Environmental protection and energy Customized development ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

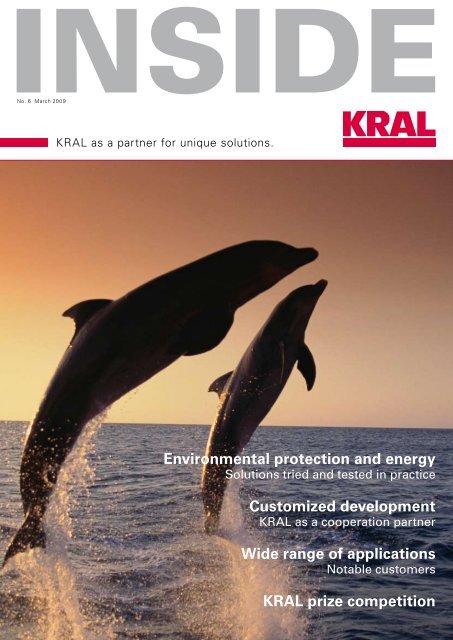

INSIDE<br />

No. 6 March 2009<br />

KRAL as a partner for unique solutions.<br />

<strong>Environmental</strong> <strong>protection</strong> <strong>and</strong> <strong>energy</strong><br />

Solutions tried <strong>and</strong> tested in practice<br />

<strong>Customized</strong> <strong>development</strong><br />

KRAL as a cooperation partner<br />

Wide range of applications<br />

Notable customers<br />

KRAL prize competition

Content<br />

Cover Story - <strong>Environmental</strong> <strong>protection</strong> <strong>and</strong> <strong>energy</strong>. 04<br />

Unique KRAL innovations protect the environment <strong>and</strong> help to save <strong>energy</strong>.<br />

KRAL agencies in countries where Spanish is spoken. 08<br />

Global customer orientation.<br />

KSB ITUR. 10<br />

KRAL collaborates with Spain’s leading pump manufacturer.<br />

OBRAS Y SERVICIOS PETROLEROS S.A. DE C.V. 12<br />

O.S.P. supports PEMEX in a variety of ways.<br />

New KRAL pump stations. 14<br />

A totally new generation of double stations has been developed in cooperation with GEA WESTFALIA.<br />

Innovative shipbuilding at the Meyer shipyard. 16<br />

Top-quality cruise ships.<br />

VKW. 20<br />

The most modern pumped storage power station in the world utilizes the natural “water” resource in Austria.<br />

Wärtsilä. 24<br />

KRAL Volumeter in test benches for large diesel engines.<br />

FLUJOMATICA S.R.L. 26<br />

KRAL fuel consumption measurement helps safeguard the livelihood of Peruvian fishermen.<br />

Pemex. 28<br />

Mexico’s biggest oil company.<br />

The Corus Group. 32<br />

Maximum operational reliability at Europe’s second largest steel producer.<br />

CAMI. 34<br />

Excellent services for manufacture of polyurethane.<br />

Deutsche Bahn Systemtechnik. 36<br />

Europe’s biggest center of excellence for railway engineering.<br />

Elco Klöckner. 38<br />

International provider of comprehensive heating solutions.<br />

Hyundai. 40<br />

KRAL fuel consumption measurement for the world’s biggest diesel engines.<br />

Caterpillar. 42<br />

High-precision engine test bench logs by mouse click.<br />

The Ammann Group. 44<br />

Customer-specific <strong>development</strong>s – a special strength of KRAL.<br />

MAN. 46<br />

Research on world-class diesel engines.<br />

Hennecke. 48<br />

Developing, designing <strong>and</strong> manufacturing machinery <strong>and</strong> equipment for polyurethane processing.<br />

Mehldau & Steinfath. 50<br />

Globally successful provider of fuel heating systems.<br />

Contest, Employee statements. 52<br />

2 Inside

editorial<br />

We care about your problems!<br />

KRAL INSIDE No. 6 is the first<br />

issue which has been translated<br />

into Spanish. I am very pleased<br />

that this brings us into closer contact<br />

with speakers of the world’s<br />

fourth most widely spoken language.<br />

At the same time, we<br />

would like to present our competent<br />

partners in Spanish-speaking<br />

countries. They help you to<br />

choose the right solution <strong>and</strong> offer<br />

you the best possible service.<br />

Nature, our most valuable resource,<br />

has inspired KRAL to<br />

develop environmentally sound<br />

solutions. Protecting the environment<br />

is very important to<br />

KRAL, to protect our quality of<br />

life <strong>and</strong> that of coming generations.<br />

In our cover story, you will<br />

learn how KRAL solutions can<br />

make a contribution to nature<br />

conservation, <strong>and</strong> simultaneously<br />

to reducing operating <strong>and</strong><br />

maintenance costs.<br />

Research <strong>and</strong> <strong>development</strong> are<br />

top priorities at KRAL. The results<br />

are unique solutions which<br />

ensure a technological head start<br />

in many application fields for our<br />

customers. In this issue, you will<br />

find a broad range of applications<br />

in which KRAL customers report<br />

about their experiences.<br />

are customer-specific solutions<br />

which are outst<strong>and</strong>ing for miniaturization<br />

combined with increased<br />

complexity <strong>and</strong> for reduction<br />

of total costs. Procurement<br />

is easy because the<br />

solution comes from one source<br />

<strong>and</strong> components do not have to<br />

be bought from multiple suppliers.<br />

In this issue, you will learn<br />

more about the customer-specific<br />

solutions provided by the<br />

Ammann Group, <strong>and</strong> the tailormade<br />

pump stations of Mehldau<br />

& Steinfath. You will also learn<br />

how KRAL, in cooperation with<br />

GEA WESTFALIA, has developed<br />

a new generation of pump<br />

stations. KRAL is able to develop<br />

optimum solutions which<br />

meet your needs, because we<br />

tackle them with you. In this<br />

way we come to a result which<br />

achieves “plug & play” status.<br />

Exploit KRAL’s high problemsolving<br />

skills. We care about<br />

your problems!<br />

More <strong>and</strong> more customers recognize<br />

KRAL’s high technical<br />

problem-solving skills, <strong>and</strong> have<br />

the confidence to tell us about<br />

their future plans. The results<br />

Fritz Huber<br />

CEO <strong>and</strong> Chairman of the<br />

Management Board<br />

INSIDE<br />

3

Cover story<br />

<strong>Environmental</strong> <strong>protection</strong> <strong>and</strong> <strong>energy</strong>.<br />

This global issue determines many actions <strong>and</strong> activities.<br />

For many countries, <strong>protection</strong> of the environment has become an overriding social <strong>and</strong><br />

economic concern. For a large part of the population, the role of environmental <strong>protection</strong><br />

is important. It is obvious that more <strong>and</strong> more people want to make a contribution to<br />

environmental <strong>protection</strong> by their personal behavior as consumers.<br />

