energize oil & gas 01/2011 - GL Group

energize oil & gas 01/2011 - GL Group

energize oil & gas 01/2011 - GL Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

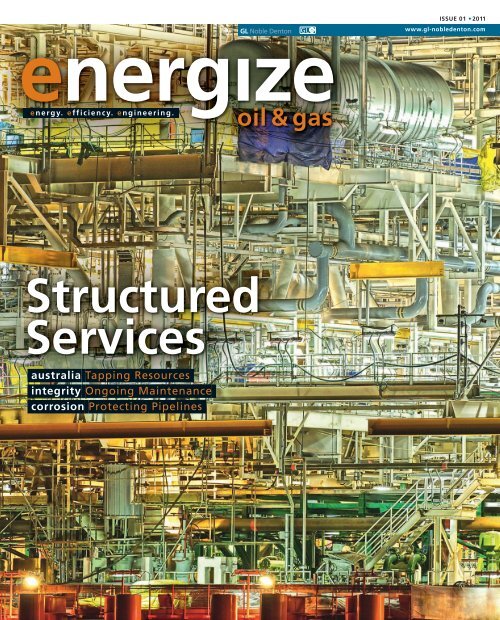

<strong>GL</strong> Noble Denton<br />

energıze<br />

e nergy. e fficiency. e ngineering.<br />

Structured<br />

Services<br />

australia Tapping Resources<br />

integrity Ongoing Maintenance<br />

corrosion Protecting Pipelines<br />

<strong>oil</strong> & <strong>gas</strong><br />

ISSUE <strong>01</strong> • 2<strong>01</strong>1<br />

www.gl-nobledenton.com

Oil & Gas<br />

change.<br />

The world’s leading <strong>oil</strong> & <strong>gas</strong> companies work with<br />

<strong>GL</strong> Noble Denton to implement operational change<br />

and mitigate risk.<br />

<strong>GL</strong> Noble Denton’s asset integrity software solution,<br />

GALIOM, manages the safety and integrity of assets<br />

across their lifecycle, and is built upon more than<br />

30 years of on- and offshore asset integrity and risk<br />

management experience.<br />

See more of what we do at<br />

www.gl-nobledenton.com<br />

Email: glnobledenton@gl-group.com

<strong>01</strong>/2<strong>01</strong>1<br />

editorial<br />

John Wishart<br />

To Our Readers<br />

After a prolonged period of turbulence, the New Year has seen a number of<br />

independent bodies forecast growth in the <strong>oil</strong> and <strong>gas</strong> industry with cautious optimism.<br />

In particular, a new Economist Intelligence Unit report on the outlook for the <strong>oil</strong> and <strong>gas</strong><br />

sector for 2<strong>01</strong>1, which has been sponsored by <strong>GL</strong> Noble Denton (download your copy from<br />

www.gl-nobledenton.com), suggests that we are likely to see increased investment in<br />

innovative solutions to industry challenges over the next 12 months. But the growing<br />

demand for energy is taking the exploration, production and distribution of <strong>oil</strong> and <strong>gas</strong> to<br />

tougher extremes of geography and climate, and pushing the boundaries of the industry’s<br />

technical knowledge to its very limits. Against this backdrop, key players in the industry<br />

will need to find more innovative solutions to mitigate risk, while operating more efficiently<br />

and sustainably.<br />

The sector’s ability to demonstrate safe operations will also be brought into sharp<br />

focus this year, following the Deepwater Horizon incident last April. A strong approach to<br />

assurance and risk management will be key. <strong>GL</strong> Noble Denton has recently joined forces<br />

with stakeholders from across the industry to explore today’s issues in assurance and risk<br />

management, and help define best practice in areas such as inspecting blow-out preventers<br />

and reviewing safety frameworks. We are also pleased to be developing guidelines for<br />

blow-out preventer certification to complement our industry-leading guidelines on marine<br />

operations and recently published standards on float-over installations and mooring (p. 29).<br />

As exploration and production continue to take us into deeper waters, the role of<br />

the FPSO is becoming increasingly important to efficient energy generation. <strong>GL</strong> Noble Denton<br />

helps operators across the world establish risk management practices that are both effective<br />

and economically feasible, and our role in hosting the 25th FPSO Research Forum in Aberdeen<br />

last autumn reinforces our reputation as a world-class provider of FPSO expertise (p. 36).<br />

While the price of <strong>oil</strong> has been volatile over the past few years, it’s encouraging to<br />

hear that industry leaders have begun to predict a period of stability, fuelled by strong growth<br />

in both demand and supply from the Asia Pacific region. Australia’s profile as a substantial<br />

producer of <strong>oil</strong> and <strong>gas</strong> is growing rapidly, and <strong>GL</strong> Noble Denton has recently opened a new<br />

office in Perth (p. 6) to better serve our current and future clients in this exciting market. We<br />

look forward to developing our presence in Australia alongside other industry operators over<br />

the coming years.<br />

Yours sincerely,<br />

John Wishart<br />

President, <strong>GL</strong> Noble Denton<br />

3

contents <strong>01</strong>/2<strong>01</strong>1<br />

26<br />

intErviEw<br />

Martin G. Brown<br />

about fpSo<br />

asset integrity<br />

Cover photo: An FPSO at night<br />

(Getty Images/Flickr RF)<br />

32<br />

SoftwArE i<br />

inspection data<br />

acquisition by<br />

GALioM<br />

38<br />

CorroSion<br />

pipelines: fighting<br />

the ravages<br />

of time<br />

22<br />

trAnSportAtion<br />

Experience and<br />

guidelines for dynamic<br />

positioning<br />

42<br />

City GAS<br />

Expert knowledge<br />

regarding the<br />

infrastructure<br />

46<br />

inSpECtion<br />

Quality assurance<br />

services for ZpMC<br />

cranes<br />

35<br />

SoftwArE ii<br />

taking hull<br />

maintenance to<br />

the next level<br />

4 energıze

16<br />

12<br />

intErviEw<br />

richard palmer<br />

about challenges<br />

in Australia<br />

<strong>01</strong>/2<strong>01</strong>1<br />

rESourCES<br />

Quality<br />

standards for<br />

unconven -<br />

t ional <strong>gas</strong><br />

14<br />

pipELinES<br />

Ensuring the<br />

integrity of<br />

pE systems<br />

08<br />

ovErviEw<br />

the Australian<br />

<strong>oil</strong> and <strong>gas</strong><br />

market<br />

profile inbrief<br />

<strong>GL</strong> noble Denton in Brief<br />

<strong>GL</strong> Noble Denton is a tEChniCAL ADviSor AnD truStED pArtnEr<br />

for the <strong>oil</strong> and <strong>gas</strong> industry.<br />

The <strong>oil</strong> and <strong>gas</strong> business segment of the <strong>GL</strong> <strong>Group</strong> helps to design,<br />

build, install and operate <strong>oil</strong> and <strong>gas</strong> onshore, maritime and<br />

offshore assets to ensure SAfEty, SuStAinABiLity AnD<br />

SupErior vALuE.<br />

<strong>GL</strong> Noble Denton is the MErGEr BEtwEEn GErMAniSChEr LLoyD’S<br />

oiL & GAS BuSinESS AnD noBLE DEnton, a premier provider of life<br />

cycle marine and offshore engineering services. Since January 2<strong>01</strong>0,<br />

they have been offering their services as <strong>GL</strong> Noble Denton.<br />

<strong>GL</strong> Noble Denton is a fullservice provider with broad upstream and<br />

midstream competence for thE CoMpLEtE ASSEt LifECyCLE.<br />

<strong>GL</strong> Noble Denton combines excellent engineering and analytical skills<br />

with operational experience of offshore, maritime and onshore <strong>oil</strong> and<br />

<strong>gas</strong> assets. The <strong>oil</strong> and <strong>gas</strong> business segment of <strong>GL</strong> employs MorE thAn<br />

3,000 EnGinEErS AnD ExpErtS in 80 CountriES.<br />

We have strong expertise in complex <strong>oil</strong> and <strong>gas</strong> assets such as<br />

