year/parts andlabor on everything else. It’s simply one of the best warranty packages in thebusiness, backed by dealers who understand how to help you make the most of it.Quality parts.Massey Ferguson parts are manufactured to meet the same high standards ofdependability you’ll find on every new <strong>WR</strong> <strong>Series</strong> SP Windrower. Consistent useof these quality parts will help keep your windrower running like new. Shop 24/7at www.agcoparts.<strong>com</strong>.Questions? Go tomasseyferguson.<strong>com</strong>Our web site opens the door toall sorts of technical information,corporate support and productspecifications. You’ll also have accessto shop massey.<strong>com</strong>, a one-stopsource for Massey Ferguson logoproducts and gifts. If you can’t findwhat you’re looking for, click on“contact us” and we’ll provide youwith access to folks who can getyou all the answers.Enjoy our exclusive publication thatoffers insights into all the joys – andchallenges – of rural life.Join our conversation.Engage.facebook.<strong>com</strong>/AGCOcorpFollow.twitter.<strong>com</strong>/AGCOcorpWatch.youtube.<strong>com</strong>/AGCOcorpLearn.blog.AGCOcorp.<strong>com</strong>AGCO Answers(877) 525-4384agcoanswers@agcocorp.<strong>com</strong>At AGCO, customer care isn’t justa department. It’s a <strong>com</strong>mitment.Contact us with your questions.We’ll do our best to answer thempromptly, or put you in touch withsomeone who can.Wel<strong>com</strong>e to the<strong>Hesston</strong> Heritage ClubWhether you’re a brand new<strong>Hesston</strong> by Massey Fergusonowner, a long time professionalproducer, or just an admirer ofthe leading name in hay, this isa web site just for you. Think ofit as your own personal <strong>Hesston</strong><strong>com</strong>munity – a portal to everythingand everyone <strong>Hesston</strong>. Go to:www.masseyferguson.us/hesstonheritage-club.And if you’d like to join thethousands who avidly collectthe famous <strong>Hesston</strong> belt buckles,go to www.masseyferguson.us/hesston-heritage-club.PAGE 31 Service & Support

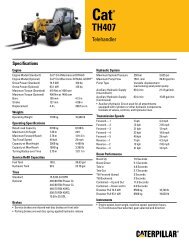

SP WINDROWER MODEL <strong>WR</strong>9770 <strong>WR</strong>9760 <strong>WR</strong>9740 <strong>WR</strong>9735 <strong>WR</strong>9725Dimensions and WeightTypeHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrolHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrolHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrolHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrolHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrolLength overall without header / in. (mm) 199.7 (5,074) 199.7 (5,074) 199.7 (5,074) 199.7 (5,074) 199.7 (5,074)Wheelbase / in. (mm) 137 (3,482) 137 (3,482) 137 (3,482) 137 (3,482) 137 (3,482)Height - top of cab / in. (mm)(23.1-26 Turf Tires)137.8 (3,501) 137.8 (3,501) 137.8 (3,501) 137.8 (3,501) 137.8 (3,501)Tread width drive tires in. (mm) 130.7 (3,320) 130.7 (3,320) 130.7 (3,320) 130.7 (3,320) 130.7 (3,320)Tread width tail wheels - min. in. (mm)84 (2,135)84 (2,135) 84 (2,135) 84 (2,135) 84 (2,135)Tread width tail wheels - max. / in. (mm) 129 (3,278) 129 (3,278) 129 (3,278) 129 (3,278) 129 (3,278)Weight (approximate) w/o header / lb. (kg) 11,420 (5,180) 11,305 (5,127) 11,254 (5,104) 10,860 (4,926) 10,300 (4,672)Speed (approximate)Field range / mph (km/h) 0 to 16 (0 to 26)* 0 to 16 (0 to 26)* 0 to 16 (0 to 26)* 0 to 16 (0 to 26)* 0 to 11 (0 to 18)Road range / mph (km/h) (optional) 0 to 21 (0 to 34) 0 to 21 (0 to 34) 0 to 21 (0 to 34) 0 to 21 (0 to 34) 0 to 15 (0 to 24)EngineModelAGCO Power66 CTAAGCO Power49 CTAAGCO Power49 CTAAGCO Power49 CTACummins 3.3Horsepower (kW) 220 (164) 188 (140) 137 (102) 137 (102) 100 (75)Displacement / cu in. (L) 403 (6.6) 299 (4.9) 299 (4.9) 299 (4.9) 201 (3.3)Fuel tank capacity / US GAL (L) 130 (492) 130 (492) 130 (492) 130 (492) 130 (492)Ground Drive SystemTypeTandem pumpFlotation SystemTypeTiresDrive wheelsTail wheelsDouble planetary gearreductionSauer Danfoss H1 AxialPiston PumpHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrolDouble planetary gearreductionSauer Danfoss H1 AxialPiston PumpHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrol23.1-26 Bias Turf (R3) 23.1-26 Bias Turf (R3)23.1-26 Radial Turf (R3) 23.1-26 Radial Turf (R3)620/75R26 Radial Bar (R1) 620/75R26 Radial Bar (R1)–18.4x26 Bias Turf (R3)**–18.4R26 Radial Bar (R1)14L-16.1,8-ply implement rib16.5L-16.1,10-ply implement rib*With High Speed Option14L-16.1,8-ply implement rib16.5L-16.1,10-ply implement rib**Not for use with 9196 disc headDouble planetary gearreductionSauer Danfoss H1 AxialPiston PumpHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrol23.1-26 Bias Turf (R3)23.1-26 Radial Turf (R3)620/75R26 Radial Bar (R1)18.4x26 Bias Turf (R3)18.4R26 Radial Bar (R1)14L-16.1,8-ply implement rib16.5L-16.1,10-ply implement ribDouble planetary gearreductionSauer Danfoss H1 AxialPiston PumpHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrol23.1-26 Bias Turf (R3)23.1-26 Radial Turf (R3)620/75R26 Radial Bar (R1)18.4x26 Bias Turf (R3)18.4R26 Radial Bar (R1)14L-16.1,8-ply implement rib16.5L-16.1,10-ply implement ribDouble planetary gearreductionSauer Danfoss H1 AxialPiston PumpHydraulic withindependent left/rightadjustable <strong>com</strong>putercontrol23.1-26 Bias Turf (R3)23.1-26 Radial Turf (R3)620/75R26 Radial Bar (R1)18.4x26 Bias Turf (R3)18.4R26 Radial Bar (R1)14L-16.1,8-ply implement rib16.5L-16.1,10-ply implement ribDraper Header MODEL 5200Dimensions and WeightsOverall widthCenter delivery and double swath model18 ft. (5.5 m) / in. (m)22 ft. (6.7 m) / in. (m)25 ft. (7.6 m) / in. (m)30 ft. (9.1 m) / in. (m)36 ft. (10.92 m) / in. (m)Width of CutCenter delivery and double swath model18 ft. (5.5 m) / in. (m)22 ft. (6.7 m) / in. (m)25 ft. (7.6 m) / in. (m)30 ft. (9.1 m) / in. (m)36 ft. (10.92 m) / in. (m)Weight with Reel lb / (kg) approximate18 ft. (5.5 m) center delivery22 ft. (6.7 m) center delivery25 ft. (7.6 m) center delivery30 ft. (9.1 m) center delivery36 ft. (10.92 m) center delivery22 ft. (6.7 m) shiftable draper25 ft. (7.6 m) shiftable draper30 ft. (9.1 m) shiftable draperWeight without Reel / lb (kg) approximate18 ft. (5.5 m) center delivery22 ft. (6.7 m) center delivery25 ft. (7.6 m) center delivery30 ft. (9.1 m) center delivery36 ft. (10.92 