Effect of Chock Design

667A Design for Operating Temp - Sintemar

667A Design for Operating Temp - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

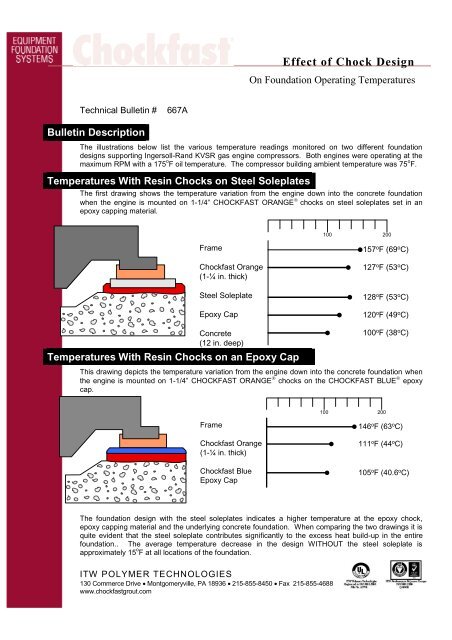

<strong>Effect</strong> <strong>of</strong> <strong>Chock</strong> <strong>Design</strong>On Foundation Operating TemperaturesTechnical Bulletin #667ABulletin DescriptionThe illustrations below list the various temperature readings monitored on two different foundationdesigns supporting Ingersoll-Rand KVSR gas engine compressors. Both engines were operating at themaximum RPM with a 175 o F oil temperature. The compressor building ambient temperature was 75 o F.Temperatures With Resin <strong>Chock</strong>s on Steel SoleplatesThe first drawing shows the temperature variation from the engine down into the concrete foundationwhen the engine is mounted on 1-1/4” CHOCKFAST ORANGE chocks on steel soleplates set in anepoxy capping material.Frame10100 20010157 o F (69 o C)<strong>Chock</strong>fast Orange(1-¼ in. thick)Steel SoleplateEpoxy Cap127 o F (53 o C)128 o F (53 o C)120 o F (49 o C)Concrete(12 in. deep)Temperatures With Resin <strong>Chock</strong>s on an Epoxy Cap100 o F (38 o C)This drawing depicts the temperature variation from the engine down into the concrete foundation whenthe engine is mounted on 1-1/4” CHOCKFAST ORANGE chocks on the CHOCKFAST BLUE epoxycap.Frame10100 20010146 o F (63 o C)<strong>Chock</strong>fast Orange(1-¼ in. thick)<strong>Chock</strong>fast BlueEpoxy Cap111 o F (44 o C)105 o F (40.6 o C)The foundation design with the steel soleplates indicates a higher temperature at the epoxy chock,epoxy capping material and the underlying concrete foundation. When comparing the two drawings it isquite evident that the steel soleplate contributes significantly to the excess heat build-up in the entirefoundation.. The average temperature decrease in the design WITHOUT the steel soleplate isapproximately 15 o F at all locations <strong>of</strong> the foundation.ITW POLYMER TECHNOLOGIES130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688www.chockfastgrout.com

<strong>Effect</strong> <strong>of</strong> <strong>Chock</strong> <strong>Design</strong>Bulletin No. 667A, Page 2<strong>Effect</strong> <strong>of</strong> <strong>Chock</strong> Height on Operating TemperatureThe illustrations below show the temperatures variations at different levels monitored on three differentfoundation designs supporting Dresser Clark HBA-8 gas engine compressors. All three engines wereoperating at the maximum RPM with an oil temperature <strong>of</strong> 170 o F. The compressor building ambienttemperature was 73 o F.Frame<strong>Chock</strong>fast Black(2 in. thick)<strong>Chock</strong>fast BlueEpoxy CapConcrete(12 in. deep)10100 20010137 o F (58.3 o C)106 o F (41 o C)93 o F (33.9 o C)74 o F (23.3 o C)The top drawing shows a 2” CHOCKFAST BLACK epoxy chock on the CHOCKFAST BLUE epoxycapping material while the lower drawing depicts a 1-1/4” CHOCKFAST ORANGE epoxy chock on acap <strong>of</strong> CHOCKFAST BLUE .Frame10100 20010135 o F (57 o C)<strong>Chock</strong>fast Orange(1-1/4 in. thick)<strong>Chock</strong>fast BlueEpoxy CapConcrete(12 in. deep)107 o F (41.7 o C)99 o F (37.2 o C)75 o F (23.9 o C)The temperature readings in the top drawing demonstrate the added cooling effect the 2” CHOCKFASTBLACK chocks have on the underlying epoxy cap <strong>of</strong> CHOCKFAST BLUE which was used in bothfoundation designs. The CHOCKFAST BLUE under the 2” CHOCKFAST BLACK chocks is 6 o F coolerdue to the additional ¾” <strong>of</strong> air space.FrameCementitiousGrout CapConcrete(12 in. deep)10100 20010137 o F (58.3 o C)113 o F (45 o C)81 o F (27.2 o C)

