Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

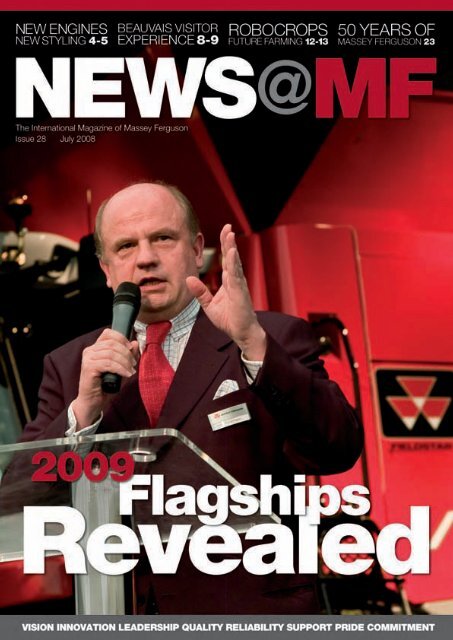

VISION INNOVATION LEADERSHIP QUALITY RELIABILITY SUPPORT PRIDE COMMITMENTGary Collar (Senior Vice President &General Manager Europe, Africa &Middle East and East Asia Pacific),and Richard Markwell proudly unveil2009 flagship modelsCONTENTSNew tractors . . . . . . . . . . . . . . . . . . . 4Experience manufacturing . . . . . . . . 8Harvesting . . . . . . . . . . . . . . . . . . . . 10Machines of the future . . . . . . . . . . 12Epic expedition to South Pole . . . . 1650 years using MF . . . . . . . . . . . . . 20AGCO news . . . . . . . . . . . . . . . . . . 22<strong>News@MF</strong>The international magazine of<strong>Massey</strong> <strong>Ferguson</strong>, a worldwidebrand of AGCO Corporation.Published by: AGCO LimitedAbbey Park Stoneleigh,Kenilworth CV8 2TQ, EnglandE-mail: mf-news@uk.agcocorp.comFax: +44 (0)24 76851182Website: www.masseyferguson.comPlease send all correspondenceand contributions to: The Editor,<strong>News@MF</strong>, Marketing Departmentat the above address.HARVESTOF SUCCESSWelcome to this summer editionof our new-style <strong>News@MF</strong>.Late May saw us hold a very successful MF international distributor and dealer event wherewe took the opportunity to celebrate our rich heritage but more importantly, to look to thefuture of <strong>Massey</strong> <strong>Ferguson</strong> and our key role in the rapidly changing farming world. As can beseen on our front cover showing our parent company AGCO’s Chairman, President and ChiefExecutive Officer, Martin Richenhagen, during the event, we revealed models from ourupcoming 2009 range including the new rotary combine and new flagship 365hp tractor withnew cab, integrated front linkage and PTO system and new styling. They certainly made astriking couple and really got the industry talking!With our long history and equally powerful position today, the past and future are inextricablylinked at MF. Both are vital for success and growth in a highly competitive market.2008 – the year we celebrate the 50th anniversary of our brand name – is truly an exciting timeto be associated with <strong>Massey</strong> <strong>Ferguson</strong>, whether you are a customer, dealer or employee.The foundations of MF’s success rest on core values which have shaped us over the yearsand will continue to resonate in every aspect of our business. We have summed them up ineight words: Vision, Innovation, Leadership, Quality, Reliability, Support, Pride andCommitment. These are our power words – they are what make us who we are.As you will see throughout this issue, these words are emblems which are firmly underpinnedby deeds and actions which have real worth and value. For example, we can point to theVision of Harry <strong>Ferguson</strong> and his idea to produce a world tractor to tackle poverty. Today, ourVision sees us exploring the very latest technology which will take farm machinery to the nextlevel and beyond, thus helping to feed an ever-growing world population. It is Vision whichdrives MF’s plans forward and enables us to not only move with the times but to set a seriesof progressive milestones.We are totally committed to delivering on the expectations of our customers, to building highqualityreliable products with innovative features and backing them up with the best support.To quote Harry <strong>Ferguson</strong> in one of his famous speeches, “If the plan be good and themachinery be good, we have the greatest and best news you have ever heard.”As we embark upon another harvest season, we recall our strong harvesting heritage, where<strong>Massey</strong>-Harris brought the world the first self-propelled combine harvester. Now, as then, goodmachinery and good planning are certainly at the top of our minds. A bumper harvest in thesetimes of rising commodity prices is something we all want to see. You can be confident that withour industry-leading support, <strong>Massey</strong> <strong>Ferguson</strong> will be helping you to keep your equipmentrunning to its highest level of performance. My very best wishes for a successful season.Richard MarkwellVice-President and Managing Director<strong>Massey</strong> <strong>Ferguson</strong> – Europe, Africa and Middle East.POWERFULVALUESVISIONPAGE 12-13INNOVATIONPAGE 6LEADERSHIPPAGE 19QUALITYPAGE 14RELIABILITYPAGE 10SUPPORTPAGE 15PRIDEPAGE 5COMMITMENTPAGE 4© AGCO Limited 20082 3

INNOVATION PRIDECOMMITMENT PRIDE LEADERSHIP INNOVATIONFURTHER INVESTMENT DRIVES TRACTOR MODELS AHEADThe MF 6499 andMF 6497 get newstyling and higherspecification.AWARDSSTACK UPFOR MF 7400TRACTORSNEW ENGINES,NEW STYLING<strong>Massey</strong> <strong>Ferguson</strong>’s investment in new product developments continues apace with thelaunch of new engines and new styling for models at the lower end of the best-sellingMF 5400 Series range plus new styling and features for the MF 6497 and MF 6499 tractors.“The extent of our tractor launch programme over the last four years is unprecedented,”comments Declan Hayden, MF Vice-President Sales & Marketing, EAME. “We arecommitted to investing heavily in our ranges to achieve best-in-sector status. No matterwhat tractor farmers may require, we have a model that has to be in the frame when itcomes to making a purchase.”These latest developments on the MF 5400 and MF 6497/99 tractors now complete therestyling and Tier III emissions-compliant engine project on all MF’s ‘4’ Series tractors builtat Beauvais in France.New power ratings and torque characteristicson new Tier IIIA Perkins engines provideincreased performance for the MF 5425,MF 5435, MF 5445 and MF 5455.NEW ENGINES FOR MF 5425-MF 5455EMISSION COMPLIANT ANDBOOSTED PERFORMANCENew power ratings and torque characteristics on new Tier IIIA Perkins1104D engines provide increased performance for the MF 5425,MF 5435, MF 5445 and MF 5455. Increases in maximum horsepowerat 2000 revs are up 11hp on the MF 5425, 13hp on the MF 5435, 10hpon the MF 5445 and 12hp on the MF 5455. Transport boost isavailable on the MF 5445 and MF 5455 which increases maximumpower by 10hp in third and fourth gear. This helps reduce journeytimes as well as improving fuel efficiency.In addition to new engines, the MF 5425-MF 5455 also get newstyling and pivoting bonnet as featured on the MF 6497 and MF 6499– see details right.The MF 5400 models are ideal for mixed farming enterprises. Powerful,economical, easy-to-use and with Dyna-4 transmission as standard,these versatile tractors are excellent for a broad range of jobsfrom loader work to soil preparation and slurry transport. There arevarious specification options available including steep nose and lowprofile cab versions, Visio roof, factory-fitted loader kit and Twin Flow100 litre/min hydraulic system.MF 6497 & MF 6499NOW EVENBETTERProviding maximum powers of 215hp and 230hp respectively,the MF 6497 and MF 6499 have won great acclaim for theirexcellent power-to-weight ratios and top-level specifications.In 2006, the MF 6497 clinched the Machine of the Year prizeat Germany’s Agritechnica Show. Now the pair of machineshave raised the bar still further with sleek new styling andintegrated front axle arrangements.With the new styling presenting a fresh, modern image, thestandard bonnet now pivots to improve access for regularservicing of the air filter and radiator. In addition, a new coolingpackage includes pivoting radiators for even better accessfor cleaning.A new, stronger and more durable front axle support casting canbe fitted with either weight frame or a front linkage. This designoptimises the steering angle for wide tyres and narrow tracksettings, minimising the turning circle and making the tractorsexceptionally manoeuvrable for their size. The design alsocombines with a reinforced sump arrangement that removesthe need for additional side and underneath rails when a frontlinkage is fitted.MF 6497 AND MF 6499 TOP FEATURES• Latest technology SisuDiesel common rail engines with fourvalves/cylinder<strong>Massey</strong> <strong>Ferguson</strong>’s 7400 Series tractors carried off yet more prizesearlier this year – this time in Central Europe.A Grand Prize for Innovation was presented to an MF 7495 atHungary’s premier farm machinery show AGRO+MASH EXPO,while an MF 7480 won a Gold Medal at Poland’s InternationalPoznan Fair.