MODUs, FPSOs, pipelines, subsea systems, OSVs – and assurance, asset<br />

integrity, safety and risk, marine operations, project management and<br />

software services to match. The scope of technical services includes safe<br />

ty, integrity, reliability and performance management.<br />

<strong>GL</strong> Noble Denton is A truLy inDEpEnDEnt ADviSor without any vested<br />

interest in selling a design, installation, fabrication or equipment.<br />

<strong>GL</strong> Noble Denton services <strong>oil</strong> and <strong>gas</strong> clients in onshore production,<br />

onshore pipelines, storage, import terminals, LNG, refineries and pet<br />

rochemicals, distribution networks as well as mobile offshore drilling<br />

units, mobile offshore production units, fixed platforms, subsea, risers<br />

and flowlines, offshore support vessels, tankers and shipping and offshore<br />

pipelines. We oversee and support the full lifecycle of an asset<br />

from project concept to decommissioning. The business segment has<br />

A <strong>GL</strong>oBAL rEACh in thE oiL AnD GAS CEntrES of the world.<br />

<strong>GL</strong> Noble Denton<br />

www.glnobledenton.com<br />

5

australia<br />

<strong>oil</strong> & <strong>gas</strong> merger<br />

6<br />

energıze

Photo: iStockphoto<br />

Australia’s resources<br />

sector is thriving.<br />

<strong>GL</strong> Noble Denton’s<br />

experts support the<br />

<strong>oil</strong> and <strong>gas</strong> industry<br />

with engineering<br />

services on site.<br />

<strong>01</strong>/2<strong>01</strong>1 7

australia <strong>gas</strong><br />

Down Under:<br />

the Future is Gas<br />

Hidden beneath Australia’s coastal waters lie immense<br />

natural <strong>gas</strong> reserves. Australia is about to become one<br />

of the world’s key players in the market<br />

Australia’s upstream <strong>oil</strong> and <strong>gas</strong> industry will<br />

grow significantly over the next 15 to 20 years.<br />

The biggest opportunity lies in <strong>gas</strong> production.<br />

As Saudi Arabia is all about <strong>oil</strong>, Australia is all about <strong>gas</strong>.<br />

The country down under has some of the world’s largest<br />

<strong>gas</strong> reserves but has made little use of them to date. The<br />

realization of major <strong>gas</strong> projects, as well as the recognition<br />

of the low-carbon emission benefits of <strong>gas</strong>, have increased<br />

the profile of Australia’s natural <strong>gas</strong> industry. In recent<br />

years, Australia experienced a boom as operators sought<br />

FPSO.<br />

The mobile offshore<br />

production<br />

unit "Northern<br />

Endeavour" in the<br />

Timor Sea, 550 km<br />

Woodside<br />

north-west of<br />

Darwin. Photos:<br />

to develop and export Australian <strong>gas</strong> as liquefied natural<br />

<strong>gas</strong> (LNG). According to the Australian Petroleum Production<br />

and Exploration Association (APPEA), the LNG production<br />

capacity is set to increase from 19.5 million tonnes per<br />

annum (mtpa) in 2<strong>01</strong>0 to 38.8 mtpa from 2<strong>01</strong>4. About a<br />

dozen consortiums are putting together plans to explore<br />

major LNG funds. The race for Australia to become one of<br />

the leading <strong>gas</strong> exporters has started.<br />

Export Opportunity<br />

Australia’s main frontier for exploration has moved in recent<br />

years to the deep-water area of the Timor Sea, although<br />

the nearby Carnarvon Basin off the coast of Western<br />

Australia is still a busy area in terms of drilling activity.<br />

There are also significant reserves of coal seam <strong>gas</strong> and<br />

<strong>oil</strong> shale. Coal seam <strong>gas</strong> is a fast-growing industry with<br />

the bulk of onshore drilling and production focused within<br />

the state of Queensland. Increasing demand for petroleum<br />

8 energıze

Production.<br />

The Pluto LNG project<br />

is located about 190 km<br />

north-west of Karratha<br />

in the Northern Carnarvon<br />

Basin.<br />

products (particularly LNG) is fuelling the exploration, development<br />

and production of both existing and new fields<br />

across Australia.<br />

“Australia has just 1.7 per cent of the world’s <strong>gas</strong> reserves,<br />

but almost 20 per cent of the OECD’s <strong>gas</strong> reserves,”<br />

says Australia’s Minister for Resources and Energy Martin<br />

Ferguson. “Our <strong>gas</strong> reserves are large enough to support<br />

projected domestic and export market growth beyond<br />

2030.” Most of Australia’s <strong>gas</strong> lies in the deep-water area<br />

beneath the Indian Ocean off the isolated northern coast of<br />

Western Australia. It represents a huge export opportunity<br />

for Australia given its close proximity to <strong>gas</strong>-hungry Japan,<br />

Korea and the fast-growing markets of China and India.<br />

The Carnarvon Basin is Australia's biggest <strong>gas</strong>-producing<br />

region, followed by the Gippsland Basin in Victoria and the<br />

Cooper-Eromanga Basin in the red centre. Together they<br />

account for 96 per cent of Australia’s total <strong>gas</strong> production.<br />

A 50 per cent of Australia’s <strong>gas</strong> production is exported. The<br />

<strong>01</strong>/2<strong>01</strong>1<br />

geographic distance between Australia and its key natural<br />

<strong>gas</strong> export markets prevents trade by conventional pipeline<br />

transport. By cooling to – 161 ºC the <strong>gas</strong> is turned into a<br />

liquid, reducing its volume and enabling transportation by<br />

ship. “Australia is currently the world’s fourth largest ex-<br />

porter of LNG; major project developments off Australia’s<br />

north-west are projected to increase<br />

this ranking to second by 2<strong>01</strong>5,” pre-<br />

dicts Minister Martin Ferguson.<br />

LNG Facilities<br />

AbstrAct<br />

The increasing LNG production<br />

capacities will enable<br />

Australia to become the 2nd<br />

largest exporter by 2<strong>01</strong>5<br />

To face the technical and<br />

Australia’s two producing LNG facilities<br />

environmental challenges<br />

are the North West Shelf Joint Venture more skilled workers from<br />

abroad will be needed<br />

and the Darwin LNG project. Australia’s<br />

first LNG project, the North West<br />

Shelf Venture, began shipping LNG in 1989. The project<br />

has since grown to include five production units and now<br />

produces up to 16.3 mtpa of liquefied natural <strong>gas</strong>.<br />

9

australia <strong>gas</strong><br />

The Darwin LNG plant produces up to 3.5 mtpa and<br />

will supply LNG to Japan for the next 17 years. There are<br />

three other large LNG projects currently being built in Aus-<br />

tralia: Pluto by Woodside, Queensland Curtis by the BG<br />

<strong>Group</strong> and Gorgon by Chevron. Once completed, Gorgon<br />

will be one of the largest natural <strong>gas</strong> projects in the world.<br />

The LNG processing facility will be located on Barrow Is-<br />

land, approximately 130 km off the remote northwestern<br />

coast of Western Australia. Gorgon LNG will be off-loaded<br />

Gas Reserves<br />

Overview. Australia’s mar-<br />

ket share of OECD countries<br />

accounts for about 20 per<br />

cent. Most of the <strong>gas</strong> lies off<br />

the isolated northern coast of<br />

Western Australia.<br />

The three biggest <strong>gas</strong>-pro-<br />

ducing regions are Carnar-<br />

von Basin (Western Australia),<br />

Gippsland Basin (Victoria)<br />

and Cooper-Eromanga Basin<br />

(Queensland). Together they<br />

account for 96 per cent of<br />

the total <strong>gas</strong> production.<br />

Australia’s economic and<br />

sub-economic <strong>gas</strong> resources<br />

as at 1 January 2009<br />

Source: APPEA. State of the Industry Report 2<strong>01</strong>0<br />

Carnarvon<br />

Basin<br />

94.4 tcf<br />

Perth<br />

Basin<br />

0.8 tcf<br />

Karratha<br />

Browse<br />

Basin<br />

33.6 tcf<br />

Broome<br />

Western Australia<br />

Perth<br />

Bonaparte Basin<br />

23.7<br />

tcf<br />

Conventional <strong>gas</strong><br />

Coal seam <strong>gas</strong><br />

tcf = trillion cubic feet<br />

Darwin<br />

Northern<br />

Territory<br />

South<br />

Australia<br />

Queensland<br />

Cooper-Eromanga<br />

Basin<br />

0.8 tcf<br />

Adelaide<br />

Otway<br />

Basin<br />

1.7 tcf<br />

Bowen, Surat,<br />

Sydney-C<br />

Gunnedah and<br />

other Basins<br />

42.3 tcf<br />

New South Wales<br />

Victoria<br />

Melbourne<br />

Bass<br />

Basin<br />

0.5 tcf<br />

7.9<br />

tcf<br />

Surat-Bowen<br />

Basin<br />

0.4 tcf<br />

Brisbane<br />

Sydney<br />

Gippsland<br />

Basin<br />

10 energıze

<strong>01</strong>/2<strong>01</strong>1<br />

via a four-kilometre long loading jetty for transport to international<br />

markets. The domestic <strong>gas</strong> will be piped to the<br />

Western Australian mainland.<br />

Upcoming Challenges<br />

Photos: BP<br />

Gas Industry. The Karratha <strong>gas</strong> plant is one of the most advanced integrated systems in the world. It has an annual<br />

