Tunnelling is our business - ALPINE Bau Gmbh

Tunnelling is our business - ALPINE Bau Gmbh

Tunnelling is our business - ALPINE Bau Gmbh

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

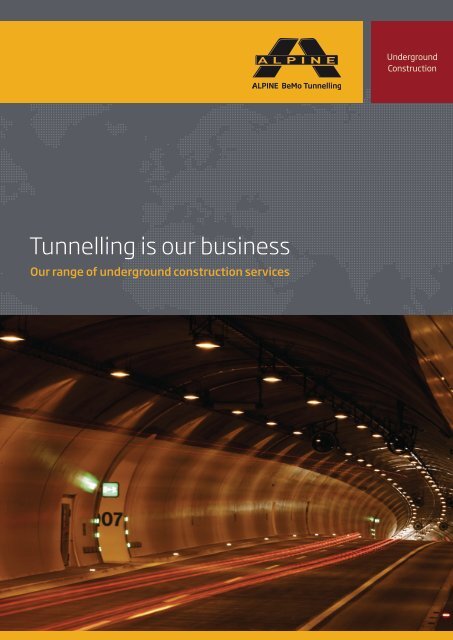

<strong>Tunnelling</strong> <strong>is</strong> <strong>our</strong> <strong>business</strong><br />

Our range of underground construction services<br />

Underground<br />

Construction

Underground<br />

Construction<br />

Founded in 1965 as a small construction<br />

machine dealership, <strong>ALPINE</strong> <strong>is</strong> now<br />

one of the leading construction groups<br />

in Europe. Today, <strong>our</strong> name <strong>is</strong> synonymous<br />

with state-of-the-art know-how,<br />

extreme flexibility, tailor-made solutions<br />

and the use of the latest in material and<br />

equipment. We cover the entire spectrum<br />

of construction output with competence<br />

in every single sector and complete projects<br />

of any kind and size reliably and on<br />

time in more than 30 countries. In doing<br />

so, we are committed to each project as if<br />

it were the only project we had.<br />

The classic construction activities are<br />

complemented by a number of services<br />

Crossrail C510<br />

King’s Cross Station<br />

North Downs Tunnel, Channel Tunnel Rail Link<br />

New Ka<strong>is</strong>er Wilhelm Tunnel<br />

Tysons Corner, DCMP<br />

Metro Project ’Stadtbahntunnel’ Karlsruhe<br />

Heidkopf Tunnel<br />

Heathrow Baggage Tunnel<br />

Bochum Lot 306<br />

Tröingebergs Tunnel<br />

Arlberg Tunnel<br />

Gotthard Base Tunnel, Lot 554 Bodio and Lot 452 Faido<br />

At the Core of Construction.<br />

Worldwide.<br />

in project admin<strong>is</strong>tration, planning and<br />

financing. Our intensive commitment to<br />

R&D <strong>is</strong> to ensure the highest possible<br />

quality in future constructions and secure<br />

<strong>our</strong> leading position in construction<br />

procedures and material.<br />

<strong>ALPINE</strong>’s success <strong>is</strong> based on the motivation<br />