“As two of the newer members of the EU, both these countries aregrowth markets for MF equipment,” says Gordon MacDonald,MF Sales Director Central Europe. “With farm size on the rise,central European farmers are increasingly looking for more powerand technology. The MF 7400 comes out on top because of itsadvanced, efficiency-enhancing features like Dyna-VT transmission,Quadlink front axle suspension and the Datatronic 3 control andmonitoring system. We are delighted that these models arereceiving high-profile recognition in the unfolding markets ofthe ‘new’ Europe.”At AGRO+MASH EXPO awards are given to machines that thejudges consider will increase the efficiency of Hungarian agricultureand positively impact on its economy. The panel was particularlyimpressed by the MF 7400’s useable technology.In Poland, the Poznan fair was opened by Marek Sawicki, Ministerof Agriculture and Rural Development, who also formed part ofthe presentation party for the Gold Medal. Figures show that, at40,000 visitors, attendance was up 100% on last year’s event –a real sign that agriculture is moving forward apace.Previous awards for the MF 7400 range include Machine of the Year2004 presented at Germany’s Agritechnica.4MF5425 MF5435 MF5445 MF5455Max power at 2000rpm 86hp 96hp 100hp 112hpRated power at 2000rpm 80hp 90hp 95hp 105hpBoost Max power at 2000rpm N/A N/A 110hp 125hpBoost rated power N/A N/A 100hp 115hpMax torque at 1500rpm 379Nm 405Nm 420Nm 463NmMax torque boost N/A N/A 463Nm 525NmThe MF5400 quickly established a strongreputation on livestock, mixed and arable farms.• Rugged front axle support with new integral linkage design• QuadLink front suspension option• ‘Power boost’ for PTO and transport• Pivoting bonnet improves engine and cooling system access• Dyna-6, 40 or 50km/h Eco transmission*Transport speed achieved at low engine rpm 40km/h or 50km/h at1900 engine revs* (top speed dependent on market/legislation)An innovation prize for the MF 7400 Series in Hungary.Pictured: Gordon MacDonald (left) with Johann Gram,Managing Director Austro Diesel which distributes MF equipment inHungary and Frederic Moreau, MF Business Manager (right).5

INNOVATION PRIDEPRIDE INNOVATIONFORMIDABLE NEW SPECIALISTSOUT IN FORCESUPERTURN ISSUPER-IMPRESSIVEThe MF 3635 V tractorThe brand-new 69-100hp MF 3600Series Specialist, Vineyard and Flextractors made their public debut atSpain’s FIMA 2008 show in Zaragoza.Speaking at the show, Philippe Fournier,MF Product Marketing Manager,commented: “These new models are afurther demonstration of MF’s vigorousdrive to introduce new innovationsin every sector. They boast featuresnot found on any other make plusclass-leading specifications, SuperTurnsteering and the roomiest cab on themarket. Importantly, they are also thefirst tractors in this category to featureTier III-compliant engines.”“The new SuperTurn steering designreally captured the attention of FIMAshowgoers,” he adds. “This allows abetter steering angle to be achieved bythe use of a cleverly designed front axlesupport casting and a ‘cutaway’ designfor the front sheet metal. Manoeuvrabilityand the ability to get into restricted areasis obviously a major customerrequirement, and SuperTurn is key tofulfilling this but without the need forcomplicated front steering linkages thatrequire a high level of maintenanceand repair.”The compact size, superb agility andoutstanding power-to-weight ratiosmake the new MF 3600 S, V and F Seriesmodels ideal workhorses for traditionaland modern vineyards, orchards andfruit farms. Additionally, the combinationof the tractors’ dimensions and poweralso mean they will suit a wide range ofmunicipal operations in confined areas.ITALY LAUNCHItaly is a major market for MF’s newspecialist tractors and the machines gottheir public launch here in March at Borgola Bagnaia, near Siena – one of thecountry’s key areas for the production ofoil, fruit and wine. “We received afantastic response to the new machines,”reports Lido Tedeschi, MF CountryManager, Italy. “I am delighted that MFhas taken direct control of this productrange which will have a greater strategicimportance for us in the Italian market.MF has a long tradition in this sector andthe specific competence of our dealernetwork will contribute to the success ofthe new machines.”KEY DEVELOPMENTWORK“The completely-new MF 3600 models have been designed by <strong>Massey</strong> <strong>Ferguson</strong>’sexperienced engineers and product specialists backed up by detailed customerconsultations throughout the whole development process,” says David Chinn,MF General Marketing Manager for Low, Medium HP and Specialist Tractors.“Customer input was fundamental to ensuring the tractors precisely meet the needsof these demanding users.”The four-year development process started with extensive market research to identifykey areas for development. What emerged in particular was the need for a spaciouscab, Power Shuttle facility and a really broad choice of widths, including a heavy-dutyF version. Extensive customer evaluation on pre-production models took place inItaly and France along with German and Spanish dealer input throughout. Theirexperiences and comments helped refine the machines still further.“Operator comf ort was a high priority,” adds David. “These tractors are expected towork hard and for long working days. It is not uncommon for some crops to betreated in excess of 25 times in a season. As a result of our development, we haveensured that the driver has the best workplace for optimum comf ort and output.”TOP FEATURES• Lively, powerful and high torque SisuDieselCitius three-cylinder engines generatingpowers of 69hp to 100hp – the first in thesector to meet the strict Tier III exhaustemission regulations. Engines can run on100% bio-diesel and are compatible withbiodegradable oil• Unique ‘SuperTurn’ front axle designprovides exceptional manoeuvrability• Exclusive electro-hydraulic independentPTO operation with a range of speedoptions including (depending on model)540rpm, 540/540E (750), 540/1000rpm,540/750rpm/ground speed,540/1000rpm/ground speed• Compact dimensions designed to fit exactrequirements• Class-leading, spacious cab• 2500kg standard lift capacity• Separate 21-litre/min pump for internalservices• Choice of proven transmissions offering30km/h, 12/12 speeds and 40km/h 24/24speeds and Power Shuttle and Speedshiftoptions• Hydraulically-adjustable linkage levellingand stabilisers for precise implementcontrol• Powerful hydraulic pumps, with up to62 litre/min option dedicated to three-pointlinkage and multiple spool valves• Up to three rear- and two mid-mountedspool valves• 70 litre fuel tank capacity• Semi-platform operator station alsoavailable• Variety of hitches and tyresNew MF 3600 models6 7Width (m)MF 3625/3635/3645/3655 (F) 1.45-2.10MF 3625/3635/3645/3655 (S) 1.30-1.70MF 3625/3635 (V) 1.00-1.50MF 3625/3635/3645/3655 (GE) 1.15-1.50