LNG capacity to produce 16.3 million tonnes.<br />

Australia’s low geopolitical risk profi le attracts major <strong>oil</strong><br />

and <strong>gas</strong> players. Nevertheless, the companies have to deal<br />

with enormous technological challenges. For the ambitious<br />

LNG projects, large offshore platforms will be required and<br />

the topsides may be amongst the largest worldwide. Deep<br />

water drilling operations will be necessary for fi eld development.<br />

Subsea assemblies connecting multiple wells to<br />

the fi xed or fl oating platforms will use the latest developments<br />

in engineering and equipment manufacturing.<br />

Most main fi elds will run subsea pipelines to onshore<br />

processing plants. The industry is also pursuing alternative<br />

development models such as fl oating LNG, which will expand<br />

the options for developing many of Australia’s smaller<br />

and more isolated <strong>gas</strong> resources.<br />

Furthermore, environmental constraints are a challenge<br />

for the <strong>oil</strong> and <strong>gas</strong> industry. Many of the operations are<br />

located in remote and environmentally sensitive areas. As<br />

a consequence, all operators must comply with strict en-<br />

vironmental regulations, such as the requirements issued<br />

by the Australian Quarantine Inspection Services. Barrow<br />

Island, for instance, is home to over twenty unique animal<br />

species and rated as an A-Class Nature Reserve.<br />

If Australia wants to take full advantage of its abundant<br />

natural resources, the country will need to import workers.<br />

The huge <strong>gas</strong> developments require a more mobile work-<br />

force and more skilled migrants than are currently available<br />

on the domestic labour market. MD<br />

<strong>GL</strong> NOBLE DENTON EXPERT:<br />

richard bailey<br />

executive vice President Asia/Pacifi c<br />

Phone: +60 3 2160 1088<br />

e-Mail: richard.bailey@gl-group.com<br />

11

australia interview<br />

Expertise for Australia<br />

Richard Palmer about the challenges of the growing Australian <strong>gas</strong> market<br />

and the services <strong>GL</strong> Noble Denton is able to offer its clients<br />

In July 2<strong>01</strong>0, <strong>GL</strong> Noble Denton opened a new<br />

office in Perth, Australia. Perth is one of the<br />

most remote cities in the world, surrounded<br />

by 1,700 miles of red desert in the east and 5,000 miles of<br />

blue ocean in the west. <strong>energize</strong> spoke with Richard Palmer,<br />

head of <strong>GL</strong> Noble Denton’s business in Australia. He told<br />

us what the company has on offer for its clients, current<br />

projects and the fast growing <strong>gas</strong> market Down Under.<br />

ENERGIZE: Why did <strong>GL</strong> Noble Denton expand its presence<br />

in Australia?<br />

RIchARD PALMER: Before opening the Perth office, we<br />

served the Australian market typically from Singapore. The<br />

<strong>oil</strong> and <strong>gas</strong> industry in Australia is warming up, and big<br />

Australian-based projects are coming up. <strong>GL</strong> Noble Denton<br />

opened the office to be best placed to serve their traditional<br />

and future clients by adding value to these projects<br />

and bringing industry experience to them. A number of<br />

the development concepts are new to the operators, and<br />

they are looking for the complete range of <strong>GL</strong> Noble Denton’s<br />

independent offerings from assurance to advanced<br />

engineering and consulting and to marine operations and<br />

execution.<br />

Australia is a large country by area but not by population.<br />

Thus, skills are limited. We can provide substantial<br />

support thanks to our expertise. The country is very remote,<br />

covering several time zones. Our clients therefore prefer to<br />

be served and interfaced locally. We are now closer to our<br />

Australian customers.<br />

ENERGIZE: Which services does <strong>GL</strong> Noble Denton offer to<br />

its clients Down Under?<br />

PALMER: Major clients of <strong>GL</strong> Noble Denton are operators of<br />

pipelines, upstream <strong>oil</strong> companies, EPC (engineering, procurement<br />

and construction) companies, offshore drilling<br />

companies and contractors, FPSO companies, LNG facilities,<br />

storage operators, financial institutions, as well as utilities.<br />

From our location in Perth, we provide a comprehensive<br />

service portfolio covering assurance and verification,<br />

risk and safety studies, advanced engineering and consulting,<br />

marine operations and project execution. The portfolio<br />

covers areas such as marine assurance, marine warranty, rig<br />

moving, naval architecture services, design verification, NDT<br />

(nondestructive testing) inspection, vendor inspection, risk<br />

and safety, RAM (reliability, availability and maintainability)<br />

modelling, flow assurance, transportation and installation<br />

consulting, due diligence, and dynamic positioning services<br />

12 energıze

Photo: Thewinchester<br />

across Australia. The Perth team is supported by expert per-<br />

sonnel from other regional and global offi ces with specifi c<br />

capabilities, such as asset integrity management and analy-<br />

sis of production performance, and the capability to sup-<br />

port clients across the entire LNG supply chain.<br />

ENERGIZE: What are your team’s current main projects?<br />

PALMER: Current projects are focusing on reliability mod-<br />

elling of LNG operations, provision of marine representa-<br />

tives for rig moves, screening studies for drilling units and<br />

effects of cyclones support for an FPSO. Further, we are<br />

working on third party verifi cation and decommissioning of<br />

a platform. We are doing vendor inspection work as well as<br />

marine survey work.<br />

Location. <strong>GL</strong> Noble Denton’s new office in Perth.<br />

ENERGIZE: What is the biggest business in Australia?<br />

PALMER: LNG is the big prize at the moment. Growing en-<br />

ergy demand, improved techniques for <strong>gas</strong> exploration and<br />

shipping as well as rising <strong>oil</strong> prices makes <strong>gas</strong> more interest-<br />

ing. Australia has one of the world’s biggest <strong>gas</strong> reserves.<br />

There are a number of companies working to get a licence<br />

for LNG exploration. <strong>GL</strong> Noble Denton brings a lot of <strong>gas</strong><br />

skills and this is what Australia needs. Some of the projects<br />

are about pipelines thousand kilometres in length. <strong>GL</strong> No-<br />

ble Denton is supporting the LNG companies by performing<br />

risk assessments, concept reviews, concept optimization<br />

and shipping studies as well as general marine consultancy.<br />

ENERGIZE: What are the biggest challenges in Australia?<br />

PALMER: Australia is fairly unique in many ways. The envi-<br />

<strong>01</strong>/2<strong>01</strong>1<br />

Profi le<br />

Richard Palmer is a Na-<br />

val Architect with over<br />

12 years experience, pre-<br />

dominantly in the fi eld<br />

of transportation and in-<br />

stallation projects world-<br />

wide relating to offshore<br />

<strong>oil</strong> and <strong>gas</strong> exploration<br />

and production. He is<br />

currently in charge of <strong>GL</strong><br />

Noble Denton’s Austra-<br />

lian operations. Richard<br />

was previously responsi-<br />

ble for the management<br />

and development of <strong>GL</strong><br />

Areas of Expertise<br />

load-out and dis-<br />

charge engineering<br />

for buoyant and non-<br />

buoyant cargoes<br />

dry transportation en-<br />

gineering<br />

marine towages<br />

fl oat-over engineering<br />

and operations<br />

stability calculations<br />

RICHARD PALMER:<br />

Phone: +61 (0)8 6365 4940<br />

E-Mail: richard.palmer@glnobledenton.com<br />

Noble Denton’s Trans-<br />

portation and Installa-<br />

tion business line. As a<br />

member of the Techni-<br />

cal Policy Board he leads<br />

the development of the<br />

transportation and fl oatover<br />

guidelines.<br />

FPS(O) towage and<br />

installation (moorings<br />

and risers)<br />

motion analysis of<br />

fl oating bodies<br />

hydrodynamic analysis<br />

and wave simulations<br />

quasi-static and<br />

dynamics mooring<br />

analysis<br />

ronment on the biggest island in the world is very sensitive.<br />

The remoteness of the country and its small population<br />

both limit resources and skills. All projects draw on the<br />

same, very limited pool of experts. That is where <strong>GL</strong> Noble<br />

Denton steps in. Most operations are very complicated<br />

since offshore is a long way from anywhere, which brings<br />

an added logistical challenge. MD<br />

13

australia pipelines<br />

Operative<br />

learning +<br />

development<br />

Best practice<br />

roll-out<br />

Leakproof PE Pipelines<br />

The development of coal seam <strong>gas</strong> reserves requires significant pipe networks to transport<br />

