UNISORB General Catalog - Your Equipment Source, Inc.

UNISORB General Catalog - Your Equipment Source, Inc.

UNISORB General Catalog - Your Equipment Source, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

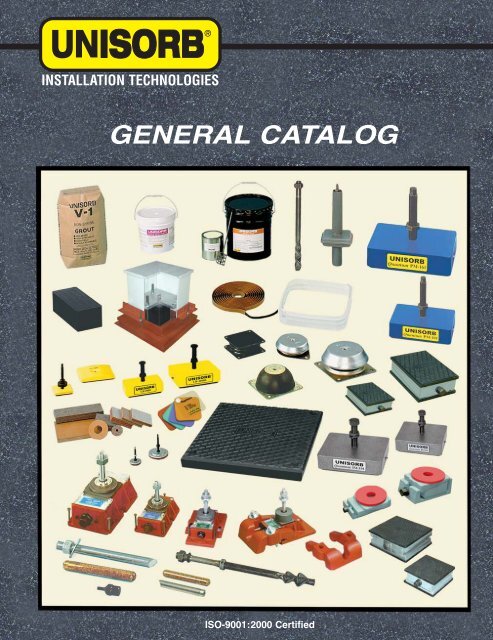

INSTALLATION TECHNOLOGIESGENERAL CATALOGISO-9001:2000 Certified

Established in 1935 as a subsidiary of The Felters Company,<strong>UNISORB</strong> is the leading specialist in engineering and manufacturingproducts and systems to ensure proper machineryinstallation.<strong>UNISORB</strong>’S growth can be attributed to the development ofmachinery installation systems to solve problems in specificapplications. Experience has shown that no one product orsystem is “best” for all applications under all conditions.Installation related factors (e.g., installation and leveling time)and the extent of vibration, shock, deflections and noise to becorrected in the operating environment must be considered ineach application.<strong>UNISORB</strong> has the only engineering staff devoted exclusivelyto the design and implementation of complete machineryinstallation systems. From concept to final installation,<strong>UNISORB</strong>’S experienced staff of designers, application engineersand field engineers assures you of optimum performanceof your mounted equipment.PAGECONTENTS1 VIBRATION ISOLATION ANCHORING PADS1 RED-LINE ANCHOR PADS2 RED-LINE PADS2 VIBRATION ANALYSIS SERVICES3 TITAN SHOCK PADS3 NEOPRENE PADS4-5 LEVEL-RITE ® MACHINERY MOUNTS6 Quantum PM PRESS MOUNTS7 Quantum IM MOUNTS7 DIE TURNOVER PADS8 RK FIXATOR ® ANCHORING/ALIGNMENT SYSTEM9 AK FIXATOR ® SYSTEM10-11 PROFESSIONAL ENGINEERING SERVICES12-13 POWER GENERATION ENGINEERED PRODUCTS14 LEV-L-INE ® MACHINERY MOUNTS15 TRI-WEDGE MACHINERY MOUNT16 INERTIA BLOCK VIBRATION ISOLATION16 IB-500 FOUNDATION ISOLATION SYSTEM17 GK BLOCK FOUNDATION ISOLATION SYSTEM17 RD FOUNDATION INSERT SYSTEM18 V-1 ® NON-SHRINK GROUT18 <strong>UNISORB</strong> ® CONCRETE REPAIR COMPOUND18 STRUCTURAL REPAIR FORMULA19 CEMENTITIOUS GROUTS20 STANDARD V-100 ® EPOXY GROUT20 DEEP POUR V-100 ® EPOXY GROUT21 DCR V-100 ® (ACID RESISTANT) EPOXY GROUT21 ADHESIVE V-100 ® EPOXY GROUT21 JOINT FILLER V-100 ®21 GROUT FORMS AND SEALANT22-23 JAKEBOLT ® HEAVY DUTY ANCHOR BOLTS23 VECTOR ANCHOR BOLTS24 CAPSULE ANCHOR SYSTEMSINSIDE BACK COVER INSTALLING MACHINE TOOLSCOPYRIGHT <strong>UNISORB</strong> ® 2008(GC/11/08)<strong>UNISORB</strong> ®INSTALLATION TECHNOLOGIESP. O. BOX 1000, JACKSON, MI 49204-1000 ■ 517-764-6060 ■ FAX 517-764-5607www.unisorb.com ■ e-mail unisorb@unisorb.com ■ 888-4-<strong>UNISORB</strong>

VIBRATION DAMPENINGQUALITIES OF ENGINEERED FELTFor thousands of years, man has used felted fiber to absorbshock and vibration. <strong>UNISORB</strong> has chosen felt pads for useunder the feet of many types of machines because of its abilityto effectively isolate against transmitted shock and vibration,and because of its predictability. <strong>UNISORB</strong> RED-LINEPADS are also highly resistant or impervious to most industrialchemicals, oils and moisture. Life expectancy, in mostcases, will exceed that of the machinery with which they areinstalled.<strong>UNISORB</strong> ® RED-LINE PADSSATISFY OSHA REQUIREMENTS<strong>UNISORB</strong> RED-LINE PADS and anchor bolts satisfy OSHArequirements for machinery installation. Proper use of theseproducts will:• Improve the efficiency of production equipment.• Provide safer, more desirable environment for workers.• Reduce down time and extend the operating life of yourmachinery.• Prevent floor damage.Harmful effects of vibration and noise may cause serious impairmentto the efficiency of your workers and the overall effectivenessof your production machinery.RED-LINE ANCHOR PADS<strong>UNISORB</strong> ®VIBRATION ISOLATIONANCHORING PADSHOW TO SPECIFY <strong>UNISORB</strong> ®ISOLATING & ANCHORING PADS<strong>UNISORB</strong> RED-LINE AND RED-LINE ANCHOR PADS TypeH, HB, E, EB, D and DB have long been the standard for achievingsuperior results in the toughest shock/vibration applications.These pads are 100% wool fiber and are suitable fornormal industrial environments being unaffected by exposureto oils, cutting fluids and coolants.<strong>UNISORB</strong> RED-LINE AND RED-LINE ANCHOR PADS TypeS. SB, F and FB are manufactured from 100% man-made fibersoffering excellent performance at a lower cost. Types S,SB, F and FB pads are recommended for use in wet or "exposedto weather" applictions or where strong concentrationsof acids or bases will be encountered.Both families of pad materials may be expected to outlive themachinery on which they are installed.Use this formula to determine the proper pad material fromthe chart below:Weight (pounds per foot)Foot length (inches) X Width (inches)= Pounds per square inchPAD TYPE SELECTIONLoadRange 0-50 50-100 100-250 Over 250(in PSI)Extra Neoprene NeopreneLight H-¼, S-½ E-½, S-½D-½, F-½Titan-½Normal H-½, S-½ E-½, F-½ D-½, F-½ Titan-½WalkingNormalHB-½, SB-½ EB-½, FB-½ DB-½, FB-½ Titan-½BONDED PADILLUSTRATEDReduced vibration contributes to more efficient operation andlonger life of costly machinery. <strong>UNISORB</strong>'s job-engineeredRED-LINE ANCHOR PADS substantially reduce vibrationtransmission and keep light and medium-duty machines from"creeping" or "walking" without the use of anchor bolts andwill materially reduce transmitted noise. Installations are fast,easy and inexpensive.NormalHeavy E-1, S-1 E-1, F-1 D-1, F-1 Titan-1ImpactWalkingHeavy EB-1, SB-1 EB-1, FB-1 DB-1, FB-1 Titan-1ImpactS-½, H-½ F-½, E-½ F-½, D-½ Titan-½Severe + + + +Horizontal Adhesive Adhesive Adhesive Adhesive1

<strong>UNISORB</strong> ®VIBRATION ISOLATION PAD MATERIALSVIBRATION ANALYSIS SERVICESRED-LINE ANCHOR PADSTYPE HB, EB, DB, SB & FBPRODUCT APPLICATIONSThe nylon-bonded surface of RED-LINE ANCHOR PADS providesa high coefficient of friction to effectively prevent machineryfrom "creeping" and "walking". These pads are notaffected by most oils and solutions found in manufacturingplants. Available in standard sheets of 36" x 60" for wool and36" x 72" for non-wool, consult the factory for quotations oncut-to-size prices. When properly installed, RED-LINE AN-CHOR PADS conform to OSHA requirements for machine anchoring.BOLT-THROUGH ISOLATIONRED-LINE PADSTYPE H, E, D, S & FAvailable in a variety of densities and thicknesses to fit machineload requirements, RED-LINE PADS provide effective,low cost vibration control for machinery. Available in standardsheets of 36" x 60" for wool and 36" x 72" for non wool,consult the factory for quotations on cut-to-size prices.VIBRATION ANALYSIS SERVICES<strong>UNISORB</strong> provides vibration analyzation services as part ofits overall engineering assistance program to meet everycustomer's machinery installation need. Our engineers arethoroughly trained in the use of state of the art vibration analyzingequipment and are experienced in analysis of technicaldata collected for every machinery shock and vibration installationproblem. Solving difficult machinery installation problemsby providing comprehensive engineered solutions is ourprimary mission. Contact Unisorb Engineering Department fordetails.This basic approach has been applied satisfactorily toequipment from ¼ horsepower electric motors to 2,000ton capacity stamping presses. The machine foot is completelyisolated from contact with either the mountingstructure or anchor bolt by isolation material. Elastomerictubing (of the appropriate size) is used for the resilientbushing around the anchor bolt.CASE HISTORY<strong>UNISORB</strong> was contacted by a company planning to relocate41 assorted cold headers, bolt makers and nutforming machines from one plant to another. We recommendedthe use of Type D-½ RED-LINE PADS withadhesive for proper machine installation but our proposalwas initially rejected by the customer as being tooexpensive. They selected a competitive non-felt materialwhich was lower in cost.Almost as soon as the machines were installed andoperating the company began to experience failure inthe installations. A significant number of machines had"walked" off their pads, and in some cases were stoppedonly by the walls of the factory.We were again contacted and our recommendation wasto reinstall at least some of the machines on RED-LINEPADS. Once our installation was completed and the resultsobserved the company requested that all of thepads in the plant be replaced. Our approach to the correctapplication of pads is now the approved standardmethod with the company.2