and qualification of <strong>our</strong> employees.<br />

High investments in training of employees<br />

and <strong>our</strong> above-average commitment<br />

in safety at work are witness that we<br />

take responsibility for <strong>our</strong> employees<br />

seriously. Responsibility for people also<br />

means responsibility for the environment.<br />

Part of <strong>our</strong> company culture <strong>is</strong> a<br />

careful use of natural res<strong>our</strong>ces.<br />

Alte Mainzer Tunnels<br />

Jagdberg Tunnel, A4<br />

Tiergarten Tunnel H3-6 & H4-3<br />

Bosruck Tunnel, Second Tube, A9<br />

Lainzer Tunnel LT31<br />

Pfänder Tunnel, Second Tube, A14<br />

450 MW HEP, Powerhouse Cavern Kops II<br />

Achrain Tunnel<br />

Tapovan V<strong>is</strong>hnugad Headrace Tunnel<br />

High-speed rail line Ebensfeld-Erfurt<br />

Metro Delhi AMEL C1 & C6<br />

Singapore Metro Downtown Line, Stage 2<br />

Singapore Metro Circle Line, Stage 3, 4 & 5<br />

PORTFOLIO<br />

<strong>ALPINE</strong> GROUP<br />

Bridge Construction<br />

Building Construction<br />

Energy<br />

Environmental Engineering<br />

Foundation Engineering<br />

Power Station Construction<br />

Railway Construction<br />

Road Construction<br />

Sports Facility Construction<br />

Underground Construction

Pfänder Tunnel,<br />

Second Tube, A14<br />

Bosruck Tunnel,<br />

Second Tube, A9<br />

Jagdberg Tunnel, A4<br />

06<br />

Lainzer Tunnel LT31<br />

Gotthard Base Tunnel,<br />

Lot 554 Bodio and<br />

Lot 452 Faido<br />

Tröingebergs Tunnel<br />

07<br />

New Ka<strong>is</strong>er Wilhelm Tunnel<br />

High-speed rail line<br />

Ebensfeld-Erfurt<br />

08<br />

Singapore Metro Circle Line<br />

Metro Delhi AMEL C1 & C6<br />

King’s Cross Station<br />

Metro Project ’Stadtbahntunnel’<br />

Karlsruhe<br />

09<br />

450 MW HEP, Powerhouse<br />

Cavern Kops II<br />

Tapovan V<strong>is</strong>hnugad<br />

Headrace Tunnel<br />

10<br />

Arlberg Tunnel<br />

Alte Mainzer Tunnels<br />

Tysons Corner, DCMP<br />

Metrorail Project<br />

11<br />

<strong>Tunnelling</strong> <strong>is</strong> <strong>our</strong> <strong>business</strong><br />

<strong>ALPINE</strong> BeMo <strong>Tunnelling</strong> <strong>is</strong> a special<strong>is</strong>t in the engineering and construction<br />

of all types of underground structures, whether new construction,<br />

refurb<strong>is</strong>hment, reinstatement or reconstruction.<br />

Our experienced staff and know-how make us a world leader in <strong>our</strong> field,<br />

as can be seen from <strong>our</strong> excellent project record. Our highly qualified and<br />

committed team of experts <strong>is</strong> known internationally for its broad scope<br />

of technical excellence and innovative solutions for the design and delivery<br />

of complex and challenging tunnel works.<br />

We are fully committed to protecting the well-being, health and safety of<br />

<strong>our</strong> staff. We therefore work hand in hand with occupational health and<br />

safety organ<strong>is</strong>ations to continuously improve <strong>our</strong> structures, systems<br />

and efforts.<br />

<strong>ALPINE</strong> BeMo <strong>Tunnelling</strong> creates value for everyday life by implementing<br />

complex infrastructure projects that contribute to the well-being of<br />

society in a safe, efficient and sustainable manner. Thanks to <strong>our</strong><br />

professional<strong>is</strong>m, together with the high quality of <strong>our</strong> services, we are<br />

a preferred contractor for partners and clients alike.<br />

<strong>ALPINE</strong> BeMo <strong>Tunnelling</strong> brings together the tunnelling strength and<br />

know-how of <strong>ALPINE</strong> and Beton- und Monierbau (BeMo).<br />

PROJECT TYPES<br />

Tunnels for roads, railways, metros<br />

and underground stations<br />

Tunnels and facilities for the water<br />

and energy sector<br />

> Underground Power Plants<br />

> Caverns<br />

> Water tunnels<br />

> Sewage tunnels<br />

> Dams<br />

Shafts & Special Underground<br />

Structures<br />

Mining<br />

STATE-OF-THE-ART<br />

TECHNOLOGY FOR ALL TYPES<br />

OF GROUND<br />

NATM (New Austrian <strong>Tunnelling</strong><br />

Method), SCL, SEM, Shotcrete<br />

Method<br />

TBM (EPB- / Slurry- / Hydro- /<br />

Mix- / Single- / Double-Shield,<br />

Gripper, Partial-face)<br />

Scandinavian Method<br />

For more information and reference<br />

projects, please v<strong>is</strong>it <strong>our</strong> websites.<br />

www.alpine.at<br />

www.alpine-bemo.com<br />

PORTFOLIO<br />

Feasibility Studies<br />

Project Planning<br />

Project Development<br />

Project Investment<br />

Construction & Reconstruction<br />

Refurb<strong>is</strong>hment & Reinstatement<br />

> Tunnels<br />

> Buildings & Structures<br />

Modern<strong>is</strong>ation<br />

Know-how Transfer<br />

> Technical Support<br />

> Consulting<br />

Engineering Services<br />

> Design & Structural Engineering<br />

> Mechanical Engineering<br />

> Survey<br />

> Geotechnical Engineering<br />

Shotcrete works<br />

Grouting<br />

Slope Protection<br />

Construction Pit & Trench<br />

Protection

04 Underground Construction<br />

Areas of expert<strong>is</strong>e<br />

UndergroUnd constrUction & tUnnelling<br />

<strong>ALPINE</strong> BeMo <strong>Tunnelling</strong> (ABT) has been a leading player in the field of tunnelling since 1964. Around 70 % of <strong>our</strong> tunnelling work <strong>is</strong> conducted<br />

outside Austria, making ABT one of Austria‘s most successful international construction companies. Our span of activities in Underground<br />

Construction & <strong>Tunnelling</strong> includes:<br />

Tunnels for roads, railways, metros and underground stations<br />

Tunnels and facilities for the water and energy sector<br />

Reconstruction of underground structures and tunnels<br />

Refurb<strong>is</strong>hment & Reinstatement of underground structures, tunnels, buildings and structures<br />

Shafts and Special Underground Structures<br />

Mining<br />

design & strUctUral engineering<br />

ABT‘s design expert<strong>is</strong>e <strong>is</strong> based on more than 40 years of experience. Key services provided by the Tunnel-Design Department<br />

include:<br />

DetaileD Design: Continuous feed-back from <strong>our</strong> tunnel-construction sites and being seamlessly involved in <strong>our</strong> projects enables<br />

optim<strong>is</strong>ation of <strong>our</strong> designs with respect to safety, quality, constructability, programme and cost saving.<br />

Value engineering ProPosals anD Feasibility stuDies: Together with the site teams Value Engineering Proposals are<br />

developed, leading to higher quality, safety, innovation and overall cost reduction for <strong>our</strong> clients.<br />

numerical moDelling: With many years of experience in th<strong>is</strong> field, the Tunnel-Design Department has the expert<strong>is</strong>e<br />

for carrying out complex 2D and 3D analyses using state-of-the-art software in order to create construction designs and feasibility studies.<br />

Th<strong>is</strong> enables the modelling of construction processes, nonlinear material behavi<strong>our</strong> (soil, rock, concrete, steel, etc.), steady state and<br />

transient seepage flow, consolidation, steady state and transient heat transfer as well as dynamics.<br />

methoD selection anD construction sequencing: In close cooperation with the site team and the Mechanical<br />

Engineering / Plant Department, construction method and construction sequences are selected.<br />

Know-how transfer & consUlting<br />

ABT’s Know-how Div<strong>is</strong>ion exports the know-how of <strong>our</strong> engineers to many countries throughout the world. The range of services<br />

includes:<br />

Technical Consulting & Support<br />

Design Know-how<br />

Value Engineering & Feasibility Studies<br />

Project Planning & Development<br />

Estimation and Tender Preparation<br />

Operation and Maintenance<br />

Mechanical Engineering Services including method selection and construction sequencing<br />

Survey and Geotechnical Engineering Services<br />

Mechanical engineering & Plant dePartMent<br />

Mechanical engineering / electrical engineering<br />

Project-specific tasks / detailed engineering services for company-owned projects and for the Know-how Div<strong>is</strong>ion<br />

> Mechanical / electrical estimation and work preparation for individual projects for consecutive construction stages<br />

> Site set-up planning & site service<br />

Safety related tasks for <strong>our</strong> company-owned facilities and sites<br />

