Thermoject® Nozzles - psg-online.de

Thermoject® Nozzles - psg-online.de

Thermoject® Nozzles - psg-online.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

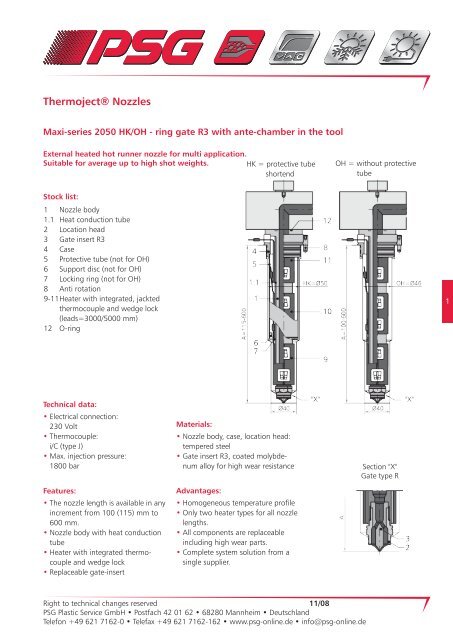

<strong>Thermoject®</strong> <strong>Nozzles</strong><br />

Maxi-series 2050 HK/OH - ring gate R3 with ante-chamber in the tool<br />

External heated hot runner nozzle for multi application.<br />

Suitable for average up to high shot weights. HK = protective tube<br />

shortend<br />

Stock list:<br />

1<br />

1.1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9-11<br />

12<br />

Nozzle body<br />

Heat conduction tube<br />

Location head<br />

Gate insert R3<br />

Case<br />

Protective tube (not for OH)<br />

Support disc (not for OH)<br />

Locking ring (not for OH)<br />

Anti rotation<br />

Heater with integrated, jackted<br />

thermocouple and wedge lock<br />

(leads=3000/5000 mm)<br />

O-ring<br />

Technical data:<br />

•<br />

•<br />

•<br />

Electrical connection:<br />

230 Volt<br />

Thermocouple:<br />

i/C (type J)<br />

Max. injection pressure:<br />

1800 bar<br />

Features:<br />

•<br />

•<br />

•<br />

•<br />

The nozzle length is available in any<br />

increment from 100 (115) mm to<br />

600 mm.<br />

Nozzle body with heat conduction<br />

tube<br />

Heater with integrated thermocouple<br />

and wedge lock<br />

Replaceable gate-insert<br />

Materials:<br />

• Nozzle body, case, location head:<br />

tempered steel<br />

• Gate insert R3, coated molyb<strong>de</strong>num<br />

alloy for high wear resistance<br />

Advantages:<br />

• Homogeneous temperature profile<br />

• Only two heater types for all nozzle<br />

lengths.<br />

• All components are replaceable<br />

including high wear parts.<br />

• Complete system solution from a<br />

single supplier.<br />

Right to technical changes reserved<br />

11/08<br />

PSG Plastic Service GmbH • Postfach 42 01 62 • 68280 Mannheim • Deutschland<br />

Telefon +49 621 7162-0 • Telefax +49 621 7162-162 • www.<strong>psg</strong>-<strong>online</strong>.<strong>de</strong> • info@<strong>psg</strong>-<strong>online</strong>.<strong>de</strong><br />

OH = without protective<br />

tube<br />

Section "X"<br />

Gate type R<br />

1

Nozzle dimensions<br />

Maxi 2050 HK/OH - ring gate R3<br />

Or<strong>de</strong>r <strong>de</strong>scription<br />

nozzle,<br />

Pos. 1-12<br />

(without pos.2<br />

and 3)<br />

A O =A-linear-expansion<br />

Article no.<br />

Ød2=16<br />

(Ø16=max./<br />

Ø10=min.)<br />

ØD1 ØD2<br />

Heating<br />

art.-no.,<br />

pos.9<br />

View "X"<br />

Heating<br />

art.-no.,<br />

pos.10<br />

Heating<br />

art.-no.,<br />

pos.11<br />

2050 OH A 100≤115 293402-115 16 42 37 332920 - -<br />

2050 HK A>115≤145 293403-145 16 46 37 332921 332921 -<br />

2050 OH A>115≤145 293402-145 16 42 37 332921 332921 -<br />

2050 HK A>145≤175 293403-175 16 46 37 332920 332921 -<br />

2050 OH A>145≤175 293402-175 16 42 37 332920 332921 -<br />

2050 HK A>175≤230 293403-230 16 46 37 332920 332920 -<br />

2050 OH A>175≤230 293402-230 16 42 37 332920 332920 -<br />

2050 HK A>230≤290 293403-290 16 46 37 332920 332920 -<br />

2050 OH A>230≤290 293402-290 16 42 37 332920 332920 -<br />

2050 HK A>290≤450 293403-450 16 46 37 332920 332920 332920<br />

2050 OH A>290≤450 293402-450 16 42 37 332920 332920 332920<br />

2050 HK A>450≤600 293403-600 16 46 37 332920 332920 332920<br />

2050 OH A>450≤600 293402-600 16 42 37 332920 332920 332920<br />

Ø d1 b<br />

Ø 14 50<br />

Ø 16 50<br />

Ø 18 60<br />

Ø 20 60<br />

Manifold height b <strong>de</strong>pends on<br />

melt channel Ød1.<br />

•<br />

•<br />

•<br />

The number of control circuits per nozzle <strong>de</strong>pends on the nozzle length.<br />