m) center delivery22 ft. (6.7 m) shiftable draper25 ft. (7.6 m) shiftable draper30 ft. (9.1 m) shiftable draperHeaderDrive - draper and reel230 (5.84)278 (7.06)314 (7.98)374 (9.50)446 (11.33)219 (5.56)267 (6.78)303 (7.70)363 (9.22)432 (10.98)2,300 (1,043)2,750 (1,247)3,100 (1,406)3,700 (1,678)4,392 (1,992)2,850 (1,293)3,200 (1,451)3,800 (1,724)1,800 (816)2,150 (975)2,400 (1,089)2,900 (1,315)3,456 (1,568)2,250 (1,021)2,500 (1,134)3,000 (1,316)HydraulicGuard angle (4 cylinder tractors, adjustable) 9° to 19°Guard angle (6 cylinder tractors, adjustable) 4° to 18°FlotationHydraulicSize of opening with draper insertsMax. / in. (mm)Min. / in. (mm)Size of opening without draper insertsMax. / in. (mm)Min. / in. (mm)Cutterbar54 (1,372)42 (1,067)70 (1,778)54 (1,372)Speed / spm (cpm) 1,300 (650)Stroke / in. (mm) 3.13 (79.38)DriveInline gearboxGuard spacing / in. (mm) 3 (76)Number of sicklesOneDraperDriveHydraulicSpeed (adjustable from cab) / ft/min (m/min) 0 to 600 (0 to 183)Width / in. (mm) 41 (1,041)TypeRubberized draperw/ reinforced slats

RazorBarDisc Header Model9183 9195 9196 Twin MaxDimensions and Weights 13' 16' 16'SICKLE Header Model 9126 9146 Twin MaxDimensions and WeightsWidth (overall) / in. (mm) 159 (4,039) 195 (4,963) 195 (4,963)Weight (with forming shields) / lb. (kg) 4,025 (1,825) 4,780 (2,168) 4,780 (2,168)HeaderHeader drive Dual hydraulic motors Dual hydraulic motors Dual hydraulic motorsInput shaft speed / (max.) rpm 2,600 2,600 2,600Header lift range / in. (mm) to in. (mm)Header flotationRadial and verticalhydraulic, adjustablefrom cabHydraulic, adjustablefrom cabRadial and verticalhydraulic, adjustablefrom cabHydraulic, adjustablefrom cabRadial and verticalhydraulic, adjustablefrom cabHydraulic, adjustablefrom cabHeader tilt 0 to 10 degrees 0 to 10 degrees 0 to 10 degreesHeader angle 0° to 10° 0° to 10° 0° to 10°CutterbedCutting width – in. (mm) 156 (3,962) 192 (4,895) 192 (4,895)Cutting height (mm) .75 to 3 (19 to 76) .75 to 3 (19 to 76) .75 to 3 (19 to 76)Number of discs 8 10 10Number of knives 16 20 20Disc speed (max.) rpm 2,600 2,600 2,600Tip speed (max.) / mph (km/h) 189 (304) 189 (304) 189 (304)Cutterbed design Modular spur gears Modular spur gears Modular spur gearsCutterbed oil capacity / qt (L) 6 (5.7) 6 (5.7) 6 (5.7)Knives 18° bottom bevel 18° bottom bevel 18° bottom bevelKnife circle diameter / in (mm) 24.5 (622) 24.5 (622) 24.5 (622)Knife tip speed / mph (kph) 189 (304) 189 (304) 189 (304)Hay ConditionerTypeHerringbone,steel-on-steelHerringbone,steel-on-steelNumber of conditioner rolls 2 2 4Herringbone,steel-on-steelLength / in. (mm) 110 (2794) 110 (2794) 110 (2794)Diameter / in. (mm) 7.75 (197) 7.75 (197) 7.75 (197)Speed rpm (maximum) 1,290 1,290 1,290Windrow width - Max. / in. (mm)Windrow width - Min. / in. (mm)Roll tension96 (2,438)40 (1,016)Spring96 (2,438)40 (1,016)Hydraulic withaccumulator96 (2,438)40 (1,016)Hydraulic withaccumulator14' (4.3m) HeaderWidth of cut / in. (mm)Width (overall) / in. (mm)Weight (less forming shields) / lb. (kg)16' (4.9m) HeaderWidth of cut / in. (mm)Width (overall) / in. (mm)Weight (less forming shields) / lb. (kg)18' (5.5m) HeaderWidth of cut / in. (mm)Width (overall) / in. (mm)Weight (less forming shields) / lb. (kg)168 (4,276)188.4 (4,786)3,850 (1,746)192 (4,877)212.4 (6,005)4,100 (1,860)216 (5,486)236.4 (6,005)4,400 (1,996)168 (4,276)188.4 (4,786)4,940 (2,240)192 (4,877)212.4 (6,005)5,210 (2,363)HeaderHeader drive Hydraulic HydraulicHeader flotation Hydraulic adjustable Hydraulic adjustableReelBats 5 5Diameter / in. (mm) 42 (1,067) 42 (1,067)Drive Belt & chain Belt & chainSpeed rpm 72 to 83 72 to 83SickleSpeed / spm (cpm) 1,840 (920) 1,840 (920)Stroke / in (mm) 3 (76.2) 3 (76.2)Guard angle (adjustable) 5° to 12° 5° to 12°Drive Timed gearboxes Timed gearboxesNumber of sickles 2 2AugersType Dual, opposed rotation Dual, opposed rotationDiameter–upper auger / in. (mm)Diameter–lower auger / in. (mm)Speed–upper auger rpmSpeed–lower auger rpmHay ConditionersTypeFrontRear (9146 only)Length in. (mm)Diameter / in. (mm)SteelRubber9 (229)10 (254)368585Herringbone, steel-on-steelHerringbone, steel-on-steel110 (2,794)7.75 (197)8 (203)N/A9 (229)10 (254)368585Herringbone, steel-on-steelor spiral rubber-on-steelN/A110 (2,794)7.75 (197)8 (203)Speed (maximum) rpm 1,026 1,026Windrow widthMin. / in. (mm)Max. / in. (mm)Adjustable40 (1,016)96 (2,438)Adjustable40 (1,016)96 (2,438)SpecificationsPAGE 33

It’s everything you could ask for.Because that’s just what you did.Every single innovation in our all new <strong>WR</strong> <strong>Series</strong> <strong>Windrowers</strong> was inspired by working hay producers.You spoke. And we listened. Maybe that’s why these windrowers go far beyond simply “measuring up”to the <strong>com</strong>petition. The <strong>WR</strong> <strong>Series</strong>. Leading-edge. State-of-the-art. Red-hot. Top-of-the-line. There justaren’t enough hyphens to describe it. Find out more at your local dealership or visit masseyferguson.<strong>com</strong>

Wel<strong>com</strong>eto the family.

Nobody Knows Hay Like <strong>Hesston</strong>.The all new <strong>WR</strong> <strong>Series</strong>masseyferguson.<strong>com</strong>Massey Ferguson is a worldwide brand of AGCO.(877) 525-4384 • <strong>MF</strong>11B019TCG 07 1 PDAGCO, Your Agriculture Company, is a premier manufacturer of agricultural equipment, providing high-techsolutions for professional farmers feeding the world. The <strong>com</strong>pany is dedicated to delivering superior customerservice, innovation and quality. AGCO products are distributed in more than 140 countries worldwide.©2011 AGCO Corporation. All rights reserved. This document and allof its contents are owned exclusively by AGCO and are protected bycopyright law. AGCO has a corporate policy of continuous productimprovement and development; therefore, specifications are subject tochange without any advance notice. AGCO is not responsible fordifferences between the specifications or illustrations contained in thispublication and the actual equipment. Equipment produced by othermanufacturers is shown in photographs in this brochure for thepurpose of illustration only and is not intended as an endorsement ofthat particular equipment or its suitability. AGCO, 4205 River GreenParkway, Duluth, GA 30096.We proudly support: