assets

1OQRNnt

1OQRNnt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LCS UWSH Procedural Development<br />

By: CWO3 Joe Theodorou, UWSH Project Manager and LCS Program Manager<br />

For the past two years, NAVSEA 00C5 has been working with the Program Executive Office to Littoral Combat<br />

Ships (LCS) with PMS 505 in developing waterborne maintenance and repairs needs for both LCS variants.<br />

Most recently, SEA 00C5, working with SUPSHIP Gulf Coast, Thrustmaster of Texas (TMOT), and PCCI, developed<br />

the removal and installation procedure for the LCS Independence Class Retractable Azimuthing Thruster (RAT), or<br />

to most of us the APU. Development of any procedure is a lengthy process to ensure safety of personnel and the integrity<br />

of the ship is not compromised. Below is a quick-look as to the overall procedural development implementation.<br />

• Sponsoring command provides statement of work<br />

• Establish funding from sponsoring command<br />

• Determine in-house engineering or need to contract<br />

• Request technical manuals and drawings<br />

• Model design through programs such as Solid Works and CAD<br />

• 00C5 Engineer approves concept designs<br />

• Fabricate required support equipment if required<br />

• Test fit and procedure on available vessel of opportunity (under-construction, dry dock, or waterborne)<br />

• Validate and approve procedure<br />

and equipment<br />

In July 2015, we were able to establish<br />

a week at TMOT, to verify our procedures<br />

and equipment to support the<br />

removal and replacement of the RAT. To<br />

give you a timeline, we started with this<br />

in August of 2014. As we know procedures<br />

are not always perfect, divers have<br />

always found ways to improve existing<br />

procedures or equipment to support jobs<br />

while maintaining safety of personnel<br />

and the integrity of the ship or submarine<br />

they are working with. Extending the opportunity<br />

to our fleet lockers, SWRMC<br />

and SRF-Yokosuka divers were able to<br />

remove and replace in a RAT in the test<br />

stand at the TMOTs facility; three divers<br />

from SWRMC and four divers from<br />

SRF-Yokosuka were in attendance.<br />

“Being directly involved in validating<br />

these procedures was extremely beneficial<br />

in ironing out and identifying problems<br />

that only a diver can relate to. By<br />

having a firsthand look into the process it<br />

allowed us to come up with better ways<br />

and improve a few of the steps versus<br />

having to discover this later on. This saves<br />

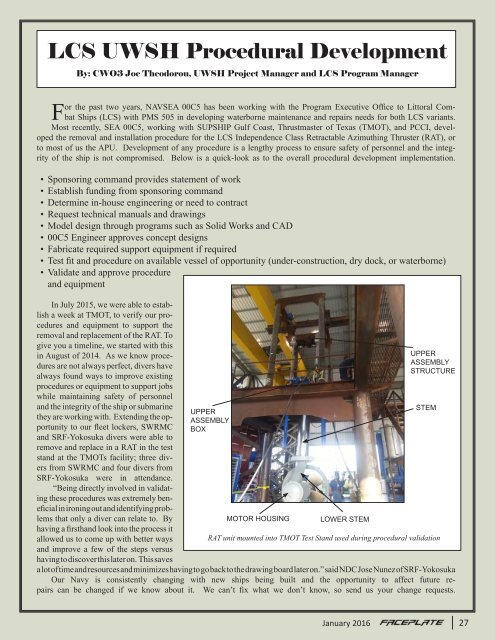

UPPER<br />

ASSEMBLY<br />

BOX<br />

MOTOR HOUSING<br />

LOWER STEM<br />

UPPER<br />

ASSEMBLY<br />

STRUCTURE<br />

RAT unit mounted into TMOT Test Stand used during procedural validation<br />

a lot of time and resources and minimizes having to go back to the drawing board later on.” said NDC Jose Nunez of SRF-Yokosuka<br />

Our Navy is consistently changing with new ships being built and the opportunity to affect future repairs<br />

can be changed if we know about it. We can’t fix what we don’t know, so send us your change requests.<br />

STEM<br />

January 2016 27