> Safety-related work preparation<br />

> Safety site superv<strong>is</strong>ion

Innovative Solutions<br />

ACHRAIN TUNNEL<br />

A bridge going underground<br />

The Achrain Tunnel <strong>is</strong> a 3-lane road<br />

tunnel with a length of 3,340 m<br />

near Dornbirn in Austria.<br />

The necessity for a fast closure of the<br />

invert by the use of shotcrete, followed<br />

by an immediate placement of the final<br />

invert arch without longitudinal subdiv<strong>is</strong>ion,<br />

and a subsequent installation of<br />

the final lining, led to a bridge solution<br />

which allowed the tunnelling works<br />

COmbISHELL™<br />

to be continued without unnecessary<br />

interruptions. The bridge was used as<br />

formwork support for the invert arch<br />

and the final lining abutment.<br />

Further construction included 13 crosspassages<br />

to the escape gallery, one<br />

crosspassage for fire & rescue vehicles<br />

and the reinstatement of the escape<br />

gallery (12 m²).<br />

Success Story: CombiShell™ <strong>Tunnelling</strong> Method<br />

With the great flexibility offered by NATM, chamber geometries were<br />

developed which neatly enveloped the complex path of the baggage<br />

handling system at Heathrow Airport whilst minim<strong>is</strong>ing overall excavation<br />

volumes. Located directly below operational aircraft stands, settlement<br />

considerations and safety of construction were of paramount<br />

importance.The novel tunnelling system util<strong>is</strong>ed sprayed concrete<br />

for both the primary and secondary linings, acting as a permanent<br />

composite structure. The design of the CombiShell™ proposal was<br />

VALUE ENGINEERING<br />

Value Engineering saves<br />

time and money for <strong>our</strong> clients<br />

Value Engineering on Channel Tunnel Rail Link’s 3.2-km-long North Downs Tunnel<br />

for the Eurostar-High-speed-trains allowed savings of several million pounds<br />

sterling and contributed towards completion five months ahead of schedule.<br />

Underground Construction<br />

undertaken by Morgan Sindall (England) and <strong>ALPINE</strong> BeMo <strong>Tunnelling</strong><br />

under a “technology transfer” agreement. <strong>ALPINE</strong> BeMo <strong>Tunnelling</strong><br />

util<strong>is</strong>es computer modelling techniques together with 40 years of<br />

experience in order to achieve economical and practical schemes.<br />

CombiShell™ <strong>is</strong> a reg<strong>is</strong>tered Trademark of <strong>ALPINE</strong> BeMo <strong>Tunnelling</strong><br />

(formerly: Beton- und Monierbau) and Morgan Sindall.<br />

Over the last 20 years, <strong>ALPINE</strong> BeMo <strong>Tunnelling</strong><br />

has constructed 650 km and designed 50 km of tunnels and<br />

other underground structures.<br />

05

06 Underground Construction<br />

Tunnels for Roads and<br />

Motorways<br />

Pfänder Tunnel, Second Tube, A14 / Bosruck Tunnel, Second Tube, A9<br />

ABT <strong>is</strong> the main contractor for the construction of the second tubes of the Pfänder and Bosruck<br />

tunnels. Both are 2-lane motorway tunnels. New Austrian <strong>Tunnelling</strong> Method (NATM) <strong>is</strong> used for<br />

the second tube of Bosruck Tunnel and was also used for the construction of the first tube of<br />

Pfänder Tunnel, which ABT built in the years 1977-1981.<br />

Jagdberg Tunnel, A4<br />

After the construction of Heidkopf Tunnel, a twin-tube 2-lane motorway tunnel, completed in<br />

2006, another contract with DEGES followed in the form of the Jagdberg Tunnel. Th<strong>is</strong> 3-lane<br />

motorway tunnel between Jena/Göschwitz and Magdala <strong>is</strong> beeing executed using the NATM<br />

method.<br />

Pfänder Tunnel, Second Tube <strong>is</strong> the first road<br />

tunnel to be built by TBM in Austria.<br />

FEATURES<br />

Pfänder Tunnel, Second Tube // The challenge <strong>is</strong> the ground – a “molasse” cons<strong>is</strong>ting<br />

of conglomerate, sandstone, marl-sandstone, marl and clay-marl, and soil. Execution <strong>is</strong><br />

being carried out by Single Shield TBM, lining with pre-cast concrete segments, crosspassages<br />

and soil by NATM.<br />

Bosruck Tunnel, Second Tube // The construction includes 14 crosspassages and<br />

seven lay-by enlargements. Excavation <strong>is</strong> being effected by drill & blast and excavator<br />

(NATM).<br />

Jagdberg Tunnel // Excavation of a 140 m deep ventilation-shaft by ra<strong>is</strong>eboring<br />

(Ø 1.5 m) and shaft sinking (Ø 8 m).<br />

Pfänder Tunnel, Second Tube<br />

Location: Bregenz-Lochau / AT<br />

Total length: 6,744 m<br />

Value: € 123.197 million<br />

Construction Period: 2007-2012<br />

Bosruck Tunnel, Second Tube<br />

Location: Spittal/Pyhrn-Ardning / AT<br />

Total length: 5,424 m<br />

Value: € 129.628 million<br />

Construction Period: 2009-2013<br />

Jagdberg Tunnel<br />

Location: Jena/Göschwitz-Magdala / DE<br />

Total length: 6,144 m<br />

Value: € 127.072 million<br />

Construction Period: 2008-2012

Tunnels for Railways<br />

Lainzer Tunnel LT31<br />

The Lainzer Tunnel LT31, comm<strong>is</strong>sioned by ÖBB was excavated using NATM (side-wall drifts) in<br />

soil. Two drives were started from each of the two starting shafts simultaneously. In addition, five<br />

escape tunnels and escape shafts were part of the contract.<br />

Gotthard Base Tunnel, Lot 554 Bodio & Lot 452 Faido<br />

TBMs and NATM were used to construct the two railway tunnel lots. <strong>ALPINE</strong> <strong>is</strong>, as part of a JV, the<br />

general contractor for railway technology of the Gotthard Base Tunnel.<br />

Tröingebergs Tunnel<br />

The Scandinavian tunnelling method (i.e. comprehensive grouting / no inner lining) was used for<br />

the Tröingebergs Tunnel.<br />

Tiergarten Tunnel H3-6 & H4-3 are other<br />

outstanding railway tunnel projects with<br />

excellent high quality.<br />

FEATURES<br />

Lainzer Tunnel LT31 // The main challenge was the inner-city tunnel drive in close<br />

proximity to densely populated residential area and (the 2 km section) just below<br />

Vienna’s ex<strong>is</strong>ting main railway line.<br />

Gotthard Base Tunnel // High speed railway line tunnel with a total length of<br />

57 km after completion and for speeds of up to 240 km/h<strong>our</strong>.<br />

Tröingebergs Tunnel // Main challenge: full face drill & blast excavation underneath<br />