<strong>UNISORB</strong> ®VIBRATION ISOLATIONPAD MATERIALSTITAN SHOCK PADSFOR EXTREME LOADINGSAND HEAVIEST IMPACTSImpact shock and vibration can do costly damage to machines,mounting devices and floors and noise may reduce efficiencyof operating personnel. TITAN SHOCK PADS offer an easyeconomical way to solve these problems.Made of a tough textile base laminated with a specially formulatedoil resistant neoprene compound, these multi-ply padsprovide protection and vibration isolation needed for machinesand equipment, ranging in size from presses to forging hammers.TITAN SHOCK PADS protect floors and machinemountings against damaging impact shock while absorbingvibration and dampening structure-borne noise.TYPICAL DEFLECTIONMANUFACTURED TOMILITARY SPECIFICATIONMIL-C-882 ETYPICAL APPLICATIONS• Ball mills.• Compressors.• Forging hammers.• Heavy presses.• Impact generatingmachine shop equipment.• Presses.• Pumps.• Structural bearings.• Central air conditioning.• Foundry equipment (jolters,shakeouts, etc.).• Generators.• Hydraulic hammers.• Motors.• Printing presses.• Refrigeration equipment.• Textile machinery.TITAN SHOCK PAD SPECIFICATIONSCONSTRUCTION -MAXIMUM SIZE -Laminated plies of oil resistantneoprene-frictioned fabric. Allplies laid straight with a continuousply of frictioned duckon each cover side. 64 pliesof frictioned duck per oneinchthickness.Mill run sheet sizes 1 /8" through11/32" thick: 48" wide. ½" thickand over: 48" x 14½'.THICKNESS TOLERANCE - ±5%TENSILE STRENGTH - 4,000 psi, minimumHEAT RESISTANCE - No visible change after 72hours at 160° F.COMPRESSION STRENGTH - Up to 1,800 psi perpendicularto the plane of laminations.DENSITY -0.0487 lbs. per cubic inch.DUROMETER - Shore A 90 ±5.Load inLbs. 7 Ply 14 Ply 21 Ply 31 Ply 39 Ply 48 Ply 64 Plyper1/815/6411/32 ½5/8 ¾ 1Sq. In. Thick Thick Thick Thick Thick Thick Thick50 .001 .003 .005 .006 .008 .010 .012100 .002 .005 .007 .010 .013 .015 .021200 .003 .008 .012 .017 .021 .025 .034500 .004 .014 .021 .031 .038 .046 .0611,000 .006 .022 .032 .047 .058 .070 .0932,000 .008 .033 .048 .070 .088 .105 .140All Dimensions in <strong>Inc</strong>hes. Thicknesses other than standard are available.NEOPRENE PADSFOR MACHINES WITH FLOORLOADING 5 TO 125 PSIThe smooth edge design of the low cost oil-resistant <strong>UNISORB</strong>NEOPRENE PAD prevents oil, grease, and dirt from accumulatingbeneath the load-bearing surface of the pad. Availablein 18" x 18" x 5 /16". Stiffness is 60 Durometer.3

<strong>UNISORB</strong> ®LEVEL-RITE ®MACHINERY MOUNTSFULL1- 3 / 8"ADJUSTMENTRANGE<strong>UNISORB</strong>'S line of LEVEL-RITE mounts are superblyengineered, unbreakable, and perfectly suited for generalpurpose machine leveling and isolation usage.Both the housing and impact plate of the <strong>UNISORB</strong>LEVEL-RITE mounts are made of ductile iron, conformingto Foundry Spec. 65-45-12. Every <strong>UNISORB</strong> LEVEL-RITE mount provides an overall height adjustment of 13/8 inches - well beyond all similar products around theworld. Additionally, <strong>UNISORB</strong> LEVEL-RITE mounts yieldoptimum performance, even with floors that are uneven.The isolation pads of all <strong>UNISORB</strong> LEVEL-RITE mountsare made from proprietary elastomers. The unique internaldesign eliminates the interdependence betweenvertical and horizontal stiffness found in other mountdesigns. This unique design ensures that each mountingpoint presents consistent vertical and horizontalload deflection characteristics, regardless of adjustmentheight. LEVEL-RITE mounts are unmatched incontrolling extreme machine induced dynamic loads,thus eliminating excessive machine motion and preventingfailures typical of most other general-purposemounts.The LEVEL-RITE mount features a high strength, grade5 hex. head adjusting bolt that will withstand punishmentwhich would shear off most other bolts. The finerthread pitch provides greater accuracy in adjustment.LEVEL-RITE mounts feature adjusting bolts with metricthreads. Special bolt lengths and configurations areavailable on request.The rectangular shape of the <strong>UNISORB</strong> LEVEL-RITEmounts provides another important advantage. Whileproviding greater resistance to walking than circularmounts, the straight leading edge surface on the rectangularmounts has proven to be more geometrically stable.UNDERCUT HEX.HEAD (FOR M30AND LARGER BOLTS)HOUSINGELASTOMERICISOLATION PADEXTERNAL HEX. HEAD(FOR M12 THRUM24 BOLTS)LOCK NUTLOCK WASHER(FOR M12 THRUM24 BOLTS ONLY)This helps eliminate pad roll and entrapment of coolantsand oils beneath the pad. The exceptionally high coefficientof friction provided by these elastomeric padsalso prevents machine walking.Mount loadings are expressed in pounds as shown inthe chart below. To determine the approximate loadapplied by a particular machine, divide the total weightby the number of mounting points. Note that in certaincases, where weight distribution may load one or moremounts significantly more than others, special considerationis required. When machinery generating highimpact is being mounted, reduce the mount rating by25% to assure maximum performance.SPECIFICATIONSLEVEL-RITE PRODUCT MAX. LOADH STANDARD MAX. MACH.A L WMOUNT CODE (LBS.) MIN./MAX BOLT SIZE FOOT TH.LR-2500 574200 2500 7.78 5.50 3.50 2.50/3.88 M12 x 1.75 x 150 2.27LR-5000 574300 5000 7.77 7.00 4.50 2.50/3.88 M16 x 2 x 150 2.08LR-7500 574400 7500 7.88 8.00 5.00 2.50/3.88 M20 x 1.5 x 150 1.91LR-12000 574500 12000 9.94 8.00 5.88 2.50/3.88 M24 x 2 x 150 3.65LR-16000 574600 16000 10.32 10.00 7.88 3.25/4.62 M24 x 2 x 150 3.40LR-25000 574700 25000 10.74 12.50 9.00 3.50/4.88 M30 X 2 x 200 3.53LR-35000 574800 35000 11.09 16.00 12.50 4.50/5.88 M36 x 2 x 250 4.52Dimensions are in inches except as shown.For mounts with higher load capacities contact Unisorb Engineering.4

LEVEL-RITE ® MACHINERY MOUNTSFOR HOLLOW BASE MACHINESHOLLOW BASE<strong>UNISORB</strong> ®LEVEL-RITE ®MACHINERY MOUNTSLR-200 AND LR-500The LR-200 and LR-500 are designedfor lighter equipment applications. TheLR-200 is for loadings up to 250 lbsper mount and the LR-500 is for upto 500 pounds. Both models havesteel bases, elastomeric isolationpads, and built-in leveling screws.LEVEL-RITE MOUNTADAPTERPLATER SERIESDesigned for hollow bases as found on certain models ofmills, lathes, grinders and other machines. Provides vibrationcontrol, leveling and support.Kit includes mounts with special length adjusting screwsand adapter plates. Specify distance between bolt holeswhen ordering. Standard kits accommodate these distances:BP-2500 Kit 19.25" - 20.75"BP-5000 Kit 23.25" - 24.75"BP-5000S Kit 25.25" - 26.75"Other spacings are available on request.The R Series are self-contained levelingmounts with ½" thick elastomericpads for all types of machinery.Rugged cast iron and anodizedsteel contruction with a free-floatingleveling screw offer vertical adjustmentsof up to 2". They will also compensatefor pitched or uneven floors.U SERIESThe U Series self-containedmounts with elastomeric pads aredesigned to accept machinery levelingscrews and are supplied withoutleveling accessories. Their rugged,heavy duty construction isdesigned for precision and finishingequipment.SPECIFICATIONSMODEL MAX A B C D E FLR-200 250 5 / 16-18 2 1 /8 Dia. 3½ 2½ 9 / 16 1¼LR-500 500 3 / 8 -16 3½ Dia. 4½ 2¾ 5 / 8 2½R9 900 M12x1.75 3x3 7 2¾ 1¾ 1¾R16 1,600 M16x2 4x4 7 2¾ 1¾ 1¾R28 2,800 M16x2 4x4 7 2¾ 1¾ 1¾R36 3,600 M24x3 6x6 7½ 2¾ 2 5 / 8 2¼R48 4,800 M16x2 4x4 7 2¾ 1¾ 1¾R100 10,800 M24x3 6x6 7½ 2¾ 2 5 / 8 2¼U9 900 - 3x3 1 - - -U16 1,600 - 4x4 1 - - -U28 2,800 - 4x4 1 - - -U36 3,600 - 6x6 1½ - - -U48 4,800 - 4x4 1 - - -U100 10,800 - 6x6 1½ - - -5

