Jade DSC: Site Readiness Instructions - Perkin Elmer Life and ...

Jade DSC: Site Readiness Instructions - Perkin Elmer Life and ...

Jade DSC: Site Readiness Instructions - Perkin Elmer Life and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Rev. 2<br />

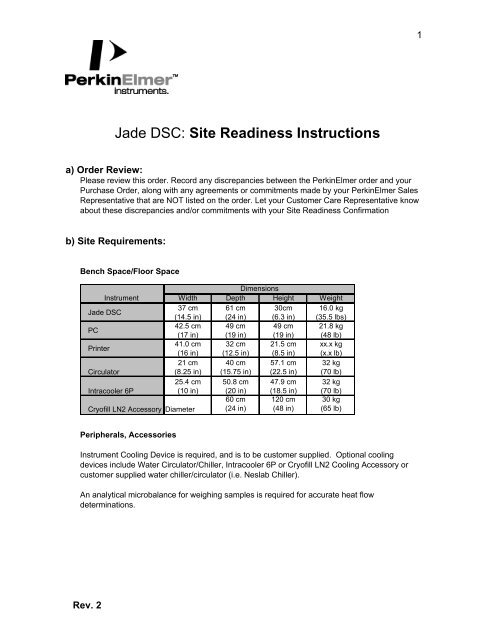

<strong>Jade</strong> <strong>DSC</strong>: <strong>Site</strong> <strong>Readiness</strong> <strong>Instructions</strong><br />

a) Order Review:<br />

Please review this order. Record any discrepancies between the <strong>Perkin</strong><strong>Elmer</strong> order <strong>and</strong> your<br />

Purchase Order, along with any agreements or commitments made by your <strong>Perkin</strong><strong>Elmer</strong> Sales<br />

Representative that are NOT listed on the order. Let your Customer Care Representative know<br />

about these discrepancies <strong>and</strong>/or commitments with your <strong>Site</strong> <strong>Readiness</strong> Confirmation<br />

b) <strong>Site</strong> Requirements:<br />

Bench Space/Floor Space<br />

Dimensions<br />

Instrument<br />

Width Depth Height Weight<br />

<strong>Jade</strong> <strong>DSC</strong><br />

37 cm<br />

(14.5 in)<br />

61 cm<br />

(24 in)<br />

30cm<br />

(6.3 in)<br />

16.0 kg<br />

(35.5 lbs)<br />

PC<br />

42.5 cm<br />

(17 in)<br />

49 cm<br />

(19 in)<br />

49 cm<br />

(19 in)<br />

21.8 kg<br />

(48 lb)<br />

Printer<br />

41.0 cm<br />

(16 in)<br />

32 cm<br />

(12.5 in)<br />

21.5 cm<br />

(8.5 in)<br />

xx.x kg<br />

(x.x lb)<br />

21 cm 40 cm 57.1 cm 32 kg<br />

Circulator<br />

(8.25 in) (15.75 in) (22.5 in) (70 lb)<br />

25.4 cm 50.8 cm 47.9 cm 32 kg<br />

Intracooler 6P<br />

(10 in) (20 in) (18.5 in) (70 lb)<br />

60 cm 120 cm 30 kg<br />

Cryofill LN2 Accessory Diameter (24 in) (48 in) (65 lb)<br />

Peripherals, Accessories<br />

Instrument Cooling Device is required, <strong>and</strong> is to be customer supplied. Optional cooling<br />

devices include Water Circulator/Chiller, Intracooler 6P or Cryofill LN2 Cooling Accessory or<br />

customer supplied water chiller/circulator (i.e. Neslab Chiller).<br />

An analytical microbalance for weighing samples is required for accurate heat flow<br />

determinations.<br />

1

c) Electrical Requirements:<br />

Power Consumption<br />

Rev. 2<br />

<strong>Jade</strong> <strong>DSC</strong> 365 Watts Maximum<br />

Computer 500 Watts Maximum<br />

Circulator 1440 Watts Maximum<br />

Intracooler 6P 840 Watts Maximum<br />

Cryofill 60 Watts Maximum<br />

Power Specifications<br />

<strong>Jade</strong> <strong>DSC</strong> 100/115 VAC, 2 Amps or 230 VAC, 1 Amp<br />