<strong>Environmental</strong> <strong>protection</strong> is indispensable<br />

if the basis of human<br />

life <strong>and</strong> health is to be preserved.<br />

Attention is on both<br />

individual parts of the environment<br />

such as soil, water, air <strong>and</strong><br />

climate, <strong>and</strong> on the interactions<br />

between them.<br />

Climate <strong>protection</strong> <strong>and</strong><br />

efficient use of <strong>energy</strong>.<br />

Climate <strong>protection</strong> is one of the<br />

most important fields of environmental<br />

<strong>protection</strong>. Currently,<br />

above all, the problems of global<br />

warming <strong>and</strong> air pollution are<br />

being discussed. The aim of climate<br />

<strong>protection</strong> is to counteract<br />

unnatural global warming<br />

<strong>and</strong> mitigate its consequences.<br />

In this context, efficient use of<br />

<strong>energy</strong> is extremely important.<br />

Lower <strong>energy</strong> consumption also<br />

means lower costs. In this way,<br />

<strong>energy</strong> saving also benefits the<br />

<strong>energy</strong> saver.<br />

Energy consumption is often associated<br />

with the release of carbon<br />

dioxide (CO 2<br />

). The most important<br />

<strong>energy</strong> sources - coal,<br />

petroleum <strong>and</strong> natural gas - con-<br />

4 Inside

cover story<br />

mate, it is urgently necessary to<br />

significantly reduce the amount<br />

of CO 2<br />

. The most important tool<br />

for climate <strong>protection</strong> is the efficient<br />

use of <strong>energy</strong>.<br />

sist largely of carbon, which reacts<br />

with atmospheric oxygen.<br />

CO 2<br />

is itself the most important<br />

anthropogenic (caused by humans)<br />

greenhouse gas. Greenhouse<br />

gases in the earth’s atmosphere<br />

cause the <strong>energy</strong><br />

which the sun radiates to be radiated<br />

back with a time delay, resulting<br />

in a rise of the average<br />

global temperature.<br />

Since the start of industrialization,<br />

the CO 2<br />

content of the atmosphere<br />

has grown by over<br />

30%, half of it since 1970. A<br />

connection between the rise<br />

of the CO 2<br />

content <strong>and</strong> climate<br />

change, with extreme weather<br />

events such as storms, floods<br />

<strong>and</strong> droughts, is considered to<br />

be certain. To protect the cli-<br />

The sustainability concept.<br />

At the center of the concept of<br />

sustainability is the insight that<br />

social responsibility, commercial<br />

efficiency <strong>and</strong> <strong>protection</strong> of<br />

the natural environment belong<br />

together.<br />

In many companies, the concept<br />

of sustainability has become an<br />

important subject. Sustainable<br />

<strong>development</strong> corresponds<br />

to the needs of today’s generation,<br />

without endangering what<br />

is possible for future generations.<br />

INSIDE<br />

5

cover story<br />

Hermetically sealed KRAL pumps with magnetic coupling.<br />

Research <strong>and</strong> <strong>development</strong>.<br />

Commercial success.<br />

Every company which desires<br />

long-term success needs commercial<br />

success. Motivated employees<br />

as well as the smallest<br />

possible use of resources <strong>and</strong><br />

the environment contribute to a<br />

long-term increase of company<br />

success. Sustainability provides<br />

many benefits for companies.<br />

Solving ecological problems<br />

with economical solutions results<br />

in unique innovations <strong>and</strong><br />

increased productivity <strong>and</strong> competitiveness.<br />

For the long-term preservation<br />

of the quality of our environment<br />

<strong>and</strong> our lives, the goals of sustainability<br />

must be pursued together.<br />

If our customers, suppliers<br />

<strong>and</strong> the politicians are all<br />

pulling together, successful solutions,<br />

which can be implemented<br />

by all stakeholders, will<br />

be found.<br />

KRAL innovations make an<br />

important contribution.<br />

KRAL is currently making important<br />

contributions to environmental<br />

<strong>protection</strong> for shipping,<br />

power generation, the burner<br />

industry <strong>and</strong> the production of<br />

polyurethane components.<br />

For many years, KRAL fuel consumption<br />

measurement has<br />

been used where large diesel<br />

engines do their job. KRAL Volumeter<br />

help operators to save<br />

fuel. Almost always, fuel consumption<br />

is reduced by slightly<br />

improved driving or operating<br />

behavior. For example, captains<br />

of ocean-going ships, fishing<br />

vessels <strong>and</strong> work boats have reported<br />

that they compare the<br />

KRAL fuel consumption display<br />

with the engine speed <strong>and</strong> set<br />

an optimum speed. In this simple<br />

way, a fishing vessel reduces<br />

its consumption from 330 to 300<br />

6 Inside

cover story<br />

Compact KRAL fuel consumption measurement system.<br />

liters/hour (87 to 79 US gallons/<br />

hour), corresponding to a 10%<br />

saving (see KRAL INSIDE, Special<br />

Issue for the Marine).<br />

Creative engineers are developing<br />

innumerable ways of saving<br />

fuel. These ideas include auxiliary<br />

sails for ocean-going ships, special<br />

paints for the hulls of ships,<br />

or greatly weight-reduced components.<br />

KRAL fuel consumption<br />

measurement measures so precisely<br />

that developers can demonstrate<br />

the effectiveness of their<br />

ideas immediately to their customers.<br />

Most innovations affect<br />

the engine directly <strong>and</strong> are tested<br />

on the test st<strong>and</strong>. The KRAL<br />

system supplies measured values<br />

immediately, <strong>and</strong> thus shortens<br />

test st<strong>and</strong> runs.<br />

The most direct way of protecting<br />

the environment is not to<br />

consume fuel in the first place.<br />

Hermetically sealed KRAL pumps<br />

with magnetic coupling ensure<br />

that neither liquids nor gas emissions<br />

reach the environment. The<br />

engine rooms of ships remain<br />

clean. Fuel cannot reach the sea.<br />

In the case of polyurethane production,<br />

no poisonous isocyanate<br />

reaches the environment.<br />

The precision of cylinder lubrication<br />

in diesel engines determines<br />

their service life. Until<br />

now the volume of lube oil has<br />

not been regulated, but has<br />

merely been estimated from the<br />

injector geometry. Our measurements<br />

have shown that significant<br />

discrepancies can occur between<br />

the actual figures <strong>and</strong> the<br />

engine manufacturers’ specifications.<br />

Overlubrication damages<br />

the pistons <strong>and</strong> cylinders. Furthermore,<br />

unused, high-grade<br />

oil ends up in the used oil tank<br />

via the overflow oil line. What a<br />

waste! KRAL enables the specifications<br />

to be closely <strong>and</strong> easily<br />

matched by precisely measuring<br />

<strong>and</strong> regulating the volume of<br />

lube oil. A great deal of money<br />

can be saved in this way.<br />

Apart from the effect of saving<br />

resources, operating <strong>and</strong> maintenance<br />

costs are significantly<br />

reduced with KRAL innovations.<br />

Thomas Flauger<br />

Marketing Manager<br />

0,6<br />

Anomaly of temperature [°C]<br />

0,4<br />

0,2<br />

0,0<br />

-0,2<br />

-0,4<br />

1900 1920 1940 1960 1980 2000<br />

Global warming: the clear rise since 1978 indicates a climate change.<br />

INSIDE<br />

7

Partner<br />

KRAL agencies in countries where<br />

Spanish is spoken – Part 1.<br />

Global customer orientation.<br />

Principally, every issue of KRAL INSIDE is dedicated to a specific country or a specific culture.<br />