Marking consecutively by starting at the gate (max. 3). Use 4 control circuits<br />

per nozzle for heat sensitive plastics, see PSG's specification<br />

The number of control circuits per nozzle can be <strong>de</strong>termined from the<br />

“Heating” section on the above table.<br />

By specifying the mold measurement “A”, with <strong>de</strong>tails of the molding material,<br />

the nozzle dimension ”A 0 ” will be ma<strong>de</strong>, allowing for expansion.

Gate dimensions<br />

Maxi 2050 HK/OH - ring gate R3<br />

Gate type pos. 2 and 3:<br />

Or<strong>de</strong>r <strong>de</strong>scription<br />

location head<br />

for 2050-R<br />

incl. gate insert<br />

Article no.<br />

R 3 - 50/52 294504-001<br />

R 3 - T 50/52* 294504-002<br />

* Pos. 2 ma<strong>de</strong> of titanium recommen<strong>de</strong>d for textiles and foils by back injection technology.<br />

Dimensions duct for wiring:<br />

Duct for<br />

wiring<br />

Article no. *BxH<br />

Cross section<br />

(mm 2 )<br />

type 1 165670 35 x 41 1254<br />

type 2 165672 37 x 11 264<br />

type 3 165674 30 x 31 784<br />

type 4 165676 24 x 31/41 616 / 856<br />

type 6 165680 17 x 29 405<br />

type 7 165682 35 x 60 1881<br />

*BxH = <strong>de</strong>pending on the size of the system (please check with PSG!)<br />

revolving<br />

Gate type R<br />

duct for wiring<br />

Manifold<br />

duct for wiring

Installation dimensions<br />

Maxi 2050 HK/OH - ring gate R3<br />

Series A Ø P1 +0,5 Ø P2 +0,5 B Ø O<br />

2050 HK-R 115 ≤ 145 50 40 70 2.0 - 4.0<br />

2050 HK-R >145 - 600 50 40 100 2.0 - 4.0<br />

2050 OH-R 100 ≤ 145 46 40 70 2.0 - 4.0<br />

2050 OH-R >145 - 600 46 40 100 2.0 - 4.0<br />

Section "X"<br />

cyl.<br />

Installation and construction note:<br />

• Cooling must be provi<strong>de</strong>d close to the gate, with circulating water.<br />

On the moving si<strong>de</strong> of the mold a fountain type cooling, opposite to the<br />

gate should be used.<br />

Measurements: General toleranzes DIN ISO 2768 mK.<br />

* Height adjustment of the whole<br />

system according to data sheet<br />

”Standardised hotrunner manifold”.

Spare parts<br />

Maxi 2050 - ring gate R3<br />

Series<br />

Or<strong>de</strong>r example:<br />

Nozzle 2050 (pos. 1-12, without pos. 2 and 3)<br />

2050 HK 385 293403-450 PP-*<br />

Series Type Mold<br />

dimension<br />

A<br />

Gate type R3 (pos. 2 and 3):<br />

Heaterband with wedge lock* and<br />

integrated jacketed thermocouple<br />

(230 V), pos. 9-11<br />

Article no. Please state plastic<br />

type or tool and<br />

processing<br />

temperature<br />

R3 50/52 294504-001<br />

Gate type Series Article no.<br />

Article no.<br />

2050 RPI Ø28x35 / 180 W / leads: 3000 332921<br />

2050 RPI Ø28x35 / 180 W / leads: 5000 332921-1<br />

2050 RPI Ø28x65 / 300 W / leads: 3000 332920<br />

2050 RPI Ø28x65 / 300 W / leads: 5000 332920-1<br />

(*) Equipment see nozzle dimensions.<br />

Gate insert<br />

pos. 3<br />

Article no.<br />

O-ring,<br />

pos. 12<br />

Article no.<br />

A 50/52 - R3 294301 No. 630 260550<br />

Location head,<br />

pos. 2<br />

Article no. Material<br />

Z 50/52 294400-001 tempered steel<br />

ZT 50/52 294400-002 titanium alloy<br />

* If melt channel differing from standard diameter is nee<strong>de</strong>d please specify here.<br />

• The hot runner nozzle is supplied complete<br />

with nozzle head fitted!<br />

• Please be sure to observe the numbering<br />

of the control circuits before<br />

shortening the cables!