The Celcon Thin-Joint System A Definitive Guide - Masonry First

The Celcon Thin-Joint System A Definitive Guide - Masonry First

The Celcon Thin-Joint System A Definitive Guide - Masonry First

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

®<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

A <strong>Definitive</strong> <strong>Guide</strong><br />

Cl/SfB<br />

Ff4

contents<br />

1 <strong>The</strong> Aircrete Advantage 1<br />

2 <strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> 2-7<br />

3 <strong>Thin</strong>-<strong>Joint</strong> Installation 8-9<br />

4 Design <strong>Guide</strong>lines 10-17<br />

5 U-Value Tables 18-19<br />

6 Frequently Asked Questions 20<br />

7 Further Information 21

Aircrete combines superb thermal and sound insulation qualities,<br />

with impressive loadbearing capabilities.<br />

Simple to work with, it has the benefit of being light and has a<br />

high resistance to water penetration, fire, frost and sulfate attack.<br />

introducing the<br />

<strong>The</strong> Aircrete Advantage<br />

<strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> combining <strong>Celcon</strong>’s new Plus<br />

block range of high quality accurately dimensioned aircrete blocks,<br />

with Celfix, a specially developed thin layer mortar.<br />

<strong>The</strong> <strong>System</strong> enables the structure of a building to be<br />

constructed faster and to a better quality, allowing follow-on<br />

trades to start work sooner in a weatherproof environment,<br />

whilst retaining the flexibility of on-site construction.<br />

Fully adopted as the preferred method of wall construction<br />

throughout most of Europe, this innovative and<br />

award-winning system has now firmly established itself<br />

within the UK.<br />

1<br />

1

2 <strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

2<br />

In recent years, pressure from stakeholders within the industry<br />

including builders, developers, architects, end users and<br />

Government agencies, require manufacturers to increase both<br />

productivity and quality of build on site whilst retaining<br />

flexibility allowing buildings to be extended or improved.<br />

H+H <strong>Celcon</strong> prides itself on being at the forefront<br />

of innovative building technology, of which the<br />

<strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> is a prime example.<br />

speed, quality and<br />

flexibility<br />

Speed Productivity has become a key aspect in choosing a<br />

construction method. <strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> allows<br />

construction times equivalent to off-site system-build solutions.<br />

This is possible due to the following benefits of the <strong>System</strong>:<br />

- Increased bond strength<br />

- No mortar ‘swimming’ allowing continued laying<br />

- Ease of mixing and laying mortar<br />

- Highly dimensionally accurate blocks<br />

- Ease of preparing/mixing small quantities<br />

when required<br />

Quality <strong>The</strong> improvements in build quality gained from<br />

the use of the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> are:<br />

-<br />

Improved thermal performance<br />

-<br />

Improved stability during construction<br />

-<br />

Improved build accuracy of finished walls<br />

Reduction of site wastage

Flexibility As with traditional building methods, the<br />

construction is carried out on site. This allows the builder to<br />

overcome problems which may have been overlooked at the<br />

design stage and simplifies change to the building should it<br />

need to be extended or adapted to suit future lifestyles:<br />

- Easy to extend or adapt later on<br />

- Construction problems can more easily<br />

be solved on site<br />

- Additional finishes are available<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

Modern Methods of<br />

Construction (MMC)<br />

is a broad based category embracing a<br />

variety of build approaches, including<br />

but not limited to Off-siteManufacture<br />

(OSM). <strong>Celcon</strong>’s <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> has<br />

been quoted as an example of MMC<br />

within the Housing Corporation<br />

Programme Notification PN 06/03<br />

‘Definitions of ‘Build Category’ for<br />

bids and allocation purposes’<br />

(see quote below).<br />

Meeting the criteria as a Non-OSM<br />

Modern Method of Construction the<br />

system incorporates innovative house<br />

building techniques and structural<br />

systems, with the presence of<br />

innovation being an essential feature,<br />

in this instance by traditional<br />

components being combined in<br />

innovative ways.<br />

“ Non-OSM Modern<br />

Methods of<br />

Construction This category is<br />

intended to encompass schemes<br />

utilising innovative housing building<br />

techniques and structural systems<br />

that fall outside the OSM categories.<br />

<strong>The</strong> presence of innovation is an<br />

essential feature that might manifest<br />

itself through an innovative non-OSM<br />

building system, through a building<br />

technique familiar in other sectors<br />

but new to house-building, or through<br />

traditional components being<br />

combined in innovative ways...<br />

Typically H+H <strong>Celcon</strong>’s <strong>Thin</strong>-<strong>Joint</strong><br />