In this one, we introduce you to our Spanish-speaking partners.<br />

Mexico City.<br />

Fluidos Técnicos, S.A. de C.V.<br />

Fluidos Técnicos, S.A. de C.V. is<br />

the leading company in Mexico<br />

for the design <strong>and</strong> production of<br />

hydraulic modules, <strong>and</strong> for sales<br />

<strong>and</strong> maintenance of pumps. The<br />

mission of Fluidos Técnicos is to<br />

ensure rapid service, <strong>and</strong> to support<br />

the customer in the choice<br />

of the best technical <strong>and</strong> also<br />

most profitable solution.<br />

Fluidos Técnicos, S.A. de C.V.<br />

has over 15 years of experience.<br />

With its own Corporate Guarantee<br />

Certificate, the company<br />

documents the use of original<br />

equipment. This concept protects<br />

renowned, globally operating<br />

companies from unjustified<br />

claims resulting from replacement<br />

parts from third party manufacturers.<br />

The Fluidos Técnicos<br />

Original Equipment Guarantee<br />

means high operational reliability<br />

for the end customer.<br />

Fluidos Técnicos, S.A. de C.V.<br />

currently has 22 employees. Its<br />

head office is in Mexico City.<br />

There are offices in Monterrey,<br />

Villahermosa <strong>and</strong> Tampico.<br />

Barcelona, Spain.<br />

Iberfluid Instruments, S.A.<br />

Iberfluid has been providing systems<br />

for measurement <strong>and</strong> monitoring<br />

of industrial processes<br />

since 1972. The Spanish company<br />

provides its customers with<br />

true added value. From the start<br />

through to completion of the industrial<br />

plant, customers experience<br />

professional support with<br />

selecting <strong>and</strong> fitting measurement<br />

<strong>and</strong> control systems, installation,<br />

commissioning, training,<br />

technical services <strong>and</strong> calibration.<br />

With Iberfluid, the customer has<br />

only one contact. The company’s<br />

metrology professionals cover a<br />

wide range of equipment for the<br />

most varied instrumentation <strong>and</strong><br />

control tasks.<br />

Iberfluid’s strength is its professional<br />

competence. The company<br />

sees itself as a true technology<br />

partner for its customers.<br />

Iberfluid has a team of 50 specialists.<br />

Its head office is in Barcelona.<br />

There are branches in<br />

Madrid, Bilbao <strong>and</strong> Seville.<br />

8 Inside

Partner<br />

KSB ITUR.<br />

Since its foundation, KSB ITUR<br />

has been dedicated to pump <strong>development</strong><br />

<strong>and</strong> production.<br />

Company HQ in Zarautz is a production<br />

facility covering an area<br />

of 21.000 m 2 , which is fitted<br />

with state-of-the-art equipment<br />

for developing, manufacturing<br />

<strong>and</strong> testing all the company’s<br />

products.<br />

Thanks to important product <strong>development</strong>s,<br />

a professional <strong>and</strong><br />

well-developed distribution network,<br />

technical customer support<br />

on a partnership basis, <strong>and</strong><br />

proximity to its customers, KSB<br />

ITUR is now one of the most significant<br />

players in the pump market,<br />

providing solutions that are<br />

tailor-made to meet the needs of<br />

its customers.<br />

Zarautz, Spain.<br />

Maya temple near Comalcalco, Tabasco (Mexico).<br />

O.S.P.<br />

Obras y Servicios Petroleros<br />

S.A. de C.V. is a 100% Mexican<br />

company, which was founded<br />

on September, 26 th 1990. O.S.P.<br />

is established in the petroleum<br />

sector <strong>and</strong> industry.<br />

O.S.P. specializes in installation<br />

<strong>and</strong> maintenance of compressors,<br />

plant controllers,<br />

centrifugal pumps, positive-displacement<br />

pumps <strong>and</strong> vacuum<br />

pumps, electric motors, internal<br />

combustion engines, valves <strong>and</strong><br />

mechanized parts processing.<br />

With its great awareness of its<br />

responsibility <strong>and</strong> ongoing service<br />

quality, O.S.P. has gained an<br />

outst<strong>and</strong>ing reputation.<br />

O.S.P.’s know-how is based on<br />

professional employees with<br />

regular further training. O.S.P.<br />

specialists have comprehensive<br />

experience of application of the<br />

international API, ASTM, ASME,<br />

ANSI <strong>and</strong> IEEE st<strong>and</strong>ards.<br />

To be continued.<br />

INSIDE<br />

9

Partner<br />

KSB ITUR.<br />

The market leader for pump production in Spain.<br />

The agency of KRAL in Spain has been a successful support partner for national<br />

customers for many years.<br />

KSB ITUR headquarter in Zarautz in Spain.<br />

History.<br />

Bombas ITUR was founded<br />

in Getaria (Spain) in 1920, its<br />

headquarters later relocating to<br />

Zarautz. The company has been<br />

making pumps since it was<br />

founded, its history giving it one<br />

of the richest traditions among<br />

the world’s pump manufacturers.<br />

With such vast experience<br />

in the pump sector, significant<br />

product innovations were always<br />

possible. Times are changing.<br />

The fact that ITUR has been in<br />

business for so long, shows how<br />

the Basques make use of their<br />

specialist knowledge of customers’<br />

wishes <strong>and</strong> requirements<br />

<strong>and</strong> flexibly implement changes<br />

in their corporate structure.<br />

The company’s professional,<br />

well-developed distribution network<br />

<strong>and</strong> technical customer<br />

support on a partnership basis<br />

bring ITUR close to its customers.<br />

This customer proximity is an<br />

important strategic element <strong>and</strong><br />

has made the company an expert<br />

in resolving pump projects.<br />

Customers rate the professional<br />

<strong>and</strong> efficient service that is provided<br />

before, during <strong>and</strong> after installation<br />

as particularly helpful.<br />

All these competences are the<br />

reason why ITUR is the market<br />

leader in Spain <strong>and</strong> is much in<br />

dem<strong>and</strong> as a contact abroad.<br />

As the market becomes ever<br />

more global <strong>and</strong> open, it is vi-<br />

Centrifugal pump.<br />

tally important that this market<br />

position is consolidated <strong>and</strong><br />

strengthened. In full awareness<br />

of this necessity, Bombas ITUR<br />

has been part of the KSB Group<br />

since 2003. KSB is a leading<br />

supplier in the European pump<br />

<strong>and</strong> valve market, <strong>and</strong> is one<br />

of the most significant global<br />

companies in this sector. KSB<br />

ITUR Spain, S.A., the result of<br />

this relationship, trades as the<br />

KSB ITUR br<strong>and</strong>. KSB ITUR is<br />

now a company with a global<br />

<strong>and</strong> specialized distribution network,<br />

the latest technical innovations<br />

<strong>and</strong> integrated, customer-oriented<br />

service. Thanks to<br />

the strength of its market presence,<br />

the Group can offer partners<br />

<strong>and</strong> customers optimum<br />

solutions that are geared to effective<br />

fluid h<strong>and</strong>ling in all areas<br />

of application.<br />

The modern production facilities<br />

at KSB ITUR cover an area of<br />

21.000 m 2 , with state-of-the-art<br />

10 Inside

Partner<br />

equipment for developing, manufacturing<br />

<strong>and</strong> testing all the<br />

products they offer on the market.<br />

There are also consultancy<br />

<strong>and</strong> sales offices in all major<br />

Spanish cities.<br />

Business activities.<br />

KSB ITUR works on the basis of<br />

international st<strong>and</strong>ards <strong>and</strong> directives.<br />

Not only is there an extensive<br />

catalog product range,<br />

the company also adapts pumps<br />

to meet the needs of their customers.<br />

From their requirements<br />

comes the motivation to develop<br />

new products, utilizing their extensive<br />

production range.<br />

Extinguisher module.<br />

Inline centrifugal pump.<br />

KSB ITUR is an established supplier<br />

in the most important pump<br />

application areas:<br />

Building services engineering:<br />

air conditioning, pressure systems,<br />

fire <strong>protection</strong>, wastewater<br />

disposal.<br />

Water management: water<br />

supply, water transportation,<br />

irrigation, desalination.<br />

Wastewater engineering: water<br />

treatment <strong>and</strong> purification.<br />

Petroleum, chemical <strong>and</strong> power<br />

engineering: loading platforms,<br />

refineries, conventional<br />

chemistry, simultaneous generation<br />

of two types of <strong>energy</strong>.<br />

Industrial engineering: vehicle<br />

manufacture, steel production,<br />

biofuels, paper industry.<br />

Marine engineering: various<br />

services, bilge pumps, engine<br />

cooling, cleaning.<br />

KSB ITUR <strong>and</strong> KRAL AG.<br />

The business relationship between<br />

KSB ITUR <strong>and</strong> KRAL began<br />

more than 20 years ago.<br />

KSB ITUR did not have a screw<br />

pump line so KRAL provided<br />

them, principally to complete<br />

the product range for shipyards<br />

<strong>and</strong> equipment suppliers.<br />

The intensive collaboration now<br />

enjoyed by KSB ITUR <strong>and</strong> KRAL<br />

evolved from these beginnings,<br />

<strong>and</strong> business relations are invariably<br />

friendly <strong>and</strong> sincere. The<br />

pumps KRAL supplies are of excellent<br />

quality <strong>and</strong> meet our sales<br />

<strong>and</strong> service requirements with<br />

ease. These aspects, as well<br />

as the excellent partnership between<br />

the two companies, contribute<br />

to the success of pump<br />

distribution on the Spanish <strong>and</strong><br />

international markets.<br />

Carlos Luján<br />

Marketing Manager<br />

INSIDE<br />

11

PARTNER<br />

OBRAS Y SERVICIOS PETROLEROS<br />

S.A. DE C.V.<br />

O.S.P. supports PEMEX in a variety of ways.<br />

The Mexican economy is subject to continuous <strong>and</strong> rapid change, to which we consistently<br />