<strong>Effect</strong> <strong>of</strong> <strong>Chock</strong> <strong>Design</strong>Bulletin No. 667A, Page 3The final drawing shows a full bed cementitious grout design. The cementitious grout cap is 20 o Fwarmer than the CHOCKFAST BLUE cap under the 2” CHOCKFAST BLACK chocks and 14 o Fwarmer than the CHOCKFAST BLUE cap under the 1-1/4” CHOCKFAST ORANGE chocks. The lack<strong>of</strong> air flow has a definite effect on the temperature <strong>of</strong> the grout cap and the underlying foundation.Date 08/2006General: Every reasonable effort is made to insure thetechnical information and recommendations on these datapages are true and accurate to the best <strong>of</strong> our knowledgeat the date <strong>of</strong> issuance. However, this information is subjectto change without notice. Prior versions <strong>of</strong> this publicationare invalid with the release <strong>of</strong> this version. Products andinformation are intended for use by qualified applicatorsthat have the required background, technical knowledge,and equipment to perform said tasks in a satisfactorymanner. Consult your local distributor for productavailability, additional product information, and technicalsupport.Warranty: ITW Polymer Technologies, a division <strong>of</strong> Illinois ToolWorks Inc., warrants that its products meet their printedspecifications. This is the sole warranty. This warrantyexpires one year after product shipment.Warranty Claims: If any product fails to meet the above,ITW Polymer Technologies will, at its option, either replacethe product or refund the purchase price. ITW PolymerTechnologies will have no other liability for breach <strong>of</strong>warranty, negligence, or otherwise. All warranty claimsmust be made in writing within one year <strong>of</strong> the date <strong>of</strong>shipment. No other claims will be considered.Disclaimer: ITW Polymer Technologies makes no otherwarranty, expressed or implied, and specifically disclaimsany warranty <strong>of</strong> merchantability or fitness for a particularpurpose.Suggestions concerning the use <strong>of</strong> products are notwarranties. The purchaser assumes the responsibility fordetermining suitability <strong>of</strong> products and appropriate use.ITW Polymer Technologies’ sole liability, for breach <strong>of</strong>warranty, negligence or otherwise, shall be thereplacement <strong>of</strong> product or refund <strong>of</strong> the purchaseprice, at ITW Polymer Technologies’ election. Under nocircumstances shall ITW Polymer Technologies be liablefor any indirect, incidental or consequential damages.Modification <strong>of</strong> Warranty: No distributor or salesrepresentative has the authority to change the aboveprovisions. No change in the above provisions will bevalid unless in writing and signed by an <strong>of</strong>ficer or theTechnical Director <strong>of</strong> ITW Polymer Technologies. Noterm <strong>of</strong> any purchase order shall serve to modify anyprovision <strong>of</strong> this document.Mediation and Arbitration: If any dispute arises relatingto products or product warranties, either the purchaseror ITW Polymer Technologies may a) initiate mediationunder the then current Center for Public Resources(CPR) Model Procedure for Mediation <strong>of</strong> BusinessDisputes, or b) initiate a non-binding arbitration underthe rules <strong>of</strong> the American Arbitration Association for theresolution <strong>of</strong> commercial disputes.