PRIDEPRIDESEE FOR YOURSELF!THE BEAUVAISVISITOREXPERIENCEVisitors on a tourof the Beauvais plant.Laurent Pernin welcomes visitorsto the MF Technology Centre.Yoann Marchand –Visitors Experience ManagerThe brand-new MF Technology Centre atthe Beauvais factory in Picardy, NorthernFrance is now the focus of fantastic new$1 million visitor reception facilities.“We are expecting the number of visitors toBeauvais to increase to nearly 20,000 thisyear,” reports Laurent Pernin, MF GeneralMarketing Manager – mid and high hptractors. “We are eager for customers tocome and see for themselves exactly howand where MF tractors are made. There’s agreat deal to see and experience. It makesfor a very good trip indeed – interesting,informative and entertaining.”On arrival, visitors are shown to theMF Technology Centre. This light andairy, ultra-modern building boasts alarge showroom and 140-seat auditorium.Here you can see landmarks in<strong>Massey</strong> <strong>Ferguson</strong>’s development,illustrating their contribution to theinnovation and advancement of technologyin the farm machinery industry. Amongthe machines on display are threefirst-off-the-production-line tractors –a <strong>Ferguson</strong> Brown A (1936) a <strong>Ferguson</strong>TE20 (1946) and MF 35 (1956). All have theserial numbers 001. Other heritage tractorsinclude an MF 65, MF 3080 Datatronic,MF 168, MF 590 and Sue II – one of theTE20 tractors that completed Sir EdmundHillary’s historic Antarctic expedition.(Read more about this on page 16).Bringing things right up-to-date, currentlyon show, is an MF 6485 and MF 6480.In order that it can be driven anddemonstrated inside the TechnologyCentre, the latter has been modified tobe electrically-powered.Next on the visitors’ itinerary is thefactory tour. You can’t fail to be impressedby the sheer scale and complexity ofthe production process. It’s a tremendousfeat of logistics and synchronisation,and an experience that leaves alasting impression.MF heritage tractors on display in theTechnology Centre.Beauvais is the largest producer of farmmachinery in France and the country’slargest exporter of agricultural equipment.The factory builds 75 different tractormodels (75-315hp) in the MF 5400,MF 6400, MF 7400 and MF 8400 Seriesranges. A new machine leaves theassembly line every five minutes.Led by red-coated factory guides, a fulltour last two and a half hours and takes inthe machining areas, heat treatment,gearbox/rear axle assembly, cab andchassis assembly, final assembly andquality control. “With the big choice ofoptions and specifications available totoday’s farmers, virtually every tractor thatmoves along the assembly lines is differentfrom the one in front,” says YoannMarchand, Visitors Experience Manager.“More than 3500 parts, components andsub-assemblies – ranging from the smallestwasher to a complete engine and cab – arestocked to feed the constantly movingassembly lines.”After the tour, visitors return to theTechnology Centre and the auditoriumwhere they are treated to a 15-minutevideo showing highlights of the factorytour. Each visitor is given a presentationbooklet plus DVDs of the factoryshowreel and the MF tractor range beforegetting the chance to visit the MF shop.• If you would like to arrange a group visit to theBeauvais plant, please speak to your localMF dealer. There are convenient flights fromall over Europe to Beauvais airport which isjust 10 minutes from the factory.BEAUVAIS PLANTPRIME NUMBERS10hectares of covered area2,500employees on-site3,500average number of partsin a tractor5,000tonnes steel used per year19,000tractors built annually25,000tonnes cast iron usedper year700,000litres of fuel used per year1,600,000litres of oil used per year33,500,000(615 tonnes) – parts used8 9

QUALITY RELIABILITYLEADERSHIP VISIONMF IN ACTIONFUEL ECONOMY AND EASY MAINTENANCEADD UP TO COST SAVINGSOperating in the dry conditions of Prinçay,mid-west France, for farmer and contractorJean Jacques Roux, top features on hisMF 7270 AL BETA combine are itssimplicity, fuel economy, ease of operationand maintenance.“We’ve definitely made financial savingsin terms of fuel consumption andmaintenance costs,” Jean Jacquescomments. “The MF 7270 averages only15 litres/ha.”Jean Jacques runs his own 170 ha farmand works under contract on a further145 ha. Wheat, oil-seed rape, sunflowerand maize are his chief concerns. “Ourharvesting window is around 15 days andwe work the combine about 200 hoursa season,” he says.The MF 7270 AL with 6m table isjust one element in his powerful<strong>Massey</strong> <strong>Ferguson</strong> fleet whichalso includes MF balerstogether with MF 7495 andMF 8240 tractors.While yields tend to be lowerin this region compared tothe wetter northern parts ofFrance, crops are easier toharvest because of the dryenvironment.BRUCE HITSA CENTURYThere was a time when farmers weredelighted when their harvesters reaped 50tonnes in day but the new MF 9895 rotarycombine fitted with 13 m table has brokenthe 100 tonnes an hour mark.During field trials in Queensland, Australia,contractor Bruce Estens regularly recordedoutput of above 100 t/hr while harvesting acrop of 9.5 tonnes/ha Buster sorghum. Atone stage, it hit a peak output of 108.6 t/hr!Bruce put 500 engine hours on theevaluation combine before it was released“We opted for the Auto Level version of theMF 7270 because we work in a hilly area,while the 4WD performance is a great help.We also really appreciate the RotarySeparator feature which suits our dryconditions,” reports Jean Jacques.The Auto Level system levels the combinerump across slopes by pivoting the frontfinal drives. This correction feature makes itpossible to work across slopes up to 20%.In addition, the combine rump can alsolevel up and down slopes up to 4%,allowing you to work as if the machine wason the flat. These AL models also comefitted with powered rear axle giving real4WD performance, more positive steeringcontrol and greater traction in difficultconditions. MF BETA combines areequipped with an electrically-adjustedrotary separator as standard. Featuringadjustable concave and speed, thisvirtually gives you two combines in one. Itprovides the operator with the ability tomatch combine settings to the condition ofthe crop, thereby optimising separationand straw quality. What’s unique about theMF rotary separator is the ability to rotatethe concave up over the top of the rotaryseparator when it is not required. Thisboosts throughput and maximises themachine’s performance in dry conditions.The separating system performs atmaximum capacity according to thetype of crop being harvested and strawquality required.