Polyethylene Pressure Pipe

Polyethylene Pressure Pipe

Polyethylene Pressure Pipe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

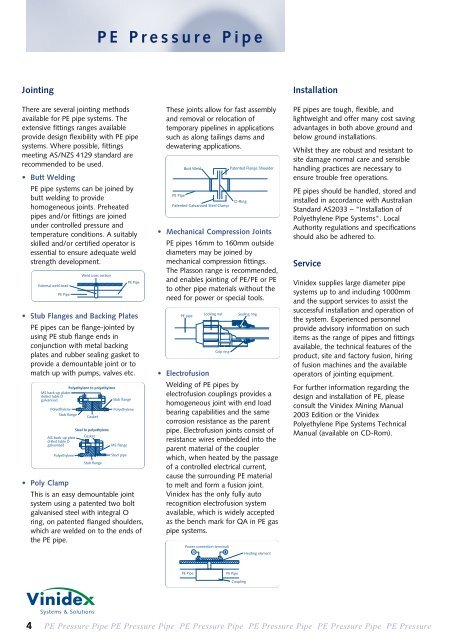

PE <strong>Pressure</strong> <strong>Pipe</strong>JointingThere are several jointing methodsavailable for PE pipe systems. Theextensive fittings ranges availableprovide design flexibility with PE pipesystems. Where possible, fittingsmeeting AS/NZS 4129 standard arerecommended to be used.• Butt WeldingPE pipe systems can be joined bybutt welding to providehomogeneous joints. Preheatedpipes and/or fittings are joinedunder controlled pressure andtemperature conditions. A suitablyskilled and/or certified operator isessential to ensure adequate weldstrength development.• Stub Flanges and Backing PlatesPE pipes can be flange-jointed byusing PE stub flange ends inconjunction with metal backingplates and rubber sealing gasket toprovide a demountable joint or tomatch up with pumps, valves etc.• Poly ClampThis is an easy demountable jointsystem using a patented two boltgalvanised steel with integral Oring, on patented flanged shoulders,which are welded on to the ends ofthe PE pipe.These joints allow for fast assemblyand removal or relocation oftemporary pipelines in applicationssuch as along tailings dams anddewatering applications.• Mechanical Compression JointsPE pipes 16mm to 160mm outsidediameters may be joined bymechanical compression fittings.The Plasson range is recommended,and enables jointing of PE/PE or PEto other pipe materials without theneed for power or special tools.• ElectrofusionWelding of PE pipes byelectrofusion couplings provides ahomogeneous joint with end loadbearing capabilities and the samecorrosion resistance as the parentpipe. Electrofusion joints consist ofresistance wires embedded into theparent material of the couplerwhich, when heated by the passageof a controlled electrical current,cause the surrounding PE materialto melt and form a fusion joint.Vinidex has the only fully autorecognition electrofusion systemavailable, which is widely acceptedas the bench mark for QA in PE gaspipe systems.InstallationPE pipes are tough, flexible, andlightweight and offer many cost savingadvantages in both above ground andbelow ground installations.Whilst they are robust and resistant tosite damage normal care and sensiblehandling practices are necessary toensure trouble free operations.PE pipes should be handled, stored andinstalled in accordance with AustralianStandard AS2033 – "Installation of<strong>Polyethylene</strong> <strong>Pipe</strong> Systems". LocalAuthority regulations and specificationsshould also be adhered to.ServiceVinidex supplies large diameter pipesystems up to and including 1000mmand the support services to assist thesuccessful installation and operation ofthe system. Experienced personnelprovide advisory information on suchitems as the range of pipes and fittingsavailable, the technical features of theproduct, site and factory fusion, hiringof fusion machines and the availableoperators of jointing equipment.For further information regarding thedesign and installation of PE, pleaseconsult the Vinidex Mining Manual2003 Edition or the Vinidex<strong>Polyethylene</strong> <strong>Pipe</strong> Systems TechnicalManual (available on CD-Rom).4 PE <strong>Pressure</strong> <strong>Pipe</strong> PE <strong>Pressure</strong> <strong>Pipe</strong> PE <strong>Pressure</strong> <strong>Pipe</strong> PE <strong>Pressure</strong> <strong>Pipe</strong> PE <strong>Pressure</strong> <strong>Pipe</strong> PE <strong>Pressure</strong>