have to respond with new ideas <strong>and</strong> services.<br />

Production hall at O.S.P.<br />

O.S.P. Service Team at PEMEX.<br />

The company Obras y Servicios<br />

Petroleros S.A. de C.V. (O.S.P.)<br />

was founded by Dr. Miguel Angel<br />

Monroy Benitez on September,<br />

26 th 1990 in Comalcalco, Tabasco.<br />

The aim was to provide<br />

better opportunities for exploration<br />

<strong>and</strong> production, as well<br />

as selling <strong>and</strong> marketing to the<br />

Mexican petroleum market. Petroleum<br />

is produced <strong>and</strong> processed<br />

in our country by PEMEX<br />

(Petroleos Mexicanos). PEMEX<br />

is a company that, in the course<br />

of its 70-year history, has developed<br />

into one of the most important<br />

petroleum producers <strong>and</strong><br />

exporters in the world. PEMEX<br />

is the biggest company in Latin<br />

America.<br />

O.S.P. specializes in the installation<br />

<strong>and</strong> maintenance of compressors<br />

<strong>and</strong> equipment controls,<br />

centrifugal-, positive-displacement<br />

<strong>and</strong> vacuum pumps,<br />

electric motors, internal-com-<br />

Top-quality innovative<br />

solutions.<br />

The business relationship between<br />

O.S.P. <strong>and</strong> KRAL AG<br />

emerged from the <strong>development</strong><br />

of a solution to save fuel. This<br />

collaboration led to new <strong>energy</strong><br />

requirement planning for the oil<br />

pumping equipment. Thanks to<br />

the KRAL system, installed by<br />

O.S.P., a precise fuel balance<br />

that can be documented has<br />

been implemented. The KRAL<br />

system measures the amount of<br />

fuel that is delivered, the amount<br />

taken from the tank <strong>and</strong> the fuel<br />

consumption of each diesel generator.<br />

PEMEX was surprised<br />

<strong>and</strong> impressed by the precision<br />

of these measurements.<br />

The KRAL fuel consumption<br />

measurement system comprises<br />

eight KRAL flowmeters, the<br />

BEM 900 electronics unit <strong>and</strong> the<br />

BEM 1000 software which was<br />

developed especially for this apbustion<br />

engines, valves, <strong>and</strong><br />

machine processing for the petroleum<br />

industry. PEMEX is our<br />

company’s most important customer.<br />

We also offer the same<br />

st<strong>and</strong>ards of quality <strong>and</strong> service<br />

to many other businesses <strong>and</strong><br />

authorities.<br />

The strategic alternative.<br />

About ten years ago, Mexico experienced<br />

a turnaround in its history<br />

when globalization reached<br />

our shores. Globalization brought<br />

numerous economic, political<br />

<strong>and</strong> social changes to Mexico.<br />

Many international companies<br />

arrived, <strong>and</strong> the business policies<br />

they brought with them required<br />

many Mexican businesses<br />

to adopt a new approach.<br />

Poor infrastructure, a lack of underst<strong>and</strong>ing<br />

of environmental issues<br />

<strong>and</strong> the need to be careful<br />

with the country’s resources, as<br />

well as new technologies, were<br />

typical of the situation.<br />

O.S.P. took these changes on<br />

board. Significant dem<strong>and</strong>s had<br />

to be countered with significant<br />

solutions. This was the only alternative<br />

in this completely new<br />

industrial situation.<br />

A complex task.<br />

O.S.P. was given the opportunity<br />

to make PEMEX more<br />

competitive in oil production.<br />

Globalization drew many foreign<br />

companies to Mexico,<br />

which, like PEMEX, are active<br />

in the petroleum industry. O.S.P.<br />

was asked to find a solution<br />

to increase the efficiency of<br />

PEMEX’s oil rigs. The aim was<br />

to avoid unnecessary drilling<br />

costs. Analyses showed that<br />

the high consumption of diesel<br />

fuel was a considerable<br />

cost factor for the rigs. Diesel<br />

engines are used to generate<br />

electricity both in drilling installations<br />

on l<strong>and</strong> <strong>and</strong> on offshore<br />

platforms.<br />

12 Inside

PEMEX oil field in Villahermosa, Mexico.<br />

plication by KRAL. The system<br />

was installed by O.S.P. <strong>and</strong> tested<br />

for one year, in cooperation<br />

with a drilling team. With the exact<br />

measurements it is now possible<br />

to identify the optimal performance<br />

point for each diesel<br />

generator. The fuel consumption<br />

previously recorded was<br />

about 20% higher than the one<br />

that was now being measured<br />

accurately. Using these figures<br />

from the KRAL measurement<br />

system, PEMEX prepared their<br />

operating <strong>and</strong> maintenance<br />

schedules for their diesel generators.<br />

The expected <strong>and</strong> allowable<br />

fuel consumption is part of<br />

these schedules. The results are<br />

in keeping with the corporate culture<br />

at PEMEX, which involves<br />

careful <strong>and</strong> environmentally<br />

safe h<strong>and</strong>ling of the valuable oil.<br />

On the basis of this positive outcome,<br />

PEMEX engaged O.S.P.<br />

to install 20 more KRAL systems<br />

for their rigs in the south<br />

of Mexico.<br />

A friendly relationship.<br />

The relationship between O.S.P.<br />

<strong>and</strong> KRAL has become increasingly<br />

secure as the challenges<br />

have become more dem<strong>and</strong>ing.<br />

There is a basis of friendship <strong>and</strong><br />

trust between our companies,<br />

as well as the common interest<br />

in working closely together<br />

to develop made-to-order solutions<br />

for our customers.<br />

Mobile KRAL fuel consumption measurement system by O.S.P.<br />

Rafael Osorio<br />

Operative Management<br />

O.S.P. Mexico<br />

INSIDE<br />

13

market<br />

New KRAL pump stations.<br />

A totally new generation of double stations has been developed<br />

in cooperation with GEA WESTFALIA.<br />

KRAL has the know-how <strong>and</strong> expertise to turn customers’ innovative ideas into unique<br />

solutions. The new pump stations of the DKC/DMC series cannot fail to impress with a<br />