Computer 100/115 VAC, 4.6 Amps or 230 VAC, 2.3 Amp<br />

Circulator 120 VAC, 12 Amps or 240 VAC, 7 Amps<br />

Intracooler 6P 120 VAC, 7 Amps or 220 VAC, 4 Amps<br />

Cryofill 120 VAC, 0.5 Amp or 240 VAC, 0.25 Amp<br />

Power Outlets<br />

Each system component (<strong>Jade</strong> <strong>DSC</strong>, Computer, Monitor, Printer <strong>and</strong> cooling accessory)<br />

requires a separate power outlet. All outlets should share a common earth ground. Additional<br />

power outlets <strong>and</strong> power consumption must be allowed for optional cooling accessories<br />

Other:<br />

This equipment is designed to operate within 10% of the selected line voltage. The supply<br />

must be smooth, clean <strong>and</strong> free of transient voltages over 40 volts.<br />

Earth grounding: less than 1 ohm resistance between the grounds of any 2 components of the<br />

system<br />

d) Gas Requirements:<br />

NOTE: ALL GASSES AND REGULATORS MUST BE SUPPLIED BY CUSTOMER<br />

For operation at or above ambient temperatures:<br />

“Sample Purge Gas” such as dry argon, nitrogen, air, oxygen; minimum purity of 99.9%<br />

Regulator outlet pressure, typical 2-3 bar or 30 to 40 psi<br />

A Nitrogen “System Purge Gas” of 50- 75 ml/min. is required. This gas should be clean<br />

<strong>and</strong> dry having minimum purity of 99.9%. Regulator Outlet Pressure set to 2-3 bar or 30<br />

to 40 psi (not to exceed 6.0 bar/90 psi).<br />

For Subambient Intracooler 6P operation:<br />

“Sample Purge Gas” such as dry argon, nitrogen, air, oxygen; minimum purity of<br />

99.99% . (A gas having a dew point ≤ -90 °C is recommended)<br />

2

Rev. 2<br />

3<br />

Regulator outlet pressure, typical 2-3 bar or 30 to 40 psi (not to exceed 6.0 bar/90 psi).<br />

A Nitrogen “System Purge Gas” of 50- 75 cc is required. This gas should be clean <strong>and</strong><br />

dry having minimum purity of 99.99%. Regulator Outlet Pressure 2-3 bar or 30 to 40 psi<br />

(not to exceed 6.0 bar/90 psi).<br />

For Subambient Liquid Nitrogen operation:<br />

A low pressure Nitrogen source is required to pressurize the LN2 Liquid Nitrogen Tank.<br />

25-30 PSI is required.<br />

“Sample Purge Gas” such as dry argon, nitrogen, helium; minimum purity of 99.99% .<br />

(A gas having a dew point ≤ -180 °C is recommended)<br />

Regulator outlet pressure, typical 2-3 bar or 30 to 40 psi (not to exceed 6.0 bar/90 psi).<br />

A Nitrogen “System Purge Gas” of 50- 75 cc is required. This gas should be clean <strong>and</strong><br />

dry having minimum purity of 99.99%. Regulator Outlet Pressure 2-3 bar or 30 to 40 psi<br />

(not to exceed 6.0 bar/90 psi).<br />

For all Autosampler subambient operation:<br />

A dry box purge may be required depending on the relative humidity in the laboratory. A<br />

separate purge line is required to control the flow between 35 to 50 ml/min. This can be<br />

accomplished using a restrictor (provided with the analyzer).<br />

Gas Line Tubing:<br />

Provided with the <strong>Jade</strong> is approximately 10 feet (~3 meters) of 1/8” Teflon tubing <strong>and</strong><br />

fittings to be used to connect one sample purge <strong>and</strong> one system purge line. Additional<br />

lengths if required due to the location of the gas source or additional sample purge gases<br />

is the responsibility of the customer. Customer is to notify the Customer Care Agent if<br />

more purge/sample gas tubing is needed.<br />

Regulators:<br />

Customer must provide the necessary regulators to connect the required purge <strong>and</strong><br />

system gases. Regulators are available from <strong>Perkin</strong><strong>Elmer</strong> at an additional cost.<br />

N5190462 Gas Split Kit provides a convenient method of splitting a single source of gas.<br />

One kit required for each split in the source gas.<br />

Filter Driers:<br />

Moisture in purge gases will negatively affect instrument performance. Filter driers<br />

N5370103 are strongly recommended to maintain a clean dry purge gas.<br />

e) Coolant requirements:<br />

The <strong>Jade</strong> <strong>DSC</strong> requires a coolant of one of the following types:<br />

Circulating water: A source of water <strong>and</strong> a drain are required. Flow rate of 5 l/min<br />

required.<br />

Chiller: A liquid circulating device such as the PolyScience Model 9102. The 9102<br />

water circulator does not include the cooling liquid. 50/50 Ethylene Glycol (non<br />

automotive grade, Fisher P/N E1774), Distilled Water <strong>and</strong> Algaecide (N0776059 8 drops<br />

per gallon) is required as the cooling media to -20 °C. Minimum temperature control ±<br />

0.1 °C is required.<br />

Intercooler 6P Refrigeration based.