<strong>UNISORB</strong> ®Quantum PM Press MountsUNDERCUT HEX. HEAD (FOR1.25 BOLTS AND LARGER) LEVEL ADJUSTING BOLT(EXTERNAL HEX. HEADFOR .75 & 1.00 BOLTS)LOCK NUTLOCK WASHER (FOR.75 & 1.00 BOLTS)HOUSINGELASTOMERIC ISOLATION PADQuantum PM Press MountsFOR HEAVY DUTY PRESSES<strong>UNISORB</strong> Quantum PM Press Mounts for heavy duty presseseliminate the need to anchor machines to the floor. Theysolve impact-shock and vibration problems while providingprecision leveling and alignment for trouble-free operation.They have extra heavy-duty construction with broad basesand larger diameter leveling bolts. Designed for use withreciprocating or impact machinery, they provide close toleranceleveling adjustment. The mounts come with appropriatelydesigned resilient isolation pads.These self-contained leveling mounts simplify machineryinstallation. No drilling, lagging, adhesives, or shimsare required. Accurate leveling is obtained simply byturning the leveling bolt. Once adjusted, a lock nut holdsthe adjustment secure. Quantum PM Press Mounts absorbshock and vibration while reducing noise. Whenproperly installed, they eliminate excessive gib wear,die damage and other alignment related problems. Theymeet OSHA standards for anchoring machinery.By properly utilizing <strong>UNISORB</strong> Quantum PM Press Mounts,excessive press motion can be eliminated and unevenweight distribution can be compensated for to preventframe distortion, which is a major cause of early machinefailure.Quantum PM Press Mounts can usually be installed onexisting shop floors. Heavy, unbroken concrete floors,preferably reinforced and resting on a good base, aredesirable. Isolation features of the press mounts resultin elimination of floor damage. At the same time theyreduce interference of nearby equipment due to pressshock and vibration.A variety of shock pads, bolt lengths and bolt diametersare available to meet the requirements of almost anypress application. Contact <strong>UNISORB</strong> Engineering forrecommendations.SPECIFICATIONSPRESSLENGTH WIDTH HEIGHT ADJUSTINGMOUNTS (MIN.)* BOLTPM-61 7.00 4.50 2.50 M16 thru M24PM-81 8.00 5.88 2.50 M20 thru M30PM-101 10.00 7.88 3.25 M20 thru M36PM-121 12.50 9.00 3.50 M24 thru M42PM-161 16.00 12.50 4.50 M30 thru M56PM-201 20.00 16.00 6.00 M42 thru M80PM-261 26.00 22.00 7.50 M64 thru M100PM-301 30.00 24.00 9.50 M80 thru M110PM-321 32.00 24.00 10.50 M80 thru M130PM-351 35.00 20.00 11.00 M80 thru M130PM-381 38.00 25.50 13.00 M100 thru M150PM-421 42.00 24.00 14.75 M100 thru M150PM-481 48.00 36.00 15.50 M130 thru M180All dimensions in inches unless otherwise specified.Summary of Benefits Reduce installation costs.*Top of mount housing to floor. Easy leveling and fast, accurate alignment. Control shock and vibration. <strong>Inc</strong>rease die life and decrease press wear. Minimize expensive downtime and maintenance. Achieve better press productivity. Rugged high strength mount construction. All elastomeric isolation pad configurations. Elimination of anchor bolts. Reduce need for special foundations. Reduce operator fatigue. Reduce motor loads. Uneven floors accommodated. Press “walking” prevented.6

<strong>UNISORB</strong> ®Quantum IM Mounts<strong>UNISORB</strong> ®IMW MOUNTSDIE TURNOVER PADS-INTRODUCING-Unisorb’s line of Quantum IM Mounts offers substantial improvementsover older models, and a quantum leap overthe competition. These dynamic patented designs incorporateseveral features highlighted by the following.<strong>UNISORB</strong> Quantum IM Mount features:● Ductile Iron Housing (ASTM 65-45-12).● Constant Horizontal Natural Frequency.● Unequaled Height Adjustment Range of 1 3/8".● High Durometer Anti-Walking Elastomeric Pads.● Hex. Head Metric Bolts (Grade 8.8).● Electro-Powder Coat Finish.● Competitive Pricing Worldwide.<strong>UNISORB</strong> Quantum IM Mounts provide optimum levelingand alignment in minutes, without anchoring either themachine or the mounts to the floor. Designed especially forinjection molding and die casting machines, <strong>UNISORB</strong>Quantum IM Mounts dampen both vertical and horizontalimpacts found in reciprocating machines. <strong>UNISORB</strong>Quantum IM Mounts meet applicable OSHA requirements.<strong>UNISORB</strong> Quantum IM Mount benefits:● <strong>Inc</strong>reased equipment life.● Simplified machine installation.● Fast, accurate alignment.● Reduced shock and vibration.● Elimination of anchor bolts.● Uneven floors accommodated.● Machine “walking” prevented.● Horizontal impact capabilities.SPECIFICATIONSNOTEFULL1-3/8”HEIGHTADJ.RANGEMOUNT HEIGHT* ADJUSTINGLENGTH WIDTHSERIES(min.) (max.) BOLTSIM-51 5.50 3.50 2.50 3.88 M12 thru M16IM-61 7.00 4.50 2.50 3.88 M16 thru M24IM-71 8.00 5.00 2.50 3.88 M20 thru M24IM-81 8.00 5.88 2.50 3.88 M20 thru M30IM-101 10.00 7.88 3.25 4.63 M24 thru M42IM-121 12.50 9.00 3.50 4.88 M24 thru M48IM-161 16.00 12.50 4.50 5.88 M30 thru M56All dimensions in inches. *Top of mount housing to floor.<strong>UNISORB</strong> IMW Mounts for injection molding and diecasting machines. These three piece wedge mountsoffer true vertical lift with enough adjustment range tomeet the demands of most applications. In addition,the IMW Mounts come standard with high friction, oilresistant nitrile butyl rubber isolation pads. Thesemounts are ideally suited for use with machines thathave no holes in the mounting feet. IMW Mounts areavailable in two sizes, and the capacities in lbs. areindicated by the names. These mounts will allowprecise leveling of machinery, and will prevent machinesfrom walking.SPECIFICATIONSMOUNTHEIGHT*LENGTH WIDTHSERIES(min.) (max.)IMW-6000 6.23 4.26 2.00 2.50IMW-20000 10.17 6.82 3.00 3.70All dimensions in inches, and include pads.Height dimensions are shown without loads.<strong>UNISORB</strong> ® DIE TURNOVER PADS<strong>UNISORB</strong> ® DTP-24-250<strong>UNISORB</strong> Die Turnover Pads are designed to replacecreosote wood blocks or other flooring methodsin die manufacture or repair areas. The 2' x 2' x2½" thick pads provide a convenient size for handlingand placement in floors for die handling areas.Pads are fastened to the floor using <strong>UNISORB</strong> capsuleanchors for a long lasting installation.7

<strong>UNISORB</strong> ® RK FIXATOR ®ANCHORING/ALIGNMENTSYSTEMNOTE: All Fixator information in this catalogpertains to machine tool applications. Call<strong>UNISORB</strong> about the use of Fixators for PowerGeneration equipment.RK FIXATOR SYSTEMS level and align machinery to tolerancesof one ten thousandth (0.0001") and make it possibleto vary adjustments at any time, even under maximum loadsrequiring only a small hand wrench to adjust. Time consumingwork and production losses normally associated with alignmentsare eliminated.While affording the most rigid machine-to-foundation connectionavailable, other benefits include built-in compensationfor uneven areas in foundations and machine bases. Truevertical lift, made possible by a 3-piece wedge design toeliminate lateral movement as machines are raised or lowered,makes the RK FIXATOR the "state-of-the-art" anchoring/alignmentsystem.INTEGRATED SYSTEM DESIGNThough similar in appearance to conventional wedge-typeleveling equipment, RK FIXATOR SYSTEMS differ significantlyin concept and application. The RK FIXATOR is not aconventional wedge system and should not be treated as one.Alignment adjustments are made after anchor nuts havebeen tightened. In this way, the anchor bolts are tighteneduniformly to predictable stress levels by adjusting the RKFIXATOR basic unit upward prior to the final alignmentprocedure eliminating the customary torquing of anchor nuts.This gives substantial savings in time and effort normallyrequired for the installation of sophisticated machine tools.RK FIXATORS SAVE MONEY BY:• Allowing faster completion of new installations.• Decreasing frequency of, and shorten time required forfuture realignments.• Maintaining machine accuracy for longer time periods.• Decreasing required maintenance.• Ensuring maximum machine productivity.BASIC DIMENSIONSDimension RK I RK II RK III RK IV RK VDØ 2.36 2.95 3.54 4.33 5.91L 6.89 6.89 8.66 10.83 13.58B 4.13 4.72 5.91 7.09 9.06H 2.17 2.95 3.74 4.53 5.31h .20 .20 .24 .32 .40MODEL NO.LOAD RANGES (PER MOUNT)*RECOMMENDEDMACHINE STATIC WEIGHTMAXIMUM ALLOWABLELIFTING LOADRK I 2,200 lbs. 20,000 lbs.RK II 4,400 lbs. 26,500 lbs.RK III 8,800 lbs. 53,000 lbs.RK IV 13,200 lbs. 80,000 lbs.RK V 26,400 lbs. 155,000 lbs.*Contact Unisorb Engineering for application assistance.8For RK Fixator options and other detailed information ask for <strong>UNISORB</strong> Fixator System <strong>Catalog</strong>

