Substation Automation System And A.C. KIOSKS - Hvpn.gov.in

Substation Automation System And A.C. KIOSKS - Hvpn.gov.in

Substation Automation System And A.C. KIOSKS - Hvpn.gov.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

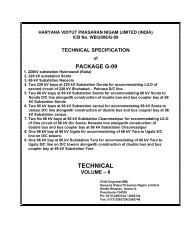

1.0 GENERAL:The substation automation system shall be offered from a manufacturer whomust have designed, manufactured, tested, <strong>in</strong>stalled and commissionedsubstation automation system which must be <strong>in</strong> satisfactory operation on 220kVsystem or higher for at least 2 (Two) years as on the date of bid open<strong>in</strong>g.1.2 The <strong>Substation</strong> <strong>Automation</strong> <strong>System</strong> (SAS) shall be <strong>in</strong>stalled to control andmonitor all the sub-station equipment from remote control centre (RCC) as wellas from local control centre.The SAS shall conta<strong>in</strong> the follow<strong>in</strong>g ma<strong>in</strong> functional parts:i) Bay control Intelligence Electronic Devices (IED s) for control andmonitor<strong>in</strong>g.ii) Station Human Mach<strong>in</strong>e Interface (HMI)iii) Redundant managed switched Ethernet Local Area Networkcommunication <strong>in</strong>frastructure with hot standby.iv) Peripheral equipment like pr<strong>in</strong>ters, display units, key boards, Mouse etc.1.3 It shall enable local station control via a PC by means of human mach<strong>in</strong>e<strong>in</strong>terface (HMI) and control software package, which shall conta<strong>in</strong> an extensiverange of supervisory control and data acquisition (SCADA) functions.1.4 It shall <strong>in</strong>clude communication gateways, <strong>in</strong>telligent electronic devices (IED) forbay control and <strong>in</strong>ter IED communication <strong>in</strong>frastructure. An architecture draw<strong>in</strong>gfor SAS is enclosed at Annexure-III.1.5 The communication gateways shall facilitate the <strong>in</strong>formation flow with remotecontrol centers. The bay level <strong>in</strong>telligent electronic devices (IED) for protectionand control shall provide the direct connection to the switchgear without the needof <strong>in</strong>terpos<strong>in</strong>g components and perform control, protection, and monitor<strong>in</strong>gfunctions.2.0 SYSTEM DESIGN :2.1 GENERAL SYSTEM DESIGN:The <strong>Substation</strong> <strong>Automation</strong> <strong>System</strong> (SAS) shall be suitable for operation andmonitor<strong>in</strong>g of the complete substation <strong>in</strong>clud<strong>in</strong>g future extensions as given <strong>in</strong>Section-Project.The systems shall be of the state-of-the art suitable for operation under electricalenvironment present <strong>in</strong> Extra high voltage substations, follow the latesteng<strong>in</strong>eer<strong>in</strong>g practice, and ensure long-term compatibility requirements andcont<strong>in</strong>uity of equipment supply and the safety of the operat<strong>in</strong>g staff.The offered SAS shall support remote control and monitor<strong>in</strong>g from RemoteControl centers via gateways.The system shall be designed such that personnel without any backgroundknowledge <strong>in</strong> Microprocessor-based technology are able to operate the system.The operator <strong>in</strong>terface shall be <strong>in</strong>tuitive such that operat<strong>in</strong>g personnel shall beable to operate the system easily after hav<strong>in</strong>g received some basic tra<strong>in</strong><strong>in</strong>g.The system shall <strong>in</strong>corporate the control, monitor<strong>in</strong>g and protection functionsspecified, self-monitor<strong>in</strong>g, signal<strong>in</strong>g and test<strong>in</strong>g facilities, measur<strong>in</strong>g as well asmemory functions, event record<strong>in</strong>g and evaluation of disturbance records.Ma<strong>in</strong>tenance, modification or extension of components may not cause aC:\Users\itms\Downloads\SAS Spec. (1).doc - 3 -

shutdown of the whole substation automation system. Self-monitor<strong>in</strong>g ofcomponents, modules and communication shall be <strong>in</strong>corporated to <strong>in</strong>crease theavailability and the reliability of the equipment and m<strong>in</strong>imize ma<strong>in</strong>tenance.Bidder shall offer the Bay level unit (a bay comprises of one circuit breakerand associated disconnector, earth switches and <strong>in</strong>strument transformer),bay mimic along with relay and protection panels and PLCC panels(described <strong>in</strong> other sections of technical specifications) housed <strong>in</strong> airconditionedKiosks suitably located <strong>in</strong> switchyard and Station HMI <strong>in</strong>Control Room build<strong>in</strong>g for overall optimization <strong>in</strong> respect of cabl<strong>in</strong>g andcontrol room build<strong>in</strong>g.2.2 SYSTEM ARCHITECTURE:The SAS shall be based on a decentralized architecture and on a concept of bayoriented,distributed <strong>in</strong>telligence.Functions shall be decentralized, object-oriented and located as close aspossible to the process.The ma<strong>in</strong> process <strong>in</strong>formation of the station shall be stored <strong>in</strong> distributeddatabases. The typical SAS architecture shall be structured <strong>in</strong> two levels, i.e. <strong>in</strong> astation and a bay level. At bay level, the IEDs shall provide all bay level functionsregard<strong>in</strong>g control, monitor<strong>in</strong>g and protection, <strong>in</strong>puts for status <strong>in</strong>dication andoutputs for commands.The IEDs should be directly connected to the switchgear without any need for<strong>in</strong>terposition or transducer.Each bay control IED shall be <strong>in</strong>dependent from each other and its function<strong>in</strong>gshall not be affected by any fault occurr<strong>in</strong>g <strong>in</strong> any of the other bay control units ofthe station.The data exchange between the electronic devices on bay and station level shalltake place via the communication <strong>in</strong>frastructure. This shall be realized us<strong>in</strong>gfibre-optic cables, thereby guarantee<strong>in</strong>g disturbance free communication. Thefibre optic cables shall be run <strong>in</strong> G.I conduit pipes. Data exchange is to berealized us<strong>in</strong>g IEC 61850 protocol with a redundant managed switched Ethernetcommunication <strong>in</strong>frastructure.The communication shall be made <strong>in</strong> 1+1 mode, exclud<strong>in</strong>g the l<strong>in</strong>ks between<strong>in</strong>dividual bay IEDs to switch, such that failure of one set of fibre shall not affectthe normal operation of the SAS. However it shall be alarmed <strong>in</strong> SAS. Each fibreoptic cable shall have four (4) spare fibres.At station level, the entire station shall be controlled and supervised from thestation HMI. It shall also be possible to control and monitor the bay from the baylevel equipment at all times.Clear control priorities shall prevent operation of a s<strong>in</strong>gle switch at the same timefrom more than one of the various control levels, i.e. RCC, station HMI, bay levelor apparatus level. The priority shall always be on the lowest enabled controllevel.The station level conta<strong>in</strong>s the station-oriented functions, which cannot be realizedat bay level, e.g. alarm list or event list related to the entire substation, gatewaysfor the communication with remote control centers.C:\Users\itms\Downloads\SAS Spec. (1).doc - 4 -

The GPS time synchroniz<strong>in</strong>g signal (as specified <strong>in</strong> the section relay &protection) for the synchronization of the entire system shall be provided.The SAS shall conta<strong>in</strong> the functional parts as described <strong>in</strong> Para 1.2 above.2.3 FUNCTIONAL REQUIREMENTS:The high-voltage apparatus with<strong>in</strong> the station shall be operated from differentplaces:i) Remote controlii) Station HMI.iii) Local Bay controller IED (<strong>in</strong> the bays)Operation shall be possible by only one operator at a time. The operation shalldepend on the conditions of other functions, such as <strong>in</strong>terlock<strong>in</strong>g, synchrocheck,etc. (see description <strong>in</strong>”Bay level control functions”).2.3.1 SELECT-BEFORE-EXECUTE:For security reasons the command is always to be given <strong>in</strong> two stages: selectionof the object and command for operation under all mode of operation exceptemergency operation. F<strong>in</strong>al execution shall take place only when selection andcommand are actuated.2.3.2 COMMAND SUPERVISION:BAY/STATION INTERLOCKING AND BLOCKINGSoftware Interlock<strong>in</strong>g is to be provided to ensure that <strong>in</strong>advertent <strong>in</strong>correctoperation of switchgear caus<strong>in</strong>g damage and accidents <strong>in</strong> case of false operationdoes not take place.In addition to software <strong>in</strong>terlock<strong>in</strong>g hardwired <strong>in</strong>terlock<strong>in</strong>g are to be provided for:a) Bus Earth switch Interlock<strong>in</strong>gb) Transfer Bus <strong>in</strong>terlock<strong>in</strong>g (if applicable)It shall be a simple layout, easy to test and simple to handle when upgrad<strong>in</strong>g thestation with future bays. For software <strong>in</strong>terlock<strong>in</strong>g the bidder shall describe thescenario while an IED of another bay is switched off or fails.A software <strong>in</strong>terlock override function shall be provided which can be enabled tobypass the <strong>in</strong>terlock<strong>in</strong>g function.2.3.3 RUN TIME COMMAND CANCELLATIONCommand execution timer (configurable) must be available for each control levelconnection. If the control action is not completed with<strong>in</strong> a specified time, thecommand should get cancelled.2.3.4 SELF-SUPERVISIONCont<strong>in</strong>uous self-supervision function with self-diagnostic feature shall be<strong>in</strong>cluded.2.3.5 USER CONFIGURATIONThe monitor<strong>in</strong>g, controll<strong>in</strong>g and configuration of all <strong>in</strong>put and output logicalsignals and b<strong>in</strong>ary <strong>in</strong>puts and relay outputs for al built-<strong>in</strong> functions and signalsshall be possible both locally and remotely.C:\Users\itms\Downloads\SAS Spec. (1).doc - 5 -