wealth of benefits taking up minimal space.<br />

GEA WESTFALIA Separator<br />

Systems GmbH is an innovative<br />

company that is continually developing<br />

its booster modules.<br />

WESTFALIA has a reputation in<br />

the market for high customer benefit<br />

<strong>and</strong> top quality. To achieve<br />

this, companies such as WEST-<br />

FALIA need a competent, efficient<br />

<strong>and</strong> reliable partner. WEST-<br />

FALIA has opted for KRAL.<br />

A second pump, just to be sure.<br />

There are critical applications<br />

where a second pump is stipulated<br />

as a safeguard. Providing<br />

this safeguard by having a<br />

st<strong>and</strong>by pump always available<br />

is the basic idea behind double<br />

stations of KRAL. The st<strong>and</strong>by<br />

section of the station block is depressurized.<br />

The corresponding<br />

pump can be quickly dismantled<br />

for maintenance. The customer’s<br />

installation, for example a ship’s<br />

engine, a production process or<br />

heating, keeps running.<br />

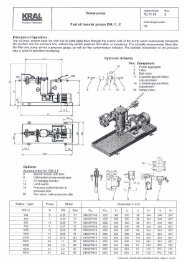

DKC pump station.<br />

More than twice as many<br />

beneftis with two pumps.<br />

KRAL double stations have been<br />

proving their worth for 40 years,<br />

<strong>and</strong> have been so extensively<br />

developed that a totally new<br />

generation has emerged. KRAL<br />

double stations are particularly<br />

beneficial to those companies<br />

that construct <strong>and</strong> complete<br />

their pump stations from<br />

individual components. In this<br />

case, the space saved amounts<br />

to more than 50%. There are an<br />

impressive number of functions<br />

combined in the compact stations,<br />

taking up minimal space.<br />

14 Inside

market<br />

Before.<br />

New!<br />

Switching valve for switching<br />

to the st<strong>and</strong>by pump.<br />

Electric or media heater for<br />

heating high-viscosity fluids.<br />

Expansion valves to avoid unacceptably<br />

high pressure in<br />

Numerous functions taking up minimal space.<br />

the st<strong>and</strong>by section of the station<br />

block.<br />

Pressure-retaining valve for<br />

constant feed pressure, even<br />

if the dem<strong>and</strong> for liquid is variable.<br />

A two-way valve for switching<br />

between liquids, for light<br />

<strong>and</strong> heavy fuel oil operation,<br />

for example.<br />

Accessible pipework connection<br />

on the front.<br />

Measurement of liquid temperature.<br />

Pressure switch for pressure<br />

monitoring.<br />

Cooling fins to cool the liquid<br />

on return.<br />

Differential pressure display<br />

for monitoring loading of the<br />

strainer.<br />

Oil leakage monitoring.<br />

Strainer cover <strong>protection</strong> to prevent<br />

accidents being caused<br />

by spurting oil.<br />

Simultaneous operation of<br />

both pumps to double the<br />

flow rate.<br />

Non-return valves to prevent<br />

backflow to the st<strong>and</strong>by<br />

pump.<br />

Precise flow measurement to<br />

monitor rates.<br />

gy. As an alternative, which has<br />

been tried <strong>and</strong> tested in practice<br />

<strong>and</strong> which is also suitable for<br />

the new double stations, KRAL<br />

provides pumps with magnetic<br />

coupling. KRAL pumps with<br />

magnetic coupling are hermetically<br />

sealed <strong>and</strong> suitable for temperatures<br />

up to 250 °C.<br />

Thomas Flauger<br />

Marketing Manager<br />

Hermetically sealed magnetic<br />

couplings.<br />

Heavy fuel oil (HFO) usually has<br />

a high proportion of abrasive<br />

components. This may damage<br />

the mechanical seals of the<br />

pumps. Increased leakage <strong>and</strong><br />

total pump failure may result.<br />

The only way to drastically improve<br />

HFO capability is to completely<br />

replace the mechanical<br />

Hermetically sealed magnetic coupling.<br />

seals with a different technolo-<br />

INSIDE<br />

15

Partner<br />

Innovative shipbuilding at the<br />

Meyer shipyard.<br />

From wooden boats to specialist ships.<br />

The Meyer shipyard in Papenburg on the Ems river, Germany, is among the most modern<br />

shipyards in Europe. Thanks to their flexibility <strong>and</strong> readiness for innovation, the shipbuilders have<br />

been able to secure a position close to the front of the highly competitive market for cruise ships.<br />

The Meyer shipyard in Papenburg: specialist in building modern cruise ships.<br />