<strong>UNISORB</strong> ®AK FIXATOR ®SYSTEM<strong>UNISORB</strong> ' s Model AKII Agile Fixator has been developedspecifically to meet industry's demand for a cost effective, truly"agile" machinery installation system.The AKII Agile Fixator is intended for use in anchorless oranchored applications and offers the capability to be quicklyconverted from one to the other without disturbing or removingthe machine base. The system can be used with resilientpads of varying stiffness and thickness to produce the vibrationisolation load deflection characteristics required by themachine builder or user.The AKII Agile Fixator's basic design incorporates the wellprovenadjusting mechanism and clamping nut torque retentionsystem of the Fixator into an updated overall mount designthat permits installation in any of six fundamentally differentways.The system may be easily converted to an anchored variationif required at a later date by the simple application of one ofthe three available anchoring techniques.Pre-layout or core drilling is not required as the anchorholes are simply drilled through the mount base afterinstallation. The use of the optional toggle clamp permitsthis to be accomplished even when overhangingmachine components prevent assess to the center orside anchor locations.• No special foundation requirements.• Final installation approach may be determined on the jobsite.• The necessity for anchor layout drawings is eliminated.• Core drilling is eliminated (unless preferred).• Anchored and non-anchored locations may be intermixedwhere necessary and are served by the same mountingsystem. Only one system needs to be specified.For AK Fixator options and other detailed information ask for <strong>UNISORB</strong> Fixator System <strong>Catalog</strong>.9

<strong>UNISORB</strong> ®PROFESSIONALENGINEERING SERVICESExpand your project team with <strong>UNISORB</strong>'s proven expertise.• Industry's most experienced staff in machinery installationdesign.• Worldwide experience in all types of equipment.• Services ranging from conceptual design assistance tofull turnkey project management.• Proven track record of innovative solutions to a widerange of installation problems.• Proven cost effective on both large and small projects.Construction documents and coordination.<strong>UNISORB</strong> provides engineered construction documents forgeneral contractors to use for bidding and construction. Theseinclude complete project specifications to assure that criticalconstruction issues are identified and completely defined. Alsoincluded is a detailed list of criteria for the inspection and approvalprocess. This documentation assures a smooth, delayfree project. We will provide complete construction management,coordination of contractors, and inspection services asdesired, assuring minimum project completion times.<strong>UNISORB</strong>'s engineering staff, the most experienced in theindustry, can provide services ranging from conceptual designto complete construction ready packages including constructionmanagement and inspection services. Whether providinga simple design review or a complete turnkey package, ourstaff is uniquely qualified to identify the critical elements of yourproject, and assure that they receive the attention they deserve.Our decades of experience creating cost effective,successful installations is at your disposal in producing aquality installation which will impact your machine's performancethroughout its useful life.Site qualifications.<strong>General</strong> design including civil/structural engineering.<strong>UNISORB</strong>'s assistance with site qualification assures that theperformance of the finished installation is predictable. On siteenvironmental vibration analysis, coupled with interpretationof basic soils and other data provides a basis for assuring thatan acceptable shock and vibration environment is establishedwithout overspending or designing solutions to nonexistentproblems.10

<strong>UNISORB</strong> ®PROFESSIONALENGINEERING SERVICESCASE HISTORY<strong>UNISORB</strong> undertook a major machine installation project withESM II of Ashland, KY. The machine was a vintage Giddings& Lewis Horizontal Boring Mill which was relocated from anothercompany. Faced with a lack of complete machine data,a site near an active railroad and an incredibly short time line,<strong>UNISORB</strong>'s Professional Engineering Services team wasselected to provide technical guidance and leadership in nearlyevery aspect of the project.Advanced engineering services.For more complex and critical installations where bothmachine and foundation are subject to large dynamicoperating forces, <strong>UNISORB</strong> can provide detailed structuralanalysis including computer modeling and finiteelement analysis. This assures that unwanted bendingand twisting in either the machine or foundation doesn'tproduce unexpected modes of vibration which adverselyaffect machine performance. These services are notrestricted to new installations, and are often very usefulin resolving problems with existing machines.The first phase was to compile data on the machine itself,drawing from <strong>UNISORB</strong>'s years of experience. Next <strong>UNISORB</strong>performed an on site vibration analysis to qualify the installationsite, and proceeded with an appropriate foundation designthat included an FEA (finite element analysis) to preciselytune the foundation's natural frequency and stiffness characteristicsto assure compatibility with those of the machine at aminimum cost.Complete construction documents were then prepared withdetailed specifications and inspection criteria to create a "bidready"package. Once the order was placed, <strong>UNISORB</strong> servedas ESM II's on site representative, assuring that documentsand critical installation procedures were followed.The project was completed within the specified time framewith a finished installation that enabled ESM II to meet productionschedule requirements.By adding <strong>UNISORB</strong>'s Professional Engineering Servicesteam to their own, ESM II assured that the best possible installationfor this important addition to their machining capabilitywas achieved at the lowest possible cost.Time resources and financial savings.Why choose <strong>UNISORB</strong>? Bottom line...<strong>UNISORB</strong> will help getyour equipment up and running faster, better and for less cost.It's our business and we are the leader! Our daily involvementin projects like yours eliminates long learning curves and assuresthat performance critical issues are addressed and notleft to chance. Whether our involvement is at the design reviewor full turnkey project level <strong>UNISORB</strong> is your best choice.Call us now at 888-4-<strong>UNISORB</strong> to discuss your project today!Construction ready package.11

<strong>UNISORB</strong>POWER GENERATIONENGINEERED PRODUCTSEach kit has its own set of engineering drawings to providethe field staff with all the necessary instructions and documentationto install a quality mounting system for the customers.Another feature of <strong>UNISORB</strong>'s mounting systems is onsite technical support. Our field engineers have what it takesto assist our customers with their machinery installation in away that assures a successful completion every time.Since 1982 <strong>UNISORB</strong> Installation Technologies has been asupplier of anchoring/alignment systems, leveling devices andgrouting materials for steam turbine installations. Our strongbackground in this field, coupled with our successful trackrecord, positions us as a leader in the industry. Our experiencepertinent to this field includes power generation, process andmanufacturing.<strong>UNISORB</strong> is the nation's leader in the manufacturing of premiumquality machinery installation systems. Our factorytrained field representatives are available during installationand system start-up to assure that maximum performance isattained.<strong>UNISORB</strong> supplies equipment for power generation equipmentmounting in kit form. These kits are designed andfurnished for each specific machine application. They includeall necessary hardware and support equipment for a completeand successful installation. A typical kit will contain groutpocket forms, grout products, foundation embedments, levelingdevices, anchor bolts and setting plates, as well as specializedtools required for major, alignment critical installations.Our grout pocket forms are unique, and make placing groutpockets simple. The form is simply slid over the anchor bolt andsecured with the top of the form even with the top of thefoundation. After the foundation is poured and stripped, the formis simply removed from the concrete by pulling up on the eye nutssupplied with it. <strong>Your</strong> grout pocket is now ready for use.The <strong>UNISORB</strong> Fixator System is utilized as the cornerstoneof the mounting packages for steam turbine installations. Thismagnificent system is capable of aligning machinery to within.0001 of an inch, and in a far shorter time than was previouslypossible using other leveling devices. One of the key featuresof the Fixator is its capability of leveling the machinery afterthe anchor nut is tightened, using only a small hand wrench.(For more information on the Fixator see page 8 of this catalog.)Needless to say, when you save time on installation you alsosave money. On some of the projects <strong>UNISORB</strong> power generationinstallation packages have been used on time savingsof up to 80% have been achieved. This amounts to significantdollar savings by our customers.<strong>UNISORB</strong> uses the latest manufacturing techniques availablefor manufacturing hardware contained in the kits. This helpsto assure high quality products - on schedule. In addition,<strong>UNISORB</strong> stocks an extensive inventory of kits for specificpower generation equipment for our customers.<strong>UNISORB</strong> uses latest manufacturing technology.<strong>UNISORB</strong> Grout Pocket Forms are unique.A large inventory of parts and kits are in stock.12