“For us the MF 7270 engine is economical,powerful and with excellent accessibility,”continues Jean Jacques. “The Freeflowtable gives even crop feed and we like thefacility to adjust the concave at the frontand rear to suit conditions. The machineis very easy to operate and maintain.Indeed, we are very satisfied withour purchase.”AL (Auto Level) versions of the MF BETA combines mean corrections can be made across slopes up to 20%.for market. “The key point is that thismachine did these speeds while still takinga perfect sample with no grain losswhatsoever, and that takes some beating,”reports Bruce.The 459hp MF 9895 is fitted with amassive 0.8m diameter x 3.55m longrotor. Hydrostatically-driven, it allows youto harvest at a constant rotor speed forimproved efficiency. The rotor is reversiblefrom the comf ort of the cab in the event ofany crop blockages. This results in lesscrop damage and maximised grain quality.A 3-speed gearbox provides more gearselection, allowing an optimum speedrange to be found.Bruce Estens (front) achieved more than100 t/hr with the new MF 9895 rotary combine.He’s seen here with a representative fromPacific Seeds, whose trial scales were usedto verify that the yield meter readings.MF BALES ARE FUELFOR WORLD’S LARGESTBIOMASS BOILERBig square bales made by <strong>Massey</strong><strong>Ferguson</strong> balers produced in Hesston,Kansas are key to efficient biofuel energyproduction at the Avedøre 2 power stationon the coast south of Copenhagenin Denmark.Avedøre 2, owned by DONG Energy is oneof the world’s most energy efficientcombined heat and power (CHP) plants. Itutilises up to 94% of the energy in the fuelfor electricity and heat generation –meeting the heat demands of 130,000households and supplying electricity to onemillion homes. The power station’sbiomass boiler plant is also the largest inthe world.Nearly 100 new MF 2100 Series balershave been ordered for Danish customersthis season, many of which will be makingbales for power station use. “The higherdensity and heavier packages made bythe new MF 2190 will be a great benefitto us, helping to further improve efficiency– simply because the straw lines willbe able to handle more material,” saysPernille Harder Andersen, informationofficer at the plant.The commissioning of Avedøre 2 in 2001replaced a number of older coal-firedgenerating units in eastern Denmark,resulting in a 10% reduction in carbondioxide emissions. The power station isdesigned specifically as a ‘multi-fuel plant’,which allows it to use a number of differentfuels from natural gas and oil through to arange of biofuels, including straw.The plant consumes around 172,000tonnes of bales including rape, cereals andryegrass from 500 different farms in easternDenmark. Every day Avedøre 2 handles65 lorry-loads of 24 bales. Currently theseloads weigh about 12 tonnes, but withthe increased density from the newMF 2190 baler the payload is expected toincrease by at least 20%, further improvingthe efficiency of the operation.The straw-fired biomass plant consists of aboiler, straw store, ash separator and asystem for handling the bottom and fly ash.The straw store holds enough bales to runthe plant for two to three days, withdeliveries arriving from Monday until noonon Saturday, every week.The whole biomass side of the plant –cranes, straw lines and feeding system –are designed exclusively to handle baledimensions of 1.2m x 1.2m x 2.5m longsquare bales.MF IN ACTIONMF 2190 balers will help to further improveefficiency at the power station becausethe straw lines will be able tohandle more material.The bale size choice also reflects years ofexperience from farmers and contractorsbaling straw for industrial and other uses.The legendary MF 190 is not only provento be the most reliable and productivebaler on the market, it also produces thebale weight and density that theircustomers demand.Avedøre 2 supplies electricityto one million homes.10 11

VISIONVISIONROBOCROPS!IMAGES OF FUTURE FARMINGImagine weeding or spraying a field wherethe only human intervention might be just asingle push of a button.“The futuristic images pictured here maylook like something from the front cover ofa sci-fi novel but such visions of potentialdevelopments in farm equipment are not asfar away as you may think,” says CampbellScott, MF Brand Development Manager.“The technology for ‘autonomous vehicles’is well advanced as is the sensoryequipment that would be required to carryout all kind of farm tasks.”The images were especially-commissionedas part of the EU’s brand-new FutureFarmproject in which universities, researchinstitutes and private companies all overEurope are collaborating to explore ways“to meet the challenges of the farmof tomorrow.”Project Leader Simon Blackmoreapproached <strong>Massey</strong> <strong>Ferguson</strong>’s parentcompany AGCO to help raise the profileof the case for robot technology.Doug Durand, Director of AGCO’sAdvanced Technology Solutions (ATS)group explains: “Consistent with ourvision and commitment to providehigh-tech solutions for professional farmersfeeding the world, AGCO is focusedon the continual evolution of technologyproducts that will ultimately resultin the full commercialisation ofautonomous vehicles.”“Significant advances are being made inthe areas of sensor fusion and wirelessconnectivity that will make autonomousvehicles a reality in many agriculturalmarkets around the world in thenot-too-distant future,” he continues.“Through our partnerships with leadingtechnology companies and institutions,AGCO is heavily involved in thedevelopment of autonomous vehicletechnology and other advanced technologyproducts ensuring that we are helping toincrease the productivity and efficiency oftoday’s – and tomorrow’s – farmers.”Simon Blackmore worked with MarkMoore, Manager Machine Managementfrom ATS and a graphic designer tobrainstorm a whole raft of ideas to come upwith these concept drawings.“The aim was to pool Simon’s knowledgeof robotics with our knowledge ofagricultural applications,” adds MarkMoore. “Key to our thinking wasto look at ways to adapt existingtechnology and to increase the visibility ofthe robotic concept by creating a setof images.”Looking at the illustrations in more detail,Fig 1 (right) shows the concept of selectiveharvesting. The ten-wheel vehicle –probably about the size of a mini tractor –includes a power train and a collectingbox. At the front, you can see lightsensors testing for ripeness of crop and aknife underneath ready to cut once itreceives the correct signal. When thecollecting box is full, it would detachautomatically and transport the crop to acentral point under its own steam. Themachines could be controlled remotely bytelemetry link which might only require the‘operator’ to set the process in motion withone pushbutton.Fig 2 (left) shows what might be possiblewhen weeding or spraying. The vehicle inthe foreground is again using sensors, thistime to detect weeds. Once thesehave been identified, tines aredeployed to agitate the soil around theweeds without disturbing the plant. In thebackground to the right, the vehicle isshown raised on stilts to handle crop at amore advanced stage of growth. Lookingto the left, the ‘wing’ on the vehicle here isactually a sprayer unit, also detectingweeds and spraying selectively.“The images certainly capture theimagination of how future farming mightlook,” says Campbell Scott. “They havealready sparked a lot of debate here at<strong>Massey</strong> <strong>Ferguson</strong> and look set to reallystimulate thinking on the greater use ofrobots in agriculture.”FIG 1: An autonomous farm vehicle might beused for selective harvesting usingsensors to detect the ripenessof the crop.FIG 2: Weeding and spraying is also possible using robot technology.1213