<strong>System</strong> would fall into this category.<br />

Housing Corporation Programme<br />

Notification PN 06/03<br />

“<br />

2<br />

3

2<br />

4<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> can be used for many forms of<br />

construction: cavity walls (inner and outer leaf), solid walls,<br />

walls adjacent to unheated spaces (formerly known as<br />

semi-exposed), partitions, separating walls and foundations.<br />

<strong>Thin</strong>-<strong>Joint</strong> diversity<br />

Cavity walls When building with the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>, the inner leaf of<br />

blockwork can be built first taking the outer leaf off the critical path of the build programme.<br />

This enables internal work to proceed whilst the outer leaf is being constructed, easier<br />

inspection of the cavity and simple installation of any additional insulation required.

Solid external walls Solid wall construction shows the<br />

<strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> at its full potential. Applying Celfix Mortar<br />

with either a ‘scoop’ or alternatively with a ‘sledge’, which is specifically<br />

designed for use with solid wall construction, the superstructure of a<br />

dwelling can be completed in 2-3 days. <strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

offers the designer a choice of solutions with the benefit of both<br />

strength and thermal insulation. <strong>The</strong> use of thin layer mortar techniques<br />

give greatly improved U-values of up to 20% when compared to<br />

conventional joints in solid external walls and can meet the thermal<br />

regulations without the need for additional insulation.<br />

Partitions Ideally suited for the construction of partition walls, the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong><br />

<strong>System</strong> adds to the existing benefits offered by <strong>Celcon</strong> blocks, such as excellent sound<br />

insulation and high fire resistance. With the speed of build and the mortar setting more quickly,<br />

it is possible for the walls to be finished i.e. plastered, without delay. <strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong><br />

<strong>System</strong> also allows greater flexibility and more choice in applied finishes, see Page 17. <strong>The</strong>se<br />

benefits can be further enhanced when Jumbo Plus Blocks are used to build partition walls.<br />

Separating walls Separating and flanking walls constructed with the <strong>Celcon</strong><br />

<strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> satisfy the sound insulation requirements of the National Building<br />

Regulations allowing the building to benefit from the construction speed of the <strong>Celcon</strong><br />

<strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> whilst retaining an homogeneous build system. For further details see<br />

<strong>Celcon</strong>’s <strong>Guide</strong> to Part E Sound Insulation Regulations or contact our Technical Services<br />

Department for detailed advice on constructions meeting the requirements for separating and<br />

flanking walls.<br />

Foundations Celfix Mortar is suitable for use in classes DS1 and DS2 soil and<br />

groundwater conditions as defined in Table 2 of BRE Special Digest 1 - Concrete in aggressive<br />

ground Part 1:2001.<br />

Extensions Whether the wall is solid or cavity construction, the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

is ideal when building extensions. <strong>The</strong> inherent speed of build enables quicker construction<br />

times, excellent thermal efficiency meeting today’s thermal requirements, reduced wastage of<br />

blocks and mortar and a potentially cleaner site.<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> 2<br />

5

2 <strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

6<br />

<strong>Thin</strong>-<strong>Joint</strong><br />

Celfix Mortar<br />

components...<br />

Produced with the latest manufacturing technology at H+H <strong>Celcon</strong>’s<br />

plant in Yorkshire, Plus and Jumbo Plus blocks benefit from sharp<br />

clear arrises and excellent dimensional tolerances making them ideal<br />

for use with the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>. <strong>The</strong>y are produced with a<br />

plain face and are supplied nationwide with any Celfix Mortar order.<br />

<strong>The</strong> key to the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> is Celfix Mortar,<br />

designed specifically for use with <strong>Celcon</strong> blocks. It is supplied<br />

dry and pre-mixed in 25kg bags, and should be added to water<br />

(approx. 4.5 litres per bag, for yield see page 12) and mixed<br />

until a thick smooth consistency is achieved, as instructed on<br />

the pack. Applied with either a ‘scoop’ or ‘sledge’ to maintain a<br />

consistent joint thickness of 2mm, it remains workable within<br />

the bucket for a number of hours, but reaches initial bond<br />

strength on the block within 10-20 minutes and full design<br />

bond strength within 1-2 hours.<br />

<strong>Celcon</strong> Plus blocks - Face size 610mm x 140mm<br />

Produced in thicknesses from 200mm upwards, they are designed for<br />

solid wall and foundation construction, meeting the CONIAC limit of<br />

20kg for repetitive lifting, and are manufactured in Solar, Standard and<br />

Hi-Strength grades.<br />

<strong>Celcon</strong> Plus blocks - Face size 610mm x 215mm<br />

<strong>The</strong> Plus blocks are produced in various thicknesses. <strong>The</strong>y are suitable<br />