<strong>UNISORB</strong> ®POWER GENERATIONENGINEERED PRODUCTSProper packaging is an integral part of our policy toassure our customers will receive quality kits, with partidentification. No expense is spared to supply the verybest materials and workmanship on this phase of ourbusiness. <strong>UNISORB</strong> customers have been very pleasedwith our packaging procedures.<strong>UNISORB</strong> has scores of satisfied customers who havetaken advantage of our superior products and servicesover the years. Please consult with <strong>UNISORB</strong>'s PowerGeneration Engineering Department for a list of thesereferences.For more information on <strong>UNISORB</strong>'s power generationproducts call our engineers at 1-888-4-<strong>UNISORB</strong>.PROJECTED COST SAVINGS<strong>UNISORB</strong> Systems vs. Conventional Methods•REDUCED LABOR - Savings of 300 to 500 man hourson typical installations. Calendar savings of 9-14days.Packaging comes complete with part identification.•REDUCED PROJECT MANAGEMENT LABOR -Fewer people are required on job sites; Fewer supervisoryhours are required; Less personnel managementrequired; Instructions and on site technicalsupport provided by <strong>UNISORB</strong>.•REDUCED ORDERING AND QUOTING REQUIRE-MENTS - One source for all material requirements;Multiple source and component quotes are eliminated;<strong>UNISORB</strong> supplies materials to customerspecifications.•REDUCED DESIGN TIME - All embedments andgrout pockets are designed; Foundation layout andcomponent drawings are furnished and can be referencedon construction drawings.•• REDUCED REWORK - <strong>Inc</strong>reased ability to deal without of spec foundation and site preparation work;Costly rework and associated delays are minimized.Only top quality goes into <strong>UNISORB</strong> packaging.13

<strong>UNISORB</strong> ®LEV-L-INE ®MACHINERY MOUNTSLEV-L-INE mounts, with their patented, coined, malleablealigning discs, provide true self-alignment withabsolutely even load distribution over the entire bearingsurface. They are designed to compensate for unevenfloor distortion found in most industrial plants, and maybe used with or without anchor bolts.• Floor line may be sloped but machine line is level.• Easily accessible, true vertical leveling adjustment.• Patented aligning disc assures intimate contactand equal distribution of weight over entire bearingsurfaces.• Mating surfaces are machined to provide quick,easy and permanent leveling.• Anchor bolt clearance hole permits bolting machineto floor.• Machined base option available.SPECIFICATIONSLEV-L-INE MODELS LL-7 LL-22 LL-33Length 5 7 / 8 5 5 / 8 6 7 / 8Width 3 3 3 / 4 4Leveling Bolt Size M10x1.25 M16x2 M20x2.5Hex Size 10mm 24mm 30mmMaximum Adjustment3/ 16All dimensions in inches unless otherwise specified.3/ 163/ 16Minimum Height 1 5 / 8 2 27 / 32 3 11 / 32Clearance Hole 1 19 / 64 1 19 / 64 1 19 / 64Disc Diameter 4 1 / 4 4 1 / 4 4 1 / 4Load Capacity (lbs.) 7,000 22,000 33,00014

<strong>UNISORB</strong> ®TRI-WEDGE MACHINERYMOUNTS• Heavy Duty Machinery Mount System.• Two Height Ranges in One Mount.• Easily Accessible Side Adjustment.• Use For All In-Place Alignment and Leveling.• Pads Provide Vibration Isolation.• Patented Designs on Mounts and Pads.The <strong>UNISORB</strong> Tri-Wedges Mount series comes in twosizes. The TW-8000 and TW-35000 are load rated at8,000 and 35,000 lbs. respectively. These similarlydesigned Tri-Wedge Mounts both utilize two stationaryand one sliding wedge to provide mechanical lift for themounts. An adjustment bolt moves the center wedgefore & aft between the stationary wedges to provide liftto the top wedge. Each model has height ranges basedon the position of a retainer within the mounts. Theretainer (shaded in the top left illustration) can beplaced in one of two retaining sockets. Placing theretainer in the socket nearest to the adjusting bolt headmoves the mount through the lower height range. Positioningthe retainer in the rear socket moves the mountthrough the upper height range.Both models may be used either with or without pads.The pads provide excellent isolation from vibrationsbetween the machine base, the mounts and the floor.Each pad is recessed approximately 1/8 of an inch toallow for a secure fit over the edges of the top andbottom of the mounts. The thickness of the pads isapproximately 1/4 inch. The TW-35000 is available withan optional vertical stud as shown in the photo below.In addition to providing precision leveling capability,these mounts also will prevent machines from walking.SPECIFICATIONSMOUNTSERIES A B C D E FTW-8000 5.31 5.31 2.00 2.30 2.20 2.50TW-35000 9.40 8.40 2.46 2.91 2.75 3.20TW-35000WITH STUD 9.40 8.40 2.52 2.91 2.75 3.08All dimensions in inches, include pads, and may vary slightly between runs.Height dimensions shown are with no load.15

<strong>UNISORB</strong> ®INERTIA BLOCKVIBRATION ISOLATIONTo realize the full potential of your production machinery,quality control or laboratory equipment, it is necessaryto create an isolated environment that controlsvibration and provides a rigid base on which to securethe equipment and obtain accurate alignment. This environmentcan be created effectively and permanentlywith the construction of an isolated inertia block.An isolated inertia block foundation consists of a concretemass with a suitable isolator. Together theseprovide a system natural frequency which will isolatethe sensitive machine from vibrations occurring in theenvironment, and control the vibrations from a sourcemachine.The concrete mass also functions as a rigid anchoringbase, required to assure permanent alignment of themachine. This rigidity has become increasingly importantas many machine builders have replaced cast ironbases with weldments to accommodate the demand formore varied designs.<strong>UNISORB</strong> ® Isolation systems include:IB-500 isolation pads designed to employ standardfoundation construction techniques to isolate vibrationstypical to the manufacturing environment.GK Block foundation isolation, a high efficiency isolatorfor sensitive equipment or severe environments.RG-80 foundation mounts designed for high isolationwith extremely heavy loads in roll grinder and otherlarge foundation applications.VIBRATION ANALYSIS SERVICESSensitive machines in severe environments may requirean ambient vibration survey to determine exactsite conditions. <strong>UNISORB</strong> stands ready to help youdecide when this service is needed. We can work withthe vibration analysis people to assure that the datacollected is representative of actual site conditions.<strong>UNISORB</strong> also has the capacity to perform on sitesurveys of this nature. Typical surveys include a day atthe site to collect data which is recorded for later analysis.The analysis can also be performed on site ifnecessary for immediate feedback. Contact <strong>UNISORB</strong>Engineering Department for details.FOUNDATION ENGINEERINGSERVICES<strong>UNISORB</strong> has the capability of developing certifiedconstruction foundation drawings that are customizedto meet equipment support requirements. <strong>UNISORB</strong>can also offer the option of unique constructiontechniques that have been developed to help reduceinstallation costs. A Finite Element Analysis (FEA) canbe performed for each unique machine to assure thatthe dynamic characteristics of the foundation will becompatible with the machine’s operation. <strong>UNISORB</strong> canalso provide in-depth post installation machine diagnosticservices to aid in the optimization of machine operations.Contact <strong>UNISORB</strong> Engineering Department for details.<strong>UNISORB</strong> ®IB-500 FOUNDATIONISOLATION SYSTEM<strong>UNISORB</strong> isolation pad materials offer superior performancebecause they have been specifically engineeredto provide optimum use of the inertia block foundationwhile using standard construction techniques. Theseproducts are unaffected by oils, coolants, cutting fluidsand other liquids normally found in the industrial environment.<strong>UNISORB</strong> isolation pad materials are conservativelyrated, providing a life expectancy which in mostcases exceeds that of the machinery being installed.The materials are manufactured in two densities: A lessdense material, designated IB-500-S2, is used to isolatesidewalls of the inertia block; A more dense material,IB-500-B1, is applied to the base surface of thefoundation (usually two layers). Both materials are manufacturedin 1/2” thick sheets and are used in layerswhere greater thickness is desired. The material isavailable from stock in 3’ x 6’ sheets for fast delivery.Special sizes may be cut to exact dimensions at thefactory or on the job site.The isolation material is protected from moisture migratingfrom fluid concrete by a water resistant covering,which also provides a tough, abrasion and puncture-resistantsurface.Although there are several methods of installation, theproper approach depends primarily on the depth of theinertia block and condition of the soil. <strong>UNISORB</strong>’S installationengineers offer assistance in determining suitablematerials and procedures to meet specific inertiablock requirements.IB-500-B1 BASE ISOLATION 2 LAYERS REQUIREDIB-500-S2 SIDEWALL ISOLATIONPAD MATERIALNOTE:TYPICALIB-500 INERTIA BLOCKSYSTEMINERTIA BLOCK<strong>UNISORB</strong> JOINTFILLER V-100OPTIONAL PIT LINER MAYBE OMITTED IF LOCAL SOILCONDITIONS PERMIT(CONSULT <strong>UNISORB</strong>ENGINEERING)VINYL OR EQUIVALENT TAPE TO BE USED ON ALLISOLATION PAD JOINTS TO PREVENT ENTRY OFFLUID CONCRETE DURING POUR16

