Citterio, Daniel - Keio University

Citterio, Daniel - Keio University

Citterio, Daniel - Keio University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

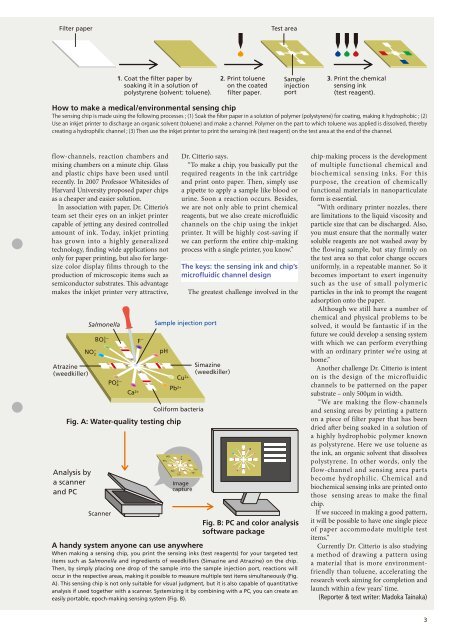

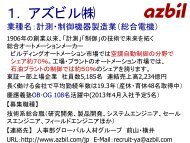

Filter paperTest area1. Coat the filter paper bysoaking it in a solution ofpolystyrene (solvent: toluene).2. Print tolueneon the coatedfilter paper.Sampleinjectionport3. Print the chemicalsensing ink(test reagent).How to make a medical/environmental sensing chipThe sensing chip is made using the following processes ; (1) Soak the filter paper in a solution of polymer (polystyrene) for coating, making it hydrophobic ; (2)Use an inkjet printer to discharge an organic solvent (toluene) and make a channel. Polymer on the part to which toluene was applied is dissolved, therebycreating a hydrophilic channel ; (3) Then use the inkjet printer to print the sensing ink (test reagent) on the test area at the end of the channel.flow-channels, reaction chambers andmixing chambers on a minute chip. Glassand plastic chips have been used untilrecently. In 2007 Professor Whitesides ofHarvard <strong>University</strong> proposed paper chipsas a cheaper and easier solution.In association with paper, Dr. <strong>Citterio</strong>’steam set their eyes on an inkjet printercapable of jetting any desired controlledamount of ink. Today, inkjet printinghas grown into a highly generalizedtechnology, finding wide applications notonly for paper printing, but also for largesizecolor display films through to theproduction of microscopic items such assemiconductor substrates. This advantagemakes the inkjet printer very attractive,NO 2AtrazineweedkillerSalmonellaBO 33ScannerPO 43Ca 2+F pHSample injection portPb 2+Cu 2+Coliform bacteriaFig. A: Water-quality testing chipAnalysis bya scannerand PCNO 2BO 33PO 43Ca 2+Dr. <strong>Citterio</strong> says.“To make a chip, you basically put therequired reagents in the ink cartridgeand print onto paper. Then, simply usea pipette to apply a sample like blood orurine. Soon a reaction occurs. Besides,we are not only able to print chemicalreagents, but we also create microfluidicchannels on the chip using the inkjetprinter. It will be highly cost-saving ifwe can perform the entire chip-makingprocess with a single printer, you know.”The keys: the sensing ink and chip’smicrofluidic channel designF pHImagecaptureThe greatest challenge involved in theSimazineweedkillerPb 2+Cu 2+Fig. B: PC and color analysissoftware packageA handy system anyone can use anywhereWhen making a sensing chip, you print the sensing inks (test reagents) for your targeted testitems such as Salmonella and ingredients of weedkillers (Simazine and Atrazine) on the chip.Then, by simply placing one drop of the sample into the sample injection port, reactions willoccur in the respective areas, making it possible to measure multiple test items simultaneously (Fig.A). This sensing chip is not only suitable for visual judgment, but it is also capable of quantitativeanalysis if used together with a scanner. Systemizing it by combining with a PC, you can create aneasily portable, epoch-making sensing system (Fig. B).chip-making process is the developmentof multiple functional chemical andbiochemical sensing inks. For thispurpose, the creation of chemicallyfunctional materials in nanoparticulateform is essential.“With ordinary printer nozzles, thereare limitations to the liquid viscosity andparticle size that can be discharged. Also,you must ensure that the normally watersoluble reagents are not washed away bythe flowing sample, but stay firmly onthe test area so that color change occursuniformly, in a repeatable manner. So itbecomes important to exert ingenuitysuch as the use of small polymericparticles in the ink to prompt the reagentadsorption onto the paper.Although we still have a number ofchemical and physical problems to besolved, it would be fantastic if in thefuture we could develop a sensing systemwith which we can perform everythingwith an ordinary printer we’re using athome.”Another challenge Dr. <strong>Citterio</strong> is intenton is the design of the microfluidicchannels to be patterned on the papersubstrate – only 500μm in width.“We are making the flow-channelsand sensing areas by printing a patternon a piece of filter paper that has beendried after being soaked in a solution ofa highly hydrophobic polymer knownas polystyrene. Here we use toluene asthe ink, an organic solvent that dissolvespolystyrene. In other words, only theflow-channel and sensing area partsbecome hydrophilic. Chemical andbiochemical sensing inks are printed ontothose sensing areas to make the finalchip.If we succeed in making a good pattern,it will be possible to have one single pieceof paper accommodate multiple testitems.”Currently Dr. <strong>Citterio</strong> is also studyinga method of drawing a pattern usinga material that is more environmentfriendlythan toluene, accelerating theresearch work aiming for completion andlaunch within a few years’ time. (Reporter & text writer: Madoka Tainaka)3