QUALITY SUPPORTSUPPORTHIGH QUALITY MANUFACTURE UNITES THE FOUR PLANTSWHICH BUILD MASSEY FERGUSON COMBINES AND BALERS.REAPING THE BENEFITSOF GLOBAL PRODUCTIONFACILITIESMulti-million dollar investments in the mostup-to-date manufacturing facilities coupledwith highly-skilled workforces are at theheart of the high quality manufacture ofMF harvesting equipment.Plants in Randers, Denmark; Breganze,Italy, Hesston in the United States andSanta Rosa in Brazil are responsible forthe production of MF’s combines andbig square balers. All plants work tointernationally-recognised manufacturingand quality management standards.Agricultural machinery has been built atRanders in Denmark for over 100 years.The team here pioneered the concept ofyield mapping and precision farming –hailed as one of the most importantbreakthroughs in modern crop production.The 12,500 m 2 plant assembles <strong>Massey</strong><strong>Ferguson</strong>’s top-of-the-range MF 7274 andMF 7278 combine models in standardand Auto Level versions. It also producesthe famous PowerFlow table. Productionvolumes at the plant have been increasingyear-on-year and 2008 will see a further20% rise in the number of machinesThe assembly line at Randers.leaving the assembly lines bound forEuropean markets.Breganze is the latest factory to jointhe line-up of manufacturing facilities.The 220,000 m 2 site was opened in 1979and is one of the most modern and efficientfarm machinery production complexes inEurope. It operates the Kaizen concept ofcontinuous improvement to optimiseproduction efficiency and ensure flexibilityin responding to changing marketdemands. Around 1000 combines areproduced annually.BALERSMoving across the Atlantic, Hesston inKansas – located in the heart of theagricultural Mid-West – is the sourceof <strong>Massey</strong> <strong>Ferguson</strong>’s 2100 Seriesbig square balers and the MF 9895Rotary combine. The plant has a 55-yearhistory manufacturing farm equipmentand its engineering team pioneered thebig baler concept in the 1970s. With aworkforce of nearly 1400, many of theemployees still live on farms or grew upMF combines in production at Breganze.there. The 144 ha site boasts over 12 haunder cover with extensive facilities formachining, fabrication and assembly.Opened in 1975, the Santa Rosa plant inthe state of Rio Grande do Sul in southernBrazil produces MF’s 3640 and 5650combines including versions for riceharvesting. It also builds machinesdeveloped from Randers source product –the well known MF 32, MF 34 and MF 38.In addition, the factory has recently startedto assemble Rotary combines sourcedfrom Hesston. Capacity is around 2220combines per year.Coming towards the end of the assembly –MF big square balers produced at Hesstonin the United States.Industry benchmarking shows that MF offerscustomers a world-class parts service“There’s no doubt that the 2007 Europeanharvest will go down as one of the mostdifficult on record for everyone involved,”reports Mike Daniels, Manager, PartsOperations, Europe, Africa and MiddleEast. “We have used the experience andinformation gained to help in our harvestsupport planning for 2008.”“The 2007 harvest was affected bya number of highly unusual events,” hecontinues. “These included, for example,adverse weather conditions which had amajor effect on the normal phasing ofthe harvest across Europe and resultedin increasing worldwide demand on oursupplier network, thus impacting theavailability of some components.”Industry benchmarking shows that MFoffers customers a world-class partsservice. Its harvest support programme isdesigned to be extremely dynamic and ableto adapt to changing conditions. “Eachharvest experience is used to furtherLATEST THINKING ON SERVICEIn tandem with parts supply, service back-up is the other crucial element in MF’scustomer support package. This back-up takes many forms from daily technicalassistance to practical local support, and once a year groups of MF and dealerstaff meet for a more formal annual review.“Service reviews are carried out every year with distributors and dealers in eachterritory,” says Stephen Williams, General Field Service Manager. “The recentevent in France for example brought together 165 dealer service managers for afive-day conference.”These reviews provide the platform for dissemination of the latest information andthinking on service issues as well as a forum for the exchange of ideas andexperiences. Topics range from highly advanced technical discussions on the fullrange of MF products to new ways of workshop operation plus Environmental,Health & Safety updates. Key suppliers are also invited to make presentations andrun workshops on specific components.“AGCO Net – our company-wide private and secure Internet facility – is anotherimportant part of our service communications with distributors and dealers,” addsStephen. This provides staff with the very latest information and data on anytechnical issues and is available round-the clock. Personnel can, for example,interrogate the knowledge database to check for solutions to technical problems.HARVEST BACKUPFINE-TUNED FOR 2008enhance our world-class service,” saysMike. “The planning process startsimmediately after the season is over witha global post harvest review of allcustomer-related issues.”“To facilitate even greater availability in ourwarehouses this year, we have arrangedeven earlier placement of pre-harvest partsorders on our suppliers and increased thedepth of stock ordered on critical parts,” heexplains. “In addition, we have been workingwith the MF dealer network to increasepre-season stocking to ensure parts areavailable close to the customer. We havealso reviewed transport arrangements withour carriers and put in place a robustescalation and review process to ensure thatany issues are responded to immediately.”URGENTThroughout the harvest period, all AGCOParts warehouses and customer servicefacilities supplying MF European combinemarkets are available 24 hours a day, sevendays a week. Later cut-off times are appliedfor emergency VOR orders for deliverythrough the normal transport routes. Inaddition, urgent parts orders can be placedup to 23.00 hrs – either for collection bydealers or customers 24 hours a day or forspecial delivery outside the normal transportprocess. MF dealers are also committed tothe highest levels of service by operating‘out of hours’ parts and service support.All AGCO warehouses in Europe areintegrated via a highly-sophisticatedcommon order processing system. If apart is not available locally, the‘Eurodirect’ system will automaticallysearch all European warehouses tolocate the part and process either adelivery overnight to the local warehouseor a direct-to-dealer or customer delivery.Complementing this comprehensive harvestback-up is the full support packageprovided by the MF dealer network. Directaccess to on-line parts ordering 24 hoursa day, seven days a week gives dealersfull visibility of parts availability throughoutthe European warehouse networkround-the-clock.Diagnostics via laptop computer are just one ofthe tools in MF service back up.14 15