<strong>UNISORB</strong> ®GK BLOCK FOUNDATIONISOLATION SYSTEMLOW FREQUENCYFOUNDATION BLOCKThe GK Block is specifically used for isolating equipmentwhere low interfering frequencies are encountered.They are typically used under concrete foundationssupporting either source or sensitive machines.The highly specialized rubber compounds used, uniquegeometrical shape, and carefully controlled load deflectioncharacteristics make the GK Block an excellentlower cost alternative to installations normally requiredto reach system natural frequencies as low as 3.5 hzvertical and 1.5 hz horizontal. GK Blocks are rated from4,000 to 18,000 lbs.Examples of GK Block Applications <strong>Inc</strong>lude:• Coordinate measuring machines.• Precision optical equipment.• Precision grinders.• Vibrating conveyors.• Lab equipment.• Presses.• <strong>Equipment</strong> operating in environments of unusuallysevere shock and vibration conditions.For other Novibra products ask for <strong>UNISORB</strong> Novibra <strong>Catalog</strong>.<strong>UNISORB</strong> ®RD FOUNDATIONINSERT SYSTEMThe <strong>UNISORB</strong> RD Foundation Insert System provides aneffective means of utilizing <strong>UNISORB</strong> highly efficient lowfrequency passive isolators. The RD Foundation Insert isa cast in place access point enabling installation of avariety of isolators specifically selected for each projectenvironment. <strong>UNISORB</strong> professional engineeringdetermines the number of RD Inserts required per projectas the desired load is controlled at each RD isolatorlocation. We assure proper loading of each isolator bymeans of adjustment within the RD Foundation Insert. ThisAdjustment also enables precision elevation alignment tothe surrounding floor ensuring a smooth transition. TheRD Foundation Inserts are provided in an engineered kitthat includes all required materials with the exception ofthe concrete, simplifying the construction process andreducing construction costs.Unisorb RD Foundation Insert (Patented)TYPICAL RESULTS OF ISOLATED INERTIA BLOCKFOUNDATION ENGINEERING VIBRATION ANALYSISThe charts show a vibration survey performed by<strong>UNISORB</strong> on an existing isolated inertia blockinstallation. A grinding machine performing a roughgrind operation on a crankshaft was installed on aninertia block isolated as shown on the typical IB-500inertia block installation details. During the rough grindthe machine generated vibrations were measured onthe foundation. The left chart shows an average of 64 ofthese measurements.Vibration measurements were also taken on the concretefloor immediately surrounding the isolated foundation.The right chart shows an average of 64 of thesemeasurements which were also taken simultaneous tomeasurements on the left chart.A comparison of the two charts is a graphic illustrationof the high degree of isolation efficiency provided by<strong>UNISORB</strong> inertia block isolation materials.17

<strong>UNISORB</strong> ®V-1 ® NON-SHRINKGROUT<strong>UNISORB</strong> ® V-1 ® NON-SHRINKGROUT• Pre-Mixed.• Extra High Strength.• Non-Shrinking.• Flowable (May be pumpedand vibrated).• High Yield.• Meets ASTM C 1107.Yield per 48 lb. bag : .40 Cubic Feet.V-1 Grout is a cement-based, flowable, non-shrink groutthat develops extremely high compressive strength in ashort period of time. It can be used in any applicationrequiring high strength support and anchoring of machinery.FAST CURING FOR MINIMUM DOWN TIMEAt an ASTM flow index of 109, V-1 Grout has a strengthof approximately 6,565 psi in 24 hours. This strengthincreases gradually and reaches its maximum of 11,875psi at 28 days.HIGH QUALITY, NON-CORROSIVE,NON-SHRINKINGV-1 Grout is composed of several carefully blended sizeranges of pure silica sand, the best quality, high earlycuring portland cement and a proprietary controlledexpansion compound. V-1 Grout is unique in that it canbe extended by adding up to 50% (by weight) peagravel, thus substantially reducing material costs onlarger pours.V-1 Grout is chloride-free, has controlled expansion andwill not shrink below its original mixing volume after therecommended water ratio is added. Controlled expansionensures a full bearing contact between machinebase and foundation.<strong>UNISORB</strong> ®CONCRETE REPAIR &STRUCTURAL REPAIR<strong>UNISORB</strong> ® CONCRETEREPAIR COMPOUND• Pre-Mixed.• Fluid Consistency.• Feather Edges.• Fast Set.• Resume Normal Traffic in 1Hour or Less.• Stronger Than Concrete.• Self-Sealing.• Conveniently Packaged: 20 & 50 lb. pails; 50 lb. bags.• Extended Set Formula Available for Long WorkingTime in Hot Climate.<strong>UNISORB</strong> Concrete Repair Compound is designed foruse in making fast repairs of concrete floors, aisle waysand drives. It is also excellent for patching and fillingchuck holes and for quick setting of anchors.Depending on the application, repairs made with<strong>UNISORB</strong> Concrete Repair Compound can be used inas little as one hour. After a three hour cure it is asstrong as most concrete floors (3,900 psi compression).<strong>UNISORB</strong> Concrete Repair Compound is self-sealingand requires no sealant when used out-of-doors, unlikemost other cementitious products.<strong>UNISORB</strong> ® STRUCTURALREPAIR FORMULA<strong>UNISORB</strong> Structural Repair Formula is a cement-based,self-bonding and quick setting wall and ceiling patchingcompound. When used for patching spalls or holesbetween ½" to 3" thick, it provides a non-shrink, highstrength repair. This product does not require primers,bonding agents, etc.IMPORTANT ADVANTAGESBecause of its high load carrying capacity, <strong>UNISORB</strong> V-1Grout withstands extremely high unit loads, distributingthem over a large area. Weaker materials, such asconcrete and inferior grout may develop structural flawswhen subjected to concentrated loads that weaken themachine-foundation connection. Controlled expansionprecludes the possibility of shrinkage related voids sothat full bearing contact is ensured between the machineand its foundation. V-1 is an excellent choicewhere high ambient temperatures will be encountered.It also exhibits superior resistance to attack by strongacids and bases.V-1 Grout exceeds ASTM 1107 and Corps of EngineersSpecification for Non-Shrink Grout CRD-C 621. Testresults are available on request.18

PHYSICAL PROPERTIES<strong>UNISORB</strong> ®CEMENTITIOUSGROUTSV-1 ® <strong>UNISORB</strong> ® CONCRETE STRUCTURALPHYSICAL PROPERTIES NON-SHRINK REPAIR COMPOUND (UCRC) REPAIRCompressive Strength (psi)24 Hours 6,565 5,200 3,00028 Days (Ultimate) 11,875 8,000 5,000Tensile Strength (psi) (28 Days) 568 476 —Flexural Strength (psi) (28 Days) 1,700 1,405 1,100Allowable Thickness (Typical) 3/4" - 2" 1/16" - 2" 1/2" - 3"Working Time 45-60 minutes 11 minutes 13 minutesinitial setting timeinitial setting timeYield .83 cu. ft./100# .80 cu. ft./100# .80 cu. ft./100#SUGGESTIONS FORCEMENTITIOUS GROUTINGGrouting should be done following established concretingprocedures in accordance with the recommendations of theAmerican Concrete Institute.PREPARATION - All grout contact surfaces must be cleanedof all oil, grease, scale, etc. Unsound concrete should bechipped out, leaving surface level, but rough.ALL GROUT CONTACT SURFACES SHOULD BE PRE-SOAKED THOROUGHLY FOR 24 HOURS PRIOR TOGROUT PLACEMENT.This will insure that the existing foundation does not pull waterfrom the newly placed grout at a rapid rate, which couldinterfere with proper curing. Excess standing water should beremoved prior to grout placement. This pre-soaking requirementis particularly important when working with new “green”foundations or floors.FORMING - Must provide for rapid continuous placement ofgrout. Adequate clearance for grout placement and head mustbe provided. Adequate venting to prevent air entrapment mustalso be provided. A minimum grout thickness of 1 1 /4" underbase plates is required.MIXING - V-1 grout can be mixed in a concrete mixing pan orin an agitator-type power mixer. Follow water mixing ratiorecommended on the bag.MIX AS FOLLOWS - Add 2 / 3 water requirement. Add grout, mixpartially, then add remainder of water and mix thoroughly for2-3 minutes.PLACEMENT - V-1 can be placed by pouring or pumping. Itis recommended that the fluid material be rodded thoroughlyor vibrated to minimize the possibility of air being trapped.Place grout from one side of cavity so it flows uniformly toadjacent and opposite sides.CURING - Forms may be removed after initial set (3 to 4 hours).At this point, final finishing may be done. No capping orpainting is required.PREVENT RAPID WATER LOSS BY COVERING WITH WETBURLAP FOR 3 TO 7 DAYS AFTER INITIAL SET. (CALL<strong>UNISORB</strong> ENGINEERING WITH QUESTIONS).CURING, SEALING, AND BONDING COMPOUNDS ARENOT REQUIRED FOR MOST APPLICATIONS.POUR 2/3OF WATER1MIX3PLACEGROUT5ADDGROUT2ADDBALANCEOF WATER4VIBRATE6TEMPERATURE CONSIDERATIONSThe higher the temperature, the faster the set; the lowerthe temperature, the slower the set. Normal winter andsummer concreting procedures should be observed intemperatures below 40°F and above 90°F.Physical properties shown are the result of independent laboratory testingperformed per industry recognized test procedures. Laboratory properties aid indetermining suitability of the product for the intended application. Field test resultsmay vary due to procedures or ambient conditions such as temperature andhumidity. Laboratory reports are available on request.For detailed grouting information ask for <strong>UNISORB</strong> Grouting Products <strong>Catalog</strong>.19