It shall also be possible to <strong>in</strong>terconnect and derive <strong>in</strong>put and output signals, logicfunctions, us<strong>in</strong>g built-In functions, complex voltage and currents, additionallogics (AND-gates, OR gates and timers).(Multi-activation of these additional functions should be possible).The Functional requirement shall be divided <strong>in</strong>to follow<strong>in</strong>g levels:a) Bay (a bay comprises of one circuit breaker and associated disconnector,earth switches and <strong>in</strong>strument transformer) Level Functions.b) <strong>System</strong> Level Functions.3.1 BAY LEVEL FUNCTIONS:In a decentralized architecture the functionality shall be as close to the processas possible. In this respect, the follow<strong>in</strong>g functions can be allocated at bay level:a) Bay control functions <strong>in</strong>clud<strong>in</strong>g data collection functionality.b) Bay protection functionsSeparate IEDs shall be provided for bay control function and bay protectionfunction.3.1.1 BAY CONTROL FUNCTIONS:3.1.1.1 OVERVIEW:FUNCTIONS:i) Control mode selectionii) Select-before-execute pr<strong>in</strong>cipleiii) Command supervision:a) Interlock<strong>in</strong>g and block<strong>in</strong>gb) Double commandiv) Synchrocheck, voltage selectionv) Run Time Command cancellationvi) Transformer tap changer control (for power transformer bays)vii) Operation counters for circuit breakers and pumpsviii) Hydraulic pump/ Air compressor control and runtime supervisionix) Operat<strong>in</strong>g pressure supervisionx) Display of <strong>in</strong>terlock<strong>in</strong>g and block<strong>in</strong>gxi) Breaker position <strong>in</strong>dication per phasexii) Alarm annunciationxiii) Measurement displayxiv) Local HMI (local guided, emergency mode)xv) Interface to the station HMI.xvi)xvii)Data storage for at least 200 eventsExtension possibilities with additional I/O's <strong>in</strong>side the unit or via fibre-opticcommunication and process bus.3.1.1.2 CONTROL MODE SELECTION:BAY:As soon as the operator receives the operation access at bay level the operationis normally performed via bay control IED. Dur<strong>in</strong>g normal operation bay controlunit allows the safe operation of all switch<strong>in</strong>g devices via the bay control IED.EMERGENCY OPERATION:It shall be possible to close or open the selected Circuit Breaker with ON or OFFpush buttons even dur<strong>in</strong>g the outage of bay IED.REMOTE MODE:Control authority <strong>in</strong> this mode is given to a higher level (Remote Control Centre)and the <strong>in</strong>stallation can be controlled only remotely. Control operation from lowerlevels shall not be possible <strong>in</strong> this operat<strong>in</strong>g mode.C:\Users\itms\Downloads\SAS Spec. (1).doc - 6 -

3.1.1.3 SYNCHRONISM AND ENERGIZING CHECK:The synchronism and energiz<strong>in</strong>g check functions shall be bay-oriented anddistributed to the bay control and/or protection devices. These features are:a) Settable voltage, phase angle, and frequency difference.b) Energiz<strong>in</strong>g for dead l<strong>in</strong>e - live bus, live l<strong>in</strong>e - dead bus or dead l<strong>in</strong>e – deadbus with no synchrocheck function.c) Synchroniz<strong>in</strong>g between live l<strong>in</strong>e and live bus with synchrocheck function.3.1.1.4 VOLTAGE SELECTION:The voltages relevant for the Synchrocheck functions are dependent on thestation topology, i.e. on the positions of the circuit breakers and/or the isolators.The correct voltage for synchroniz<strong>in</strong>g and energiz<strong>in</strong>g is derived from the auxiliaryswitches of the circuit breakers, the isolator, and earth<strong>in</strong>g switch and shall beselected automatically by the bay control and protection IEDs.3.1.1.5 TRANSFORMER TAP CHANGER CONTROL:Raise and lower operation of OLTC taps of transformer shall be facilitatedthrough Bay controller IED.3.1.2 BAY PROTECTION FUNCTIONS:3.1.2.1 GENERAL:The protection functions are <strong>in</strong>dependent of bay control function. The protectionshall be provided by separate protection IEDs (numerical relays) and otherprotection devices as per section Relay & Protection. IEDs, shall be connected tothe communication <strong>in</strong>frastructure for data shar<strong>in</strong>g and meet the real-timecommunication requirements for automatic functions. The data presentation andthe configuration of the various IEDs shall be compatible with the overall systemcommunication and data exchange requirements.3.1.2.2 EVENT AND DISTURBANCE RECORDING FUNCTION:Each IED should conta<strong>in</strong> an event recorder capable of stor<strong>in</strong>g at least 200 timetaggedevents. This shall give alarm if 70% memory is full. The disturbancerecorder function shall be as per detailed <strong>in</strong> the technical specification of C&RPanels.3.2 SYSTEM LEVEL FUNCTIONS:3.2.1 STATUS SUPERVISION:The position of each switchgear, e.g. circuit breaker, isolator, earth<strong>in</strong>g switch,transformer tap changer etc., shall be supervised cont<strong>in</strong>uously. Every detectedchange of position shall be immediately displayed <strong>in</strong> the s<strong>in</strong>gle-l<strong>in</strong>e diagram onthe station HMI screen, recorded <strong>in</strong> the event list and a hard copy pr<strong>in</strong>tout shallbe produced. Alarms shall be <strong>in</strong>itiated <strong>in</strong> the case of spontaneous positionchanges.The switchgear positions shall be <strong>in</strong>dicated by two auxiliary switches, normallyclosed (NC) and normally open (NO), which shall give ambivalent signals. Analarm shall be <strong>in</strong>itiated if these position <strong>in</strong>dications are <strong>in</strong>consistent or if the timerequired for operat<strong>in</strong>g mechanism to change position exceeds a predef<strong>in</strong>ed limit.The SAS shall also monitor the status of sub-station auxiliaries. The status andcontrol of auxiliaries shall be done through separate one or more IED and allalarm and analogue values shall be monitored and recoded through this IED.C:\Users\itms\Downloads\SAS Spec. (1).doc - 7 -

3.2.2 MEASUREMENTS:Analogue <strong>in</strong>puts for voltage and current measurements shall be connecteddirectly to the voltage transformers (VT) and the current transformers (CT)without <strong>in</strong>termediate transducers. The values of active power (W), reactive power(VAR), frequency (Hz), and the rms values for voltage (U) and current (I) shall becalculated.The measured values shall be displayed locally on the station HMI and <strong>in</strong> thecontrol centre. The abnormal values must be discarded.The analogue values shall be updated every 2 seconds.Threshold limit values shall be selectable for alarm <strong>in</strong>dications.Suitable no. of Transducers shall be provided to facilitate the flow of 4-20mAAnalogue signals as per Annexure–I from the bay level equipments (i.e circuitbreaker, AC Kiosks, Transformers, etc.) to its respective C&R Panel BCU andStation level equipments (i.e. ACDB, DCDB, Battery Chargers, L.T. Transformer,Generator, etc.) to station auxiliary BCU, as per its respective approveddraw<strong>in</strong>gs, for remote control & supervision at Station HMI’s thereof by thesuccessful SCADA supplier.3.2.3 EVENT AND ALARM HANDLING:Events and alarms are generated either by the switchgear, by the control IEDs,or by the station level unit. They shall be recorded <strong>in</strong> an event list <strong>in</strong> the stationHMI. Alarms shall be recorded <strong>in</strong> a separate alarm list and appear on the screen.All, or a freely selectable group of events and alarms shall also be pr<strong>in</strong>ted out onan event pr<strong>in</strong>ter.The alarms and events shall be time-tagged with a time resolution of 1 ms.3.2.4 STATION HMI:3.2.4.1 SUBSTATION HMI OPERATION:On the HMI the object has to be selected first. In case of a block<strong>in</strong>g or<strong>in</strong>terlock<strong>in</strong>g conditions are not met, the selection shall not be possible and anappropriate alarm annunciation shall occur. If a selection is valid the position<strong>in</strong>dication will show the possible direction, and the appropriate control executionbutton shall be pressed <strong>in</strong> order to close or open the correspond<strong>in</strong>g object.Control operation from other places (e.g. REMOTE) shall not be possible <strong>in</strong> thisoperat<strong>in</strong>g mode.3.2.4.2 PRESENTATION AND DIALOGUES:GENERAL:The operator station HMI shall be a redundant with hot standby and shall providebasic functions for supervision and control of the substation. The operator shallgive commands to the switchgear on the screen via mouse clicks or keyboardcommands.The HMI shall give the operator access to alarms and events displayed on thescreen. Aside from these lists on the screen, there shall be a pr<strong>in</strong>tout of alarms orevents <strong>in</strong> an event log.An acoustic alarm shall <strong>in</strong>dicate abnormalities, and all unacknowledged alarmsshall be accessible from any screen selected by the operator.The follow<strong>in</strong>g standard pictures shall be available from the HMI:C:\Users\itms\Downloads\SAS Spec. (1).doc - 8 -