<strong>gas</strong> and water. Pipeline integrity is paramount – <strong>GL</strong> Noble Denton ensures it<br />

<strong>GL</strong> Noble Denton provides the <strong>gas</strong> and water<br />

sectors with consultancy services and test fa-<br />

cilities associated with Polyethylene (PE) pres-<br />

sure pipelines. These services are delivered by highly skilled<br />

consultants and engineers coupled with unique test facili-<br />

ties. <strong>GL</strong> Noble Denton has been involved in the technical<br />

development of PE for over 40 years.<br />

In order to develop the coal seam <strong>gas</strong> reserves in<br />

Queensland, a signifi cant number of wells will be drilled<br />

over the next fi ve years. Each well will produce both <strong>gas</strong><br />

and water, requiring appropriate pipe networks for trans-<br />

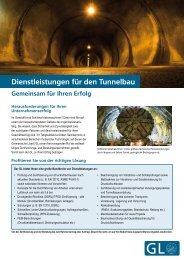

Policy +<br />

procedure<br />

development<br />

+ update<br />

Training<br />

Client/<br />

<strong>GL</strong> project<br />

meetings<br />

Best practice identifi cation<br />

(water + <strong>gas</strong>) + business<br />

improvement<br />

Data capture<br />

Audit<br />

Zero non-compliance<br />

Reduced Audit Right 1st time<br />

Management<br />

information<br />

reporting<br />

Findings<br />

Exception report<br />

+ serious<br />

non-compliance<br />

On-site<br />

mentoring<br />

Operative<br />

learning +<br />

development<br />

Reported KPI’s<br />

portation. The material of choice for much of these networks<br />

is PE. <strong>GL</strong> Noble Denton’s considerable expertise in PE<br />

pipelines is now being focussed on this new and exciting<br />

market, as Australian operators look to tackle the issues associated<br />

with installing leak-tight PE systems.<br />

Through the acquisition of Advantica, <strong>GL</strong> Noble<br />

Denton’s heritage can be traced back to British Gas<br />

Research and Development whose research activities led<br />

to signifi cant advances in PE technology, facilitating the<br />

introduction of PE as a material of choice to the UK <strong>gas</strong><br />

sector. <strong>GL</strong> Noble Denton continues this proud tradition,<br />

offering high-end consultancy services to PE manufacturers<br />

and pipeline operators around the world.<br />

PE Quality Assurance<br />

Extensive research and test facilities allow <strong>GL</strong> Noble Denton<br />

to provide quality assurance and certifi cation to manufacturers<br />

and operators of PE pipelines, backed by over 30<br />

years experience in the PE business. Tests are performed<br />

to recognized standards (GIS standards PL2 or equivalent<br />

European standards). In addition to assisting the industry<br />

in the development of new products, carrying out type approval<br />

tests and supporting production testing, <strong>GL</strong> Noble<br />

Systematic Approach. <strong>GL</strong> Noble Denton assists clients in<br />

the development of their own working practices to build<br />

safe, leak-tight systems. This specifi c approach delivers<br />

real benefi ts in terms of construction improvements,<br />

safety culture and reduced joint failures on PE pipework.<br />

14 energıze

ABSTRACT<br />

Polyethylene (PE) is the material<br />

of choice for pipe networks –<br />

to ensure system integrity<br />

<strong>GL</strong> Noble Denton offers<br />

high-end consultancy ser -<br />

vices to PE manufacturers<br />

and pipeline operators<br />

<strong>01</strong>/2<strong>01</strong>1<br />

joint quality testing<br />

product development<br />

Denton offers a technical service for all<br />

types of PE pipes and fi ttings and is ac-<br />

credited under the BS ISO 90<strong>01</strong>:2000<br />

standard. Testing services include:<br />

full scale rapid crack propagation<br />

(RCP) testing<br />

type approvals testing<br />

Continuous Improvement<br />

Its heritage in developing engineering procedures for PE<br />

construction enables <strong>GL</strong> Noble Denton to assist clients in<br />

developing their own internal policies, procedures and<br />

working practices to build safe, leak-tight systems. This<br />

is especially important in Australia as the produced saline<br />

water is categorized as a pollutant. Even small leaks will<br />

very quickly lead to incidents that must be reported to the<br />

environmental regulator. The integrity of the PE system is<br />

therefore paramount.<br />

In-depth knowledge of PE, <strong>gas</strong> industry best practice in PE<br />

construction and a detailed understanding of on-site construc-<br />

tion and safety practices, coupled with highly-skilled auditors,<br />

deliver real benefi ts in terms of construction improvements,<br />

safety culture and reduced joint failures on PE pipework.<br />

Accelerated Pneumatic Pressure Testing<br />

Many years of research led to the development of com-<br />

plex algorithms to account for pressure, temperature and<br />

PE pipe creep which would otherwise mask leakage when<br />

undertaking pressure testing. Applying these calculations<br />

ensures accurate pressure testing and reduces pressure test<br />

time by up to 75 per cent. This can yield signifi cant time<br />

savings for pipeline operators where pneumatic pressure<br />

testing is undertaken SB<br />

Stability Test.<br />

High pressure can<br />

have disastrous<br />

effects on a pipe.<br />

<strong>GL</strong> NOBLE DENTON EXPERT:<br />

Simon Brooks<br />

Head of Technology Business Development<br />

Phone: +44 1509 282 326<br />

E-Mail: simon.brooks@gl-group.com<br />

15

australia resources<br />

Shale GaS Coal Seam GaS<br />

Unconventional Gas<br />

The increasing demand for energy is boosting the search for unconventional <strong>gas</strong> resources.<br />

<strong>GL</strong> Noble Denton offers new solutions to the challenges faced in taking <strong>gas</strong> to market<br />

Unconventional <strong>gas</strong> resources will play an in-<br />

creasingly important role in fulfilling future en-<br />

ergy requirements as conventional sources of<br />

natural <strong>gas</strong> mature and decline. This has become the case<br />

recently in Australia where coal seam <strong>gas</strong> is emerging as a<br />

significant source of <strong>gas</strong> supply and is a potential feedstock<br />

for liquefied natural <strong>gas</strong> exports from Eastern Australia. <strong>GL</strong><br />

Noble Denton has worked on several key projects utilizing<br />

unconventional <strong>gas</strong> sources and transporting them to market<br />

– an area of expertise which is going to expand into the future.<br />

16 energıze<br />

Photos: Dreamstime (3), Wusel007

The main sources of unconventional <strong>gas</strong> are:<br />

Coal seam <strong>gas</strong> – this is <strong>gas</strong> deposits that are stored<br />

within coal formations, either adsorbed into the coal or<br />

trapped within the pore spaces within the coal seam.<br />

Shale <strong>gas</strong> – this refers to natural <strong>gas</strong> which is stored in<br />

shale formations.<br />

Natural <strong>gas</strong> hydrates – these are crystalline solids com-<br />

posed of water and natural <strong>gas</strong> in a form of a physical<br />

compound where individual <strong>gas</strong> molecules exist within<br />

‘cages’ of water molecules.<br />

<strong>01</strong>/2<strong>01</strong>1<br />

Bio<strong>gas</strong> – this is a mixture of methane and carbon di-<br />

BioGaS<br />

oxide produced from the anaerobic digestion of waste<br />

materials.<br />

Natural GaS hydrateS<br />

Considerable Knowledge<br />

The <strong>gas</strong> composition from these uncon-<br />

ventional <strong>gas</strong> sources differs from typi-<br />

cal natural <strong>gas</strong>. In certain cases the <strong>gas</strong>es<br />