<strong>UNISORB</strong> ® STANDARDV-100 ® EPOXY GROUT<strong>UNISORB</strong> ® DEEP POURV-100 ® EPOXY GROUTSTANDARD V-100 ® EPOXY GROUTDEEP POUR V-100 ® EPOXY GROUT• Permanent.• Easy Installation.• Fast Cure.• Minimum Material Usage. Less expensive thancementitious grouts for many applications.• Withstands Severe Shock Loads.• Easy Repair of Foundations and Pulled AnchorBolts.Yield per 11# Kit: 181.5 cu. in. (.10 cu. ft.).Yield per 22# Kit: 363 cu. in. (.21 cu. ft.).Yield per 55# Kit: 907.5 cu. in. (.53 cu. ft.).<strong>UNISORB</strong> Standard V-100 Epoxy Grout is a twocomponent,100% solids, filled epoxy system that curesvery rapidly at normal room temperature. It sets up atough, durable impact and vibration resistant grout whicheliminates chronic re-grouting common to manyinstallations. Pours as thin as 1 / 16 " and as thick as 1"may be made with Standard V-100 Epoxy Grout . It is aproven method of grouting, re-grouting, and anchoringhard-to-hold heavy machinery.Standard V-100 Epoxy Grout can be used to groutshears, lathes, punches, presses, grinding machines,machine tools, compressors, pumps, engines, generators,motors, crushers, grinding mill bases, truck andtrack scales, column bases, sole plates, rails, hoistbases, canning machinery, etc.<strong>UNISORB</strong> Deep Pour V-100 Epoxy Grout is made forgrouting applications where maximum cross sectionsare involved and where minimum machinery down timecan be allowed. Pours as deep as 8" can be made withthe grout while providing high flowability without compromisingstrength of the installation. The Deep PourGrout is resistant to oils, greases, acids, alkalies andsolvents to a much greater degree than cementitiousmaterials. Tensile and flexural strengths are at leasteleven times that of concrete and the compressivestrength is about four times that of concrete.Shipped in pre-measured one cubic foot kits, the groutkits contain individually packaged components: 1. BaseResin; 2. Hardener; 3. Two bags of Blended Aggregate.The hardener and aggregate are mixed with the baseresin at the job site.The grout is self-leveling and will flow into spaces undermachines to fill voids completely before solidifying. At70°F, an 8" pour of epoxy grout will be ready to use in 24hours @ 11,000 psi.The Deep Pour V-100 Epoxy Grout provides a costeffective solution to large volume, thick cross sectionpours in grouting, re-grouting and in anchoring hard-toholdmachinery. The three part formula is easy to mix onthe job site and the formulation simplifies most equipmentinstallations. Up to 14,000 psi compressivestrengths may be attained.PHYSICAL PROPERTIES STANDARD V-100 ® DEEP POUR V-100 ® DCR V-100 ® ADHESIVE V-100 ®Compressive Strength (psi)6 Hours 9,000 — 11,200 —3 Days 15,250 11,600 16,700 —7 Days (Ultimate) 16,800 14,000 20,000 14,000Tensile Strength (psi) 4,800 1,536 3,000 5,200Flexural Strength (psi) 6,800 4,600 6,000 11,000Allowable Thickness (Typical)1/16" - 1" 1" - 8" ¾" - 8" 1/32" - ¼"Working Time 10-15 minutes 60 minutes 40 minutes 45 minutesYield 16.5 cu. in. per lb. 1 cu. ft. (1,728 cu. in. per kit) 1 cu. ft./kit 450 cu. in./kit20For detailed grouting information ask for <strong>UNISORB</strong> Grouting Products <strong>Catalog</strong>.

<strong>UNISORB</strong> ® DCR V-100 ® GROUTADHESIVE V-100 ® GROUTJOINT FILLER V-100 ®<strong>UNISORB</strong> ® DCR V-100 ®(ACID RESISTANT) EPOXY GROUT<strong>UNISORB</strong> DCR V-100 (Acid Resistant) Epoxy Grout is athree component, 100% solids epoxy resin system. It isspecifically designed for applications requiring highmechanical strength due to high unit loading typical indie cart rail and crane rail systems. Its tremendouscompressive strength characteristic makes it ideallysuited for in-plant rail installations of all types. It ischemically inert, and therefore resistant to HydrochloricAcid, Sulfuric Acid, Nitric Acid, Sodium Hydroxide, TSPDetergent and Kerosene.<strong>UNISORB</strong> DCR V-100 (Acid Resistant) Epoxy Grout isformulated for medium thickness pours. It is recommendedfor applications varying from approximately 3 /4" to 8"cross sections. Flow characteristics of DCR V-100 alloweasy placement within this thickness range. Convenientlypackaged in 1 / 2 cu. ft. and 1 cu. ft. kits.<strong>UNISORB</strong> ® ADHESIVE V-100 ®EPOXY GROUT• Paste Consistency.• Bonds to Most Surfaces.• One to One Mix Ratio.• Short Cure Time.This is a general purpose industrial adhesive for usesin bonding, filling, patching and in temporary and permanentmachinery installations.A two gallon kit consists of two 1 gallon cans providing450 cu. in. of material. With a 1:1 mix ratio you need useonly as much as is required. Reseal the cans of unmixedadhesive for future applications.<strong>UNISORB</strong> ® JOINT FILLER V-100 ®• Remains Flexible.• Seals Out Liquids.• Tough and Puncture Resistant.• Keeps Out Chips and Debris.• Promotes Good Housekeeping.• Convenient Kit <strong>Inc</strong>ludes Mixing Paddle, Pail, Resinand Hardener.Yield: 432 cu. in.Recommended to fill and seal the exposed top edge of<strong>UNISORB</strong> foundation isolation materials. Also useful tofill and seal saw cut control joints in concrete floors.SPECIALIZED V-100 ® EPOXYGROUTING PRODUCTSV-100 epoxy grouting products are also available withthese special features:Low-Temp Air Temperatures from 25°F to 65°FHi-Temp Up to 325°F Service TemperatureXtra-Temp Up to 425°F Service TemperatureCR Hi Flow For indoor or outdoor crane rail applicationswhere extreme loads are encountered.<strong>UNISORB</strong> ®GROUT FORMSAND SEALANT<strong>UNISORB</strong> ® GROUT FORMSAND SEALANT<strong>UNISORB</strong> Grout Forms are designed to reduce the timerequired to pour grouting materials for machinerymounting bases. The easy-to-use plastic Grout Formseliminate on site forms construction while providing foruniformity in size, shape and thickness of poured groutbases. Forms are easy to remove after grout has set bysimply cutting the plastic form with a knife and removing.Square Grout Forms are available in 9" and 11" sizes. A12" x 15" rectangular form is also available. The 9"forms are available in heights up to 8" and are designedfor use with <strong>UNISORB</strong> Model RK-I Fixators. The 11"forms are made in heights up to 10" and are for use with<strong>UNISORB</strong> Model RK-II and RK-III Fixators. The 12" x15" forms are available in heights up to 11" and are foruse with the RK-IV and RK-V Fixators.Supplied with the Grout Forms is a high-tack butylrubber sealant in roll form which is applied to the baseof the Grout Forms. When the Grout Forms are pressedinto position on a clean, dry foundation the sealantprevents the grout from leaking under the form. Sealantrequires no cure time and grout can be poured immediatelyafter forms are in position. Application temperaturefor the sealant is from 20°F to 120°F. Excesssealant can be removed from cured grout with mineralspirits.Grout Forms assure excellent results when used with all<strong>UNISORB</strong> Grouts.For detailed grouting information ask for <strong>UNISORB</strong> Grouting Products <strong>Catalog</strong>.21