a) S<strong>in</strong>gle-l<strong>in</strong>e diagram show<strong>in</strong>g the switchgear status and measured valuesb) Control dialogues with <strong>in</strong>terlock<strong>in</strong>g and block<strong>in</strong>g details.This control dialogue shall tell the operator whether the device operation ispermitted or blocked.a) Measurement dialoguesb) Alarm list, station / bay-orientedc) Event list, station / bay-orientedd) <strong>System</strong> status3.2.4.3 HMI DESIGN PRINCIPLES:Consistent design pr<strong>in</strong>ciples shall be adopted with the HMI concern<strong>in</strong>g labels,colors, dialogues and fonts. Non-valid selections shall be dimmed out.The object status shall be <strong>in</strong>dicated us<strong>in</strong>g different status colors for:a) Selected object under commandb) Selected on the screenc) Not updated, obsolete values, not <strong>in</strong> use or not sampledd) Alarm or faulty statee) Warn<strong>in</strong>g or blockedf) Update blocked or manually updatedg) Control blockedh) Normal state3.2.4.4 PROCESS STATUS DISPLAYS AND COMMAND PROCEDURES:The process status of the substation <strong>in</strong> terms of actual values of currents,voltages, frequency, active and reactive powers as well as the positions of circuitbreakers, isolators and transformer tap-changers shall be displayed <strong>in</strong> the stations<strong>in</strong>gle-l<strong>in</strong>e diagram.In order to ensure a high degree of security aga<strong>in</strong>st undesired operation, a"select-before-execute" command procedure shall be provided. After the"selection" of a switch, the operator shall be able to recognize the selecteddevice on the screen, and all other switchgear shall be blocked. Ascommunication between control centre and device to be controlled is established,the operator shall be prompted to confirm the control action and only then f<strong>in</strong>alexecute command shall be accepted. After the “execution” of the command theoperated switch<strong>in</strong>g symbol shall flash until the switch has reached its newposition.The operator shall be <strong>in</strong> a position to execute a command only, if the switch isnot blocked and if no <strong>in</strong>terlock<strong>in</strong>g condition is go<strong>in</strong>g to be violated. The<strong>in</strong>terlock<strong>in</strong>g statements shall be checked by the <strong>in</strong>terlock<strong>in</strong>g schemeimplemented at bay and station level.After command execution the operator shall receive a confirmation that the newswitch<strong>in</strong>g position has been reached or an <strong>in</strong>dication that the switch<strong>in</strong>g procedurewas unsuccessful with the <strong>in</strong>dication of the reason for non-function<strong>in</strong>g.3.2.4.5 SYSTEM SUPERVISION & DISPLAY:The SAS system shall be comprehensively self-monitored such that faults areimmediately <strong>in</strong>dicated to the operator, possibly before they develop <strong>in</strong>to seriousC:\Users\itms\Downloads\SAS Spec. (1).doc - 9 -

situations. Such faults are recorded as a faulty status <strong>in</strong> a system supervisiondisplay. This display shall cover the status of the entire substation <strong>in</strong>clud<strong>in</strong>g allswitchgear, IEDs, communication <strong>in</strong>frastructure and remote communication l<strong>in</strong>ks,and pr<strong>in</strong>ters at the station level, etc.3.2.4.6 EVENT LIST:The event list shall conta<strong>in</strong> events that are important for the control andmonitor<strong>in</strong>g of the substation.The event and associated time (with1 ms resolution) of its occurrence has to bedisplayed for each event.The operator shall be able to call up the chronological event list on the monitor atany time for the whole substation or sections of it.A pr<strong>in</strong>tout of each display shall be possible on the hard copy pr<strong>in</strong>ter.The events shall be registered <strong>in</strong> a chronological event list <strong>in</strong> which the type ofevent and its time of occurrence are specified. It shall be possible to store allevents <strong>in</strong> the computer for at least one month.The <strong>in</strong>formation shall be obta<strong>in</strong>able also from a pr<strong>in</strong>ted event log.The chronological event list shall conta<strong>in</strong>:a) Position changes of circuit breakers, isolators and earth<strong>in</strong>g devicesb) Indication of protective relay operationsc) Fault signals from the switchgeard) Indication when analogue measured values exceed upper and lowerlimits.Suitable provision shall be made <strong>in</strong> the system to def<strong>in</strong>e two level of alarmon either side of the value or which shall be user def<strong>in</strong>ed for eachmeasurand.i) Loss of communication.Filters for selection of a certa<strong>in</strong> type or group of events shall be available. Thefilters shall be designed to enable view<strong>in</strong>g of events grouped per:a) Date and timeb) Bayc) Deviced) Function e.g. trips, protection operations etc.e) Alarm class.3.2.4.7 ALARM LIST:Faults and errors occurr<strong>in</strong>g <strong>in</strong> the substation shall be listed <strong>in</strong> an alarm list andshall be immediately transmitted to the control centre.The alarm list shall substitute a conventional alarm tableau, and shall constitutean evaluation of all station alarms. It shall conta<strong>in</strong> unacknowledged alarms andpersist<strong>in</strong>g faults. The date and time of occurrence shall be <strong>in</strong>dicated.The alarm list shall consist of a summary display of the present alarm situation.Each alarm shall be reported on one l<strong>in</strong>e that conta<strong>in</strong>s:C:\Users\itms\Downloads\SAS Spec. (1).doc - 10 -

a) The date and time of the alarmb) The name of the alarm<strong>in</strong>g objectc) A descriptive textd) The acknowledgement state.Whenever an alarm condition occurs, the alarm condition must be shown on thealarm list and must be displayed <strong>in</strong> a flash<strong>in</strong>g state along with an audible alarm.After acknowledgement of the alarm, it should appear <strong>in</strong> a steady (i.e. notflash<strong>in</strong>g) state and the audible alarm shall stop. The alarm should disappear onlyif the alarm condition has physically cleared and the operator has reset the alarmwith a reset command. The state of the alarms shall be shown <strong>in</strong> the alarm list(Unacknowledged and persistent, Unacknowledged and cleared, Acknowledgedand persistent).Filters for selection of a certa<strong>in</strong> type or group of alarms shall be available as forevents.3.2.4.8 OBJECT PICTURE:When select<strong>in</strong>g an object such as a circuit breaker or isolator <strong>in</strong> the s<strong>in</strong>gle-l<strong>in</strong>ediagram, the associated bay picture shall be presented first. In the selectedobject picture, all attributes likea) Type of block<strong>in</strong>gb) Authorityc) Local / remote controld) RSCC / SAS controle) Errorsf) Etc.,Shall be displayed.3.2.4.9 CONTROL DIALOGUES:The operator shall give commands to the system by means of mouse clicklocated on the s<strong>in</strong>gle-l<strong>in</strong>e diagram. It shall also be possible to use the keyboardfor command activation. Data entry is performed with the keyboard. Dedicatedcontrol dialogues for controll<strong>in</strong>g at least the follow<strong>in</strong>g devices shall be available:a) Breaker and disconnectorb) Transformer tap-changer3.2.5 USER-AUTHORITYV LEVELS:It shall be possible to restrict activation of the process pictures of each object(bays, apparatus...) with<strong>in</strong> a certa<strong>in</strong> user authorization group. Each user shallthen be given access rights to each group of objects, e.g.:a) Display onlyb) Normal operation (e.g. open/close of switchgear)c) Restricted operation (e.g. by-passed <strong>in</strong>terlock<strong>in</strong>g)d) <strong>System</strong> adm<strong>in</strong>istratorFor ma<strong>in</strong>tenance and eng<strong>in</strong>eer<strong>in</strong>g purposes of the station HMI, the follow<strong>in</strong>gauthorization levels shall be available:(i) No eng<strong>in</strong>eer<strong>in</strong>g allowed(ii) Eng<strong>in</strong>eer<strong>in</strong>g/configuration allowed(iii) Entire system management allowedThe access rights shall be def<strong>in</strong>ed by passwords assigned dur<strong>in</strong>g the log-<strong>in</strong>procedure. Only the system adm<strong>in</strong>istrator shall be able to add/remove users andC:\Users\itms\Downloads\SAS Spec. (1).doc - 11 -

change access rights.3.2.6 REPORTS:The reports shall provide time-related follow-ups of measured and calculatedvalues.The data displayed shall comprise:A. Trend reports:• Day (mean, peak)• Month (mean, peak)• Semi-annual (mean, peak)• Year (mean, peak)B. Historical reports of selected analogue Values:• Day (at 15 m<strong>in</strong>utes <strong>in</strong>terval)• Week• Month• YearIt shall be possible to select displayed values from the database <strong>in</strong> the processdisplay on-l<strong>in</strong>e. Scroll<strong>in</strong>g between e.g. days shall be possible. Unsure valuesshall be <strong>in</strong>dicated. It shall be possible to select the time period for which thespecific data are kept <strong>in</strong> the memory.Follow<strong>in</strong>g pr<strong>in</strong>touts shall be available from the pr<strong>in</strong>ter and shall be pr<strong>in</strong>ted ondemand:i. Daily voltage and frequency curves depict<strong>in</strong>g time on X-axis and the appropriateparameters on the Y-axis. The time duration of the curve is 24 hours.ii. Weekly trend curves for real and derived analogue values.iii. Pr<strong>in</strong>touts of the maximum and m<strong>in</strong>imum values and frequency of occurrence andduration of maximum and m<strong>in</strong>imum values for each analogue parameter for eachcircuit <strong>in</strong> 24 hr period.iv. Provision shall be made for logg<strong>in</strong>g <strong>in</strong>formation about breaker status like numberof operation with date and time <strong>in</strong>dications.v. Equipment operation details shift wise and dur<strong>in</strong>g 24 hours.vi. Pr<strong>in</strong>tout on adjustable time period as well as on demand for MW, MVAR, Current,Voltage on each feeder and transformer as well as Tap Positions, temperatureand status of pumps and fans for transformers.vii. Pr<strong>in</strong>tout on adjustable time period as well as on demand system frequency andaverage frequency.viii. Reports <strong>in</strong> specified formats which shall be handed over to successful bidder.3.2.7 Trend display (historical data)It shall be possible to illustrate all types of process data as trends - <strong>in</strong>put andoutput data, b<strong>in</strong>ary and analogue data. The trends shall be displayed <strong>in</strong> graphicalform as column or curve diagrams with a maximum of 10 trends per screen.Adjustable time span and scal<strong>in</strong>g ranges must be provided.It shall be possible to change the type of value logg<strong>in</strong>g (direct, mean, sum, ordifference) on-l<strong>in</strong>e <strong>in</strong> the w<strong>in</strong>dow. It shall also be possible to change the update<strong>in</strong>tervals on-l<strong>in</strong>e <strong>in</strong> the picture as well as the selection of threshold values foralarm<strong>in</strong>g purposes.C:\Users\itms\Downloads\SAS Spec. (1).doc - 12 -

3.2.8 Automatic disturbance file transferAll recorded data from the IEDs with <strong>in</strong>tegrated disturbance recorder as well asdedicated disturbance record<strong>in</strong>g systems shall be automatically uploaded (eventtriggered or once per day) to a dedicated computer and be stored on the harddisc.3.2.9 Disturbance analysisThe PC-based work station shall have necessary software to evaluate all therequired <strong>in</strong>formation for proper fault analysis.3.2.10. IED Parameter Sett<strong>in</strong>gIt shall be possible to access al protection and control IEDs for read<strong>in</strong>g theparameters (sett<strong>in</strong>gs) from the station HMI or from a dedicated monitor<strong>in</strong>gcomputer. The sett<strong>in</strong>g of parameters or the activation of parameter sets shall onlybe allowed after enter<strong>in</strong>g a password.3.2.11 Automatic sequencesThe available automatic sequences <strong>in</strong> the system should be listed and described,(e.g. sequences related to the bus transfer). It must be possible to <strong>in</strong>itiate predef<strong>in</strong>edautomatic sequences by the operator and also def<strong>in</strong>e new automaticsequences.3.3 Gateway3.3.1 Communication Interface(a)(b)The <strong>Substation</strong> <strong>Automation</strong> <strong>System</strong> shall have the capability to supportsimultaneous communications with multiple <strong>in</strong>dependent remote master stations.The <strong>Substation</strong> <strong>Automation</strong> <strong>System</strong> shall have communication ports as follows:-Two ports for Remote Control CentreTwo ports for Regional <strong>System</strong> Coord<strong>in</strong>ation Centre (RSCC)The communication <strong>in</strong>terface to the SAS shall allow scann<strong>in</strong>g and control ofdef<strong>in</strong>ed po<strong>in</strong>ts with<strong>in</strong> the substation automation system <strong>in</strong>dependently for eachcontrol centre. The substation automation system shall simultaneously respondto <strong>in</strong>dependent scans and commands from employer's control centres (RCC &RSCC). The substation automation system shall support the use of a differentcommunication data exchange rate (bits per second), scann<strong>in</strong>g cycle, and/orcommunication protocol to each remote control centre. Also, each controlcentre’s data scan and control commands may be different for different datapo<strong>in</strong>ts with<strong>in</strong> the substation automation system's database.3.3.2 Remote Control Centre Communication InterfaceEmployer will supply communication channels between the <strong>Substation</strong><strong>Automation</strong> <strong>System</strong> and the remote control centre. The communication channelsprovided by Employer will consist either of power l<strong>in</strong>e carrier, microwave, opticalfibre, VSAT or leased l<strong>in</strong>e, the details of which shall be provided dur<strong>in</strong>g detailedEng<strong>in</strong>eer<strong>in</strong>g.3.3.3 Interface Equipment:The Contractor shall provide <strong>in</strong>terface equipment for communicat<strong>in</strong>g between<strong>Substation</strong> <strong>Automation</strong> system and Remote control centre and between<strong>Substation</strong> <strong>Automation</strong> system and Regional <strong>System</strong> Coord<strong>in</strong>ation Centre(RSCC). However, the communication channels available for this purpose arespecified <strong>in</strong> section project.C:\Users\itms\Downloads\SAS Spec. (1).doc - 13 -

4.2 Bay Level UnitThe bay unit shall use <strong>in</strong>dustrial grade components. The bay level unit, based onmicroprocessor technology, shall use numerical techniques for the calculationand evaluation of externally <strong>in</strong>put analogue signals. They shall <strong>in</strong>corporateselect-before-operate control pr<strong>in</strong>ciples as safety measures for operation via theHMI. They shall perform all bay related functions, such as control commands,bay <strong>in</strong>terlock<strong>in</strong>g, data acquisition, data storage, event record<strong>in</strong>g and shall provide<strong>in</strong>puts for status <strong>in</strong>dication and outputs for commands. They shall be directlyconnected to the switchgear. The bay unit shall acquire and process all data forthe bay (Equipment status, fault <strong>in</strong>dications, measured values, alarms etc.) andtransmit these to the other devices <strong>in</strong> sub-station automation system. In addition,this shall receive the operation commands from station HMI and control centre.The bay unit shall have the capability to store all the data for at least 24 hours.One no. Bay level unit shall be provided for supervision and control of each765kV, 400kV, 220kV, 132kV, 66kV and 33kV bay (a bay comprises of onecircuit breaker and associated disconnector, earth switches and <strong>in</strong>strumenttransformer). The Bay level unit shall be equipped with analogue and b<strong>in</strong>ary<strong>in</strong>puts/outputs for handl<strong>in</strong>g the control, status monitor<strong>in</strong>g and analoguemeasurement functions. All bay level <strong>in</strong>terlocks are to be <strong>in</strong>corporated <strong>in</strong> the Baylevel unit so as to permit control from the Bay level unit/ local bay mimic panel,with all bay <strong>in</strong>terlocks <strong>in</strong> place, dur<strong>in</strong>g ma<strong>in</strong>tenance and commission<strong>in</strong>g or <strong>in</strong> caseof cont<strong>in</strong>gencies when the Station HMI is out of service.The Bay level unit shall meet the requirements for withstand<strong>in</strong>g electromagnetic<strong>in</strong>terference accord<strong>in</strong>g to relevant parts of IEC 61850. Failure of any s<strong>in</strong>glecomponent with<strong>in</strong> the equipment shall neither cause unwanted operation nor leadto a complete system breakdown.4.2.1 Input/Output (I/O) modulesThe I/O modules shall form a part of the bay level unit and shall provide coupl<strong>in</strong>gto the substation equipment. The I/O modules shall acquire all switchgear<strong>in</strong>formation (i.e. data com<strong>in</strong>g directly from the switchgear or from switchgear<strong>in</strong>terlock<strong>in</strong>g devices) and transmit commands for operation of the switchgear.The measured values of voltage and current shall be from the secondaries of<strong>in</strong>strument transformers. The digital <strong>in</strong>puts shall be acquired by exception with 1ms resolution. Contact bounc<strong>in</strong>g <strong>in</strong> digital <strong>in</strong>puts shall not be assumed as changeof state.4.3 Air-conditioned kioskThe Air-conditioned Kiosk offered shall house Bay level units, bay mimic, relayand protection panels, PLCC panels etc. one each for a diameter <strong>in</strong> 765 &400kVsub-stations, for two adjacent bays <strong>in</strong> 220kV, 132kV & 66kV Level, forfour adjacent bays <strong>in</strong> 33kV level of 220/33kV T/F and all 33kV bays of132/33kV T/F start<strong>in</strong>g from Bay No.1 as per GELO drg. In case of <strong>in</strong>completediameter the kiosk shall have necessary space for accommodat<strong>in</strong>g the futurebay IEDs. The layout of equipment/panel shall be subject to Owner’s approval.The Kiosk shall be provided with fire alarm system with at least two detectorsand it shall be wired to SAS. The detailed requirement of Kiosk is enclosed asAnnexure-II. The air conditioner provided <strong>in</strong> Kiosk shall be controlled andmonitored from substation automation system. One additional Kiosk for eachvoltage level, if required, shall be provided for hous<strong>in</strong>g bus bar protectionpanels at suitable location <strong>in</strong> switchyard.4.4 Extendibility <strong>in</strong> futureOffered substation automation system shall be suitable for extension <strong>in</strong> future foradditional bays. Dur<strong>in</strong>g such requirement, all the draw<strong>in</strong>gs and configurations,C:\Users\itms\Downloads\SAS Spec. (1).doc - 16 -