RELIABILITYQUALITY COMMITMENTUSING FERGUSON TE20S, IN 1958, EXPLORER SIR EDMUND HILLARYLED THE FIRST MECHANISED EXPEDITION TO THE SOUTH POLETO THE POLE…BY TRACTOR!One of the 20th Century’s truly greatexplorers and adventurers, Sir EdmundHillary died in early January, just days afterthe 50th anniversary of his famousAntarctic expedition. As well as being oneof the first people to reach the summit ofMount Everest, on January 4 1958, drivingtrusty ‘Fergie’ tractors, his team becamethe first overland explorers to reachthe South Pole since Captain Scott’sexpedition in 1912.In his now famous telegram he told the‘<strong>Massey</strong>-Harris-<strong>Ferguson</strong> Farming Company’:“Despite quite unsuitable conditions of softsnow and high altitudes our <strong>Ferguson</strong>sperformed magnificently and it was theirextreme reliability that made our trip to thePole possible. Stop. Thank you for yourgood wishes = Hillary”At the time the press described this as the‘The Last Great Journey in the World’,although the expedition’s official titlewas The Commonwealth Trans-AntarcticExpedition 1955-58. Led by Englishman SirVivian Fuchs its aim was to be the first tocross the continent overland – 50 yearsafter Shackleton’s ill-fated attempt – whilegathering scientific data.In common with Shackleton, Fuchs’ planwas to make the journey from each sideof the continent from the Weddell Sea tothe Ross Sea with teams including menfrom Britain, New Zealand, Australia andSouth Africa.Hillary led the New Zealand team and theirprimary role was to set up depots andstash supplies of fuel, food and equipmentin a line towards the Pole.“For unloading the ship it was necessary, ofcourse, to have vehicles. Our problemwas overcome by the generosity of<strong>Massey</strong>-Harris-<strong>Ferguson</strong> in the UK andtheir agents C.B. Norwood in New Zealand.These firms lent us five <strong>Ferguson</strong> tractorsmodified to operate in snow conditions,”he wrote.“We are heading hell-bent for the Pole.God willing and crevasses permitting”Sir Edmund HillaryOn reaching his destination, Hillarycommented: “Our <strong>Ferguson</strong>’s had broughtus over 1250 miles (2000 km) of snow andice, crevasses and blizzard to be the firstvehicles to drive to the South Pole.”The TE20 tractors travelled over1250 miles (2000 km) acrosssnow and ice. They were fittedwith full tracks and painted red(as opposed to the normal<strong>Ferguson</strong> grey) to make themeasier to spot in the snow.One of the actual <strong>Ferguson</strong> TE20s (named‘Sue’ by the team) that was used on thisremarkable expedition is now in thenew <strong>Massey</strong> <strong>Ferguson</strong> Technology Centrein Beauvais, France.Sir Edmund Hillary sent a telegram to thecompany praising the performance of theTE20 tractors.A <strong>Massey</strong> <strong>Ferguson</strong> tractor is now at workat Mkomazi National Park in Tanzania toassist in the conservation of criticallyendangered black rhinos. Today, there areonly 101 left in the country.The 120hp MF 5365 4WD tractor will carryout a whole raft of duties on the 3270 km 2reserve, ranging from cutting fire breaks,maintaining fencing, roads and airstrips aswell as transporting rhino.“Essential to us is reliability, easymaintenance and good haulage and liftcapacity,” explains Tony Fitzjohn of theGeorge Adamson Wildlife PreservationTrust who has spearheaded work at theMkomazi Game Reserve for the last 17years. “We’ve been running an MF 375since the project started and it’s given usfantastic service which is why weredetermined to replace it with another<strong>Massey</strong>. As well as being our key powerunit, the new tractor will have to go to therescue of other machines on the reserveand haul them out of trouble.”Save the Rhino International and theEuropean Association of Zoos and Aquariapledged the majority of funds for the newMF TRACTORJOINS TANZANIARHINO PROJECTMF 5365 tractor. <strong>Massey</strong> <strong>Ferguson</strong>provided a generous discount and itsTanzanian distributor, FMD is supplyingfree operator and maintenance training forMkomazi staff.Save the Rhino International works toconserve critically endangered rhinocerosspecies in the wild. At the turn of the 19thcentury there were approximately onemillion rhinos. Today there are fewer than21,500 surviving in the wild. The MkomaziRhino Sanctuary currently holds nineEastern Black Rhino with a plan to increasethis to 12.Tony Fitzjohn hasspent the last 30years living in theAfrican bush startingat the famous GeorgeAdamson camp atthe Kora NationalPark in Kenya. “As faras I am concerned,you always start aproject in Africa witha tractor and trailer,”he says. “And for me,the tractor should be a <strong>Massey</strong> <strong>Ferguson</strong>.The <strong>Massey</strong>s just keep going which is justwhat we need in the remote bush. Being400 miles from anywhere, we have to bevery self-sufficient and we carry out all ourown maintenance. The great advantage of<strong>Massey</strong> <strong>Ferguson</strong> is that you can alwaysget genuine parts. It’s good to know wealso have the support of the nationaldistributor.”• For more information on Save the Rhinoor to make a donation, go towww.savetherhino.orgSALES OF GROUNDS CARE KIT TAKE OFFAn exceptional first 12 months across Europe for <strong>Massey</strong><strong>Ferguson</strong>’s new lawn and garden products saw total retail salesof more than €7.5 million (£5.6 million) recorded during 2007.In the Netherlands for example, sales of MF grounds careincreased 150% since the introduction of the completely newline-up last year and these are set to double again in 2008.“The new MF range has gone down really well with ourcustomers,” says Jan Meijerink, Manager of distributorMechatrac’s Tuin En Park (Town & Park) division. “We have ateam of specialists working with the range and have increasedthe number of outlets selling the equipment.”Meanwhile, new products have been added to the MF groundscare range for 2008 including five all-new walk-behind rotarymowers. Available from appointed <strong>Massey</strong> <strong>Ferguson</strong> dealersAn MF 5365 is carrying out key duties at theMkomazi National Park in Tanzania.throughout Europe, the newly-expanded range now comprisessix self-propelled machines with cutting widths of 48cm, 53cmand 84cm. All are capable of mulching cut grass, returning it tothe ground to act as a natural green fertiliser.Complementing the extended line-up of MF walk-behind mowersare more additions to ride-on mowers and garden tractors which,together with two new 1500 Series compact tractors, furtherreinforces <strong>Massey</strong> <strong>Ferguson</strong>’s aim of becoming a major force inthe professional, estate and top-end residential grass andgrounds care market across Europe.Also rapidly gaining acceptance both on- and off-farm is theMF 20 MD diesel-powered side-by-side utility vehicle. With builtin safety ROPS, the impressive growth in sales is set to continuein 2008 with the addition of summer and winter cab versions.16 17

QUALITY RELIABILITY COMMITMENTLEADERSHIP PRIDE COMMITMENTMF 5400S STARTAS FAVOURITESFOR CIVILDUTIESYellow-liveriedMF 5400 Seriesmowing the grass atHong Kong airport.MF RECEIVESTOP BRAND STATUS IN UK<strong>Massey</strong> <strong>Ferguson</strong> has beennamed a Business Superbrand.Coinciding with its 50th anniversary year,<strong>Massey</strong> <strong>Ferguson</strong> has been voted a UKBusiness Superbrand.“We are delighted to have been chosen as one of theUK’s top 500 brands especially in this, our goldenjubilee year when we are celebrating the creation ofthe name <strong>Massey</strong> <strong>Ferguson</strong>,” says Declan Hayden,MF Vice-President Sales & Marketing – Europe,Africa and Middle East. “The requirements forSuperbrand status certainly reflect MF’s own corevalues of providing customers with the best possibleproducts and the best possible back-up.”The Business Superbrands programme presentsexpert and consumer opinion on branding, andcelebrates exceptional brands in over 50 countries.Brands do not apply to enter, they are speciallyselected and then voted on by an expert paneland business professionals. Voters are asked toassess each brand based on their perception of itsstrength in the market. They bear in mind thefollowing definition: “A Business Superbrand hasestablished the finest reputation in its field andoffers customers emotional and/or tangibleadvantages over competitors. It must representquality, reliability and distinction.”It’s not only agriculture where <strong>Massey</strong><strong>Ferguson</strong> tractors serve as useful andversatile power trains. MF 5400 Series areperforming essential duties at Hong Kongairport and at racecourses allover Japan.