will need <strong>gas</strong> treatment to remove trace<br />

components in order to meet pipeline<br />

transportation specifications. <strong>GL</strong> Noble<br />

aBSTraCT<br />

Denton has developed considerable knowledge in<br />

<strong>GL</strong> Noble Denton uses technoeconomic<br />

models to identify the<br />

most appropriate <strong>gas</strong> processing<br />

technology<br />

The use of OPTAGON software is<br />

helpful in taking unconventional<br />

<strong>gas</strong> reserves to the market<br />

17

Monterey<br />

australia resources<br />

TraNSporT.<br />

LNG, Compressed<br />

Natural Gas (CNG),<br />

Adsorbed Natural<br />

Gas (ANG) and Gas<br />

to Liquids (GtL)<br />

are technology<br />

options for<br />

unconventional <strong>gas</strong><br />

transportation.<br />

Mowry<br />

Bakken<br />

Gammon<br />

Mancos/Green River/<br />

Baxter<br />

Niobara<br />

Cane Creek/<br />

Hovenweep Pierre<br />

McClure<br />

Lewis and<br />

Mancos<br />

Barnett and<br />

Woodford<br />

Woodford<br />

Palo<br />

Duro<br />

Barnett<br />

New Albany<br />

Excello/Mulky<br />

Pearsall<br />

Caney and<br />

Woodford<br />

Haynesville/<br />

Bossier<br />

Antrim<br />

Utica/<br />

Marcellus/<br />

Huron<br />

the production and processing requirements for<br />

these unconventional <strong>gas</strong> streams and has developed<br />

techno-economic models which assess each<br />

technology option from a technical, economic<br />

as well as environmental (carbon footprint) perspective.<br />

These models allow the most appropriate<br />

<strong>gas</strong> processing technology to be selected<br />

to treat the unconventional <strong>gas</strong>es to meet the<br />

<strong>gas</strong> quality specifications.<br />

Gas Quality and Safety<br />

Chattanooga<br />

Horton Bluff<br />

Floyd and<br />

Conasauga/Neal<br />

Shale Gas. The total resource potential of all<br />

the basins in the USA is about 500 to 1 ,000 tcf.<br />

The potential adverse impact of these trace components<br />

on the <strong>gas</strong> network and end-users also needs to be as-<br />

Recent<br />

Unconventional<br />

Gas Projects<br />

carried out by<br />

<strong>GL</strong> Noble Denton<br />

Techno-economic modelling of coal seam <strong>gas</strong><br />

and conversion into LNG<br />

Assessment of the impact of unconventional<br />

<strong>gas</strong>es on the network for the HSE<br />

Techno-economic modelling for the treatment<br />

of bio<strong>gas</strong> streams for various clients<br />

Production, processing and transportation of<br />

natural <strong>gas</strong> hydrates for the BG <strong>Group</strong><br />

Assessment of transportation options for coal<br />

seam <strong>gas</strong> wells in Scotland<br />

Supply chain availability modelling of coal<br />

seam <strong>gas</strong> and conversion into LNG<br />

sessed. <strong>GL</strong> Noble Denton has a substantial track record<br />

in <strong>gas</strong> quality measurements and can provide guidance on<br />

the impact of <strong>gas</strong> quality variations on <strong>gas</strong> grids and end<br />

use equipment. In a recent project, this expertise was put<br />

to use for the UK Health and Safety Executive (HSE) where<br />

safety cases and risk assessments were carried out to de-<br />

termine the impact of introducing coal seam <strong>gas</strong>, shale <strong>gas</strong><br />

and bio<strong>gas</strong> into the network.<br />

Often these unconventional <strong>gas</strong> sources are stranded –<br />

transportation by pipeline is not a feasible option, which<br />

means that alternative transportation technologies need<br />

to be considered. <strong>GL</strong> Noble Denton has developed tech-<br />

no-economic models to assess the various transportation<br />

18 energıze

Carnavon<br />

<strong>01</strong>/2<strong>01</strong>1<br />

Perth<br />

options and provide cost comparisons for the different<br />

options.<br />

Supply Chain Availability<br />

To ensure the fi nancial viability of developing unconventional<br />

<strong>gas</strong> resources, steps must be taken at all stages of<br />

the project life cycle to maximize production availability.<br />

Given the often complex and extensive nature of the facilities<br />

and infrastructure required to take unconventional <strong>gas</strong><br />

reserves to market, this extends beyond the process plant<br />

alone. In assessing the availability of such a project, all aspects<br />

of the <strong>gas</strong> supply chain must be considered. These<br />

may include the production facilities, gathering systems,<br />

process plant, transportation technologies (e.g. LNG liquefaction),<br />

logistics, and export routes to market. <strong>GL</strong> Noble<br />

Browse<br />

Bonaparte<br />

Estimated<br />

Australian <strong>gas</strong><br />

reserves<br />

Coal Seam Gas. Most of the<br />

exploration takes place in the<br />

eastern part of the continent.<br />

Amadeus<br />

Cooper-<br />

Eromanga<br />

Otway<br />

Adavale<br />

Bowen-Surat<br />

Bass<br />

Gippsland<br />

Photos: Dreamstime (3), Woodside, Wusel007<br />

Denton has extensive capability and a long track record<br />

in developing fully integrated <strong>gas</strong> supply chain availability<br />

models using their own OPTAGON software. Such models<br />

can provide essential input to inform key decisions at each<br />

stage of a project’s life cycle. SB<br />

<strong>GL</strong> NOBLE DENTON EXPERTS:<br />

Luisa Shelenko<br />

Consultant Unconventional Gas<br />

phone: +44 1509 282 852<br />

E-Mail: luisa.shelenko@gl-group.com<br />

Neil Wragg<br />

Senior Consultant asset optimisation<br />

phone: +44 1509 282 390<br />

E-Mail: neil.wragg@gl-group.com<br />

LNG Tanker. Berthed at the Karratha Gas Plant,<br />

North West Shelf Venture, Western Australia.<br />

19

offshore<br />

<strong>oil</strong> & <strong>gas</strong> merger<br />

The offshore industry faces<br />

huge challenges. Through<br />

the <strong>GL</strong> <strong>Group</strong> synergies,<br />

<strong>GL</strong> Noble Denton specialises<br />

in the provision of worldclass<br />

personnel and<br />

expertise in support<br />

of offshore marine<br />

operations.<br />

20<br />

energıze

Photo: Dreamstime<br />

<strong>01</strong>/2<strong>01</strong>1 21

offshore dynamic positioning<br />

Brain Power for Moving<br />

Heavy Equipment<br />

As <strong>oil</strong> and <strong>gas</strong> exploration has to enter into ever more remote and hostile<br />

environments to extract hydrocarbons, technical challenges keep mounting.<br />

Smart solutions can help, such as DP float-overs<br />

Placement. The “Rong<br />

Doi” topside was successfully<br />

installed via fl oatover<br />

in offshore Vietnam.<br />

22 energıze

<strong>01</strong>/2<strong>01</strong>1<br />

Neither direct positioning nor fl oat-over installa-<br />

tions are by themselves innovative technologies.<br />

Direct positioning was invented in the 1960s as<br />

a method of keeping ships and other fl oating structures in<br />

more or less fi xed position using a number of thrusters arranged<br />

around the hull. Computers nowadays pick up much<br />

of the fi ne-tuning during the process, using position input<br />

from a variety of sources, such as wind and motion sensors,<br />

seafl oor beacons, radar or GPS signals to compute the<br />

amount and direction of compensation movements.<br />

Attractive Alternative<br />

Float-overs have been the preferred method of installing<br />

<strong>oil</strong> platform topsides and similar large structures on top of<br />

their subsea supports. The conventional approach involves<br />

complex mooring and tethering systems whereby the barge<br />

carrying the topside to the installation site is slowly manoeuvred<br />

into the correct position so it can lower its cargo<br />

onto the supporting structure and hold it there while the<br />

topside is welded into place. It was the enormous effort,<br />

time and cost associated with this method that prompted<br />

<strong>GL</strong> Noble Denton to look for alternatives. On the open sea,<br />

the window of opportunity for such a complex procedure is<br />

often very small, and risk increases<br />

in proportion to the duration of<br />

ABSTRACT<br />

the operation.<br />

Float-overs are the preferred<br />

method of installing<br />

While many fl oat-over instal- topsides for offshore rigs<br />

lations have been done in recent Direct positioning technology<br />

lowers the cost and<br />

years, the fact that each instance<br />

risk involved in complex<br />

is celebrated in the press as a ma- installation projects<br />

jor accomplishment proves that<br />

they are by no means routine. And the bold idea of fl oating<br />

a barge carrying a large topside into the tight space,<br />

or “jacket”, between its future legs without holding on to<br />

something tangible can seem adventurous to an outsider.<br />

The fi rst such installation combining advanced direct<br />

23<br />

Photo: Ken Doerr

offshore dynamic positioning<br />

Equipment.<br />

Large thrusters<br />

bring the offshore<br />

vessel<br />

into the computercalculated<br />

position.<br />

positioning equipment and know-how with a floatover<br />

installation – a 2006 topside installation in the Gulf of<br />

Thailand – was thus carried out not only with the necessary<br />

redundant equipment, some of it specifically developed for<br />

this purpose, but also with a mooring system ready for all<br />

eventualities.<br />

The Precision of the Process<br />

<strong>GL</strong> Noble Denton engineered and planned the entire operation<br />

and was awarded the marine superintendency.<br />

Extensive Experience<br />

In addition to the many feasibility studies, <strong>GL</strong> Noble Denton has performed<br />

these float-overs to date:<br />

Bunga Raya A topside (DP assistance)<br />

Bunga Raya E topside (DP assistance)<br />

Rong Doi topside (DP)<br />

EGP-3A topside (moored)<br />

Bunga Orkid A topside (DP)<br />

Umm Shaif CSP-1 topside (DP)<br />

Umm Shaif UAP topside (DP)<br />

Umm Shaif CP-1 topside (moored)<br />

Maersk Oil Qatar – BG topside (DP)<br />

Maersk Oil Qatar – BE topside (DP)<br />

The installation went so smoothly that a subsequent sister<br />

project was carried out solely relying on direct positioning,<br />

without a mooring system as a back-up. The speed and<br />

precision of the process soon convinced other operators<br />

to try this method. The advantages speak for themselves:<br />

a DP float-over takes considerable less time and saves substantial<br />

cost compared to the traditional mooring method.<br />

In addition, it reduces risk exposure significantly. There are<br />

fewer parties involved, and no moorings or anchor handling<br />

tugs are needed.<br />

Photo: Ken Doerr<br />

Operation. Float-over<br />

of a topside by a<br />

semi-submersible<br />

heavy lift vessel.<br />

24 energıze<br />

Photo: Thrustmaster of Texas, Inc.

