UFGS 09 30 13 Ceramic Tiling - The Whole Building Design Guide

UFGS 09 30 13 Ceramic Tiling - The Whole Building Design Guide

UFGS 09 30 13 Ceramic Tiling - The Whole Building Design Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

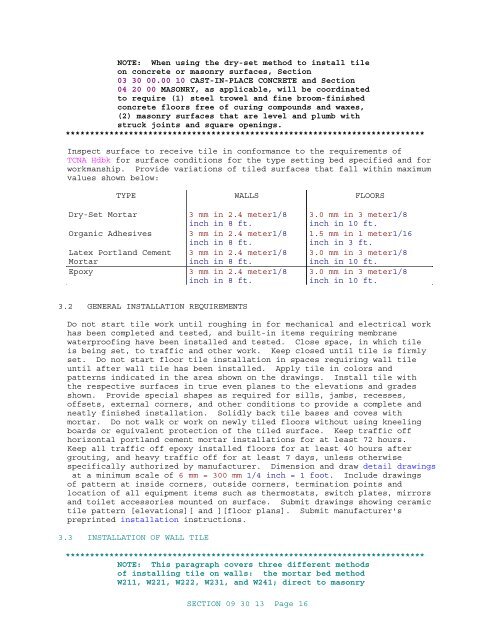

NOTE: When using the dry-set method to install tileon concrete or masonry surfaces, Section03 <strong>30</strong> 00.00 10 CAST-IN-PLACE CONCRETE and Section04 20 00 MASONRY, as applicable, will be coordinatedto require (1) steel trowel and fine broom-finishedconcrete floors free of curing compounds and waxes,(2) masonry surfaces that are level and plumb withstruck joints and square openings.**************************************************************************Inspect surface to receive tile in conformance to the requirements ofTCNA Hdbk for surface conditions for the type setting bed specified and forworkmanship. Provide variations of tiled surfaces that fall within maximumvalues shown below:TYPE WALLS FLOORSDry-Set MortarOrganic AdhesivesLatex Portland CementMortarEpoxy3 mm in 2.4 meter1/8inch in 8 ft.3 mm in 2.4 meter1/8inch in 8 ft.3 mm in 2.4 meter1/8inch in 8 ft.3 mm in 2.4 meter1/8inch in 8 ft.3.0 mm in 3 meter1/8inch in 10 ft.1.5 mm in 1 meter1/16inch in 3 ft.3.0 mm in 3 meter1/8inch in 10 ft.3.0 mm in 3 meter1/8inch in 10 ft.3.2 GENERAL INSTALLATION REQUIREMENTSDo not start tile work until roughing in for mechanical and electrical workhas been completed and tested, and built-in items requiring membranewaterproofing have been installed and tested. Close space, in which tileis being set, to traffic and other work. Keep closed until tile is firmlyset. Do not start floor tile installation in spaces requiring wall tileuntil after wall tile has been installed. Apply tile in colors andpatterns indicated in the area shown on the drawings. Install tile withthe respective surfaces in true even planes to the elevations and gradesshown. Provide special shapes as required for sills, jambs, recesses,offsets, external corners, and other conditions to provide a complete andneatly finished installation. Solidly back tile bases and coves withmortar. Do not walk or work on newly tiled floors without using kneelingboards or equivalent protection of the tiled surface. Keep traffic offhorizontal portland cement mortar installations for at least 72 hours.Keep all traffic off epoxy installed floors for at least 40 hours aftergrouting, and heavy traffic off for at least 7 days, unless otherwisespecifically authorized by manufacturer. Dimension and draw detail drawingsat a minimum scale of 6 mm = <strong>30</strong>0 mm 1/4 inch = 1 foot. Include drawingsof pattern at inside corners, outside corners, termination points andlocation of all equipment items such as thermostats, switch plates, mirrorsand toilet accessories mounted on surface. Submit drawings showing ceramictile pattern [elevations][ and ][floor plans]. Submit manufacturer'spreprinted installation instructions.3.3 INSTALLATION OF WALL TILE**************************************************************************NOTE: This paragraph covers three different methodsof installing tile on walls: the mortar bed methodW211, W221, W222, W231, and W241; direct to masonrySECTION <strong>09</strong> <strong>30</strong> <strong>13</strong> Page 16