BuBBledecK Product guide - Armtec

BuBBledecK Product guide - Armtec

BuBBledecK Product guide - Armtec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

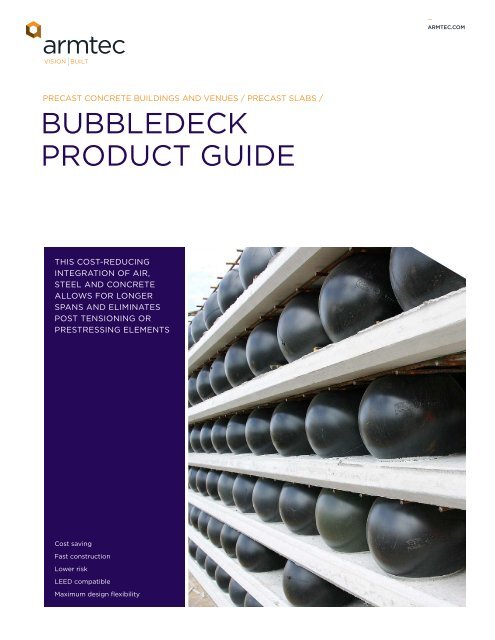

_ARMTEC.COMPrecast Concrete Buildings and Venues / Precast Slabs /BUBBLEDECKPRODUCT GUIDEthis cost-reducingintegration of air,steel and concreteallows for longerspans and eliminatespost tensioning orprestressing elementsCost savingFast constructionLower riskLEED compatibleMaximum design flexibility

_BUBBLEDECKOur BubbleDeck precast floor system is comprised of large plastic balls insertedinto a steel lattice, into which concrete is poured. The floor maintains its full biaxialstrength but requires less concrete, thus indirectly reducing carbon emissions fromthe manufacture of cement.While typical dimensions are 2.4 to 4.2m wide and 9 to 14m long, BubbleDeckslabs are tailored for each project to minimize required quantities and overall cost.Cost savingRequires up to 35% less concrete thantraditional concrete structuresGreen attributesUses less construction materials,consumes less energy, and emits less CO 2_TYPICAL APPLICATIONS• Offices• Educational and institutional buildings• Hotels• Condominiums and apartments_AVAILABILITYContact your <strong>Armtec</strong> representativefor availability in your area.Fast constructionVirtually no formwork, no downturnbeams or drop heads and fastcoverage of up to 35m² per panelReduced health and safety risksOff-site manufacturing, fewer vehiclemovements and crane lifts, and asimple installation processINSTALLATIONPROP1. Temporary Shoring Typically 2m spacing.PLACE2. Place Elements Semi-precast panels lifted into position.3. Joint Reinforcement Reinforce loose straight splice bars and shearsacross the columns.POUR4. Preparation Seal joints, clean and moisten precast concrete layer.5. Concreting Pour, vibrate and float.6. Temporary Work Remove, typically after 1 or 2 weeks, according tospecific site advice.York UniversityLife Sciences BuildingBubbleDeck was engaged for York University’sLife Sciences Building because of the largerspans achieveable from a site-cast concretestructure, without the need for post tensioningor prestressed elements. Using BubbleDeckreduced the overall construction time, andenabled the consultants to fast-track the designwithout the finalized interior programming. Thetotal timeline from design inception to structurecompletion was less than twelve months. Thecontractor was able to set over 6,000m² in afour week period, completing the concretestructure before the start of fall classes.

_BUBBLEDECKSPECIFICATIONSBubbleDeck slabs are suitable for use in all building types—especially open floordesigns such as commercial, educational and institutional buildings. Although thetechnology can be adjusted to suit almost any slab arrangement, experience—gained over more than 400 completed projects around the world—shows thatmost building functions fall into the slab categories shown in the table below.Experience also shows the most cost effective application of BubbleDeck technologyis through semi-precast elements. On most projects, this approach eliminates over95% of the slab formwork required of a traditional concrete structure.A BubbleDeck slab edge technique eliminates virtually all edge formwork andincorporates a safety rail. Workers aren’t exposed to a work site situation requiringfall arrest around the building edge. This technique also allows accurate setting ofbuilding envelope anchors (precast anchors, curtain wall pockets and threadedinserts to attach brick ledgers).The sizes of the elements are tailored to each project to minimize the numberrequired, reducing overall cost. Note: this may be limited by local transportation.BUBBLEDECK SLABSGeometry Parameters and SpansType ThicknessBallDiameter Span MassConcreteOn Sitemm mm m kg/m² m³/m²BD230 230 180 7 - 10 370 .10BD280 280 225 8 - 12 460 .14BD340 340 270 9 - 14 550 .18BD390 390 315 10 - 16 640 .20BD450 450 360 11 - 18 730 .25_NOTE• The slab types in the table can beapplied over the range of spans andstrength in the graph.• The final design will dictate theultimate choice of slab and reinforcing.Moment Strength kNm/m400350300250200150100500170 230 280 340 390 4501917151311975Span mø8-12/75 ø10-16/100 ø12-18/125 ø14-20/150 ø16-22/175 ø18-25/200Slab Thickness mm

_BUBBLEDECK<strong>Armtec</strong> is a leading Canadian infrastructure and construction materials company combining creativeengineered solutions, relevant advice, dedicated people, proven products and a national presence witha local focus on exceptional customer service.1-877-5-ARMTEC | ARMTEC.COMPROD-C05-G06-P01_PG-2011-11-E<strong>Armtec</strong> / <strong>Product</strong>s and Services / Precast Concrete Buildings and Venues / Precast Slabs / BubbleDeck / <strong>Product</strong> Guide | 2011-11