The Meyer shipyard is a company<br />

with a tradition which began<br />

in 1795. From the beginning,<br />

its experts <strong>and</strong> specialists have<br />

never stopped building ships of<br />

the most varied kinds.<br />

Tradition <strong>and</strong> progress as<br />

recipe for success.<br />

The Meyer shipyard was founded<br />

for building wooden ships.<br />

The company is still owned by<br />

the Meyer family, now in the<br />

sixth generation. For over 200<br />

years, the company has been<br />

constantly developing, <strong>and</strong> it is<br />

now at the latest state of the<br />

art.<br />

After the years of wooden shipbuilding,<br />

the company showed<br />

an early pioneering spirit, which<br />

has been the basis of the steady<br />

<strong>development</strong> of the shipyard. Of<br />

the about 20 shipyards which existed<br />

in the small town on the<br />

Ems in 1920, only the Meyer<br />

shipyard has survived. Innovation<br />

<strong>and</strong> flexibility run through<br />

the whole history of the company,<br />

<strong>and</strong> make its success - it has<br />

grown continuously against the<br />

trend in the German shipbuilding<br />

industry. In 1872, Joseph<br />

L. Meyer began building steelhulled<br />

ships driven by steam<br />

engines, <strong>and</strong> thus secured the<br />

company’s future.<br />

Between the two world wars,<br />

the shipyard mainly built trawlers,<br />

pilot vessels, lightships<br />

<strong>and</strong> passenger ships for coastal<br />

travel. In 1960, the company<br />

began building gas tankers, <strong>and</strong><br />

in 1964, with the MALMÖ, the<br />

first roll-on-roll-off (RoRo) ferry<br />

was delivered in Papenburg.<br />

In the last decades of the 20 th<br />

century, the Meyer shipyard<br />

gained an excellent international<br />

reputation for building car <strong>and</strong><br />

passenger ferries, RoRo <strong>and</strong><br />

passenger ships, gas tankers,<br />

<strong>and</strong> above all luxurious cruise<br />

ships.<br />

16 Inside

lindtext<br />

AIDAbella, owned by the club shipping company AIDA Cruises.<br />

The Meyer shipyard builds luxury<br />

liners for customers throughout<br />

the world. New large-scale<br />

orders are bringing additional<br />

work to Papenburg. Very recently,<br />

the US entertainment company<br />

Disney placed an order for<br />

building two cruise ships.<br />

Up to now, the shipyard has supplied<br />

23 luxury liners in various<br />

size classes. Most recently, in<br />

April 2008, the “AIDAbella” was<br />

delivered to AIDA Cruises.<br />

The theater on board a luxury liner for NCL.<br />

Living room of a suite.<br />

Bedroom of a suite.<br />

With another four club ships<br />

for AIDA Cruises, five ships of<br />

the post-Panmax class (gross<br />

tonnage 122.000) for Celebrity<br />

Cruises, <strong>and</strong> the two ships<br />

(gross tonnage 124.000) for<br />

INSIDE<br />

17

Partner<br />

The Celebrity Solstice in dry dock.<br />

Luxury liner for NCL.<br />

Disney Cruise Line, eleven ships<br />

are under construction or on order<br />

from the shipyard. The ships<br />

will be completed by 2012.<br />

Today, the company has over<br />

2.500 employees. Over 8.000<br />

jobs in the shipbuilding industry<br />

<strong>and</strong> suppliers depend directly on<br />

the Meyer shipyard.<br />

Most modern shipyard<br />

in Europe.<br />

The Meyer shipyard was the first<br />

compact shipyard in Europe, <strong>and</strong><br />

is among the most modern today.<br />

The two roofed dry dock<br />

sheds, the advanced production<br />

plant <strong>and</strong> the concept of short<br />

paths are what make the shipyard<br />

successful. That is short<br />

paths in both the organizational<br />

sense, for fast decisions, <strong>and</strong><br />

the spatial sense, for distances<br />

on the shipyard site. In 2008, the<br />

second dry dock is being extended<br />

by 120 m, so that larger ships<br />

can still be built.<br />

Specialist shipbuilding, above<br />

all building large passenger <strong>and</strong><br />

cruise ships, is technically <strong>and</strong><br />

logistically very dem<strong>and</strong>ing.<br />

All activity fields are therefore<br />

equipped with the most modern<br />

computer technology - from preliminary<br />

to final design engineering<br />

<strong>and</strong> on to production.<br />

Shipbuilding at the Meyer shipyard<br />

works on the “Lego principle”.<br />

This means that small<br />

parts are produced first, <strong>and</strong> assembled<br />

into larger <strong>and</strong> larger<br />

units. Steel plates become sections,<br />

sections become blocks.<br />

About 70 blocks, weighing up<br />

to 800 tons each, form a ship.<br />

As far as possible, the technical<br />

equipment too is preassembled<br />

before it is fitted to the ship.<br />

Thanks to modular construction<br />

from individual prefabricated<br />

blocks, the ship can be built in<br />

the shortest time.<br />

First class service<br />

by KRAL AG.<br />

In the four new AIDA ships<br />

which are being built, fuel <strong>and</strong><br />

18 Inside

Partner<br />

lubricant pumps by KRAL AG are<br />

fitted. For heavy oil, we increasingly<br />

use the high quality KRAL<br />

pumps with magnetic coupling.<br />

These hermetically sealed<br />

pumps contribute to increased<br />

safety on board our ships. The<br />

fact that fuel can no longer escape<br />

supports our intention of<br />

clean ships in a clean environment.<br />

For older ships, we have<br />

accepted the attractive offer of<br />

the KRAL pump upgrade project,<br />

<strong>and</strong> replaced pumps with mechanical<br />

seals with magnetically<br />

coupled KRAL pumps.<br />

The Pride of Hawaii was delivered to NCL in 2006. The ship is now working as the Norwegian Jade.<br />

As far as KRAL is concerned,<br />

we particularly appreciate the<br />

helpfulness of the Austrians.<br />

In one case, in a deadline situation<br />

which was really tight for<br />

us, we received large lubricating<br />

oil pumps for a ferry within just<br />

3 days. In another case, KRAL<br />

showed that it was close to its<br />

customer despite the distance.<br />

On a request for quick service,<br />

KRAL engineers responded immediately.<br />

In a few hours they<br />

were working here, <strong>and</strong> they<br />

solved the problem overnight.<br />

Magnetically coupled KRAL pump for a clean, safe engine room.<br />

Peter Hackmann<br />

Communications Manager<br />

Meyer Werft GmbH<br />

KRAL pump with marine flange.<br />

INSIDE<br />

19

PARTNER<br />

<strong>Environmental</strong>ly friendly<br />

hydro-powered <strong>energy</strong> generation<br />

in Austria.<br />

The most modern pumped storage power station in the world<br />

utilizes the natural “water” resource in Vorarlberg.<br />

Provisional control station during commissioning.<br />

Pump <strong>and</strong> converter.<br />

The new Kopswerk II power<br />

station is a milestone for Vorarlberger<br />

Illwerke AG <strong>and</strong> for the<br />

exploitation of hydro-power in<br />

Austria. It supplies high-quality<br />

peak-load <strong>and</strong> control-load electricity<br />

from renewable hydropower.<br />

When the dem<strong>and</strong> on<br />

the network is low, water is<br />

pumped up to the Kopssee<br />

Lake, which lies at an elevation<br />

of 1.800 m. When the dem<strong>and</strong><br />

for <strong>energy</strong> increases, the water<br />

falls through large pipes to the<br />

power station in the valley below,<br />

where the hydro-<strong>energy</strong><br />

is used to generate electricity.<br />

Kopswerk II increases Illwerke’s<br />

capacities by 85% in pumping<br />

operation <strong>and</strong> by 36% in turbine<br />

operation.<br />

Changes in the electricity<br />

market.<br />

Many customers in Austria want<br />

their electricity to come from<br />

the renewable <strong>energy</strong> sources<br />

of wind <strong>and</strong> water. The intensity<br />

of the wind <strong>and</strong> lulls in<br />

its force cannot be controlled.<br />

The liberalization of the electricity<br />

market in Europe has led to<br />

an increased dem<strong>and</strong> for peakload<br />

<strong>and</strong> control-load <strong>energy</strong> <strong>and</strong><br />

