Mini-span Bridges / technical guide - Armtec

Mini-span Bridges / technical guide - Armtec

Mini-span Bridges / technical guide - Armtec

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

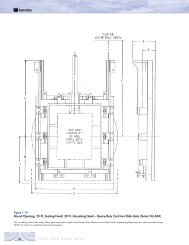

mini-<strong>span</strong> bridges_NOTE• Obtaining permits for diversionwork(s) and installation of themini-<strong>span</strong> are the responsibilityof the owner• For design of foundation/footing call<strong>Armtec</strong> for un-factored footing loads• Foundation should be investigated byqualified local geo<strong>technical</strong> engineerINSTALLATION OF mini-<strong>span</strong> bridgeINSTALLATION1. Foundation PreparationA properly prepared foundation, to support the footing plates, is essential fora successful <strong>Mini</strong>-Span installation. The elevation, grade and alignment of thefooting plates are dependant on the foundation.Foundation material of poor or non-uniform bearing capacity must beremoved to prevent differential footing settlement. Replacement foundationsoils must provide a uniform and relatively yielding support.2. Footing Design<strong>Mini</strong>-Span structures are typically designed so that the footing plates beardirectly on the foundation or bedding. If required, a concrete footing should bedesigned by a local qualified structural engineer, using available soils data,un-factored footing loads provided by <strong>Armtec</strong>, and appropriate design methods.It’s the responsibility of the owner to determine the scour line of the creek, andposition the footings and detail rock armour accordingly.3. Assembly and Installation<strong>Mini</strong>-Span structures are preassembled and lifted into place on the preparedfoundation. The total assembled weight of the structure is noted on the Bill ofMaterial. Factory installed lifting lugs are provided. Slings must be of sufficientlength such that the lifting angle is no flatter than a 1 (horizontal): 2 (vertical)slope, to prevent overstressing the lifting lugs.If concrete footings are required, the <strong>Mini</strong>-Span is lowered onto the cast-inplaceor precast footings after they are installed to the correct grade andalignment. Holes shall be drilled into the top surface of the footings, matchingthe holes pre-drilled in the footing plate. The footing plate is then bolted to thefooting using 12.5mmø x 100lg anchor bolts.4. Backfill and Footing ProtectionTo protect the critical backfill, a geotextile should be placed on the outside ofthe structure, over the granular foundation and footing plate. To protect thefootings and foundation from scour, a layer of angular armour rock/rip rapshould be placed inside the structure, above the footing plates. The owner’sengineer shall make site specific recommendations for scour protection.mini-<strong>span</strong> bridge