densely populated residential area with overburden of only 14 m to 25 m.<br />

Underground Construction<br />

Lainzer Tunnel LT31<br />

Location: Vienna / AT<br />

Total length: 3,645 m<br />

Value: € 155 million<br />

Construction period: 2006-2010<br />

Gotthard Base Tunnel<br />

Location: Erstfeld - Bodio / CH<br />

Total length: Lot Faido 27,045 m,<br />

Lot Bodio 31,673 m<br />

Value: € 2097.50 million<br />

Construction period: 2001-2014<br />

Tröingebergs Tunnel<br />

Location: Falkenberg / SE<br />

Total length: 1,170 m<br />

Value: € 22 million<br />

Construction period: 2005-2007<br />

07

08 Underground Construction<br />

New Ka<strong>is</strong>er Wilhelm Tunnel<br />

The original Ka<strong>is</strong>er Wilhelm Tunnel was completed<br />

in 1877 and no longer meets current safety<br />

standards. The approx. 4,200-m-long tunnel<br />

<strong>is</strong> to be built predominantly in clay, clay-slate,<br />

silt- and sandstone. Along a length of about 400<br />

m the tunnel will be driven through soft ground<br />

with little overburden. The TBM chosen <strong>is</strong> able to<br />

switch between open and EPB mode. The tunnel<br />

<strong>is</strong> being lined with 2-m-long and 0.4-m-thick reinforced<br />

pre-cast concrete segments. Delivery of<br />

the tunnel lining segments and removal of about<br />

High-speed rail line Ebensfeld-Erfurt<br />

<strong>Bau</strong>mleite Tunnel and VP Lichtenfels, Kulch & Lichtenholz<br />

Tunnels are sections of the 107 km long<br />

high-speed rail line Ebensfeld-Erfurt. <strong>Bau</strong>mleite<br />

Tunnel <strong>is</strong> to be built in lower lacustrine limestone<br />

(carst formations) and executed with the NATM<br />

method. Concerning VP Lichtenfels, the special<br />

feature of the Kulch Tunnel <strong>is</strong> the undercutting<br />

of the LIF 1 Federal Highway with a shallow<br />

covering protected by a double pipe roof. The<br />

Lichtenholz Tunnel <strong>is</strong> being driven in geologically<br />

difficult “Feuerletten” over a length of 300 m. The<br />

“Feuerletten” <strong>is</strong> character<strong>is</strong>ed by intense swelling,<br />

producing an increase in volume of up to 30 %.<br />

350,000 m³ spoil has to be done by train. Both<br />

tunnel tubes will be connected by eight crosspassages<br />

with a length of 15 m each.<br />

FEATURES<br />

Structural Analys<strong>is</strong> and Detailed Design<br />

Underpassing residential area with the<br />

tunnel crown just below ground surface<br />

Parallel construction in the vicinity of the<br />

ex<strong>is</strong>ting old tunnel<br />

construction, design & structural engineering<br />

by <strong>ALPINE</strong> BeMo <strong>Tunnelling</strong> GmbH<br />

FEATURES<br />

<strong>Bau</strong>mleite Tunnel – High-speed rail<br />

line Ebensfeld-Erfurt // We are also<br />

responsible for Structural Analys<strong>is</strong> and<br />

Detailed Design. Challenges during construction<br />

are the shallow overburden and<br />

carst formations.<br />

VP Lichtenfels, Kulch & Lichtenholz<br />

Tunnels – High-speed rail line Ebensfeld-<br />

Erfurt // The 2-track railway tunnels<br />

include a 175-m-long rail viaduct, five<br />

new road bridges and 3,360,000 m3 of<br />

earth moving.<br />

New Ka<strong>is</strong>er Wilhelm Tunnel<br />

Location: Ediger-Eller - Cochem / DE<br />

Total length: 4,242 m<br />

Value: € 78.587 million<br />

Construction period: 2009-2012<br />

<strong>Bau</strong>mleite Tunnel –<br />

High-speed rail line<br />

Location: Ebensfeld-Erfurt / DE<br />

Total length: 1,314 m<br />

Value: € 41.668 million<br />

Construction period: 2009-2012<br />

VP Lichtenfels, Kulch & Lichtenholz<br />

Tunnels – High-speed rail line<br />

Location: Ebensfeld-Erfurt / DE<br />

Total length: Kulch Tunnel: 1,331 m,<br />

Lichtenholz Tunnel: 931 m<br />

Value: € 109.979 million<br />

Construction period: 2009-2013<br />

Photo: Wolfgang Sitter

Tunnels for Metros and<br />

Underground Stations<br />

Singapore Metro Circle Line, Stage 3, 4 & 5, C852 & C855 / Metro Delhi AMEL C1 & C6<br />

As a special<strong>is</strong>t for the design & construction of metro projects, we are active in countries all<br />

over the world. After successful completion of Singapore Metro Circle Line, C852 & C855 and<br />

Metro Delhi AMEL C1 & C6, we are currently working on the € 340 million project Downtown<br />