for the construction of solid and cavity wall types and manufactured in<br />

Solar, Standard and Hi-Strength grades.<br />

<strong>Celcon</strong> Jumbo Plus blocks - Face size 610mm x 270mm<br />

<strong>The</strong> Jumbo Plus block is produced in various thicknesses. <strong>The</strong>y are<br />

suitable for the construction of cavity wall types, manufactured in Solar,<br />

Standard and Hi-Strength grades. <strong>The</strong>se larger format blocks can increase<br />

the speed of construction whilst improving the thermal performance of<br />

the building by reducing cold bridging through the mortar.

...and tools<br />

As with any new building system, new tools and equipment will be required.<br />

<strong>The</strong> following is a list of such items with an indication as to how many are required<br />

per working team.<br />

Tools required<br />

1 Scoop*/sledge per blocklayer<br />

1 Sanding board* between 2 blocklayers<br />

1 Block rasp* between 2 blocklayers<br />

1 Block cutting square* per blocklayer<br />

1 Bucket/large tub per gang<br />

1 Whisk attachment for drill per gang<br />

1 <strong>Masonry</strong> hand saw<br />

or<br />

1 Mechanical hand<br />

per blocklayer<br />

saw/circular saw<br />

Alternatively<br />

between 2 blocklayers<br />

1 Band saw per plot<br />

*<strong>The</strong>se items are available from H+H <strong>Celcon</strong> (through appointed<br />

stockists). For prices and availability please contact our Sales<br />

Office on 01732 886444.<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong><br />

just add water!<br />

Sledge for<br />

thin-joint<br />

applications,<br />

200mm walls<br />

or above<br />

Scoops<br />

2<br />

7

3 <strong>Thin</strong>-<strong>Joint</strong><br />

8<br />

Installation<br />

a step by step guide<br />

Building with the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> is a fast and<br />

simple process. <strong>The</strong> greatest benefits are achieved where<br />

the blockwork inner leaf is constructed first, creating a<br />

weather tight environment for follow on trades to work in.<br />

With the brickwork taken off the critical path, it can be<br />

constructed within the remaining build programme, using<br />

several types of widely available wall ties produced for use<br />

with <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>s, see page 16.<br />

2<br />

3<br />

1 To gain the maximum benefit from the<br />

<strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>, it is necessary to<br />

adapt the schedule of materials and services supplied to<br />

the site, e.g. the blockwork should reach first floor level<br />

in 1-2 days, therefore scaffolding needs to be in place<br />

before starting the build. Lintels and floor joists will need<br />

to be on site during this period.<br />

<strong>The</strong> first course of blocks should be bedded normally using<br />

a conventional designation (iii) mortar. Conventional mortar<br />

is required to accommodate any irregularities in the<br />

supporting structure. This base course can use Celfix Mortar<br />

if the <strong>System</strong> has been used in the foundations or the slab<br />

is sufficiently flat.<br />

It is essential that the blocks are laid accurately, true to level<br />

(±1mm) and vertical (many builders use a simple laser level for<br />

speed and accuracy). <strong>The</strong> perpend joints on the first course can<br />

be of Celfix Mortar giving a more rigid base in a shorter time.<br />

Should any irregularities or imperfections occur on the bed<br />

course, surfaces should be sanded down using a proprietary<br />

sanding board. <strong>Joint</strong>ing faces should be clean and free from<br />

dust, if necessary, cleaned using a stiff brush.<br />

4

8 Provided the initial stages are followed,<br />

the quality and speed of the <strong>Celcon</strong><br />

<strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> allows continual building, with no<br />

