Technology And Innovation Special Supplier - Yizumi Rubber Machinery

Injection Moulding is an important processing technique for converting elastomeric materials into final products. In this special edition of Technology & Innovation, we bring you an exclusive interview with Wang Shihai, General Manager of ‘Yizumi Rubber Machinery Co., Ltd. Guangdong Yizumi Precision Machinery Co., Ltd is a hi-tech enterprise focussing on Design, R&D, Production, Sales and Service of moulding machines. Yizumi is a company that innovates regularly and focuses on providing cutting-edge technology to its customers.

Injection Moulding is an important processing technique for converting elastomeric materials into final products. In this special edition of Technology & Innovation, we bring you an exclusive interview with Wang Shihai, General Manager of ‘Yizumi Rubber Machinery Co., Ltd. Guangdong Yizumi Precision Machinery Co., Ltd is a hi-tech enterprise focussing on Design, R&D, Production, Sales and Service of moulding machines. Yizumi is a company that innovates regularly and focuses on providing cutting-edge technology to its customers.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

| YIZUMI |<br />

In <strong>Rubber</strong> Moulding Industry, the<br />

emphasis is on enhancing the process<br />

efficiency and reducing the energy<br />

consumption. How do your solutions<br />

help your buyers?<br />

Energy consumption and<br />

efficiency are things we all<br />

emphasize. Let's talk about<br />

energy consumption. Some people<br />

think that energy saving machine is<br />

simply adopting servo motor hydraulic<br />

pump. However, this is one-sided.<br />

For the conventional RIM, curing time<br />

takes up a large proportion in the<br />

whole cycle (some may reach more<br />

than 80 percent), you will find<br />

adopting servo motor pump is not an<br />

optimized option after TCO (Total<br />

Cost of Ownership) evaluation.<br />

For example, energy saving motor and<br />

variable pump combination is more<br />

optimal than servo motor and rated<br />

pump in TCO. RIM heating and<br />

machine movement also takes up a big<br />

proportion of energy consumption.<br />

Besides different kinds of energysaving<br />

power unit, <strong>Yizumi</strong> analyzes<br />

consumption of each heating unit and<br />

machine movement, and we have<br />

achieved the real energy saving effect<br />

on machine. For example, by analysis<br />

on every single detail when designing<br />

oil circuit and selecting components<br />

with lower energy consumption, while<br />

improving oil circuit design and some<br />

component models with a higher<br />

material cost to reach the goal that to<br />

lower TCO.<br />

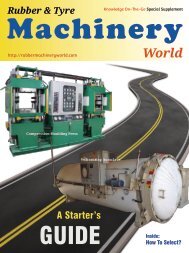

YL2-V280L European Standard<br />

Low Bed <strong>Rubber</strong> Injection<br />

Moulding Machine<br />

Regarding high efficiency, <strong>Yizumi</strong> has<br />

improved moving speed of the secondgeneration<br />

machine to a suitable range to<br />

reduce cycle time; with improved clamping<br />

force to meet higher curing pressure<br />

and reduce curing time. Meanwhile,<br />

optional and automation devices are<br />

provided in order to reduce cycle time. All<br />

those updates above have improved the<br />

machine efficiency.<br />

19<br />

<strong>Technology</strong> & <strong>Innovation</strong> | MAR 2016