also to take advantage of the opportunity<br />

for pumped storage in<br />

major alpine reservoirs, to exploit<br />

hydro-power. The response<br />

20 Inside

Surge tank<br />

Pressure tunnel<br />

Tafamunt excess<br />

tunnel<br />

High-pressure tunnel<br />

Underground<br />

hydroelectric<br />

power plant<br />

Tailrace tunnel<br />

The entire Kopswerk II power station.<br />

INSIDE<br />

21

PARTNER<br />

Versalspitze<br />

2.000 m<br />

Kopssee<br />

Lake<br />

1.809 m<br />

Surge tank<br />

Kopswerk ll<br />

Cavern<br />

Entry tunnel<br />

L 188<br />

from Illwerke was to develop<br />

<strong>and</strong> build their most powerful<br />

pumped storage power station,<br />

Kopswerk II. „Kopswerk II<br />

will optimize the two renewable<br />

<strong>energy</strong> sources of hydro-power<br />

<strong>and</strong> wind <strong>energy</strong>, by allowing<br />

precisely coordinated interplay<br />

between the two”, says illwerke<br />

vkw CEO Dr. Ludwig Summer.<br />

„With this power station, we<br />

can consolidate our good position<br />

as a supplier of peak-load<br />

<strong>and</strong> control-load <strong>energy</strong> on the<br />

European electricity market.”<br />

Focus on environmental<br />

<strong>protection</strong>.<br />

The power station is mainly located<br />

inside the mountain <strong>and</strong><br />

is hardly visible from outside.<br />

No additional water resources<br />

are being used, as the power<br />

station uses the Kopssee Lake<br />

<strong>and</strong> the existing Rifa balancing<br />

reservoir as the lower reservoir.<br />

This was an important requirement<br />

for being able to successfully<br />

conclude, in record time,<br />

the strict environmental impact<br />

assessment being performed in<br />

Vorarlberg for the first time. The<br />

purpose of supervising the ecological<br />

integrity of the construction<br />

was to keep interference for<br />

Kopswerk II.<br />

Turbine <strong>and</strong> pumping capacity:<br />

Generator power:<br />

Gross head:<br />

No. of generator sets: 3<br />

Running speed:<br />

man <strong>and</strong> nature at a minimum.<br />

In 1958, the plant at Lünersee<br />

was regarded as the most powerful<br />

pumped storage power station<br />

in the world. Now Kopswerk<br />

II ranks as what is currently the<br />

most modern pumped storage<br />

power station. Vorarlberg is<br />

again living up to its reputation<br />

as the “hydro-power pioneer”.<br />

KRAL pumps used in<br />

state-of-the-art power<br />

station technology.<br />

Kopswerk II is designed as a<br />

pumped storage power station.<br />

The power station takes advantage<br />

of the drop between the<br />

Kopssee Lake (1.800 m) <strong>and</strong><br />

Partenen-Rifa (1.000 m). The<br />

water of the Kopssee Lake is<br />

fed to the power plant via a<br />

pressure tunnel <strong>and</strong> a highpressure<br />

tunnel. The generating<br />

sets, which comprise turbines,<br />

pumps <strong>and</strong> generators,<br />

are housed in a generator cavern,<br />

the transformers in a separate<br />

transformer cavern. The<br />

water used in Kopswerk II then<br />

flows into the Rifa balancing reservoir<br />

via a tailrace tunnel. This<br />

serves both as a tailrace balancing<br />

reservoir <strong>and</strong> as a pumping<br />

water storage reservoir.<br />

The supply systems for the lubricating<br />

oil for maintaining the<br />

footstep <strong>and</strong> radial bearings of<br />

the power station turbines <strong>and</strong><br />

pumps are fitted with KRAL<br />

pumps from the K2900 series,<br />

with additional pumps from the<br />

CK series.<br />

Rifa balancing<br />

reservoir 1.005 m<br />

450 megawatts<br />

600 MVA<br />

approx. 800 m<br />

500 rpm<br />

KRAL AG, which is also a successful<br />

Vorarlberg company,<br />

provides us with an extensive<br />

range of pump products that<br />

meets in full all our requirements<br />

with regard to performance<br />

<strong>and</strong> reliability.<br />

Information provided by<br />

illwerke vkw<br />

Andreas Neuhauser<br />

Communications Manager<br />

22 Inside

lindtext<br />

Far too Much Lubrication!<br />

KRAL Volumeter ® – precise cylinder lubricating<br />

oil measurement for diesel engines.<br />

KRAL Volumeter <strong>and</strong> KRAL electronic systems<br />

for optimal regulation of the volume of cylinder<br />

lube oil.<br />

High operating costs reduce the profits<br />

of merchant shipping companies. The<br />

precision of cylinder lubrication in diesel<br />

engines determines their service life.<br />

Until now the volume of lube oil has<br />

merely been estimated from the injector<br />

geometry. Our measurements have<br />

shown that significant discrepancies can<br />

occur between the actual figures <strong>and</strong><br />

the engine manufacturers’ specifications.<br />

What a waste! In addition overlubrication<br />

damages the pistons <strong>and</strong><br />

cylinders.<br />

License to Print Money.<br />

Overlubrication can cause additional<br />

costs of up to 277.000 USD per ship <strong>and</strong><br />

year. The KRAL cylinder lube oil meter<br />

allows the volume of lube oil to be regulated<br />

extremely accurately <strong>and</strong> helps to<br />

save expensive lube oil.<br />

www.kral.at<br />

www.kral-usa.com<br />

KRAL AG, Bildgasse 40, Industrie Nord, 6890 Lustenau, Austria, Tel.: +43 / 55 77 / 8 66 44 - 0, Fax: 8 84 33, e-mail: info@kral.at<br />

KRAL -USA, Inc., P.O. Box 2990, Matthews, NC 28106, USA, Tel.: +1 / 704 814 - 6164, e-mail: sales@kral-usa.com

Partner<br />

Wärtsilä in Switzerl<strong>and</strong>.<br />

The center for low-speed Wärtsilä two-stroke marine diesel engines<br />

is located in Switzerl<strong>and</strong>.<br />

Two-stroke marine diesel engines are used for the propulsion of ocean-going vessels such<br />

as tankers, bulk carriers <strong>and</strong> container ships. These marine diesel engines from Wärtsilä are<br />

developed in Winterthur.<br />

was put into service in September<br />

2006.<br />

A lot of these new research <strong>and</strong><br />

<strong>development</strong> findings were initially<br />

tested in the Diesel Technology<br />

Center in Oberwinterthur.<br />

At the Diesel Technology Center,<br />

Wärtsilä Schweiz has stateof-the-art<br />

research <strong>and</strong> training<br />

equipment available. Company<br />

HQ is located in Winterthur town<br />

center. At present, over 500 people<br />

from 40 countries work for<br />

Wärtsilä in Switzerl<strong>and</strong>.<br />

The main building of Wärtsilä Schweiz AG (© Wärtsilä).<br />

Wärtsilä in Switzerl<strong>and</strong> emerged<br />

from the diesel engine business<br />

of the Sulzer brothers, Gebrüder<br />

Sulzer AG, in Winterthur.<br />

The diesel engine business effectively<br />

started in 1893 with<br />

the signing of a cooperation<br />

agreement between Sulzer <strong>and</strong><br />

Rudolf Diesel over the use of the<br />

latter’s new engine technology.<br />

Sulzer manufactured the first<br />

diesel engines in Winterthur in<br />

1903. Since 1909, the licensing<br />

of the technology has played an<br />

important role in the global sales<br />

of our engines.<br />

Marine diesel engines have long<br />

been one of the most important<br />

products at Winterthur. Development<br />

milestones at Winterthur<br />

include airless fuel injection<br />

(1930), turbocharging (1946),<br />

the use of heavy fuel oil (1950),<br />

loop scavenging (from 1950) <strong>and</strong><br />

conversion to uniflow scavenging<br />

(1983). Development of elec-<br />

Wärtsilä 6RT-flex50 (© Wärtsilä).<br />

tronically controlled fuel injection<br />

(common rail) began in 1981. In<br />

1998, this led to the production<br />

of the first low-speed, electronically<br />

controlled common rail RTflex<br />

engine <strong>and</strong> in 2001, the first<br />

RT-flex marine diesel engines<br />

were commissioned.<br />

Nowadays, research <strong>and</strong> <strong>development</strong><br />

focuses particularly on<br />

reducing the exhaust emissions<br />

of two-stroke engines. We provide<br />

efficient solutions for the<br />

low emission limits of the future.<br />

By installing highly-efficient<br />

waste heat recovery systems,<br />

it is possible to achieve<br />

fuel savings <strong>and</strong> reduce emissions<br />

up to 12%.<br />

The 14-cylinder RT-flex96C engines<br />

developed in Winterthur,<br />

with power outputs of up to<br />

84.420 kW, are the largest marine<br />

diesel engines in the world.<br />

The first engine of this series<br />

Center of excellence for<br />

Wärtsilä two-stroke engines<br />

in Winterthur.<br />

Our objectives are:<br />

The research <strong>and</strong> <strong>development</strong><br />

of new technologies for<br />

Wärtsilä two-stroke engines.<br />

The design <strong>and</strong> <strong>development</strong><br />

of new two-stroke engines<br />

both in Winterthur <strong>and</strong><br />

in close collaboration with selected<br />

licensees.<br />

Assisting the manufacture of<br />

modern, superior quality engines<br />

with sophisticated production<br />

processes in active<br />

partnership with licensees.<br />

Best service for our customers<br />

in the Customer Assistance<br />

Center, which also<br />

h<strong>and</strong>les warranties for the<br />

two-stroke engines. Our customer<br />

service <strong>and</strong> our service<br />

features are available to<br />

our customers <strong>and</strong> partners<br />

24-7, all-year round.<br />

Marketing cost-efficient <strong>energy</strong><br />

solutions for all types <strong>and</strong><br />

sizes of merchant ships, in<br />

24 Inside

Partner<br />

The Wärtsilä 14RT-flex96C is the world’s largest marine diesel engine (© Wärtsilä).<br />