Rev. 2<br />

4<br />

Cryofill: LN2 cooling system requires 50 liters of liquid nitrogen to operate. It is the<br />

customer responsibility to make the LN2 available at the installation site of the <strong>Jade</strong> <strong>DSC</strong>.<br />

LN2 consumption is approximately 2.5 liters/hour <strong>and</strong> dependent on temperature range.<br />

NOTE: when h<strong>and</strong>ling LN2 wear appropriate safety gear as specified by your<br />

corporate safety officer or LN2 supplier<br />

f) Environmental Requirements:<br />

Laboratory Environment<br />

Temperature range 15 to 40°C<br />

Humidity

Rev. 2<br />

• Chassis: Mini Tower (MT)<br />

• Factory Installed Operating System: Microsoft® Windows® XP Professional SP2<br />

• Memory: 512 MB, Non-ECC 533 MHz, DDR2 1x512, Four DIMM slots<br />

• Hard Drive: 80GB SATA, 7200 RPM<br />

• Networking: Broadcom®, 10/100/1000, Ethernet Remote Wake Up <strong>and</strong> PXE Support<br />

• External I/O Ports: 8 USB 2.0 (2 front, 6 rear), 1 Ethernet (RJ45), 2 serial (9-pin) (16550<br />

compatible), 1 parallel (25-hole, bidirectional), 1 VGA out<br />

• Expansion Slots: 2 PCI up to 4.2” H x 11” L, 1 PCIe x1 up to 4.2” H x 9” L, 1 PCIe x16<br />

• CD-RW: 48x Max CD Rewriteable Drive<br />

• Video: Integrated video, Intel® GMA950<br />

• Floppy Drive 3.5" 1.44MB diskette drive st<strong>and</strong>ard<br />

• Mouse: Dell USB 2-button optical mouse with scroll<br />

• Keyboard: Dell USB Keyboard (No Hot Keys)<br />

• Audio: Integrated ADI 1981 AC97 codec<br />

Software Requirements<br />

XP Professional/SP2 is required.<br />

i) Installation Overview:<br />

At receipt of the instrumentation, customer is to determine if any obvious shipping damage<br />

has occurred <strong>and</strong> is to notify the shipping company immediately.<br />

The customer is to unpack <strong>and</strong> verify the layout of Instruments <strong>and</strong> accessories with an eye<br />

to possible missing or damaged parts.<br />

You should unpack the instrument <strong>and</strong> accessories. The instrument should be placed on the<br />

bench along with associated components.<br />

Customer to hold Packing Material for CSE<br />

The <strong>Jade</strong> <strong>DSC</strong> is to be installed by a PKI Service Engineer, you should hold the instrument<br />

packing material for the Customer Service Engineer (CSE).<br />

Physical Installation (Instrument Only)<br />

The physical installation will vary based on system configuration.<br />

Physical Installation (Accessories)<br />

[As Required]<br />

Installation Test St<strong>and</strong>ards<br />

A PKI Service Engineer will test the instrument in order to insure that its performance meets<br />

<strong>Perkin</strong><strong>Elmer</strong>’s manufacturing specifications. Reference materials are supplied with the<br />

instrument to test its functionality.<br />

Customer Orientation<br />

The customer must be available for an instrumentation orientation.<br />

j) Miscellaneous:<br />

If IQOQ validation is required for this instrument, please contact your local Service<br />

representative at 1800 762 4000.<br />

If additional purge gas splitter kits, filter driers or any additional spares supplies or accessories<br />

are needed please contact your local Service representative at 1800 762 4000.<br />

5

If a journal is required for this analyzer, please contact your local Sales /Service<br />

representative at 1800 762 4000. (The Journal is a binder that should be located near the<br />

instrument. It provides an organized means of storing miscellaneous instrument information<br />

such as: service records, certificates tracking usage etc.)<br />

Sample Preparation:<br />

All reference materials required for installation check-out are shipped in the instrument start-up<br />

kit.<br />

Rev. 2<br />

6