need to wait for mortar to set. With the brickwork<br />

taken off the critical path this allows the first lift<br />

to be easily achievable in one day and building to<br />

roof plate within 2-3 days.<br />

Blocks can be cut with traditional hand tools,<br />

such as a hand saw and a cutting square.<br />

However, builders have found it more efficient<br />

on larger sites to use mechanical tools such as<br />

electric hand saws or circular saws.<br />

Wall ties are available for cavity wall<br />

construction, enabling the greatest<br />

benefits to be achieved by building<br />

6<br />

the inner leaf first.<br />

Supplied dry and pre-mixed in bags, Celfix Mortar should<br />

be added to water (full guidance is given on the bag) in<br />

a clean bucket. Mixing using a power tool with whisk<br />

attachment set at a low speed, achieves the thick smooth<br />

consistency required. Celfix is workable for several hours<br />

whilst in the bucket. Celfix Mortar should be applied<br />

using either a scoop, available in sizes from 75–200mm,<br />

or by using sledges, available in sizes from 200-300mm.<br />

Both of which will provide a consistent joint thickness of<br />

2mm. As laying proceeds, blocks should be pressed<br />

firmly against the mortared vertical face whilst lowered<br />

onto the mortared bed below, ensuring that the joints<br />

are fully filled.<br />

5<br />

<strong>Thin</strong>-<strong>Joint</strong> Installation 3<br />

7<br />

9

4 Design <strong>Guide</strong>lines<br />

10<br />

FIRE RESISTANCE<br />

Structural design<br />

Fire resistance<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> should be used following the general<br />

recommendations of BS 8000 Part 3:2001 and BS 5628-3:2001 and<br />

BBA certificate 01/3816. In addition, <strong>Celcon</strong>’s ‘Book of Blocks’<br />

contains advice on general site practice. <strong>The</strong> inherent properties of<br />

aircrete applies equally to thin-joint masonry.<br />

Walls constructed using the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> can be designed in accordance<br />

with the structural Eurocode for masonry ENV1996.1.1. Better values of masonry<br />

compressive strength are achieved with Celfix Mortar when compared to general purpose<br />

mortar. It is also possible to design to BS 5628-1:1992 assuming a characteristic<br />

compressive strength of <strong>Celcon</strong> thin-joint masonry based on Table 2 values given for<br />

designation (i) mortars.<br />

<strong>The</strong> characteristic flexural strengths of <strong>Celcon</strong> thin-joint walls can be taken to have the<br />

same values as those for designation (i) mortars in BS 5628-1:1992 Table 3.<br />

<strong>Celcon</strong> blocks have excellent resistance to fire. Extensive use has proved their<br />

capability in fire-break walls and as protective cladding for other forms of construction,<br />

for example steel frames.<br />

<strong>Celcon</strong> blocks are classified as non-combustible and have a class 0 surface spread of<br />

flame as described in the National Building Regulations.<br />

<strong>The</strong> figures given in the table below have been derived from Eurocode 6:<br />

Design of <strong>Masonry</strong> Structures:Part 1-2. General rules – Structural fire design (DD ENV<br />

1996-1-2:1997) together with the UK National Application Document.<br />

If <strong>Celcon</strong> blocks are to be used in cavity wall constructions, either in new build or<br />

renovation work, the thickness shown below may be reduced; contact the Technical<br />

Services Department for further advice.<br />

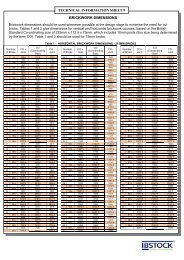

Minimum block thickness excluding finishes(mm)<br />

Loadbearing wall Non-loadbearing wall<br />

up to up to<br />

Fire resistance (hours) 1 2 4 6 1 2 4 6<br />

Solar range 100 130 200 - 75 100 140 -<br />

Standard & Hi-Strength ranges 90 100 190 215 75 75 100 150

Sound insulation<br />

<strong>The</strong>rmal insulation<br />

Sound insulation of any masonry construction depends on the<br />

density and porosity of the material used. <strong>The</strong> structure of<br />

aircrete, consisting of a vast number of tiny, noninterconnecting<br />

air cells, gives high resistance to airborne sound.<br />

This considerably improves on the normally accepted mass law<br />

relationship applied to other types of masonry materials.<br />

<strong>Celcon</strong>’s products have excellent sound insulation qualities,<br />

which can easily achieve the requirements for internal and<br />

separating (party) walls and floors as well as flanking elements<br />

of the new Part E of the Building Regulations. <strong>The</strong> use of Celfix<br />

Mortar provides the added benefits of further improvements in<br />

sound insulation as well as faster speed of build.<br />

For further information regarding sound insulation please<br />

contact our Marketing department and request a copy of our<br />

<strong>Celcon</strong> Solutions to Part E brochure. An example of a separating<br />