“Hong Kong’s Chek Lap Kok Internationalairport is the largest airport in Asia and hasbeen voted the best airport in the world forsix years in succession,” reports PeterDelaney, MF Regional Manager in the EastAsia Pacific region. “When it opened in1998 it was the most expensive civilengineering project ever undertaken.”“It now relies on three MF 5460 tractors toprovide the vital role of grass cuttingaround the runways and taxi ways. Two ofthe tractors are used for mowingoperations and the third is fitted with a bulkgrass collector. The Airport Authoritypurchased the tractors in 2006 afterdeciding to bring the work in-house, havingpreviously relied on a contractor to do thejob with a fleet of small tractors.”Cutting the grass at the airport is not justfor cosmetic purposes but also plays animportant role in the safety and security.“Maintaining the grass at the correct lengthis vital for deterring birds from areas closeto the runways,” adds Peter. “Too long andit will attract nesting birds, too short and itwill encourage birds to land and feed. WithHong Kong’s year-round hot and humidclimate the grass grows very quickly andtherefore has to be cut daily between thehours of 1am and 5am when the runways areMF’s Business Manager for Japan. “Thestarting gates are operated by an affiliatedclosed. With its high-torque engine, company, Japan Starting System and MFeasy-to-use transmission and excellentmanoeuvrability and visibility, the MF 5400 isideal for this heavy-duty mowing application.”Such a critical job means reliability isparamount. Vincent Cheng, Director ofHong Kong’s MF distributor Shine TechServices Ltd, confirms that the tractorstractors, supplied by MSK Farm MachineryCo Ltd, are their preferred brand.”Modifications include removal of cabs,fitting of dual turf tyres and the installationof special towing rigs. The tractors areliveried in JRA’s colours of white and darkgreen with the conspicuous exception ofhave performed faultlessly from the red MF logo on the grille and on theday one.leading edge of the visor!In Japan, a number of MF 5400 Seriesmodels have been modified specifically for“<strong>Massey</strong> <strong>Ferguson</strong> has long been a leadingbrand in Japan and we are delighted withtowing starting gates around racecourses. this high profile application of our“Horse racing in Japan is organised bythe government-owned Japan RacingAssociation (JRA) which conducts 3400races per year all around the country,drawing an annual crowd of some eightmillion people,” explains Peter Mathias.renowned MF 5400 series,” says Peter. “Aswell as powering and manoeuvring thestarting gates, it is also very important thatthe tractors can be relied upon to get thestarting gates out of the way before thehorses come round for their second lap!”Powering and positioning the starting gates at Japanese racecourse is no mean feat.LOGOON ICESnow and ice might seem a long wayaway right now but MF’s distributor inJapan, MSK Farm Machinery Corp (MFM) made an early start on markingMF’s 50th anniversary.As their contribution to the SapporoSnow Festival, MF M apprenticesworked evenings and weekendsin very cold conditions to createtheir own unique MF 50th ice sculpturein the main tractor sale display areaof the distributor’s Obihiro branch.The sculpture lasted until mid-Marchand proved a big attraction atopen days and for customers visitingthe branch to view and test drivenew equipment.The Sapporo Snow Festival is oneof Japan’s largest winter eventsand some two million people makethe trip to see the hundreds of beautifulsnow statues and ice sculptureswhich line Odori Park for seven daysin February.DISTRIBUTORSALUTES MF 50MF distributors and dealers from allover the world are joining in theyear of jubilee.Pictured are staff from Indonesiandistributor, PT Traktor Nusantaraall kitted out in their MF 50thanniversary polo shirts. All newMF tractors sold by PT TraktorNusantra in 2008 are also beingfitted with a commemorative plate.Staff at PT Traktor NusantaraATRACTORINYOURWALLET!Agriculture plays a key role inAfrican economies, and MFequipment has been an integralof part of the continent’sagricultural development.Reflecting this crucial link, the NationalBank of Ethiopia uses an illustration of an MF 100Series at work on the back of a 10 Birr note.“<strong>Ferguson</strong> machines were some of the first tractors into Africa and we havebeen fully committed to the mechanisation of agriculture there ever since,” says JeremyDawe, General Sales Manager – Africa. “Today, we have a range of machines specificallydesigned for the tough and diverse requirements of African farmers.”• If you know of any other unusual places where MF machinery crops up like this, let us know.18 19

QUALITY RELIABILITYRELIABILITY QUALITYMF IN ACTIONOVER 50 YEARS WITH MFLivestock enterprise, Chapel Farm inWales has seen over a dozen MF tractorspass through its gates since the 1950s.Farmed by three generations of theAttewell family, their latest MF machinesarrived early this year in the shape of anMF 5470 and MF 6470.“I remember our first <strong>Ferguson</strong> TE20 whenI was a boy in the early 1950s and sincethen we’ve always been <strong>Massey</strong>,” saysLen Attewell, whose father Wyndhamcame to Chapel Farm in the 1930s.Today, trading as L H Attewell andPartners, Len runs the operation with36-year-old son, Ben.Farming 187 ha on the Severn Estuary inCaldicot, Monmouthshire and having givenup dairy in the mid 1970s, they now focuson beef (400-450 head Pedigree Limousinand Limousin cross) and sheep. The sheepfeed on their 54 ha of salt marsh and, as aresult, this ‘Salt Marsh Lamb’ is sold as adelicacy to local master butcher, DouglasWillis of Cwmbran who buys their entireoutput. A further 20 ha is down to maizewhich is used for forage. Silage is anotherkey crop.The Attewell’s MF tractor parade readsas follows: TE20 (x 2), MF 35, MF 135,MF 290, MF 690, MF 372, MF 390T (x 2),MF 6265 (x2), MF 5455, MF 5470 andMF 6470. Their 47-year old MF 35 is stillgoing strong and is used regularly with apressure washer and as a generalrunaround machine. “We’ll never sell it,”adds Len emphatically.“I’m a <strong>Massey</strong> man through andthrough and my son’s grown up withthem,” he remarks. “It’s not thatwe’ve never looked at other makesof machine, it’s just that they’venever come up to the mark. I canremember a tractor salesrepresentative turning up atthe farm one day andmy father saying: “If itisn’t red, we don’twant to know!”“The latest modelsare so fantasticespecially the bigcomf ortable cabs.And the Dyna-4 andDyna-6 gearboxesare really brilliant –you can find a gearto virtually everything.Mowing, muck spreading,hedge trimming, baling –they are so easyto use.”…ANDABRAND-NEW CONVERTMeanwhile, 160 miles (256 km) east of Chapel Farm and itsrich MF history, Athelington Hall in Suffolk, England saw itsfirst-ever <strong>Massey</strong> <strong>Ferguson</strong> tractor arrive in mid 2007.The man behind the decision to switch to <strong>Massey</strong> <strong>Ferguson</strong>from a competitor’s make was 23-year-old John Havers whofarms with his father, Peter.“After all our years with another brand, my dad was shockedwhen I said I wanted an MF and I had a difficult job to get himto make the move!” John explains. “But we had ademonstration MF 6485 from our local dealer, TNS, and I likedit so much that my mind was made up.”After a year on the farm, John is certain that the MF 6485 wasthe right choice.