Guidelines for Float-Over Installations and Moorings<br />

<strong>GL</strong> Noble Denton has issued new guidelines for fl oat-over installations and for moorings. They have been developed on the basis of<br />

the company’s experience as the industry’s leading consultancy and assurance service for fl oatover operations and mooring instal-<br />

lations. They are now available for <strong>oil</strong> and <strong>gas</strong> companies, designers and contractors and describe current “industry good practice”<br />

which help <strong>oil</strong> and <strong>gas</strong> companies to have their mooring systems or fl oat-over operations approved by <strong>GL</strong> Noble Denton.<br />

All <strong>GL</strong> Noble Denton guidelines can be downloaded from: www.gl-nobledenton.com/en/rules_guidelines.php<br />

Industry fi rst: Float-over Guidelines<br />

THE “FLOAT-OVER GUIDELINES” (0031/ND) are an industry fi rst<br />

and refl ect the current popularity of fl oat-over operations. The<br />

guidelines draw on <strong>GL</strong> Noble Denton’s unique experience of<br />

fl oat-over operations, both on to fl oating hulls and fi xed plat-<br />

forms. The recent trend to use dynamic positioning (DP) for the<br />

fl oat-over operation is also covered. The guidelines now com-<br />

plete the whole topside or deck installation sequence namely,<br />

loadout, transportation and the fl oat-over operation itself.<br />

THE “MOORING GUIDELINES” (0032/ND) embrace not only<br />

the ISO 199<strong>01</strong>-7 standard on station keeping, but also ad-<br />

dress quayside moorings and short term moorings for marine<br />

operations such as loadouts and fl oat-overs. These guidelines<br />

are drawn from the involvement of <strong>GL</strong> Noble Denton in the<br />

design and operation of fl oating installations, mobile offshore<br />

units and installation vessels around the globe.<br />

Nevertheless, a DP installation requires careful prepara-<br />

tion, highly specialised equipment and careful guidance by<br />

highly experienced experts. In 2<strong>01</strong>1, <strong>GL</strong> Noble Denton is-<br />

sued new guidelines for fl oat-over installations (0031/ND),<br />

including the use of direct positioning for fl oat-over opera-<br />

tions. Describing current “industry good practice”, these<br />

guidelines draw on the extensive experience gathered in<br />

fl oat-over projects over many years. <strong>GL</strong> Noble Denton also<br />

offers approval services for fl oat-over operations based on<br />

these rules to minimise operational risk and fulfi l the re-<br />

quirements of insurance warranty. Furthermore, <strong>GL</strong> Noble<br />

<strong>01</strong>/2<strong>01</strong>1<br />

Four further guidelines updated<br />

THE “SELF-ELEVATING PLATFORMS – GUIDELINES FOR ELE-<br />

VATED OPERATIONS” (0009/ND) incorporate the recent up-<br />

dates to SNAME T&R Bulletin 5 and include <strong>GL</strong> Noble Denton's<br />

“Good Practice Recommendations for Preloading at ‘Diffi cult’<br />

Locations” and for “Jack-Up Recovery from Punch-Throughs”.<br />

THE “GUIDELINES FOR LOADOUTS” (0<strong>01</strong>3/ND) now reference<br />

“Guidelines for Mooring” to update the mooring sections.<br />

THE “CONCRETE OFFSHORE GRAVITY STRUCTURES – GUIDELINES<br />

FOR APPROVAL OF CONSTRUCTION, TOWAGE AND INSTALLA-<br />

TION” (0<strong>01</strong>5/ND) include many updates and now also reference<br />

“Guidelines for Moorings and Float-over Installations”.<br />

THE “SEABED AND SUB-SEABED DATA REQUIRED FOR AP-<br />

PROVALS OF MOBILE OFFSHORE UNITS (MOU)” (0<strong>01</strong>6/ND)<br />

now incorporates clarifi cation of the required depth of in-<br />

trusive site investigations, and the data expected from them.<br />

Denton, having pioneered fl oat-overs using direct position-<br />

ing, continues to offer independent expertise, consulting<br />

and assurance as well as operations management and ex-<br />

ecution services for fl oat-over projects. SNB<br />

<strong>GL</strong> NOBLE DENTON EXPERT:<br />

Robert W. Thomson<br />

Dynamic Positioning<br />

Phone: +1 832 300 6718<br />

E-Mail: bob.thomson@gl-nobledenton.com<br />

25

offshore fpso<br />

26<br />

Offshore.<br />

FPSOs have experienced<br />

massive growth over<br />

the last ten years, with<br />

more growth predicted.<br />

energıze

<strong>01</strong>/2<strong>01</strong>1<br />

Oil and <strong>gas</strong> production is increasingly moving<br />

to remote, offshore locations and into deeper<br />

and deeper waters as new fields are found in<br />

extremely challenging environments. Fresh <strong>oil</strong> and <strong>gas</strong> dis-<br />

coveries, such as those off the coast of West Africa and Bra-<br />

zil or in the North Sea, require new thinking from industry<br />

experts who must join forces to combine the best technolo-<br />

gy available. To extract remote hydrocarbons safely and ef-<br />

ficiently, operators now tend to prefer floating production,<br />

“Maximizing Asset Integrity”<br />

Floater Integrity Management (FIM) is the key to a long, productive and successful life of<br />

an FPSO, says Martin G. Brown, Consultant Naval Architect with <strong>GL</strong> Noble Denton<br />

ABStRACt<br />

storage and offloading (FPSO) systems to sea-bed mounted<br />

platforms. At the 25th FPSO Research Forum held in Aber-<br />

deen, Scotland, in September 2<strong>01</strong>0, the international del-<br />

egates reported on progress made at Forum-inspired joint<br />

industry projects and exchanged other technology news.<br />

The FPSO forum is one<br />

of the most important<br />

opportunities to discuss<br />

technology-focused topics<br />

<strong>GL</strong> Noble Denton focuses<br />

on FIM – without effective<br />

maintenance programmes,<br />

floating structures will<br />

quickly deteriorate<br />

To learn more about the technical<br />

challenges facing the global FPSO market<br />

we spoke with Martin G. Brown, Consul-<br />

tant Naval Architect with <strong>GL</strong> Noble Den-<br />

ton. He was lead organizer for the very<br />

successful Aberdeen Forum, a fact that<br />

highlighted the group’s role and reputa-<br />

tion as a global supplier of FPSO expert-<br />

ise. The event is held in different centres<br />

around the world to share the burden of travel. The first<br />

FPSO Forum for 2<strong>01</strong>1 will be held in Monaco in March.<br />

ENERGIZE: Why is the FPSO Forum so important to the<br />

industry, and what were the main results of the particu-<br />

lar meeting last September in Aberdeen?<br />

27

offshore fpso<br />

BROWN: The first FPSO Forum was held in 1998 and<br />

the event – which is held twice a year – is now acknowl-<br />

edged to be one of the most important opportunities for<br />

industry experts to discuss technology-focused topics sur-<br />

FIM.<br />

rounding the use of FPSOs. Forums are held in the middle<br />

of so-called “JIP Weeks” where the steering<br />

The aim is to ensure<br />

management and<br />

continuous follow-up<br />

teams of a number of Joint Industry Projects<br />

(JIP) share knowledge and experiences.<br />

of floating units from<br />

During these meetings, progress reports are<br />

a safety, environmental,<br />

operational,<br />

maintenance and<br />

given on several active JIPs such as those studying<br />

fatigue, computational fluid dynamics (CFD),<br />

quality management mooring integrity, corrosion and rogue waves.<br />

viewpoint. The JIP meetings are closed to the media, allow-<br />

Aberdeen.<br />

The latest FPSO<br />

Forum, organized<br />

by <strong>GL</strong> Noble<br />

Denton, was held<br />

in the Scottish <strong>oil</strong><br />

capital of Europe.<br />

ing participants to speak freely and to share experiences,<br />

whether good or bad, in confidence. To date, meetings have<br />

been focused on hydrodynamic, structural and marine issues.<br />

ENERGIZE: An FPSO can be described as a cross between a<br />

ship and an <strong>oil</strong> processing facility. How does this affect <strong>GL</strong><br />