alarm/event list etc. displayed shall be designed <strong>in</strong> such a manner that itsextension shall be easily performed by the employer. Dur<strong>in</strong>g such event, normaloperation of the exist<strong>in</strong>g substation shall be unaffected and system shall notrequire a shutdown. The contractor shall provide all necessary software toolsalong with source codes to perform addition of bays <strong>in</strong> future and complete<strong>in</strong>tegration with SAS by the user. These software tools shall be able to configureIED, add additional analogue variable, alarm list, event list, modify <strong>in</strong>terlock<strong>in</strong>glogics etc. for additional bays/equipment which shall be added <strong>in</strong> future.5.0 Software structureThe software package shall be structured accord<strong>in</strong>g to the SAS architecture andstrictly divided <strong>in</strong> various levels. Necessary firewall shall be provided at suitablepo<strong>in</strong>ts <strong>in</strong> software to protect the system.An extension of the station shall be possible with lowest possible efforts.Ma<strong>in</strong>tenance, modification or an extension of components of any feeder may notforce a shut-down of the parts of the system which are not affected by the systemadaptation.5.1.1 Station level software5.1.1.1 Human-mach<strong>in</strong>e <strong>in</strong>terface (HMI)The base HMI software package for the operator station shall <strong>in</strong>clude the ma<strong>in</strong>SAS functions and it shall be <strong>in</strong>dependent of project specific hardware versionand operat<strong>in</strong>g system. It shall further <strong>in</strong>clude tools for picture edit<strong>in</strong>g, eng<strong>in</strong>eer<strong>in</strong>gand system configuration. The system shall be easy to use, to ma<strong>in</strong>ta<strong>in</strong>, and toadapt accord<strong>in</strong>g to specific user requirements. <strong>System</strong>s shall conta<strong>in</strong> a librarywith standard functions and applications.5.1.2 Bay level software5.1.1.1 <strong>System</strong> softwareThe system software shall be structured <strong>in</strong> various levels. This software shall beplaced <strong>in</strong> a non-volatile memory. The lowest level shall assure systemperformance and conta<strong>in</strong> basic functions, which shall not be accessible by theapplication and ma<strong>in</strong>tenance eng<strong>in</strong>eer for modifications. The system shallsupport the generation of typical control macros and a process database for userspecific data storage. In case of restoration of l<strong>in</strong>ks after failure, the softwarealong with hardware shall be capable of automatically synchroniz<strong>in</strong>g with therema<strong>in</strong><strong>in</strong>g system without any manual <strong>in</strong>terface. This shall be demonstrated bycontractor dur<strong>in</strong>g <strong>in</strong>tegrated system test.5.1.1.2 Application softwareIn order to ensure robust quality and reliable software functions, the ma<strong>in</strong> part ofthe application software shall consist of standard software modules built asfunctional block elements. The functional blocks shall be documented andthoroughly tested. They form part of a library. The application software with<strong>in</strong> thecontrol/protection devices shall be programmed <strong>in</strong> a functional block language.5.1.1.3 Network Management <strong>System</strong>:The contractor shall provide network management system software for follow<strong>in</strong>gmanagement functions:a. Configuration Managementb. Fault ManagementC:\Users\itms\Downloads\SAS Spec. (1).doc - 17 -

c. Performance Monitor<strong>in</strong>gThis system shall be used for management of communication devices and otherIEDs <strong>in</strong> the system. This NMS can be loaded <strong>in</strong> DR work-station and shall beeasy to use, user friendly and menu based. The NMS shall monitor all thedevices <strong>in</strong> the SAS and report if there is any fault <strong>in</strong> the monitored devices. TheNMS shall(a)(b)(c)(d)Ma<strong>in</strong>ta<strong>in</strong> performance, resource usage, and error statistics for all managed l<strong>in</strong>ksand devices and present this <strong>in</strong>formation via displays, periodic reports and ondemand reports.Ma<strong>in</strong>ta<strong>in</strong> a graphical display of SAS connectivity and device status.Issue alarms when error conditions occursProvide facility to add and delete addresses and l<strong>in</strong>ks5.1.1.4 The contractor shall provide each software <strong>in</strong> two copies <strong>in</strong> CD to load <strong>in</strong>to thesystem <strong>in</strong> case of any problem related with Hardware/Communication etc.6.0 TESTSThe substation automation system offered by the bidder shall be subjected tofollow<strong>in</strong>g tests to establish compliance with IEC 61850 for EHV sub-stationequipment <strong>in</strong>stalled <strong>in</strong> sheltered area <strong>in</strong> the outdoor switchyard and specifiedambient conditions:6.1 Type Tests:6.1.1 Control IEDs and Communication Equipment:a. Power Input:i. Auxiliary Voltageii. Current Circuitsiii. Voltage Circuitsiv. Indicationsb. Accuracy Tests:i. Operational Measured Valuesii. Currentsiii. Voltagesiv. Time resolutionc. Insulation Tests:i. Dielectric Testsii. Impulse Voltage withstand Testd. Influenc<strong>in</strong>g Quantitiesi. Limits of operationii. Permissible ripplesiii. Interruption of <strong>in</strong>put voltagee. Electromagnetic Compatibility Test:i. 1 MHZ. burst disturbance testii. Electrostatic Discharge Testiii. Radiated Electromagnetic Field Disturbance Testiv. Electrical Fast transient Disturbance Testv. Conducted Disturbances Tests <strong>in</strong>duced by Radio Frequency Fieldvi. Magnetic Field Testvii. Emission (Radio <strong>in</strong>terference level) Test.viii. Conducted Interference Testf. Function Tests:C:\Users\itms\Downloads\SAS Spec. (1).doc - 18 -

i. Indicationii. Commandsiii. Measured value Acquisitioniv. Display Indicationsg. Environmental tests:i. Cold Temperatureii. Dry Heatiii. Wet heativ. Humidity (Damp heat Cycle)v. Vibrationvi. Bumpvii. Shock6.2 Factory Acceptance Tests:The supplier shall submit a test specification for factory acceptance test (FAT)and commission<strong>in</strong>g tests of the station automation system for approval. For the<strong>in</strong>dividual bay level IED’s applicable type test certificates shall be submitted.The manufactur<strong>in</strong>g phase of the SAS shall be concluded by the factoryacceptance test (FAT). The purpose is to ensure that the Contractor has<strong>in</strong>terpreted the specified requirements correctly and that the FAT <strong>in</strong>cludescheck<strong>in</strong>g to the degree required by the user.The general philosophy shall be to deliver a system to site only after it has beenthoroughly tested and its specified performance has been verified, as far as siteconditions can be simulated <strong>in</strong> a test lab. If the FAT comprises only a certa<strong>in</strong>portion of the system for practical reason, it has to be assured that this testconfiguration conta<strong>in</strong>s at least one unit of each and every type of equipment<strong>in</strong>corporated <strong>in</strong> the delivered system.If the complete system consists of parts from various suppliers or some parts arealready <strong>in</strong>stalled on site, the FAT shall be limited to sub-system tests. In such acase, the complete system test shall be performed on site together with the siteacceptance test (SAT).6.3 Integrated Test<strong>in</strong>g;The <strong>in</strong>tegrated system tests shall be performed as detailed <strong>in</strong> subsequentclauses as per follow<strong>in</strong>g configuration:(i)Redundant Station HMI, DR work station, two switches (i.e. for twodiameters) along with all IEDs for the Dia and pr<strong>in</strong>ters.All other switches for complete sub-station as detailed <strong>in</strong> section project shall besimulated as needed.6.3.1 Hardware Integration Tests:The hardware <strong>in</strong>tegration test shall be performed on the specified systems to beused for Factory tests when the hardware has been <strong>in</strong>stalled <strong>in</strong> the factory. Theoperation of each item shall be verified as an <strong>in</strong>tegral part of system. Applicablehardware diagnostics shall be used to verify that each hardware component iscompletely operational and assembled <strong>in</strong>to a configuration capable of support<strong>in</strong>gsoftware <strong>in</strong>tegration and factory test<strong>in</strong>g of the system. The equipment expansioncapability shall also be verified dur<strong>in</strong>g the hardware <strong>in</strong>tegration tests.C:\Users\itms\Downloads\SAS Spec. (1).doc - 19 -

