06.13 Style HP-70ES EndSeal® Couplings

06.13 Style HP-70ES EndSeal® Couplings

06.13 Style HP-70ES EndSeal® Couplings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

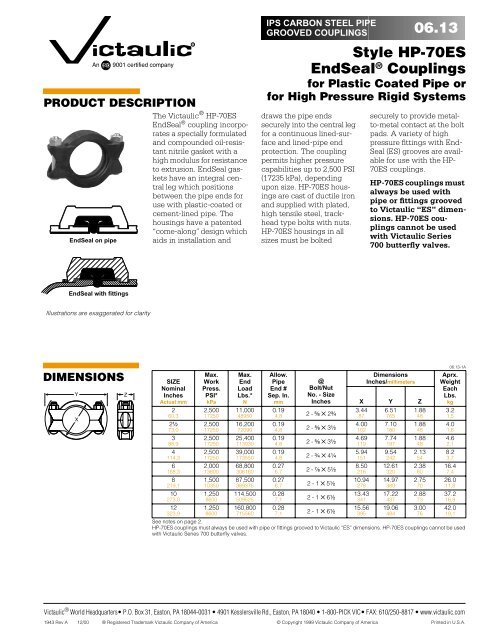

RPRODUCT DESCRIPTIONEndSeal on pipeThe Victaulic ® <strong>HP</strong>-<strong>70ES</strong>EndSeal ® coupling incorporatesa specially formulatedand compounded oil-resistantnitrile gasket with ahigh modulus for resistanceto extrusion. EndSeal gasketshave an integral centralleg which positionsbetween the pipe ends foruse with plastic-coated orcement-lined pipe. Thehousings have a patented“come-along” design whichaids in installation andIPS CARBON STEEL PIPEGROOVED COUPLINGS <strong>06.13</strong><strong>Style</strong> <strong>HP</strong>-<strong>70ES</strong>EndSeal ® <strong>Couplings</strong>for Plastic Coated Pipe orfor High Pressure Rigid Systemsdraws the pipe endssecurely into the central legfor a continuous lined-surfaceand lined-pipe endprotection. The couplingpermits higher pressurecapabilities up to 2,500 PSI(17235 kPa), dependingupon size. <strong>HP</strong>-<strong>70ES</strong> housingsare cast of ductile ironand supplied with plated,high tensile steel, trackheadtype bolts with nuts.<strong>HP</strong>-<strong>70ES</strong> housings in allsizes must be boltedsecurely to provide metalto-metalcontact at the boltpads. A variety of highpressure fittings with End-Seal (ES) grooves are availablefor use with the <strong>HP</strong>-<strong>70ES</strong> couplings.<strong>HP</strong>-<strong>70ES</strong> couplings mustalways be used withpipe or fittings groovedto Victaulic “ES” dimensions.<strong>HP</strong>-<strong>70ES</strong> couplingscannot be usedwith Victaulic Series700 butterfly valves.EndSeal with fittingsIllustrations are exaggerated for clarityDIMENSIONSYZXSIZENominalInchesActual mmMax.WorkPress.PSI*kPaMax.EndLoadLbs.*NAllow.PipeEnd #Sep. In.mm@Bolt/NutNo. - SizeInchesDimensionsInches/millimeters<strong>06.13</strong>-1AAprx.WeightEachLbs.kgX Y Z2 2,500 11,000 0.193.44 6.51 1.88 3.260,3 17250 48950 4,8 2 - ⁵⁄₈ ✕ 2³⁄₄ 87 765 48 1,52¹⁄₂ 2,500 16,200 0.194.00 7.10 1.88 4.073,0 17250 72090 4,8 2 - ⁵⁄₈ ✕ 3¹⁄₂ 102 180 48 1,83 2,500 25,400 0.194.69 7.74 1.88 4.688,9 17250 113030 4,8 2 - ⁵⁄₈ ✕ 3¹⁄₂ 119 197 48 2,14 2,500 39,000 0.195.94 9.54 2.13 8.2114,3 17250 173550 4,8 2 - ³⁄₄ ✕ 4¹⁄₄ 151 242 54 3,76 2,000 68,800 0.278.50 12.61 2.38 16.4168,3 13800 306160 6,7 2 - ⁷⁄₈ ✕ 5¹⁄₂ 216 320 60 7,48 1,500 87,500 0.2710.94 14.97 2.75 26.0219,1 10350 389375 6,7 2 - 1 ✕ 5¹⁄₂ 278 380 70 11,810 1,250 114,500 0.2813.43 17.22 2.88 37.2273,0 8600 509525 7,1 2 - 1 ✕ 6¹⁄₂ 341 437 73 16,912 1,250 160,800 0.2815.56 19.06 3.00 42.0323,9 8600 715560 7,1 2 - 1 ✕ 6¹⁄₂ 395 484 76 19,1See notes on page 2.<strong>HP</strong>-<strong>70ES</strong> couplings must always be used with pipe or fittings grooved to Victaulic “ES” dimensions. <strong>HP</strong>-<strong>70ES</strong> couplings cannot be usedwith Victaulic Series 700 butterfly valves.Victaulic ® World Headquarters• P.O. Box 31, Easton, PA 18044-0031 • 4901 Kesslersville Rd., Easton, PA 18040 • 1-800-PICK VIC• FAX: 610/250-8817 • www.victaulic.com1943 Rev.A 12/00 ® Registered Trademark Victaulic Company of America © Copyright 1999 Victaulic Company of America Printed in U.S.A.

