Mortar Cement

Lafarge mortar cement brochure

Lafarge mortar cement brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

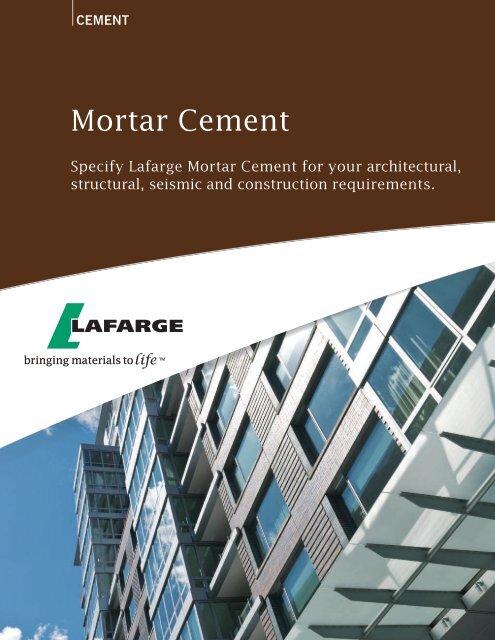

cement<strong>Mortar</strong> <strong>Cement</strong>Specify Lafarge <strong>Mortar</strong> <strong>Cement</strong> for your architectural,structural, seismic and construction requirements.

Lafarge inNorth AmericaThe Lafarge Group is theworld leader in buildingmaterials, with top-rankingpositions in all of itsbusinesses: <strong>Cement</strong>,Aggregates & Concreteand Gypsum. The Groupemploys 78,000 employeesin 78 countries. Lafargeis the largest diversifiedsupplier of constructionmaterials in the UnitedStates and Canada.The Lafarge Group placesinnovation at the heart ofits priorities, working forsustainable constructionand architectural creativity.Lafarge <strong>Mortar</strong> <strong>Cement</strong> is suitable for all masonryconstruction, especially projects that require higher flexural bond and compressivestrengths. Superior performance extends to such key areas as durability, weatherresistance and aesthetics.> Bond and Compressive Strengths. Inindependent testing, mortars made withLafarge <strong>Mortar</strong> <strong>Cement</strong> exceeded theflexural bond strengths required in:• ASTM C 1329 Standard Specificationfor <strong>Mortar</strong> <strong>Cement</strong>;• International Building Code Standard2103.7 <strong>Mortar</strong> and• CSA-A3002 Masonry and <strong>Mortar</strong> <strong>Cement</strong>.They also achieved flexural bond andcompressive strengths that meet allseismic zone requirements – enhancingstructural stability and maintaining themargin of safety.> Durability. Independent lab testsconfirm that mortars made with Lafarge<strong>Mortar</strong> <strong>Cement</strong> perform equal to orbetter than those made with portlandcement and lime on both high and lowIRA brick.page 2 | Lafarge <strong>Cement</strong>

Physical Requirements for<strong>Mortar</strong> <strong>Cement</strong>Based upon ASTM C 1329TypeFlexural Bond Strength28 Days MinimumPSI MPaN 70 0.5S 100 0.7M 115 0.8> Permeability. <strong>Mortar</strong> is often exposedto freezing and thawing cycles. <strong>Mortar</strong>smade with Lafarge <strong>Mortar</strong> <strong>Cement</strong> withstandthese weather extremes with lowwater absorption rates and increasedwater repellence. These factors, togetherwith good workmanship, ensure tight anddense joints.> Workability and Boardlife. Plasticityand water retention are importantaspects of workability. Lafarge <strong>Mortar</strong><strong>Cement</strong> retains a maximum amount ofwater to provide plasticity to achieveexcellent boardlife.> Minimal Shrinkage. Reducing shrinkageis an important factor in preventingcracks in mortar. In laboratory tests,mortars prepared with Lafarge <strong>Mortar</strong><strong>Cement</strong> demonstrated minimal shrinkage.> Mixing. Mixing is faster and easier, becauseLafarge <strong>Mortar</strong> <strong>Cement</strong> ingredientscome in one bag. Only sand and watermust be added on site.> Uniformity. Because ingredients arecombined to exact specifications at theLafarge plant, Lafarge <strong>Mortar</strong> <strong>Cement</strong> providesuniform mortar color and strength.The following table is a suggested guide for the selection of mortar types; however,other considerations, such as climate, exposure, type of masonry unit, applicablebuilding codes and engineering requirements should also be considered.Suggested Guide for Selection of <strong>Mortar</strong> TypeLocation Building Segment mortar TypeRecommended AlternativeExterior, above grade load-bearing wall sparapet wallsnon-load-bearing wall N sExterior, at or foundation walls, retaining walls,1S Mbelow grademanholes, sewers,pavements, walls, patiosMInterior load-bearing wall snon-load-bearing partitions N s1Masonry exposed to weather in a nominally horizontal surface is extremely vulnerable to weathering.<strong>Mortar</strong> for such masonry should be selected with due caution.page 3 | Lafarge <strong>Cement</strong>