6.3.2 Integrated <strong>System</strong> Tests:6.4 Field Tests:Integrated system tests shall verify the stability of the hardware and the software.Dur<strong>in</strong>g the tests all functions shall run concurrently and all equipment shalloperate a cont<strong>in</strong>uous 100 Hours period. The <strong>in</strong>tegrated system test shall ensurethe SAS is free of improper <strong>in</strong>teractions between software and hardware whilethe system is operat<strong>in</strong>g as a whole.The field tests shall completely verify all the features of SAS hardware andsoftware.7.0 SYSTEM OPERATION7.1 <strong>Substation</strong> Operation7.1.1 NORMALOPERATIONOperation of the system by the operator from the remote RCC or at thesubstation shall take place via <strong>in</strong>dustry standard HMI (Human Mach<strong>in</strong>e <strong>in</strong>terface)subsystem consist<strong>in</strong>g of graphic color VDU, a standard keyboard and a cursorposition<strong>in</strong>g device (mouse).The colored screen shall be divided <strong>in</strong>to 3 fields:i) Message field with display of present time and dateii) Display field for s<strong>in</strong>gle l<strong>in</strong>e diagramsiii) Navigation bar with alarm/condition <strong>in</strong>dicationFor display of alarm annunciation, lists of events etc a separate HMI View nodeshall be provided.All operations shall be performed with mouse and/or a m<strong>in</strong>imum number offunction keys and cursor keys. The function keys shall have different mean<strong>in</strong>gsdepend<strong>in</strong>g on the operation. The operator shall see the relevant mean<strong>in</strong>gs asfunction tests displayed <strong>in</strong> the command field (i.e. operator prompt<strong>in</strong>g). Forcontrol actions, the switchgear (i.e. circuit breaker etc.) requested shall beselectable on the display by means of the cursor keys. The switch<strong>in</strong>g elementselected shall then appear on the background that shall be flash<strong>in</strong>g <strong>in</strong> a differentcolor.The operator prompt<strong>in</strong>g shall dist<strong>in</strong>guish between:-- Prompt<strong>in</strong>g of <strong>in</strong>dications e.g. fault <strong>in</strong>dications <strong>in</strong> the switchgear, and- prompt<strong>in</strong>g of operational sequences e.g. execution of switch<strong>in</strong>g operationsThe summary <strong>in</strong>formation displayed <strong>in</strong> the message field shall give a rapiddisplay of alarm/message of the system <strong>in</strong> which a fault has occurred and alarmannunciation lists <strong>in</strong> which the fault is described more fully.Each operational sequence shall be divided <strong>in</strong>to s<strong>in</strong>gle operation steps which are<strong>in</strong>itiated by means of the function keys/WINDOW command by mouse. Operatorprompt<strong>in</strong>g shall be designed <strong>in</strong> such a manner that only the permissible keys areavailable <strong>in</strong> the command field related to the specific operation step. Only thoseswitch<strong>in</strong>g elements shall be accessed for which control actions are possible. Ifthe operation step is rejected by the system, the operator prompt<strong>in</strong>g shall besupported by additional comments <strong>in</strong> the message field. The operation statusC:\Users\itms\Downloads\SAS Spec. (1).doc - 20 -

shall be reset to the correspond<strong>in</strong>g preced<strong>in</strong>g step <strong>in</strong> the operation sequence bypress<strong>in</strong>g one of the function keys. All operations shall be verified. Incorrectoperations shall be <strong>in</strong>dicated by comments <strong>in</strong> the message field and must not beexecuted.The offer shall <strong>in</strong>clude a comprehensive description of the system.The above operation shall also be possible via WINDOWS based system bymouse.8.0 POWER SUPPLYPower for the substation automation system shall be derived from substation220V DC system. Inverter of suitable capacity shall be provided for station HMIand its peripheral devices e.g. pr<strong>in</strong>ter etc. In the event of Power failure,necessary safeguard software shall be built for proper shutdown and restart.9.0 DOCUMENTATIONThe follow<strong>in</strong>g documents shall be submitted for employer’s approval dur<strong>in</strong>gdetailed eng<strong>in</strong>eer<strong>in</strong>g:(a)(b)(c)(d)(e)<strong>System</strong> Architecture Draw<strong>in</strong>gHardware SpecificationSiz<strong>in</strong>g Calculations of various componentsResponse Time CalculationFunctional Design DocumentThe follow<strong>in</strong>g documentation to be provided for the system <strong>in</strong> the course of theproject shall be consistent, CAD supported, and of similar look/feel. All CADdraw<strong>in</strong>gs to be provide <strong>in</strong> “dxf” format.• List of Draw<strong>in</strong>gs• <strong>Substation</strong> automation system architecture• Block Diagram• Guaranteed technical parameters, Functional Design Specification andGuaranteed availability and reliability• Calculation for power supply dimension<strong>in</strong>g• I/O Signal lists• Schematic diagrams• List of Apparatus• List of Labels• Logic Diagram (hardware & software)• Panel Room Layout draw<strong>in</strong>g• Control Room Lay-out• Test Specification for Factory Acceptance Test (FAT)• Product Manuals• Assembly Draw<strong>in</strong>g• Operator’s Manual• Complete documentation of implemented protocols between variouselements• List<strong>in</strong>g of software and loadable <strong>in</strong> CD ROM• Other documents as may be required dur<strong>in</strong>g detailed eng<strong>in</strong>eer<strong>in</strong>g.Four sets of hard copy and Four sets of CD ROM conta<strong>in</strong><strong>in</strong>g all the as builtdocuments/draw<strong>in</strong>gs shall be provided.10.0 TRAINING, SUPPORT SERVICES, MAINTENANCE AND SPARESC:\Users\itms\Downloads\SAS Spec. (1).doc - 21 -

Dur<strong>in</strong>g Guaranteed Availability Period, the Contractor shall take cont<strong>in</strong>ual actionsto ensure the guaranteed availability and shall make available all the necessaryresources such as specialist personnel, spare parts, tools, test devices etc. forreplacement or repair of all defective parts and shall have prime responsibility forkeep<strong>in</strong>g the system operational.11.2 RELIABILITYAND AVAILABILITYThe SAS shall be designed so that the failure of any s<strong>in</strong>gle component,processor, or device shall not render the system unavailable. The SAS shall bedesigned to satisfy the very high demands for reliability and availabilityconcern<strong>in</strong>g:• Mechanical and electrical design• Security aga<strong>in</strong>st electrical <strong>in</strong>terference (EMI)• High quality components and boards• Modular, well -tested hardware• Thoroughly developed and tested modular software• Easy-to-understand programm<strong>in</strong>g language for application programm<strong>in</strong>g• Detailed graphical documentation and application software• Built-<strong>in</strong> supervision and diagnostic functions• Security− Experience of security requirements− Process know-how− Select before execute at operation− Process status representation as double <strong>in</strong>dications• Distributed solution• Independent units connected to the local area network• Back-up functions• Panel design appropriate to the harsh electrical environment and ambientconditions• Panel ground<strong>in</strong>g immune aga<strong>in</strong>st transient ground potential riseOutage1) OutageThe state <strong>in</strong> which substation automation system or a unit of SAS is unavailablefor Normal Operation as def<strong>in</strong>ed <strong>in</strong> the clause 7.1 due to an event directlyrelated to the SAS or unit of SAS. In the event, the owner has taken anyequipment/ system other than Sub-station <strong>Automation</strong> <strong>System</strong>for schedule/forced ma<strong>in</strong>tenance, the consequent outage to SAS shall not beconsidered as outage for the purpose of availability.2) Actual outage duration (AOD)The time elapsed <strong>in</strong> hours between the start and the end of an outage. The timeshall be counted to the nearest 1/4 th of an hour. Time less than 1/4 th of an hourshall be counted as hav<strong>in</strong>g duration of 1/4 th of an hour.3) Period Hours (PH)The number of hours <strong>in</strong> the report<strong>in</strong>g period. In a full year the period hour are8760h (8784h for a leap year).4) Actual Outage hours (AOH)The sum of actual outage duration with<strong>in</strong> the report<strong>in</strong>g periodAOH = ∑ AOD5) Availability:C:\Users\itms\Downloads\SAS Spec. (1).doc - 24 -