Line, Stage 2, C917 & C918 in Singapore, using Slurry TBMs and EPB TBMs for the bored<br />

twin tunnels.<br />

King’s Cross Station Redevelopment<br />

The purpose of th<strong>is</strong> metro project in Central London was the connection of ex<strong>is</strong>ting metrolines<br />

and St. Pancras Station (King’s Cross). A complex subterranean construction was<br />

necessary, i.e. pedestrian tunnels, stair and escalator shafts and vertical shafts. LaserShell™<br />

method in conjunction with the TunnelBeamer™ real-time surveying package was used as,<br />

tunnelling system for the London clay. We have also recently been awarded the € 280 million<br />

contract C510, Whitechapel and Liverpool Street Station Tunnels, as part of the Crossrail<br />

project.<br />

Metro Project ‘Stadtbahntunnel’ Karlsruhe<br />

The works for the inner city ‘Stadtbahntunnel’ Karlsruhe have already commenced and the<br />

tunnel driving will start in 2012. The 4.6-km project will include 3.9 km of tunnel and seven<br />

underground metro stations. A similar project in confined space was the inner city lot 306 of<br />

the metro Rhine-Ruhr-Bochum.<br />

C855: Slurry TBM meets the challenging geology<br />

of extremely fine and soft ground, weathered rock<br />

and exceptionally strong granite.<br />

FEATURES<br />

Singapore Metro Circle Line, Stage 4 & 5, C852 & C855 // Construction of three<br />

metro stations (Holland, Buona V<strong>is</strong>ta, NUH) by cut & cover and architectural fitting of<br />

the station ONH.<br />

King’s Cross Station Redevelopment // Th<strong>is</strong> site was a technical challenge<br />

because of its proximity to the ex<strong>is</strong>ting metro-lines, railway lines and<br />

h<strong>is</strong>torical buildings above the excavated zones.<br />

Metro Project ’Stadtbahntunnel’ Karlsruhe // The aim of th<strong>is</strong> soph<strong>is</strong>ticated<br />

construction project <strong>is</strong> to free the inner city of traffic and enhance recreational<br />