Property Requirements for <strong>Mortar</strong> 1Based upon IBC 2103.7(2), ASTM C 270, Table 2, and CSA-A179<strong>Cement</strong> <strong>Mortar</strong> Average Water AirType Type Compressive Retention ContentStrengthat 28 Days Min.(Min. Psi) (MPa) (Min. %) (Max. %)<strong>Mortar</strong> M 2500 (17.2) 75 12<strong>Cement</strong> or S 1800 (12.4) 75 12<strong>Cement</strong>/ N 750 (5.2) 75314Lime O 350 (2.4) 753141Laboratory-prepared mortar only.2Determined in accordance with applicable standards.3When structural reinforcement is incorporated in the above noted mortars, the maximum air contentshall be 12 percent.2> Basic Use: Lafarge Types N, S and M<strong>Mortar</strong> <strong>Cement</strong> meet ASTM C 1329 andIBC 2103.7 Standards for <strong>Mortar</strong> <strong>Cement</strong>and are used to make Type N, S and Mmasonry mortars as defined in ASTM C270. When mixed with 2-1/4 to 3 partsloose, damp masonry sand meeting therequirements of ASTM C 144 and potablewater, Lafarge <strong>Mortar</strong> <strong>Cement</strong> producesmortar with flexural strengths meetingthe requirements of ASTM C1329.> Composition and Materials: Lafarge<strong>Mortar</strong> <strong>Cement</strong> is composed of portlandcement, plasticizers, and air entrainingadditives. These components are proportionedat the cement plant under controlledconditions to assure uniformity ofperformance.> Size: Type N available in 70 lb / 31.8kg bags, Type S available in 75 lb / 34 kgbags. Type M available in 80 lb / 36.3 kgbags.> Limitations: Lafarge <strong>Mortar</strong> <strong>Cement</strong>should be mixed with clean, damp, loosemasons’ sand and potable water. The useof admixtures in masonry constructionshould have prior approval by the specifier,comply with ASTM C 1384, and betested in the mortar at the temperatureextremes anticipated at the job site.Insufficient mixing and improper sandcontents can reduce the quality of themasonry mortar. Overloading a mixer willreduce masonry mortar quality regardlessof length of mixing. See mixing instructionsprinted on bag.> Mixing: Place 2/3 of the required mixingwater and half of the sand in themixer. Next, add the mortar cement andthen add the remaining sand. Mix for twominutes to permit the fluidizing of the ingredientsto become effective. Next, addthe remaining water to obtain the desiredworkability. Five minutes of mixing isrecommended after all ingredients are inthe mixer. At no time should the amountof material in the mixer cover the mixerblades when they are at the top of theirtravel.> Retempering: <strong>Mortar</strong>s shall be retemperedas needed to restore workability.Unused mortar shall be discarded aftertwo hours.> Tooling of Joints: Tooling of masonrymortar joints increases the density, durability,and water resistance of the mortar.Tooling also increases the bond betweenthe masonry mortar and the masonryunit. The moisture content of the masonrymortar at the time of tooling will affectfinal masonry mortar color. Delayedtooling normally results in darker mortarjoints while early tooling will cause lighterjoints.page 4 | Lafarge <strong>Cement</strong>

CEMENTProduct NameLafarge <strong>Mortar</strong> <strong>Cement</strong>s:Type N, Type S and Type MManufacturerLafarge North America Inc.Lafarge Building Materials Inc.12018 Sunrise Valley DriveSuite 500Reston, VA 20191Lafarge Canada Inc.334 avenue AvroPointe-Claire, Quebec H9R 5W5www.lafarge-na.comTechnical DataLafarge <strong>Mortar</strong> <strong>Cement</strong> is suitable for allmasonry construction, especially projectsthat require higher flexural bond andcompressive strengths.> Applicable standards: Lafarge <strong>Mortar</strong><strong>Cement</strong> conforms to the requirements ofASTM C 270 The Standard Specificationsfor <strong>Mortar</strong> for Unit Masonry and InternationalBuilding Code Section 2103.7.When mixed with sand meeting therequirements of ASTM C 144 StandardSpecification for Aggregate for Masonry<strong>Mortar</strong> and an appropriate amount ofwater, Lafarge Types N, S and M <strong>Mortar</strong><strong>Cement</strong> will result in Type N, S and M<strong>Mortar</strong> (respectively) meeting the requirementsof ASTM C 270, ASTM C 1329and IBC 2103.7(2).A certificate attesting to this will befurnished by the manufacturer uponrequest.PrecautionsDirect contact with wet cement shouldbe avoided. If contact occurs, the skinshould be washed with water as soon aspossible. Exposure can cause serious,potentially irreversible tissue destructionin the form of chemical (caustic) burns.If cement gets into the eyes, immediatelyrinse thoroughly with water and seekmedical attention. For more information,reference the applicable Lafarge MaterialSafety Data Sheet (MSDS). The MSDSshould be consulted prior to use of thisproduct and is available upon requestand online at www.lafarge-na.com.Limited WarrantyLafarge warrants that Lafarge <strong>Mortar</strong><strong>Cement</strong> meets the requirements ofASTM C 1329, IBC 2103.7 and CSA-A179. Lafarge makes no other warranty,whether of merchantability or fitness fora particular purpose with respect to Lafarge<strong>Mortar</strong> <strong>Cement</strong>. Having no controlover its use, Lafarge will not guaranteefinished work in which Lafarge <strong>Mortar</strong><strong>Cement</strong> is used.page 5 | Lafarge <strong>Cement</strong>

LAFARGE NORTH AMERICA INC.Lafarge Building Materials Inc.12018 Sunrise Valley DriveSuite 500Reston, VA 20191Lafarge Canada Inc.334 avenue AvroPointe-Claire, Quebec H9R 5W5www.lafarge-na.compbMOCE 5/10