MATERIAL SPECIFICATIONSHousing: Ductile iron conformingto ASTM A-395, grade 65-45-15, and ASTM A-536, grade65-45-12.Coating: Black or Green enamel❏ Optional: Hot dippedgalvanized and othersGasket*:❏ Grade “T” nitrileHigh modulus nitrile (specialEndSeal design). Speciallycompounded with excellentoil resistance and a highmodulus for resistance toextrusion. Temperaturerange: 20°F to +150° F (–29°Cto +66°C).Recommended for petroleumproducts, air with oil vapors,vegetable and mineral oilswithin the specified temperaturerange. Not recommendedfor hot waterservices over +150°F (+66°C)or for hot dry air over +140°F(+60°C).For maximum gasket lifeunder pressure extremes,temperature should be limitedto +110°F (+49°C).*Services listed are General ServiceRecommendations only. Itshould be noted that there areservices for which these gasketsare not recommended. Referenceshould always be made tothe latest Victaulic GasketSelection Guide for specific gasketservice recommendationsand for a listing of serviceswhich are not recommended.Bolts/Nuts: Electroplated, heattreated carbon steel, track-headtype, conforming to physicalproperties of ASTM A-183, minimumtensile 110,000 PSI (758340kPa).NOTES* Working Pressure and End Load are total, from all internal and external loads, based on standard weight (ANSI) steel pipe, “ES” cut or roll grooved in accordancewith Victaulic specifications. Contact Victaulic for performance on other pipe.WARNING: FOR ONE TIME FIELD TEST ONLY, the Maximum Joint Working Pressure may be increased to 1¹⁄₄ times the figures shown.# For field installation only. <strong>HP</strong>-<strong>70ES</strong> is essentially rigid and does not permit expansion and contraction.<strong>HP</strong>-<strong>70ES</strong> couplings must always be used with pipe or fittings grooved to Victaulic “ES” dimensions. <strong>HP</strong>-<strong>70ES</strong> couplings cannot be used with Victaulic Series 700butterfly valves.@ Number of bolts required equals number of housing segments.Metric thread size bolts are available (color coded gold) for all coupling sizes upon request. Contact Victaulic for details.WARNING: Piping systems must always be depressurized and drained before attempting disassembly and removal of any Victaulic piping products.This product shall be manufactured by Victaulic Company. All products shall be installed in accordance with current Victaulic installation/assembly instructions.Victaulic reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.<strong>06.13</strong> - 2