(Party) wall solution is shown above.<br />

Given the excellent thermal properties inherent with <strong>Celcon</strong> aircrete<br />

blocks, the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> can offer enhanced benefits.<br />

Approved Document ‘L1 & 2’ of the Building Regulations requires that<br />

heat loss through mortar joints be taken into consideration when<br />

calculating U-values for walls. <strong>The</strong> use of <strong>Celcon</strong> thin-joint blockwork<br />

minimises these effects by reducing the relative area of mortar per m2 of wall. <strong>The</strong> actual performance of the wall, with regard to heat loss,<br />

will actually be better than similar walls built using traditional<br />

mortar with normal format blocks. For example in a solid wall<br />

solution an improvement of up to 20% in U-value can be achieved.<br />

Design <strong>Guide</strong>lines<br />

Comparison of AAC mass law<br />

with established formula for a<br />

range of materials<br />

NPL = National Physical Laboratory<br />

Average Sound Reduction Index R, dB<br />

50 100 200 300 500<br />

70<br />

60<br />

50<br />

40<br />

30<br />

50 100 200 300 500<br />

Superficial Density, kg/m 2<br />

<strong>Masonry</strong> outer leaf<br />

Cavity closer<br />

Minimum 75mm<br />

clear cavity<br />

Minimum <strong>Celcon</strong><br />

100mm Standard<br />

or Hi-Strength<br />

Plaster or<br />

Plasterboard<br />

on dabs<br />

Aircrete Mass Law R=22.9 log(m)-4.2<br />

NPL Mass Law R=14.5 log(m)+10<br />

70<br />

60<br />

50<br />

40<br />

30<br />

4<br />

11

Cutting blocks<br />

Cavity insulation<br />

Scaffolding systems<br />

Generally it is not possible to use a conventional<br />

putlog tied scaffold where the inner leaf<br />

blockwork is built ahead of the outer leaf. <strong>The</strong><br />

most versatile and cost effective solution is to use<br />

a proprietary system scaffold to build an<br />

‘independent’ scaffold. <strong>System</strong>s such as Kwikstage<br />

or Cuplok are readily available throughout the UK.<br />

It is also advisable to make sure that the setting<br />

out of the scaffolding takes into account the outer<br />

leaf being built at a later date.<br />

<strong>The</strong>re are a number of ways that <strong>Celcon</strong> blocks can be cut. <strong>The</strong> traditional method is to<br />

use a hand saw. However, depending on the size of the project, builders have found it<br />

more efficient to use mechanical tools such as electric hand saws, circular saws and<br />

band saws, particularly when cutting the larger blocks.<br />

To maximise the productivity advantage of the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong><br />

<strong>System</strong> the inner leaf can be built first. In addition to achieving an<br />

immediate weathertight structure, this also allows for easy inspection<br />

of the cavity side of the blockwork and permits the use of partial fill<br />

or full fill insulation. Since the inner leaf blockwork is free of wall<br />

ties and mortar snots, insulation boards can be placed up against the<br />

blockwork with helical type wall ties driven through the insulation<br />

into the blockwork behind. Because the insulation boards are fixed by<br />

mechanical ties, they cannot become loose during construction. Thus<br />

the risk of rain penetration is significantly reduced.<br />

Design <strong>Guide</strong>lines 4<br />

13

4 Design <strong>Guide</strong>lines<br />

14<br />

Wall junctions<br />

Walls should normally be bonded in at returns and<br />

junctions unless a movement joint is required.<br />

Where a section of wall has to be constructed after other work,<br />

bonding can be replaced by a straight joint, providing proprietary flat<br />

strip shear ties are built in across the joint (as shown) or helical ties driven in during<br />

construction. This method of jointing is preferable to bonding under circumstances where<br />

differential movement is likely to occur (e.g. where sections of wall are built off different<br />

foundations). Where an inner leaf is built prior to the outer leaf, helical ties can be<br />

driven through the inner leaf into the internal partition (penetration into the partition<br />

should be a minimum of 50mm). <strong>The</strong>se ties can be positioned irrespective of coursing.<br />