Each SAS shall have a total availability of 99.98 % i.e. the ratio of total timeduration m<strong>in</strong>us the actual outage duration to total time duration.12.0 Guarantees RequiredThe availability for the complete SAS shall be guaranteed by the Contractor.Bidder shall <strong>in</strong>clude <strong>in</strong> their offer the detailed calculation for the availability. Thecontractor shall demonstrate their availability guaranteed by conduct<strong>in</strong>g theavailability test on the total sub-station automation system as a whole aftercommission<strong>in</strong>g of total Sub-station <strong>Automation</strong> system. The test shall verify thereliability and <strong>in</strong>tegrity of all sub-systems. Under these conditions the test shallestablish an overall availability of 99.98%. After the lapse of 1000 Hours ofcumulative test time, test records shall be exam<strong>in</strong>ed to determ<strong>in</strong>e theconformance with availability criterion. In case of any outage dur<strong>in</strong>g theavailability test, the contractor shall rectify the problem and after rectification, the1000 Hours period start after such rectification. If test object has not been metthe test shall cont<strong>in</strong>ue until the specified availability is achieved.The contractor has to establish the availability <strong>in</strong> a maximum period of threemonths from the date of commencement of the availability test.After the satisfactory conclusion of test both contractor and employer shallmutually agree to the test results and if these results satisfy the availabilitycriterion, the test is considered to be completed successfully. After that thesystem shall be taken over by the employer and then the guarantee period shallstart.13.0 Spares13.1 Consumables:All consumables such as paper, cartridges shall be supplied by the contractor tillthe SAS is taken over by the owner.13.2 Availability Spares:In addition to mandatory spares as listed <strong>in</strong> section project for SAS, the bidder isrequired to list the spares, which may be required for ensur<strong>in</strong>g the guaranteedavailability dur<strong>in</strong>g the guaranteed availability period. The f<strong>in</strong>al list of spares shallform part of scope of supply and accord<strong>in</strong>gly the price thereof shall be quoted bythe bidder and shall be considered <strong>in</strong> the evaluation of the bids. Dur<strong>in</strong>g theguaranteed availability period, the spare parts supplied by the Contractor shall bemade available to the Contractor for usage subject to replenishment at theearliest. Thus, at the end of availability period the <strong>in</strong>ventory of spares with theEmployer shall be fully replenished by the Contractor.However, any additional spares required to meet the availability of the system(which are not a part of the above spares supplied by the Contractor) would haveto be supplied immediately by the Contractor free of cost to the Employer.14.0 LIST OF EQUIPMENTSQuantity of equipments shall be decided by bidder <strong>in</strong> order to achieveguaranteed reliability and availability as declared by bidder.i) Station HMIii) Redundant Station HMI (<strong>in</strong> Hot-stand by mode)iii) Bay level units along with bay mimiciv) Disturbance Recorder Work Station(Ma<strong>in</strong>tenance HMI)v) Color Laser Pr<strong>in</strong>ter – 1 No. (For Reports & Disturbance records)C:\Users\itms\Downloads\SAS Spec. (1).doc - 25 -

vi) Dot matrix pr<strong>in</strong>ters - (one each for Alarms and log sheets)vii) All <strong>in</strong>terface equipment for gateways to RCC and RSCCviii) Communication <strong>in</strong>frastructure between Bay level units, Station HMI, Pr<strong>in</strong>ters,gateways, redundant LAN etc. as requiredix) Any other equipment as necessary.C:\Users\itms\Downloads\SAS Spec. (1).doc - 26 -

Annexure-IBasic Monitor<strong>in</strong>g requirements are:- Switchgear status <strong>in</strong>dication- Measurements (U, I, P, Q, f)- Event- Alarm- W<strong>in</strong>d<strong>in</strong>g temperature of Transformers.- Ambient temperature.- Status and display of 415V LT system, 220V & 48V DC system.- Status & Display of Fire protection <strong>System</strong> and AC <strong>System</strong>.- Acquisition of all counters <strong>in</strong> PLCC panels through potential free contacts fromPLCC or <strong>in</strong>dependently by count<strong>in</strong>g the receive/send commands.- Acquisition of alarm and fault record from protection relays Disturbance.- Monitor<strong>in</strong>g the state of batteries by display<strong>in</strong>g DC voltage, charg<strong>in</strong>g current andload current etc.- Tap-position of TransformerList of InputsThe list of <strong>in</strong>put for typical bays is as below:-Analogue <strong>in</strong>putsi) For l<strong>in</strong>eCurrentii)R phaseY phaseB phaseVoltageY-B phaseB-R phaseFor TransformerCurrent R phaseY phaseB phaseWTI (for transformer)Tap position (for transformer only)iii) For Bus couplerCurrent R phaseY phaseB phaseiv) Commona) Voltage for Bus-I, Bus-II and Transfer bus wherever applicableVoltage R-Y phaseY-B phaseB-R phaseb) Frequency for Bus-I and Bus-IIc) Ambient temperature (switchyard).C:\Users\itms\Downloads\SAS Spec. (1).doc - 27 -

d) LT systemi) Voltage R-Y, Y-B, B-R of Ma<strong>in</strong> Switch Board section-Iii) Voltage R-Y, Y-B, B-R of Ma<strong>in</strong> Switch Board section-IIiii) Voltage R-Y, Y-B, B-R of Diesel Generatoriv) Current from LT transformer-Iv) Current from LT transformer-IIvi) Current from Diesel Generatorvii) Voltage of 220V DCDB-Iviii) Voltage of 220V DCDB-IIix) Current from 220V Battery set-Ix) Current from 220V Battery set-IIxi) Current from 220V Battery charger-Ixii) Current from 220V Battery charger-Ixiii) Voltage of 48V DCDB-Ixiv) Voltage of 48V DCDB-IIxv) Current from 48V Battery set-Ixvi) Current from 48V Battery set-IIxvii) Current from 48V Battery charger-Ixviii) Current from 48V Battery charger-IDigital InputsThe list of <strong>in</strong>put for various bays/SYSTEM is as follows:1. L<strong>in</strong>e baysi) Status of each pole of CB, Isolator, Earth switchii)CB troubleiii)CB operation/clos<strong>in</strong>g lockoutiv)Pole discrepancy optdv) Trip coil faultyvi)LBB optdvii)Bus bar protn trip relay optdviii)Ma<strong>in</strong> bkr auto recloser operatedix)Tie/transfer auto recloser operatedx) A/r lockoutxi)Tie/transfer bkr a/r lockoutxii)Direct trip-I/II sentxiii)Direct trip-I/II receivedxiv)Ma<strong>in</strong> I/II block<strong>in</strong>gxv)Ma<strong>in</strong> I/II-Inter trip sendxvi)Ma<strong>in</strong> I/II-Inter trip receivedxvii) O/V STAGE – I operatedxviii) O/V STAGE – II operatedxix)FAULT LOCATOR FAULTYxx)MAIN-I/II CVT FUSE FAILxxi)MAIN-I PROTN TRIPxxii) MAIN-II PROTN TRIPxxiii) MAIN-I PSB ALARMxxiv) MAIN-I SOTF TRIPxxv) MAIN-I R-PH TRIPxxvi) MAIN-I Y-PH TRIPxxvii) MAIN-I B-PH TRIPxxviii) MAIN-I STARTxxix) MAIN-I/II Carrier aided tripxxx) MAIN-I/II fault <strong>in</strong> reverse directionxxxi) MAIN-I/II ZONE-2 TRIPxxxii) MAIN-I/II ZONE-3 TRIPC:\Users\itms\Downloads\SAS Spec. (1).doc - 28 -

xxxiii)xxxiv)xxxv)xxxvi)xxxvii)xxxviii)xxxix)xl)xli)xlii)xliii)xliv)xlv)xlvi)xlvii)MAIN-I/II weak end <strong>in</strong>feed optdMAIN-II PSB alarmMAIN-II SOTF TRIPMAIN-II R-PH TRIPMAIN-II Y-PH TRIPMAIN-II B-PH TRIPMAIN-II startMAIN-II aided tripMAIN-I/II fault <strong>in</strong> reverse directionBack-up o/c optdBack-up e/f optd220V DC-I/II source failSPEECH CHANNEL FAILPLCC Protection Channel-I FAILPLCC Protection Channel-II FAIL2. Transformer baysi) Status of each pole of CB, Isolator, Earth switchii)CB troubleiii)CB operation/clos<strong>in</strong>g lockoutiv)Pole discrepancy optdv) Trip coil faultyvi)LBB optdvii)Bus bar protn trip relay optdviii)REF OPTDix)DIF OPTDx) OVERFLUX ALARM (MV)xi)OVERFLUX TRIP (MV)xii)OVERFLUX ALARM (HV)xiii)OVERFLUX TRIP (HV)xiv)HV BUS CVT ½ FUSE FAILxv)MV BUS CVT ½ FUSE FAILxvi)OTI ALARM/TRIPxvii) PRD OPTDxviii) OVERLOAD ALARMxix)BUCHOLZ TRIPxx)BUCHOLZ ALARMxxi)OLTC BUCHOLZ ALARMxxii) OLTC BUCHOLZ TRIPxxiii) OIL LOW ALARMxxiv) back-up o/c (HV) optdxxv) back-up e/f (HV)optdxxvi) 220v DC-I/II source failxxvii) TAP MISMATCHxxviii) GR-A PROTN OPTDxxix) GR-B PROTN OPTDxxx) back-up o/c (MV) optdxxxi) back-up e/f (MV)optd3. Transformer baysi) Status of each pole of CB, Isolator, Earth switchii)CB troubleiii)CB operation/clos<strong>in</strong>g lockoutiv)Pole discrepancy optdv) Trip coil faultyC:\Users\itms\Downloads\SAS Spec. (1).doc - 29 -

vi)LBB optdvii)Bus bar protn trip relay optdviii)REF OPTDix)DIF OPTDx) HV BUS CVT ½ FUSE FAILxi)OTI ALARM/TRIPxii)PRD OPTDxiii)BUCHOLZ TRIPxiv)BUCHOLZ ALARMxv)OIL LOW ALARMxvi)Back-up impedance relayxvii) 220v DC-I/II source failxviii) GR-A PROTN OPTDxix)GR-B PROTN OPTD4 Bus Bar Protectioni) Bus bar ma<strong>in</strong>-I tripii)Bus bar ma<strong>in</strong>-II tripiii)Bus bar zone-I CT openiv)Bus bar zone-II CT openv) Bus transfer CT sup. Optdvi)Bus transfer bus bar protn optdvii)Bus protection relay fail5. Auxiliary systemi) Incomer-I On/Offii)Incomer-II On/Offiii)415V Bus-I/II U/Viv)415v bus coupler breaker on/offv) DG set bkr on/offvi)Alarm/trip signals as listed <strong>in</strong> Section: DG setvii)LT transformer-I Bucholz Alarm & tripviii)LT transformer-II Bucholz Alarm & tripix)LT transformer-I WTI Alarm & tripx) LT transformer-II WTI Alarm & tripxi)LT transformer-I OTI Alarm & tripxii)LT transformer-II OTI Alarm & tripxiii)PLCC exchange failxiv)Time sync. Signal absentxv)Alarm/trip signals as listed <strong>in</strong> Section: Battery and Battery chargerxvi)220v dc-I earth faultxvii) 220v dc-II earth faultNOTE:-The exact number and description of digital <strong>in</strong>puts shall be as per detailedeng<strong>in</strong>eer<strong>in</strong>g requirement Apart from the above mentioned digital <strong>in</strong>puts,m<strong>in</strong>imum of 200 <strong>in</strong>puts shall be kept for use <strong>in</strong> future.C:\Users\itms\Downloads\SAS Spec. (1).doc - 30 -