Noble Denton’s approach to working with such vessels?<br />

Hybrid.<br />

FPSOs are a cross between a<br />

ship and an <strong>oil</strong> processing<br />

facility.<br />

BROWN: Seeking a balance between the marine and pro-<br />

cess functions is one of our industry’s key challenges. The<br />

two aspects require very different technical backgrounds,<br />

and it is important to get the balance right between these<br />

disciplines. Due to production demands and the remote<br />

areas FPSOs operate in, these units are only dry-docked<br />

for exceptional repair and maintenance needs. If <strong>GL</strong> Noble<br />

Denton engineers and designers are involved from the start<br />

of the design process then we are in a position to identify<br />

opportunities for safe, efficient life-long operations together<br />

with tangible cost savings at this vital early stage. Introducing<br />

concepts such as Floater Integrity Management<br />

(FIM) at an early design stage is key to a successful and<br />

productive life of an FPSO. It includes recommendations<br />

on inspection, maintenance and repair based on a project<br />

specific risk-based assessment. It also allows operators to<br />

optimize the value of their <strong>oil</strong> and <strong>gas</strong> assets throughout<br />

their life cycle while at the same time reducing the risk of<br />

accidents and production shut downs.<br />

ENERGIZE: How is the cooperation between <strong>GL</strong> Noble<br />

Denton and owners and operators evolving?<br />

BROWN: FPSO technology has developed significantly since<br />

its introduction in the early 1980s when most vessels were<br />

28 energıze

converted <strong>oil</strong> tankers, which limited options for major chang-<br />

es in vessel layout. Today many FPSOs are newbuilds. Where<br />

<strong>GL</strong> Noble Denton is involved with vessel design at any early<br />

stage, we can provide an effective cradle-to-grave service. We<br />

believe that maintaining a lifelong involvement in the asset<br />

is in the best interests of the FPSO, its crew and its opera-<br />

tor. Each vessel has its own idiosyncrasies, maintenance and<br />

repair history and we believe that it is operationally effective<br />

to keep the knowledge and experience within the company.<br />

FPSOs are frequently relocated at the end of their field life<br />

and thus need to be maintained in a safe and suitable condi-<br />

tion to enable a prolonged profitable life and low risk removal.<br />

ENERGIZE: What are the key challenges facing FPSO op-<br />

erators?<br />

BROWN: The technical complexity of an FPSO requires a<br />

different approach compared to managing tankers and<br />

fixed offshore platforms. Generally, aging offshore infra-<br />

structure presents the industry with a constant and grow-<br />

ing challenge, made more acute by a shortage of people<br />

with the combined experience of both marine (shipping)<br />

and offshore (<strong>oil</strong> and <strong>gas</strong>) operations that are needed to<br />

support the growing FPSO fleet.<br />

Also, as many floating production systems are now ap-<br />

proaching the middle or end of their design lives, operators<br />

are seeking assurance regarding continued integrity of their<br />

assets, from the process train to the risers, subsea architec-<br />

ture, hull, marine systems and moorings. If maintenance<br />

regimes have been kept up to date, then extending the<br />

working life can be very cost-effective. If not, a costly refit<br />

might be necessary.<br />

ENERGIZE: Human factors and aging equipment are key<br />

parameters affecting the safe and effective long-term<br />

operation of an FPSO. What is your approach?<br />

BROWN: Yes, these are indeed some of the most difficult<br />

issues the industry is facing. Aging offshore infrastructure<br />

presents the industry with a constant and growing chal-<br />

lenge. Our approach is to focus on FIM – without effective<br />

integrity programmes, floating structures will deteriorate<br />

quicker than bottom mounted fixed structures.<br />

<strong>01</strong>/2<strong>01</strong>1<br />

Profile<br />

MARtIN G. BROWN The Consultant<br />

Naval Architect with<br />

<strong>GL</strong> Noble Denton was Project<br />

Manager for the 25th FPSO Research<br />

Forum in Aberdeen last October. It was the<br />

first time <strong>GL</strong> Noble Denton hosted the event which<br />

takes place twice a year.<br />

<strong>GL</strong> NOBLE DENTON ExPErT:<br />

Martin G. Brown,<br />

Consultant Naval Architect<br />

Phone: +44 1224 289 108<br />

E-Mail: martin.brown@nobledenton.com<br />

ENERGIZE: Asset integrity is a key concern in FPSO man-<br />

agement. How does <strong>GL</strong> Noble Denton approach this issue?<br />

BROWN: Maximizing asset integrity is key to ensuring FPSOs<br />

have a long, safe and productive life. If you visit an FPSO at<br />

a shipyard, there can be hundreds of people working on-<br />

site. Offshore, however, the number of maintenance people<br />

present at any one time is limited due to limited personnel<br />

on board (p.o.b.) accommodation constraints. The integrity<br />

of the hull, topsides and subsea systems must be maintained<br />

without the risks and high costs incurred by dry-docking. As<br />

the vessel ages the number of problems increases but with<br />

well planned interventions maintenance backlogs can be<br />

kept under control.<br />

ENERGIZE: What will be the future role of <strong>GL</strong> Noble Denton<br />

in the FPSO market?<br />

BROWN: <strong>GL</strong> Noble Denton draws on over 100 years of maritime<br />

and offshore energy experience. Much of this time was<br />

dedicated to working with the huge variety of vessels used<br />

to find and safely extract hydrocarbons from under the sea.<br />

Floating production is a growing market in which we can<br />

put our extensive experience and expertise to good use. We<br />

look forward to a long and fruitful relationship with this<br />

market. BMM<br />

29

integrity<br />

<strong>oil</strong> & <strong>gas</strong> merger<br />

30<br />

energıze

Photo: Dreamstime<br />

Safety, effi ciency, environment<br />

protection:<br />

<strong>GL</strong> Noble Denton<br />

offers a holistic asset<br />

integrity management<br />

capability for the<br />

entire life cycle of<br />

<strong>oil</strong> and <strong>gas</strong> assets.<br />

<strong>01</strong>/2<strong>01</strong>1 31

integrity software I<br />

32<br />

Gas Plant.<br />

The software product<br />

GALIOM improves the<br />

reliability of inspection<br />

and maintenance.<br />

GALIOM Makes Inspection<br />

Data Acquisition an Easy Job<br />

ultrasonic wall thickness reading is one of the more labour-intensive inspection<br />