Where enhanced sound insulation is required, an acoustic sealant can be applied to each<br />

side of the vertical straight joint.<br />

3M 3<br />

Movement joints<br />

As for all masonry walls, the accommodation of movement should be<br />

considered at the design stage. <strong>The</strong> following general recommendations<br />

apply to aircrete:<br />

- Walls in excess of 6m long should be designed as a series<br />

of panels separated by movement joints at not more than<br />

6m centres<br />

- <strong>The</strong> position of the first joint from the corner should be<br />

designed to be within 3m of a corner or fixed end<br />

- An alternative to movement joints is the use of bed-joint<br />

reinforcement, where entire wall panels are reinforced.<br />

This alternative is recommended particularly for an<br />

externally rendered solid wall construction or an outer<br />

leaf of rendered blockwork. This also applies to separating<br />

walls which should not contain movement joints<br />

6M

Construction of movement joints<br />

Straight, unbonded vertical joints are the most common<br />

form of movement joint. <strong>The</strong>y can be formed by butting<br />

the <strong>Celcon</strong> blocks against each other as a dry joint, or<br />

by leaving a 10mm gap filled with fibreboard.<br />

Bed joint reinforcement<br />

Movement joints should normally be continued through all surface<br />

finishes using stop beads (at one or both edges of the joint) to end<br />

the finish. Alternatively, a proprietary type of cover strip or an<br />

architrave pinned to one edge of the joint can be used.<br />

Where lateral stability demands continuity across the joint, propriety<br />

flat strip shear ties should be set in at 450mm maximum vertical<br />

centres. <strong>The</strong>se should be set parallel to the plane of the wall,<br />

allowing the plain end to become de-bonded if movement occurs<br />

within the blockwork panel, thus creating a movement joint.<br />

For areas of high stress (e.g. at openings or where the blocks are under concentrated<br />

imposed loads) horizontal bed-joint reinforcement is recommended. It should be of<br />

adequate length to distribute stresses to nearby movement joints or into adjacent<br />

areas of blockwork. For example, it should extend at least 600mm into the adjacent<br />

blockwork each side of an opening. Reinforcement should normally have a mortar cover<br />

of a minimum of 13mm to internal faces of blockwork and 25mm to external faces.<br />

Entire wall panels may be reinforced so that movement joints which would otherwise be<br />

advisable can be omitted. Where a wall is supported by a floor which is itself subject to<br />

deflection, the first two courses of the wall should be reinforced.<br />

Only bed-joint reinforcement which has been specifically<br />

manufactured for use with thin layer mortar masonry should be used<br />

with the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>.<br />

Movement joints and bed-joint reinforcement around openings are not<br />

normally required for housing where independent finishes are being<br />

used, i.e. dry lining, weather boarding, tiles on battens etc. Our<br />

Technical Services Department will be pleased to give<br />

recommendations for specific projects.<br />

For further information on movement joints please see page 21<br />

for contact details.<br />

Design <strong>Guide</strong>lines 4<br />

15

4 Design <strong>Guide</strong>lines<br />

16<br />

Lintels<br />

Wall ties<br />

Detailing around windows<br />

When forming window openings, the blockwork can be taken up in full block<br />

heights and then cut blocks used to build up to sill level and lintel heights.<br />

Alternatively, whole blocks can be cut to allow the lintel to fit. Reveals can<br />

be formed by cutting the required block thickness to suit the reveal,<br />

applying the Celfix Mortar and then placing into position. Nailing may be<br />

required to temporarily support the first reveal block. Subsequent blocks can<br />

then be built above this as work proceeds.<br />

When using <strong>Celcon</strong>’s <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> there are several types of lintels<br />

available, the most common of which are concrete, steel box and combined<br />

(or ‘top hat’) lintels.<br />

For cavity walls, whether they are of block/block or brick/block<br />

construction, the box lintel is recommended. If using a combined lintel,<br />

propping will be required until the outer skin is brought up to support the<br />

lintel and prevent it rotating.<br />

For solid wall constructions H+H <strong>Celcon</strong> recommend the combined type lintel<br />

with a 100mm block either side at lintel level.<br />

Bedding lintels on a traditional sand/cement mortar bed allows them to be<br />

more easily and accurately positioned.<br />

Being at the forefront of innovation H+H <strong>Celcon</strong> is currently developing<br />

reinforced aircrete lintels for use with solid wall construction techniques. <strong>The</strong>se<br />

lintels will offer the benefits of speed of installation, the continuation of surface<br />

for finishing and remove any concerns regarding thermal bridging.<br />

<strong>The</strong>re are several types of wall ties suitable for thin layer mortar masonry. Generally the<br />