1.0 CONSTRUCTION:SPECIFICATION OF AC KIOSKANNEXURE-IIThe Kiosk shall be made of “sandwich <strong>in</strong>sulated panels” 80 mm thick with poly UrethaneFoam (PUF) as filler material between polyester pre-coated cold rolled steel. The<strong>in</strong>sulation characteristics of PUF material shall conform to follow<strong>in</strong>g requirement:Sr.No. Particular Parameters1. Thickness 78.6 mm2. Density 40 kg/m 33. Compressive Strength 1.2 kg.cm 34. Tensile Strength 3.6 kg/m 25. Bend<strong>in</strong>g Strength 4.0 Kg/m 26. Adhesion Strength 2.9 Kg/m 27. Dimension Stability At -25 o C : 0.1% at 38 o C : 0.1%ant at 38 o C : 0.4%8. Temperature Range -15 o C to 95 o C9. Thermal Conductivity 0.02 kcal/hr/m/ o C10. Fire Resistance As per BS-4735 HorizontalBurn

iiconditioner shall be runn<strong>in</strong>g at a time and on failure of the same or as describedhereunder, the other unit shall start automatically. To ensure longer life of the system,the redundant units shall also be runn<strong>in</strong>g <strong>in</strong> cyclic operation through the controller.However, dur<strong>in</strong>g runn<strong>in</strong>g of one air-conditioner unit, if <strong>in</strong>side temperature of the shelterreaches to a predef<strong>in</strong>ed (i.e. 35 o C), the other unit shall start runn<strong>in</strong>g to ma<strong>in</strong>ta<strong>in</strong> thetemperature to specified value (i.e. 23+2 o C) and gives alarm for such situation. Afterachiev<strong>in</strong>g this temperature, the other unit shall aga<strong>in</strong> shut off.SEQUENCE OF OPERATION OF THE UNIT:Suitable arrangement shall be made to operate the unit <strong>in</strong> the follow<strong>in</strong>g order.However, the actual operation arrangement shall be f<strong>in</strong>alized dur<strong>in</strong>g detailedeng<strong>in</strong>eer<strong>in</strong>g.1. Evaporator Fan2. Condenser Fan3. CompressoriiiCONSTRUCTION:The air condition<strong>in</strong>g unit shall be completely self-conta<strong>in</strong>ed. All components of the unitsshall be enclosed <strong>in</strong> a powder coated cab<strong>in</strong>et and colour of same shall be matched withkiosk colour. The unit shall be assembled, wired, piped, charged with refrigerant andfully factory tested as a system to ensure trouble free <strong>in</strong>stallation and start up. Suitableisolation or other by pass<strong>in</strong>g arrangement shall be provided such that anyunit/component could be ma<strong>in</strong>ta<strong>in</strong>ed/repaired without affect<strong>in</strong>g the runn<strong>in</strong>g standby unit.The ma<strong>in</strong>tenance of unit shall be possible from outside the kiosk.IvREQUIRED FEATURES OF VARIOUS COMPONENTS:The compressor shall be very reliable, trouble free and long life i.e. hermitically sealedScroll type of reputed make suitable for operation. Compressor should be <strong>in</strong>stalled onvibration isolated mount<strong>in</strong>gs or manufacturers recommended approved mount<strong>in</strong>g. Valveshall be provided for charg<strong>in</strong>g/topp<strong>in</strong>g up of refrigerant. The bidder shall furnish details oftheir compressor <strong>in</strong>dicat<strong>in</strong>g the MTBF, life of compressor and cont<strong>in</strong>uous run time ofcompressor without failure.The contractor shall also furnish details of all accessories i.e. refrigeration system,evaporator coil, condenser coil, evaporator blower filter, cab<strong>in</strong>et, <strong>in</strong>door supply andreturn grill etc.VThe kiosk shall be erected at least 300 mm above the f<strong>in</strong>ished ground level with suitablepedestal to avoid any entry of water.3. PROTO TESTING:One kiosk meet<strong>in</strong>g the specified requirement as described above, shall be fabricated atthe factory and offered for proto <strong>in</strong>spection at the factory. This proto shall be equippedwith all required accessories like air-condition<strong>in</strong>g system, fire and smoke detector,light<strong>in</strong>g, various cut outs etc. The offered kiosk shall be <strong>in</strong>spected for f<strong>in</strong>ish, all fitt<strong>in</strong>gsand accessories, open<strong>in</strong>g <strong>in</strong>clud<strong>in</strong>g doors and locks. The kiosk shall be tested for dustand ra<strong>in</strong> protection to check out any leakage and air tightness. The follow<strong>in</strong>g ma<strong>in</strong> testsshall be carried out:a) Illum<strong>in</strong>ation <strong>in</strong>side the kiosk shall be switched off and it shall be checked that no lightC:\Users\itms\Downloads\SAS Spec. (1).doc - 32 -

enters through panel jo<strong>in</strong>ts, holes and other jo<strong>in</strong>ts <strong>in</strong> the kiosk.b) Water Leakage Test (with a water pipe with suitable pressure from all sides for onehour.)c) Work<strong>in</strong>g and functional tests of all accessories like air-condition<strong>in</strong>g system, fire andsmoke detector, light<strong>in</strong>g arrangements as per technical specificationd) Start up test for air conditionere) Satisfactory operation of air conditioner <strong>in</strong>stalled on Kiosk.f) The total heat load for panels and devices to be placed <strong>in</strong>side the kiosk <strong>in</strong>clud<strong>in</strong>gPLCC, all IEDs etc. shall be calculated and equivalent calculated heat<strong>in</strong>g load(maximum value from among the calculated values for various kiosk) shall be placed<strong>in</strong>side the kiosk and the kiosk shall be made operational for four hours with allaccessories and <strong>in</strong>side & outside temperature of kiosk shall be recorded.On successful completion of proto test<strong>in</strong>g, all other system shall be manufactured after<strong>in</strong>corporation of all alteration/modifications observed/suggested dur<strong>in</strong>g/after prototest<strong>in</strong>g.The detail test procedure shall be submitted by the contractor and get it approved fromthe owner before commencement of proto test<strong>in</strong>g.C:\Users\itms\Downloads\SAS Spec. (1).doc - 33 -

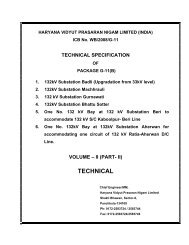

Annexure-IIITYPICAL ARCHITECTURAL DRAWINGOFSUBSTATION AUTOMATION SYSTEMRouterHMI View NodeStation HMIDR Work StationGateway GPSClockRedundant ManagedEthernet Station BusIEC 61850IEC 61850Switchfor Dia1Switchfor Dia.2Switchfor Dia.3Switchfor Dia.NFibre opticConnectionIEC 61850IEDs forControl &protectionIEDs forControl &protectionIEDs forControl &protectionIEDs forControl &protectionNote:1. The redundant managed bus shall be realized by high speed optical bus us<strong>in</strong>g<strong>in</strong>dustrial grade components and shall be as per IEC 61850.2. The IEDs and switches for each of the dia. of 765kV and 400kV shall haveseparate kiosk. For 220kV, 132kV, 66kV yards, IEDs for two adjacent bays canbe housed <strong>in</strong> one Kiosk along with its switch. For 220/33kV T/F, IEDs for fouradjacent 33kV bays can be housed <strong>in</strong> one Kiosk along with its switches and For132/33kV T/F, IEDs for all 33kV bays of a T/F can be housed <strong>in</strong> one Kioskalong with its switches.3. Inside the sub-station, all connections shall be realized as per IEC 61850protocol.4. For gateway, it shall communicate with Remote Supervisory Control Centre(RSCC) on IEC 60870-5-101 protocol.5. The router to Remote Control Centre (RCC) shall communicate on IEC 60870-5-101 protocol.6. The pr<strong>in</strong>ter as required shall be connected to station bus directly and can bemanaged either from station HMI, HMI view node or disturbance recorder workstation.