quality for pedestrians.<br />

Underground Construction<br />

Singapore Metro Circle Line, Stage 3,<br />

4 & 5, C852 & C855<br />

Location: Singapore / SG<br />

Total length: 16,436 m<br />

Value: € 274 million<br />

Construction period: 2003–2010<br />

Metro Delhi AMEL C1 & C6<br />

Location: Delhi / IN<br />

Total length: 8,260 m<br />

Value: € 210.7 million<br />

Construction period: 2007–2010<br />

King’s Cross Station Redevelopment<br />

Location: London / UK<br />

Total length: 350 m<br />

Value: € 95.115 million<br />

Construction period: 2002–2008<br />

Metro Project<br />

’Stadtbahntunnel‘ Karlsruhe<br />

Location: Karlsruhe / DE<br />

Total length: 3,900 m<br />

Value: € 313 million<br />

Construction period: 2010–2015<br />

09

10 Underground Construction<br />

450 MW HEP, Powerhouse<br />

Cavern Kops II<br />

The ‘Kopswerk II’ <strong>is</strong> part of a new pump-storage<br />

scheme with three machine units and a total<br />

generation capacity of 450 MW. All new construction<br />

of the ‘Kopswerk II’ <strong>is</strong> situated underground,<br />

such as a power tunnel, surge chamber, pressure<br />

tunnel, powerhouse and transformer cavern.<br />

Therefore the maximum environmental protection<br />

could be achieved. The only installations that<br />

will be v<strong>is</strong>ible above ground are the switchyard<br />

and an access road.<br />

Tapovan V<strong>is</strong>hnugad Headrace Tunnel<br />

We have been comm<strong>is</strong>sioned to construct a head<br />

race tunnel (HRT) for 4 x 130 MW HEP Tapovan for<br />

<strong>our</strong> client NTPC. We are using a Double Shield TBM<br />

and precast hexagonal-shaped segmental lining<br />

for the 8-km-long HRT section. The remaining<br />

4.5-km-long section and adits are excavated by<br />

road header or drill & blast method (NATM).<br />

FEATURES<br />

Tailrace gallery – excavation of 90 m<br />

soft rock section below the Ill river, under<br />

the protection of a pipe arch (pipe roofing)<br />

and two groundwater lowering wells.<br />

Mucking: Material management & spoil<br />

removal using a mucking shaft to load<br />

the crusher in a chamber below the cavern.<br />

Onward transportation by conveyor belt to<br />

landfill area.<br />

FEATURE<br />

Challenging Himalaya region, heavily<br />

fractured and unstable fault zone and<br />

highly abrasive quartzite layers<br />

Powerhouse Cavern Kops II<br />

Location: Partenen / AT<br />

Excavation works:<br />

> Powerhouse cavern: ~ 114,000 m³<br />

> Powerhouse cavern concrete lining<br />

works: 48,000 m³<br />

> Transformer cavern: ~ 11,000 m³<br />

> Surge Chamber: ~ 9,000 m³<br />

> 1,782 m various galleries: ~ 78,000 m³<br />

Value: € 50 million<br />

Construction period: 2004-2008<br />

Tapovan V<strong>is</strong>hnugad<br />

Headrace Tunnel<br />

Location: Chamoli d<strong>is</strong>trict,<br />

Uttarakhand / IN<br />

Total length: 11,771 m<br />

Value: € 76 million<br />

Construction period: 2006-2012

Refurb<strong>is</strong>hment & Reinstatement<br />

Safety engineering upgrade, Arlberg Tunnel<br />

The Arlberg Tunnel <strong>is</strong> a 2-track railway tunnel. The enlargement and upgrade was necessary due to<br />

new tunnel safety regulations. Six escape exits and six niches were built. The ex<strong>is</strong>ting<br />

h<strong>is</strong>torical stone masonry was enlarged, cleaned and reinforced. Furthermore, the invert of both<br />

tracks was deepened and a ballastless concrete track slab system was built.<br />

Modern<strong>is</strong>ation, Alte Mainzer Tunnels<br />

For modern<strong>is</strong>ation and enlargement of the very shallow Alte Mainzer Tunnels in soft ground, an<br />

innovative grouted anchor system was installed according ABT’s special proposal. The systematic<br />

ground pre-strengthening around the ex<strong>is</strong>ting tunnel has reduced settlements to a maximum of<br />

10 mm and allowed to abandon the installation of compensation grouting.<br />

ABT’s innovative grouted anchor system has<br />

reduced settlements to a maximum of 10 mm.<br />

FEATURES<br />

Safety engineering upgrade, Arlberg Tunnel // All construction had to be done<br />

without interrupting railway-operations. Th<strong>is</strong> was achieved by closing one track and<br />

keeping the second one in operation.<br />

Modern<strong>is</strong>ation Alte Mainzer Tunnels // Construction, Design & Structural<br />

Engineering by ABT and the challenge of underpassing main roads, buildings and<br />

ancient walls.<br />

Know-how Transfer<br />

Tysons Corner, Silver Line, Dulles Corridor Metrorail Project (DCMP)<br />

Our know-how and <strong>our</strong> experience in tunnel construction are in increasing demand abroad. We<br />

also export <strong>our</strong> know-how to the United States, e.g. for the project Tysons Corner, Silver Line,<br />

DCMP near Washington D.C.. Among other know-how transfer projects to the US were the Beacon<br />

Hill Station Project, C170 in Seattle, Reach 5 for San Vicente Pipeline near San Diego and the Los<br />

Angeles Metro Gold Line Eastside Extension.<br />

Underground Construction<br />

Arlberg Tunnel, safety<br />

engineering upgrade<br />

Location: Langen am Arlberg / AT<br />

Total length: 10,250 m<br />

Value: € 112 million<br />

Construction period: 2005-2010<br />

Alte Mainzer Tunnels, modern<strong>is</strong>ation<br />

Location: Mainz / DE<br />

Total length: 908 m<br />

Value: € 32.06 million<br />

Construction period: 2007-2009<br />

Tysons Corner, Dulles Corridor<br />

Metrorail Project<br />

Location: Vienna, Virginia / USA<br />

Total length: 1,036 m<br />

Value: € 4.5 million<br />

Construction period: 2009–2011<br />

11

<strong>ALPINE</strong> BeMo <strong>Tunnelling</strong> GmbH<br />

Bernhard-Hoefel-Strasse 11 · 6020 Innsbruck · Austria · Phone +43 512 3311-0 · Fax +43 512 392655<br />

office@alpine-bemo.com · www.alpine-bemo.com · www.alpine.at<br />

Subject to changes, printing and typographical errors. Date: 09.2011 / I