NTN - Precision Rolling Bearings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Data<br />

1 Grease lubrication<br />

Grease lubrication is the most common, as it<br />

simplifies the main spindle structure more than other<br />

lubricating systems. With an adequate amount of<br />

quality grease prefilled, this system can be used over a<br />

wide range of speed. The allowable maximum speed<br />

varies with the type and size of bearing: for a highspeed<br />

angular contact ball bearing, the dmn value<br />

should be 1.410 6 as a guideline. For applications<br />

exceeding this range, consult <strong>NTN</strong> Engineering.<br />

Grease types<br />

A lithium-based grease, with a mineral oil base, is<br />

commonly used as a lubricant for rolling bearings. Its<br />

operating temperature range is -30˚C to 130˚C.<br />

When the temperature increase must be limited, as<br />

with the main spindle of a machine tool, <strong>NTN</strong><br />

recommends the use of a synthetic-oil-based grease<br />

(diester, diester+mineral oil) which penetration is NLGI<br />

grade 1 or 2.<br />

Table 7.3 lists technical data for greases commonly<br />

used for machine tool main spindles.<br />

Amount of grease required<br />

Usually, a bearing for the main spindle of a machine<br />

tool requires that grease volume be low so heat<br />

generated by the stirring of the grease during highspeed<br />

operation is minimal. A guideline for the amount<br />

of grease used for a main spindle bearing is given<br />

below.<br />

¡Angular contact ball bearing<br />

(dmn value 65010 3 ); 15% of bearing free space<br />

(dmn value 65010 3 ); 12% of bearing free space<br />

¡Cylindrical roller bearing; 10% of bearing free space<br />

¡Tapered roller bearing; 15% of bearing free space<br />

The space in the bearing typically used for main<br />

spindles are listed in dimension tables. Determine a fill<br />

amount by referring to the relevant dimension table.<br />

Before filling a bearing with grease, remove the<br />

rustproof coating from the bearing with clean wash oil<br />

and allow the bearing to dry completely. Then fill and<br />

uniformly distribute an appropriate amount of grease in<br />

the bearing with an syringe, plastic bag, etc.<br />

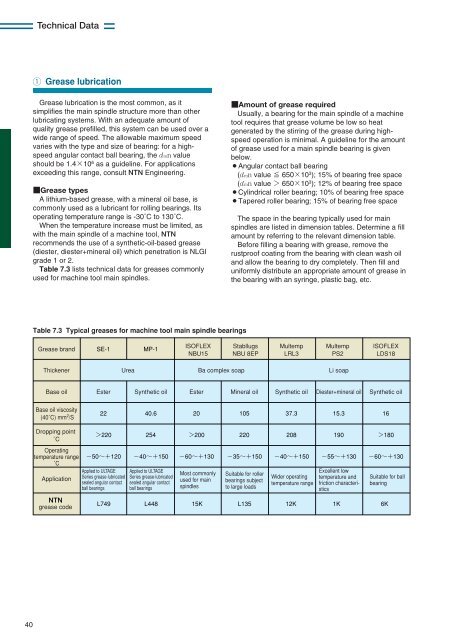

Table 7.3 Typical greases for machine tool main spindle bearings<br />

Grease brand<br />

SE-1<br />

MP-1<br />

ISOFLEX<br />

NBU15<br />

Stabllugs<br />

NBU 8EP<br />

Multemp<br />

LRL3<br />

Multemp<br />

PS2<br />

ISOFLEX<br />

LDS18<br />

Thickener<br />

Urea<br />

Ba complex soap<br />

Li soap<br />

Base oil<br />

Ester<br />

Synthetic oil<br />

Ester<br />

Mineral oil<br />

Synthetic oil<br />

Diester+mineral oil<br />

Synthetic oil<br />

Base oil viscosity<br />

<br />

(40˚C) mm 2 /S<br />

22<br />

40.6<br />

20<br />

105<br />

37.3<br />

15.3<br />

16<br />

Dropping point<br />

˚C<br />

220<br />

254<br />

200<br />

220<br />

208<br />

190<br />

180<br />

Operating<br />

temperature range<br />

˚C<br />

Application<br />

50120<br />

Applied to ULTAGE<br />

Series grease-lubricated<br />

sealed angular contact<br />

ball bearings<br />

40150<br />

Applied to ULTAGE<br />

Series grease-lubricated<br />

sealed angular contact<br />

ball bearings<br />

60130<br />

Most commonly<br />

used for main<br />

spindles<br />

35150<br />

Suitable for roller<br />

bearings subject<br />

to large loads<br />

40150<br />

Wider operating<br />

temperature range<br />

55130<br />

Excellent low<br />

temperature and<br />

friction characteristics<br />

60130<br />

Suitable for ball<br />

bearing<br />

<strong>NTN</strong><br />

grease code<br />

L749<br />

L448<br />

15K<br />

L135<br />

12K<br />

1K<br />

6K<br />

40