tasks. using a data logger and galiom cuts time, effort and costs<br />

energıze

Photo: BP<br />

abstract<br />

Carrying out technical inspections and compil-<br />

ing inspection data is laborious work. Oil and<br />

<strong>gas</strong> operators spend millions on having their<br />

platforms and pipelines inspected and wall thickness data<br />

collected. While electronic data loggers, which record data<br />

over time or in relation to location, are commercially avail-<br />

able and used extensively, data reporting is often done<br />

manually using paper forms. Electronic data is rarely kept<br />

in a centralized database.<br />

Automatic Process<br />

“This poses a challenge to managing advanced risk assess-<br />

ments,” says Mathews Varkey, GALIOM Programme Man-<br />

ager at <strong>GL</strong> Noble Denton, referring to Risk-Based Inspec-<br />

tion (RBI). During the analysis, engineers spend numerous<br />

hours gathering and formatting data before some mean-<br />

ingful trend can be derived. An advanced risk-based in-<br />

spection and maintenance software product such as <strong>GL</strong><br />

Noble Denton’s GALIOM can ease operators’ minds, he<br />

The advanced risk-based inspection<br />

and maintenance<br />

software product GALIOM<br />

reduces risks and costs<br />

GALIOM facilitates data<br />

acquisition and helps<br />

inspectors to validate the<br />

results and plans<br />

<strong>01</strong>/2<strong>01</strong>1<br />

explains. “The data logger module as-<br />

sists inspectors with wall thickness<br />

measurements, reducing the time it<br />

takes them to enter the huge amounts<br />

of data collected during inspection.”<br />

“To give an example,” Mathews con-<br />

tinues, “a petrochemical company that<br />

had been using a legacy system for sev-<br />

eral years decided to switch to a more<br />

advanced process. Implementing GALIOM brought a totally<br />

automated solution to this scenario.” The GALIOM imple-<br />

mentation team first examined the data loggers the client<br />

GALIOM<br />

GALIOM is a combined asset integrity management<br />

and risk-based inspection and maintenance<br />

software product that can be used for<br />

any <strong>oil</strong>, <strong>gas</strong> or petrochemical facility.<br />

The data logger module assists the inspector<br />

with the wall thickness measurements<br />

and also reduces the data entry time for huge<br />

amount of data collected during inspection.<br />

GALIOM helps to achieve the best possible<br />

balance between cost and risk by minimizing<br />

unplanned downtime and optimizing production.<br />

GALIOM enables risk mitigation and inspection<br />

strategies to be developed and implemented<br />

with the aim of optimizing maintenance<br />

whilst staying within acceptable risk levels.<br />

was using. The team then used the GALIOM data logger<br />

integration module to enable the software to communicate<br />

with the hardware and automate the ultrasonic wall thick-<br />

ness recording and data synchronization processes. Now<br />

the customer can capture data with the existing data log-<br />

gers and process and monitor them using GALIOM.<br />

The GALIOM module deployed by the customer plans,<br />

prepares and defines the scope of the inspection work. The<br />

two-way communication between GALIOM and the data<br />

loggers accelerates the inspection activities considerably.<br />

The test points are automatically generated by the GALIOM<br />

data logger module, and subsequently downloaded into<br />

the logging device for the inspection.<br />

“In the field, the inspector does not need to create<br />

test points any more, which saves a tremendous<br />

33

integrity software I<br />

Maintenance. Due to GALIOM data inspectors and<br />

engineers stay on top of things.<br />

amount of time,” says Mathews. Following each inspection,<br />

or at the end of the day, the data is downloaded<br />

into GALIOM for validation and reporting. GALIOM helps<br />

the inspector to validate the results and plans, and to<br />

create packages for reinspection. Finally, the wall thickness<br />

data collected is transferred into a monitored database for<br />

trending and analysis. Anomalous data goes through<br />

GALIOM’s inspection memo and the anomaly screening<br />

module to initiate repairs and replacements. “GALIOM<br />

allows inspectors and engineers to acquire high-quality<br />

data effi ciently,” says Mathews. MV<br />

Thailand: GALIOM Software<br />

Manages Risk for PTT CHEM<br />

<strong>GL</strong> NOBLE DENTON EXPERT:<br />

mathews Varkey<br />

galiom Programme manager<br />

Phone: +60 321610088-1059<br />

e-mail: mathews.varkey@gl-group.com<br />

Thailand’s petrochemical manufacturer PTT CHEM has selected <strong>GL</strong> Noble Denton’s GALIOM software to<br />

manage risk anD reliability in their “Risk and Reliability Methodology (RRM) Implementation Project”. The<br />

software solution from <strong>GL</strong> Noble Denton will be applied to plant insPection anD maintenance in 13 PTT<br />

CHEM plants in Thailand.<br />

PTT CHEM has been faced with the challenge of having a consistent risk and reliability methodology across<br />

all its petrochemical and chemical production plants. The implementation project will make GALIOM fully integrated<br />

with PTT CHEM’s SAP system for asset synchroniZation, work orDer generation anD trans-<br />

Ferring insPection Plans. The scope also includes data migration of risk based inspection (RBI), reliability<br />

centred maintenance (RCM) and safety integrity levels (SIL) data from existing RRM software.<br />

34 energıze<br />

Photo: Dreamstime

Taking Hull Maintenance<br />

to the Next Level<br />

Maintenance of a vessel’s hull structure is a major concern for shipowners and FPsO operators<br />

alike. a well-chosen and effectively implemented hull maintenance strategy not only reduces<br />

the risk of incidents but assures integrity and safeguards the environment<br />

Ship managers continuously monitor their ves-<br />

sels’ structural condition in order to detect de-<br />

ficiencies in the hull structure at an early time<br />

and initiate necessary maintenance actions. Typically, moni-<br />

toring is done by appointed crew members through peri-<br />

odic visual inspections. Because of the size and complexity<br />

of the tanks and cargo holds, the location and extent of<br />

coating breakdown, defects, corrosion, etc. are hard to<br />

document with sufficient accuracy us-<br />

abstract<br />

ing text descriptions and photos only,<br />

<strong>GL</strong> HullManager is a soft- unless their exact location in the strucware<br />

application designed<br />

ture can be expressed reliably.<br />

to support the entire hull<br />

structure inspection process<br />

Offshore FPSO operators Critical Work<br />

will benefit from <strong>GL</strong> Hull-<br />

Manager as an integrity tool FPSO operators may not always have<br />

and communication aid the option of dry-docking their units.<br />

Tank structure inspections must therefore<br />

be conducted on a campaign basis. This is critical work,<br />

and several operators have discovered material cracking<br />

and defective coating in their FPSOs that must be addressed<br />

if these units are to continue operating for the long term.<br />

Planning, preparing, executing, reporting on, and assessing<br />

hull structure inspections is a crucial process that<br />

requires utmost diligence. This is where <strong>GL</strong> HullManager<br />

maintenance software and service package comes in.<br />

<strong>01</strong>/2<strong>01</strong>1<br />

integrity software II<br />

“<strong>GL</strong> HullManager uses a 3-D model of the vessel to<br />

show actual plates and stiffeners or frames of each tank<br />

or other space in the ship,” explains Dr Christian Cabos,<br />

<strong>GL</strong>’s Head of Department – CAE Development. “Inspection<br />

forms with images of the structural members of the inspected<br />

tank can be printed out to mark findings and positions<br />

on photos using a pen during the inspection. This<br />

information can be entered into the software in an easy<br />

onboard interactive process with the 3-D model.”<br />

The ability to represent all findings visually is particularly<br />

helpful in the <strong>oil</strong> and <strong>gas</strong> sector, where marine management<br />

have to present their assessments to senior operations<br />

management, who are not typically from<br />

3D modelling. The software solution<br />

<strong>GL</strong> HullManager is based on a 3D geometric<br />

representation of the particular vessel.<br />

35

integrity software II<br />

Fleet. The FPSO unit<br />

Petrojarl Cidade DRDO<br />

belongs to the Teekay<br />

Corporation.<br />

a marine background and benefit from the ability<br />

to visualize the issue at hand using a virtual model of the<br />

unit.<br />

Uniform Reporting Standard<br />

<strong>GL</strong> HullManager can make information on the condition of<br />

hull structures available to any employee across the company<br />

once the inspection results have been ap-<br />

Iacs.<br />

proved and synchronized. Stored in a lifecycle<br />

International<br />

database, hull condition data for each individu-<br />

Association of<br />

Classification<br />

al vessel can be traced over time. Sister vessels<br />

Societies,<br />

from the same fleet can be compared easily. A<br />

headquartered<br />

dashboard overview of the entire ship makes it<br />

in London, was<br />

founded in<br />

easy to pinpoint any critical findings by crew or<br />

Hamburg in<br />

third-party inspectors.<br />

1968.<br />

“For shipping companies, the true value of<br />

hull inspection can be seen once you apply a<br />

uniform reporting standard,” says Christian Cabos. Pregenerated<br />

inspection forms, including a checklist based on<br />

IACS recommendations and the accompanying <strong>GL</strong> guideline<br />

for rating defects, ensure such uniform reporting across<br />

a fleet of vessels with varying crews. “Since the images on<br />

the inspection forms are based on the 3-D model of the<br />

actual vessel, the quality of reports prepared by crew members<br />

increases significantly.”<br />

As for the <strong>oil</strong> and <strong>gas</strong> producer, there is considerable<br />

value to be gained from a consistent assessment process<br />

across the entire range of assets, from marine systems to<br />

topsides to subsea equipment. <strong>GL</strong> Noble Denton’s full suite<br />

of modular integrity software, including <strong>GL</strong> HullManager, is<br />

a major step towards implementing a truly consistent risk<br />

management approach.<br />

The <strong>GL</strong> HullManager shipping package comprises shipboard<br />

and onshore software, associated training and a<br />

hull survey guideline. The software solution supports the<br />

inspection, reporting, and assessment of the condition of<br />

a ship’s hull with respect to coating condition, corrosion,<br />

structural defects and findings on outfittings. A compre-<br />

36 energıze

FPSO. The 3-D model of the vessel helps to<br />

improve the quality of inspection reports.<br />

<strong>01</strong>/2<strong>01</strong>1<br />

Application.<br />

<strong>GL</strong> HullManager<br />

makes it possible<br />

to attach<br />

photos and<br />

mark fi ndings<br />