most effective are helical type ties that can be driven into the face of the blockwork at a<br />

level which will course with the outer leaf mortar joint. Insulation can be placed against<br />

the inner leaf before wall ties are inserted. Helical type ties (as<br />

manufactured by Helifix) can also incorporate clips for partial fill insulation<br />

and are positioned as the outer leaf proceeds, thus minimising the risk of<br />

injury from projecting metal and reducing the build up of mortar snots. Ties<br />

are also available which may be laid in the thin-joint beds as block laying<br />

proceeds. This is particularly appropriate where both leaves are built<br />

together. All ties should conform to BS 1243, British Standard Draft for<br />

Development 140:Part 2, or a BBA Certificate. It is recommended that ties<br />

are not driven in to the wall until it is restrained at the head by the timber<br />

joists/flooring system.<br />

For further information on wall ties please see page 21 for contact details.

Stability<br />

Temporary propping of walls always needs to be considered at the design<br />

stage (see for example BS5628 Part 1, clause 20.4). It may be necessary for<br />

a number of reasons – in particular due to site or weather conditions.<br />

With housing, internal partition walls and partially completed external walls<br />

can be vulnerable when they are subject to temporary loadings, the most<br />

common of which is the moving of plant and/or materials, or in exposed<br />

conditions, wind load.<br />

Finishes<br />

One of the benefits of the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> is that, due to the greater accuracy,<br />

alternative finishes may be considered, in particular thin coat sprayed systems.<br />

Spray finish - plaster or render<br />

Applied direct to blockwork with a total thickness of 3-4mm, the use of spray<br />

plaster/render can greatly reduce the time taken to apply an internal/external<br />

finish, it therefore complements the inherent speed of the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong><br />

<strong>System</strong>.<br />

Internal tiling<br />

Tiles can be bonded direct to blockwork provided surfaces are dry or almost<br />

dry and are free from dust, oil and other forms of contamination. Tiling<br />

should be fixed with a proprietary adhesive, using the solid-bed technique.<br />

Design <strong>Guide</strong>lines 4<br />

17

6 Frequently Asked Questions<br />

20<br />

What Certification has been given to the <strong>System</strong>?<br />

<strong>The</strong> <strong>Celcon</strong> <strong>Thin</strong>-joint <strong>System</strong> is approved by the BBA (see certificate No. 01/3816), NHBC and<br />

Building Control.<br />

Are you sure that you can build the inner leaf first without bringing the outer leaf<br />

up at the same time?<br />

<strong>The</strong> BBA has approved this as "normally permissible to build the inner leaf to storey height ahead of the<br />

outer leaf". Like all masonry walls, depending on the lengths of walls involved and on the weather and<br />

exposure conditions, temporary propping may be required.<br />

Is coursing with brickwork an issue with the thin-joint? What sort of tie can I use?<br />

No, because ties can be installed by driving into the face of the blockwork at a level which will course<br />

with the outer leaf. Several types of driven ties are available for the purpose, such as helical ties.<br />

Is there any quality improvement in the construction?<br />

Potential is high for quality improvement, including cleanliness of the site and reduced wastage of<br />

blocks and mortar as well as the build quality of the construction.<br />

Where can we get the thin-joint tools from?<br />

<strong>The</strong> hand tools used with the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>, such as scoop and cutting square, are available<br />

from builders’ merchants, contact details are available through our Sales office on 01732 886444. For<br />

specialist equipment such as circular saw, please see list at the back of the brochure.<br />

Who uses the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>?<br />

Builders throughout the industry from sole traders to the National housebuilders use the <strong>Celcon</strong> <strong>Thin</strong>-<br />

<strong>Joint</strong> <strong>System</strong> for the construction of extensions through to complete sites. It is used in domestic as well<br />

as commercial/industrial work and has the potential for improving both productivity and quality of<br />

construction benefits.<br />

It has been found that attitude counts for a lot, if the builders want to make it work, it will and it<br />

does. Some have given it the ‘thumbs down’ but in contrast others have said they would now not want<br />

to go back to traditional unless they had to!<br />

Is training available for the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>?<br />

<strong>Thin</strong>-joint training is available at various levels from demonstrations at builders’ merchants and colleges<br />

to instruction on site start-ups. Contact the Technical Services Department on 01732 880580 to find out more<br />

details. Please note that our instructors are only on site to demonstrate. <strong>The</strong>y are unable to build for you.<br />