<strong>UNISORB</strong> ®JAKEBOLT ®HEAVY DUTY ANCHOR BOLTSAdjustableprojection to6" or 12" maxBolt is alwaysverticalregardless oflocation insleeve100% Steelhousing.CompletelywatertightALL STEEL HOUSING7½" x 7½" x 2½"TUBE DIA. "D"ACCentralizingbushingLaterallyadjustableStandard boltdiametersfrom ½" to 2"High tensilestrengthanchor & studassemblyBHeavy Duty JAKEBOLTS offer a truly cost effective way toprovide strong, problem-free, high quality anchors for virtuallyany concrete foundation/machinery application. They are designedto be hung from a template or welded directly to reinforcingsteel, then cast in place during new foundationcontruction.Constructed entirely of steel, the Heavy Duty JAKEBOLTSare tough, durable, and MIG welded watertight to prevent contaminationof internal components during installation. EachJAKEBOLT comes supplied with a centralizing bushing whichdoubles as a seal and protects against contamination duringgrouting. JAKEBOLTS are manufactured with retractable studsto allow a "Clear Floor" condition at any time. Anchor studscan be adjusted to project above the floor from 0" to 6" or from0" to 12", depending on the bolt specified for the installation.The entire internal anchor assembly can be adjusted laterallyas well as vertically to compensate for normal constructionvariances in both hole location and machine foot thickness.The Heavy Duty JAKEBOLT incorporates 90,000 psi tensilestrength steel in the bolts. The all-steel anchor assembly isdesigned for service under the most severe conditions. Specialversions of the Heavy Duty JAKEBOLT are available uponrequest by consulting <strong>UNISORB</strong> Engineering.SPECIFICATIONSModel Projection Over-All Top Tube Tube Total BoltBolt Above Length Length Dia. CenterlineSize Floor "A" "B" "C" "D" Movement½ x 6 0-6 20 11½ 2½ 1¾5/8 x 6 0-6 20 11½ 2½ 1½¾ x 6 0-6 20 11½ 2½ 1½7/8 x 6 0-6 20 11½ 2½ 1¼1 x 6 0-6 20 11½ 2½ 1¼1¼ x 6 0-6 20 11½ 2½ 11½ x 6 0-6 20 11½ 2½ ¾1¾ x 6 0-6 26½ 18 3¼ 1¼2 x 6 0-6 26½ 18 3¼ 15/8 x 12 0-12 25 3 / 4 11½ 2½ 1½¾ x 12 0-12 25 3 / 4 11½ 2½ 1½7/8 x 12 0-12 25 3 /4 11½ 2½ 1¼1 x 12 0-12 25 3 /4 11½ 2½ 1¼1¼ x 12 0-12 25 3 /4 11½ 2½ 11½ x 12 0-12 25 3 /4 11½ 2½ ¾1¾ x 12 0-12 32¼ 18 3¼ 1¼2 x 12 0-12 32¼ 18 3¼ 1All dimensions in inches.22

<strong>UNISORB</strong> ®JAKEBOLT ®HEAVY DUTY ANCHOR BOLTSCASE HISTORY<strong>UNISORB</strong> ®VECTOR ANCHOR BOLTSMade from high quality forged steel, VECTOR BOLTShave a series of angular facets which resolve verticalstress forces into a cone-shaped pressure pattern. Anadvantage of this unique design is the increased contactarea between the bolt and the grout. The wedgeshaped design on the bottom of the bolt transfers thetensile load of the stud into a lateral compressional loadin the foundation assuring maximum pull out strengths.The increase in load transfer to the foundation results ina reduction of the embedment depth required to obtainfull strength of the anchor. This reduction in requiredembedment depth lowers the installation cost by reducingthe core drilling and grouting requirements.VECTOR BOLTS are available in the diameters andlengths shown below in a 90,000 PSI minimum tensilestrength material.JAKEBOLT ANCHORSA large metalworking facility involved in the manufacturingof oil field equipment installed their machinesusing <strong>UNISORB</strong> Heavy Duty JAKEBOLT Anchors.JAKEBOLTS are installed when the foundations arepoured. This approach offered the following advantagesover previously used methods:• No expertise in grouting techniques are required bythe installation crew.• The foundation does not require special preparationsuch as pre-cast holes and pre-wetting.• There is no time delay to allow the grout to curewhen setting machines.Several machines have been installed successfullyusing this method and the company has been verysatisfied with the results. Use of all-steel Heavy DutyJAKEBOLTS has become the standard installationmethod for this company.<strong>UNISORB</strong> ®VECTOR ANCHOR BOLTSSPECIFICATIONSmm BASIC DIMENSIONSTYPE INCH d b a c wSTANDARD LENGTH "L"EM- mm 12 30 24 70 19 150 200 - - - -inch121(Ref.)/2 1 3 /16 1 2 3 /4 .75 6 8 - - - -EM- mm 16 40 32 90 24 150 200 250 300 360 -inch165(Ref.)/8 1 5 /8 1 1 /4 3 1 /2 .94 6 8 10 12 14 -EM- mm 20 50 40 100 30 200 250 300 360 400 460inch203(Ref.)/4 2 1 1 /2 4 1.2 8 10 12 14 16 18EM- mm 24 60 48 135 36 300 360 400 460 - -inch2415(Ref.)/16 2 3 /8 1 7 /8 5 3 /8 1.4 12 14 16 18 - -EM- mm 30 75 60 150 46 300 400 460 600 - -inch30(Ref.) 1 3 /16 3 2 3 /8 6 1.8 12 16 18 24 - -EM- mm 36 90 72 180 55 400 600 - - - -inch36(Ref.) 1 7 /16 3 1 / 2 2 7 /8 7 2.2 16 24 - - - -Other sizes & lengths available. Contact <strong>UNISORB</strong> Engineering.23

<strong>UNISORB</strong> ®CAPSULE ANCHORSYSTEMS24

INSTALLINGMACHINETOOLSWORK PIECEWORKTABLECOLUMNSPINDLERUNWAYHere’s what to consider:First, determine if the machine requires anchoring.Before designing a foundation for a particular machine tool,two questions must be answered:1) Does the machine require support from its foundation tomaintain alignments between machine elements?2) Will shock and vibration isolation be required to assure thedesired levels of finish quality and accuracy?An excellent example of a machine that requires a largeamount of support to operate properly is the above illustratedhorizontal-boring mill. In this application, the only connectionbetween the machine column and work table (and hencespindle and work piece) is the floor or foundation.In designing the foundation for an alignment-critical machine,these factors are important:1) Foundation thickness. The stiffness of a foundation varieswith the cube of its thickness. The stiffer the required support,the more concrete required.2) All machine elements should be mounted on the samefoundation block.3) Local soil conditions must be taken into account to assurethat the foundation will be stable on the soil on which it isplaced.Second, use correct foundation reinforcing designs andadequate methods of anchoring for the equipment beinginstalled.In order for the foundation to become an integral part of themachine tool structure, a connection of adequate rigidity mustbe provided. In many types of machinery, a means of adjustingthe relationship of the machine base to the foundation is alsonecessary.Several approaches may be followed:1. Anchor Bolts and Shims: (generally inadequate wherealignment requirements are critical.)2. Leveling Screws: provide for faster adjustment than theshimming methods, but there is a tendency for machines to“creep” under load and for adjustments to be difficult and timeconsuming.3. Anchor Bolts and Grout: provide strong, continuous rigidsupport between the machine and the foundation. Grouting isused to assure that the voids between the machine base andthe foundation surface are completely filled, and to spreadconcentrated loads over a larger area.4. Leveling Wedges: provide a more rigid support than doesthe leveling screw. The most elementary of these is a twopiecewedge. Three-piece wedges provide greater mechanicaladvantage and permit more precise alignment. The<strong>UNISORB</strong> LEV-L-INE for general purpose installation andFIXATOR SYSTEM for high precision requirements are excellentchoices.Third, isolate support critical machines.The first step involves carefully evaluating the environmentinto which the machine is to be placed.For support critical machines (and for non-support criticalmachines when high amplitude and low frequency vibrationsare involved) an isolated inertia block foundation is the bestsolution. The concrete foundation is isolated from the rest ofthe environment. Limiting the transmission of shock and vibrationfrom the environment to the machine or, in the case of asource machine, from the machine to the environment is thegoal.Either IB-500 isolation material or rubber GK Blocks may beused.The IB-500 isolation material approach can be carried outusing normal construction practices and is substantiallyless involved. The GK Block approach is used for naturalfrequency requirements in the 4hz range. Using eithermethod, an isolation efficiency of over 90% is usuallyattainable.Fourth, be sure the machine that is non-support critical ismounted properly.If you determine a machine is non-support critical, it is stilldesirable to provide some sort of mounting device to complywith OSHA requirements, to permit the machine to beleveled easily, prevent “walking,” and isolate from shock andvibration. This can usually be accomplished by the use of afree standing mount, such as <strong>UNISORB</strong> LR Series.CONCLUSIONCorrect installation is second in importance only to theproper selection of the machine tool itself in guaranteeingoptimum performance from a piece of equipment, and aproper return on invested capital.When you realize that correctly installing a machine toolrarely costs more than one percent of the total value of themachine, it’s false economy not to spend the time andmoney necessary to make the proper installation.By taking advantage of <strong>UNISORB</strong>’s products and engineering,you can be sure that your machine will be correctlyinstalled.For a more complete discussion of machinery installation,request <strong>UNISORB</strong>’S BULLETIN: “Preventing MachineInstallation Problems,” along with information on a freeseminar in your plant.

MACHINEINSTALLATION EXPERTISE SINCE 1935Since 1935, <strong>UNISORB</strong> has been serving the machineryinstallation needs of all segments of the manufacturingindustry. As part of our commitment to provide the bestinstallation products and services, <strong>UNISORB</strong> maintainsthe only industry staff of engineers devoted exclusivelyto the design and implementation of complete machineryinstallation systems. From concept to final installation,<strong>UNISORB</strong> ensures optimum performance of mountedequipment.Depend on <strong>UNISORB</strong>ʼsyears of experiencefor:•••••••Machinery MountsVibration Isolation SystemsAnchoring/Alignment SystemsVibration Analysis ServicesProfessional Engineering ServicesIsolated Foundation DesignAdvanced Grouting TechnologiesISO-9001:2000 Certified