TT_Vol3 Issue2 - Raytheon

TT_Vol3 Issue2 - Raytheon

TT_Vol3 Issue2 - Raytheon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESIGN FOR SIX SIGMA -<br />

CRITICAL PARAMETERS MANAGEMENT –<br />

DESIGNING WHAT THE CUSTOMER WANTS<br />

Integrated Defense Systems (IDS) is proactively<br />

and aggressively using Design for Six<br />

Sigma (DFSS) as an important new method<br />

of managing the performance parameters<br />

most important to our customers. Since<br />

many engineers don’t have frequent contact<br />

with customers, how can they ensure<br />

that their designs really meet customer<br />

needs? Skip Creveling, author of Design for<br />

Six Sigma in Technology and Product<br />

Development states: “Few things focus a<br />

team on the most important customer<br />

needs, product requirements, design<br />

parameters, performance metrics and deliverables<br />

for a product’s success better than<br />

Critical Parameter Management (CPM)”.<br />

What is CPM? How does it relate to DFSS?<br />

CPM is the process of defining and managing<br />

the performance parameters most<br />

important to the customer in a predictive,<br />

proactive and robust manner.<br />

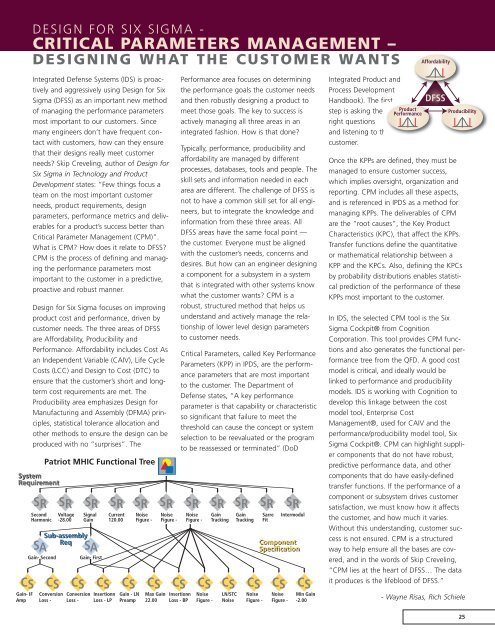

Design for Six Sigma focuses on improving<br />

product cost and performance, driven by<br />

customer needs. The three areas of DFSS<br />

are Affordability, Producibility and<br />

Performance. Affordability includes Cost As<br />

an Independent Variable (CAIV), Life Cycle<br />

Costs (LCC) and Design to Cost (DTC) to<br />

ensure that the customer’s short and longterm<br />

cost requirements are met. The<br />

Producibility area emphasizes Design for<br />

Manufacturing and Assembly (DFMA) principles,<br />

statistical tolerance allocation and<br />

other methods to ensure the design can be<br />

produced with no “surprises”. The<br />

Performance area focuses on determining<br />

the performance goals the customer needs<br />

and then robustly designing a product to<br />

meet those goals. The key to success is<br />

actively managing all three areas in an<br />

integrated fashion. How is that done?<br />

Typically, performance, producibility and<br />

affordability are managed by different<br />

processes, databases, tools and people. The<br />

skill sets and information needed in each<br />

area are different. The challenge of DFSS is<br />

not to have a common skill set for all engineers,<br />

but to integrate the knowledge and<br />

information from these three areas. All<br />

DFSS areas have the same focal point —<br />

the customer. Everyone must be aligned<br />

with the customer’s needs, concerns and<br />

desires. But how can an engineer designing<br />

a component for a subsystem in a system<br />

that is integrated with other systems know<br />

what the customer wants? CPM is a<br />

robust, structured method that helps us<br />

understand and actively manage the relationship<br />

of lower level design parameters<br />

to customer needs.<br />

Critical Parameters, called Key Performance<br />

Parameters (KPP) in IPDS, are the performance<br />

parameters that are most important<br />

to the customer. The Department of<br />

Defense states, “A key performance<br />

parameter is that capability or characteristic<br />

so significant that failure to meet the<br />

threshold can cause the concept or system<br />

selection to be reevaluated or the program<br />

to be reassessed or terminated” (DoD<br />

Integrated Product and<br />

Process Development<br />

Handbook). The first<br />

step is asking the<br />

right questions<br />

and listening to the<br />

customer.<br />

Once the KPPs are defined, they must be<br />

managed to ensure customer success,<br />

which implies oversight, organization and<br />

reporting. CPM includes all these aspects,<br />

and is referenced in IPDS as a method for<br />

managing KPPs. The deliverables of CPM<br />

are the “root causes”, the Key Product<br />

Characteristics (KPC), that affect the KPPs.<br />

Transfer functions define the quantitative<br />

or mathematical relationship between a<br />

KPP and the KPCs. Also, defining the KPCs<br />

by probability distributions enables statistical<br />

prediction of the performance of these<br />

KPPs most important to the customer.<br />

In IDS, the selected CPM tool is the Six<br />

Sigma Cockpit® from Cognition<br />

Corporation. This tool provides CPM functions<br />

and also generates the functional performance<br />

tree from the QFD. A good cost<br />

model is critical, and ideally would be<br />

linked to performance and producibility<br />

models. IDS is working with Cognition to<br />

develop this linkage between the cost<br />

model tool, Enterprise Cost<br />

Management®, used for CAIV and the<br />

performance/producibility model tool, Six<br />

Sigma Cockpit®. CPM can highlight supplier<br />

components that do not have robust,<br />

predictive performance data, and other<br />

components that do have easily-defined<br />

transfer functions. If the performance of a<br />

component or subsystem drives customer<br />

satisfaction, we must know how it affects<br />

the customer, and how much it varies.<br />

Without this understanding, customer success<br />

is not ensured. CPM is a structured<br />

way to help ensure all the bases are covered,<br />

and in the words of Skip Creveling,<br />

“CPM lies at the heart of DFSS… The data<br />

it produces is the lifeblood of DFSS.”<br />

- Wayne Risas, Rich Schiele<br />

25