What are the setting times of Celfix once mixed with water?<br />

Celfix remains workable in the bucket for several hours. However, after being applied to the block it<br />

takes 10 minutes for initial set and 1-2 hours for full design strength to be achieved.<br />

How do I get over the issues of coursing with lintels?<br />

Whatever the masonry, opening sizes and course heights have to be worked out prior to building.<br />

Unlike traditional masonry, any irregular course height can be simply achieved, as <strong>Celcon</strong> blocks are so<br />

easy to cut.<br />

What is the workability of the <strong>System</strong> in the following conditions?<br />

...in cold weather? Unlike traditional mortar, Celfix can be used down to 0 o C but the blockwork MUST be<br />

considered in relationship to the overall site operation. See BRE Defect Action Sheet (Site) DAS 64 (‘bad<br />

weather working’) which provides good practice guidance for masonry.<br />

...in wet weather? Work should have same protection as other types of masonry BUT as Celfix sets<br />

more quickly than traditional mortar, there is less risk of joints being washed out!<br />

...effect of block suction? Will depend on weather conditions. Adjust to suit.

Mechanical tools<br />

Band saw<br />

(to hire) Brandon tool hire Tel: 01179 718535<br />

(to buy) Mobile Applications Tel: 01782 790824<br />

Circular saw (S915)<br />

(to hire) Brandon tool hire Tel: 01179 718535<br />

(to buy) Mobile Applications Tel: 01782 790824<br />

Alligator Saw<br />

(to hire) Brandon tool hire Tel: 01179 718535<br />

(to buy) <strong>Celcon</strong> stockists<br />

Power Mixer<br />

(to hire) Brandon tool hire Tel: 01179 718535<br />

(to buy) Refina Tel: 01202 632270<br />

Movement joint ties<br />

Halfen Ltd Tel: 08705 316300<br />

Tackburn Ltd Tel: 01527 68559<br />

Steel/concrete fixing ties<br />

Tackburn Ltd Tel: 01527 68559<br />

Demonstrations<br />

<strong>Thin</strong>-<strong>Joint</strong> demonstrations allow the basic principles of the <strong>System</strong> to be highlighted,<br />

the correct method of using the tools to be demonstrated and extra hints on general<br />

good site practice. This allows the user to see the full potential from the <strong>Celcon</strong><br />

<strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong>. In many instances, this gives the opportunity of ‘hands-on’<br />

experience, but always, the answers to any questions you might have.<br />

For further information about thin-joint demonstrations please contact the Technical<br />

Services Department on 01732 880580 who will be happy to discuss the possibility of<br />

arranging a demonstration for you.<br />

Our Technical Services Department can be contacted on<br />

01732 880580 or tsd@celcon.co.uk<br />

Other sources of information<br />

H+H <strong>Celcon</strong> produces a variety of publications that advise on the correct use of <strong>Celcon</strong> products.<br />

Please contact the marketing department on<br />

01732 880520 or marketing@celcon.co.uk<br />

for further details or visit our website at www.celcon.co.uk<br />

Bed <strong>Joint</strong> reinforcement<br />

Technical: 01732 880580 www.celcon.co.uk<br />

<strong>The</strong>re are pictures in this literature of persons not wearing appropriate personal protective equipment; these are ‘real life’ situations,<br />

over which we have no control. H+H <strong>Celcon</strong> Limited does not advocate the non-wearing of the recommended protective equipment.<br />

BRC<br />

Murfor<br />

Further Information 7<br />

Tel:<br />

Tel:<br />

01785<br />

222288<br />

0114<br />

2561561<br />

Tackburn Ltd Tel: 01527 68559<br />

Cavity wall ties<br />

Helifix<br />

Ancon<br />

Tel:<br />

Tel:<br />

0208<br />

7355200<br />

0114<br />

2755224<br />

Powertie Tel: 01928 787127<br />

Tackburn Ltd Tel: 01527 68559<br />

Plastering/external rendering<br />

Sto limited Tel: 01256 332770<br />

Marmorit Tel: 0800 7313076<br />

Alsecco<br />

K<br />

Rend<br />

Tel:<br />

Tel:<br />

01782<br />

374066<br />

02828<br />

260766<br />

21

®<br />

H+H <strong>Celcon</strong> Limited<br />

<strong>Celcon</strong> House, Ightham,<br />

Sevenoaks, Kent TN15 9HZ<br />

Tel: 01732 886333<br />

www.celcon.co.uk