“We run 1600 pigs and have 127 ha down to a mixture ofrape wheat and barley,” he remarks. “We also do contractarable work on a further 55 ha. The big attraction for me withthe MF 6485 is its comf ort – it is a noticeably smoother rideand it’s incredibly quiet in the cab. In the main, I use the tractorwith a five-furrow reversible plough and although it’s only155hp, it’s well up to the job. On top of all that, it’s a really nicelooking tractor too.”Len and Ben Attewell –MF tractors have beenpart of their farmoperation for over50 years. Latest modelsare a 2008 MF 5470and MF 6470 whiletheir MF 35 hasbeen in servicefor 47 years.John Havers –made the right choice in switching to MF.HALF A CENTURY OF HARVESTING75-year old Danish farmer JohannesJensen is celebrating over 50 yearsworking with MF combines.“I’ve never used any other make ofcombine – MF models have been part ofmy life since 1957 when I was a farmbailiff on an enterprise which ran a56hp MF 780,” he explains.Today, Johannes is still farming in theDjursland area in eastern Jutland. In1960, he bought his own farm and hisown MF 780 that he later replaced withan MF 87. For some years, he ran bothhis own farm and that of his parents.Then, in 1994, he took sole responsibilityfor the family farm where he still liveswith his wife. Currently, he owns a1973-vintage MF 525 with 12 ft (4 m)table which he bought second-hand in1977 and is still going strong.MF IN ACTIONGrowing 10 ha of malting barley and10 ha of winter wheat, Johannes doesmost of the work himself with a little helpfrom a contractor for sowing the wheat,together with his nephew who owns aneighbouring farm and who lends a handduring harvest.The farm’s land lies 2 m below sea levelin a 2500 ha area known as Kolindsundwhich is surrounded by a dyke. A seriesof pumps is used to pump water intodrainage channels. As one might expect,the soil is heavy clay. Yields average8-9 t/ha for wheat and 6-7 t/ha forbarley. The latter is sold to make beerwhile the wheat goes for fodder. Strawis sold to a local cattle farmer.“What I like about MF combines is theirreliability, durability and low cost ofownership,” adds Johannes. “They haveserved me very well over the years.”MF combine devotee, Johannes Jensen.NOW AND THENAnyone who has ever been harvesting on a hot day in the late afternoon will reallyappreciate the atmosphere of this evocative shot. Successfully working together to getthe job done are a brand-new MF 9895 rotary combine and 46-year old MF 35 tractor.The picture was taken by MF demonstrator, Jacob Johnsen during the evaluation of theMF 9895 last season, near the town of Jelling in his native Denmark, on land belongingto local dealer, Holge Skjoldemose. “It was one of those magic moments – late onSunday afternoon when for once no-one was in a rush,” says Jacob. “MF technologyspanning nearly 50 years was on display – it was a great sight.”2021

AGCO NEWSKEY INVESTMENTS INSISU DIESEL ENGINEDEVELOPMENTAND PRODUCTIONMASSEY FERGUSON 50TH ANNIVERSARYEVENTS FIRE UP PRIDE AND COMMITMENTIn a series of passionate and fiery displaysof product, support and customertestimonials, <strong>Massey</strong> <strong>Ferguson</strong> celebratedits 50th anniversary in style in front of 1700distributors, dealers and staff from 65countries at Les Fontaines, Chantilly and itsEuropean Operations in Beauvais, France.In an event that acknowledged thecompany’s 167 year history and itsnumerous landmarks in tractor andharvesting innovations, it also showcasedits recent multi-million dollar investmentsin its support services in Beauvais with theinauguration of a new auditoriumalongside the Technology Centre andInternational Training Centre whichopened in November 2007.Although acknowledged as a celebrationof 50 years since the formation of theworld’s most sold farm machinery brand,the event was also a platform to inspire<strong>Massey</strong> <strong>Ferguson</strong> dealer and staff andreveal impressive new tractor andcombine plans.Declan Hayden, <strong>Massey</strong> <strong>Ferguson</strong> VicePresident Sales and Marketing Europe,Africa and Middle East told the audience:“Today we are like a dragon – a giant reddragon breathing fire and willing and ableto take on all-comers when it comes toproviding the best product and supportthrough our dealer network.”In a finale which supported <strong>Massey</strong><strong>Ferguson</strong>’s philosophy that actions speaklouder than words and, as ademonstration of its own commitment tomaintaining leadership in productdevelopment and innovation, it unveiledits 2009 harvesting and 365hp flagshiptractor developments as the ultimate inbirthday celebration presents.Engine assembly – the combined production at Sisu Diesel plantsin Finland and Brazil is expected to reach 40,000 units in 2008.The cylinder block line.22<strong>Massey</strong> <strong>Ferguson</strong>’s sister brand, Sisu Diesel is making majorinvestments in the development and production of more fuel efficientand reliable diesel engines that comply with Tier III emissionsstandards. The three-year investment programme will doubleproduction capacity at both the Nokia plant in Finland and the MogiDas Cruzes plant in Brazil.“SisuDiesel engines are fitted to the majority of <strong>Massey</strong> <strong>Ferguson</strong>’sbig tractors and have established a fantastic reputationfor reliability and top performance,” says Campbell Scott, MF BrandDevelopment Manager.Sisu Diesel’s engine assembly process has been entirely reorganisedwith a focus on boosting the level of automation. “Robots are beingemployed increasingly along fully-automated and flexible productionlines,” explains Mauno Ylivakeri, Sisu Diesel Research andDevelopment Director. “The warehouse systems have also beenautomated, and the internal logistics for completed engines arehandled by state-of-the-art automated guided vehicles.”Production of engine parts has been improved throughmodernisation of the manufacturing processes of selected keycomponents and increasing capacity to meet expanding needs.Production efficiency of cylinder blocks has also been boosted ashas the flexibility of manufacturing different engine types. “All 2- and4-valve cylinder heads are built on a new flexible and automatedproduction line,” adds Mauno. “In addition, production capacity ofgear wheels, rocker-arm assemblies and housings has beenincreased to meet future demand.”Engine research and development is another key focus of investmentThe engine development laboratory will feature eight new engine testbenches together with state-of-the-art management and datacollection systems. Testing capacity will be doubled, while thetechnical sophistication of the test benches, cooling capacity andventilation will improve considerably. It will also be possible to testbigger engines.FACTORY VISITMore than 60 personnel from <strong>Massey</strong> <strong>Ferguson</strong>’s Italian dealernetwork (pictured) recently visited the Sisu Diesel plant atLinnavuori in Nokia, Finland to see engine manufacture at firsthand. “It was a great opportunity to hear about the latestthinking on engine technology and Sisu Diesel’s plans for thefuture,” says MF’s Cinzia Peghin who led the group.23

PRIDE INTHE TRIPLETRIANGLE!At the <strong>Massey</strong> <strong>Ferguson</strong> 50th anniversarycelebrations in France, giant images ofthe brand were proudly projected ontothe magnificent Chateau des Fontaines inChantilly where the event was held.More details on page 23.© AGCO Limited 2008 - Englishis a worldwide brand of AGCO Corporation