at the Diesel Technology Center<br />

(DTC) is used to study engine<br />

processes, develop new<br />

technologies <strong>and</strong> test new components.<br />

The Diesel Technology<br />

Center also has test facilities<br />

available for fuel injection,<br />

common rail <strong>and</strong> exhaust valve<br />

systems. Operation of the DTC<br />

complies in every respect with<br />

the requirements of local environmental<br />

legislation.<br />

The “Wärtsilä L<strong>and</strong> & Sea Academy”<br />

provides training for licensee<br />

personnel, shipowners <strong>and</strong><br />

ship operators, as well as inhouse<br />

courses. Training concentrates<br />

on the operation <strong>and</strong><br />

maintenance of Wärtsilä twostroke<br />

engines.<br />

KRAL Volumeter ® on<br />

Wärtsilä test benches.<br />

When developing new systems<br />

<strong>and</strong> comparing simulations or<br />

calculations, the st<strong>and</strong>ards reclose<br />

cooperation with shipbuilders,<br />

shipyards, shipowners<br />

<strong>and</strong> ship operators.<br />

Long-term service provision,<br />

tailored to meet the requirements<br />

of shipowners (Global<br />

Customer Agreements). They<br />

ensure the operation <strong>and</strong><br />

maintenance of the entire engine<br />

room.<br />

Close collaboration<br />

with our licensees.<br />

Wärtsilä two-stroke engines are<br />

manufactured under license in<br />

eight countries, throughout the<br />

world. Wärtsilä works closely together<br />

with its licensees in <strong>development</strong>,<br />

manufacture <strong>and</strong><br />

operation. We support our licensees<br />

on-site with qualified professionals<br />

during the production,<br />

installation <strong>and</strong> commissioning<br />

of our engines.<br />

Diesel Technology Center.<br />

The two-stroke research engine<br />

This container ship is driven by a Wärtsilä<br />

8RT-flex96C engine (© Wärtsilä).<br />

quired by today’s measurement<br />

technology keep getting higher.<br />

With Wärtsilä’s marine diesel<br />

engines, there is also the<br />

factor of fitness for marine applications,<br />

including tough ambient<br />

conditions <strong>and</strong> the vibration<br />

resistance of the components.<br />

KRAL Volumeter of the OMG<br />

series meet our expectations of<br />

high-precision <strong>and</strong> dynamic flow<br />

measurement to our utmost satisfaction.<br />

The convincing operating<br />

principle, the high quality of<br />

the equipment, <strong>and</strong> not forgetting<br />

the excellent support, are all<br />

crucial for successful data acquisition.<br />

Great praise is due in this<br />

respect to Mr. Matter, the Manager<br />

of the KRAL agency, Matter<br />

Hydraulik AG, in Switzerl<strong>and</strong>.<br />

Mr. Matter is always available to<br />

advise <strong>and</strong> assist us during our<br />

many trials, to make sure that<br />

deadlines are met.<br />

Michael Hamberger<br />

Fuel Injection & Hydraulics<br />

Research & Development<br />

Wärtsilä Schweiz AG<br />

INSIDE<br />

25

Partner<br />

FLUJOMATICA S.R.L.<br />

KRAL fuel consumption measurement helps safeguard the<br />

livelihood of Peruvian fishermen.<br />

Fishing <strong>and</strong> fish processing are among the most important export industries of Peru. Peru relies<br />

on its large fleet of small fishing boats, whose owners are suffering vast financial losses because<br />

of the rising costs of fuel. The call for precise consumption measurement systems is getting ever<br />

louder.<br />

For several years, some Peruvian<br />

fishing companies have been<br />

testing fuel consumption measurement<br />

systems for their boats,<br />

without being able to show any<br />

viable results or reach any useful<br />

conclusions. These tests were<br />

performed with turbine, ultrasonic<br />

<strong>and</strong> positive displacement<br />

measuring systems from various<br />

manufacturers.<br />

TASA (Tecnológica de Alimentos S.A.) fishing boat.<br />

Peruvian fishing boats.<br />

KRAL – FLUJOMATICA<br />

collaboration.<br />

In 2006, FLUJOMATICA heard<br />

about KRAL <strong>and</strong> promptly got in<br />

touch with KRAL - USA, Inc., to<br />

obtain extensive advice about<br />

consumption measurement systems.<br />

Initially, FLUJOMATICA<br />

acquired a consumption measurement<br />

system with PLC control,<br />

including two OME series<br />

KRAL flowmeters fitted with<br />

temperature sensors. The system<br />

proved its worth when trialed<br />

with a CAT 3512, the main<br />

engine of a boat in the TASA<br />

(Tecnológica de Alimentos S.A.)<br />

fleet. TASA is Peru’s most important<br />

fishing company. The<br />

results achieved persuaded the<br />

customer to immediately install<br />

the same system in six more<br />

boats. The aim is to install a<br />

KRAL fuel consumption measurement<br />

system on all the fleet’s<br />

boats as quickly as possible. On<br />

the basis of this positive experience<br />

with KRAL, two more major<br />

Peruvian fishing companies<br />

have registered their interest.<br />

One of these companies has al-<br />

26 Inside

The Peruvian Central Railway (FCCA) tests KRAL fuel consumption measurement systems.<br />

ready been successfully testing<br />

a KRAL fuel consumption measurement<br />

system for six months.<br />

This company is planning to use<br />

a KRAL consumption measurement<br />

system on all 20 of its<br />

ships very shortly.<br />

KRAL at EXPOPESCA 2007<br />

in Lima.<br />

In November 2007, in Lima,<br />

Peru, KRAL was represented<br />

at EXPOPESCA 2007, the international<br />

exhibition dedicated to<br />

fishing <strong>and</strong> fish processing. Our<br />

agency in Peru, FLUJOMATICA<br />

S.R.L., presented a KRAL consumption<br />

measurement system,<br />

incorporated into a control<br />

<strong>and</strong> monitoring system for the<br />

diesel engines of commercial<br />

fishing boats. The trade fair<br />

was a total success <strong>and</strong> was<br />

attended by numerous interested<br />

visitors from Peru, Chile<br />

<strong>and</strong> Ecuador. In addition to this,<br />

FLUJOMATICA has already received<br />

requests from other<br />

countries for fuel consumption<br />

measurement in fishing boats,<br />

trucks <strong>and</strong> various other areas<br />

of application.<br />

Between sea <strong>and</strong> sky.<br />

FLUJOMATICA is also testing<br />

KRAL fuel consumption measurement<br />

systems in the locomotives<br />

of the Peruvian Central<br />

Railway (Ferrocarril Central<br />

Andino, FCCA). This is the second-highest<br />

railway in the world,<br />

its trains running between sea<br />

level <strong>and</strong> 4.818 meters above<br />

sea level. This difficult terrain<br />

<strong>and</strong> the frequent load changes<br />

require a correspondingly rapid<br />

response from the system,<br />

so engineers were tasked with<br />

combining all these factors in<br />

a high-precision consumption<br />

measurement system.<br />

The future looks optimistic.<br />

In countries such as Peru, it is<br />

not just the quality or the price/<br />

performance ratio of a product<br />

that is crucial. In many cases,<br />

our systems have been rejected<br />

because they are so precise<br />

that they demonstrably measure<br />

<strong>and</strong> document illicit withdrawal<br />

of fuel or adverse operating<br />

practices.<br />

The KRAL training event in Miami<br />

(USA) in May 2008 provided<br />

an excellent opportunity to clarify<br />

these objections, to learn more<br />

about KRAL products <strong>and</strong> to<br />

look to the future with optimism.<br />

Richard J. Meighan<br />

Sales Manager<br />

KRAL-USA, Inc.<br />

INSIDE<br />

27

partner<br />

Mexico is an important country for oil.<br />

The PEMEX petroleum company – an important branch of industry<br />

for Mexico.<br />

Mexico is one of the most important petroleum exporting countries. According to estimates,<br />

Mexico is the sixth-largest crude oil producer, with well over 15 billion barrels of oil at its<br />

disposal. PEMEX is very well looked after in Mexico by the KRAL partner companies, O.S.P.<br />

<strong>and</strong> Fluidos Técnicos.<br />

Lázaro Cárdenas announces the expropriation<br />

of petroleum resources.<br />

Ing. Hector Lara Sosa Refinery, Cadereyta Nvo. Leon.<br />

The “El Señor del Mar” floating unit.<br />

The <strong>development</strong>, production,<br />

sales <strong>and</strong> marketing of the oil are<br />

exclusively in the h<strong>and</strong>s of the<br />

state-owned company PEMEX<br />

(Petróleos Mexicanos), which<br />

was founded in 1938.<br />

Company history.<br />

On March 18, 1938, President<br />

Lázaro Cárdenas del Río nationalized<br />

what had previously<br />

been the US-American <strong>and</strong><br />

Dutch petroleum groups in Mexico.<br />

This was based on constitutional<br />

provisions transferring<br />

all the country’s resources to<br />

state ownership, which were<br />

already in place in 1917. On<br />

June 7, 1938, PEMEX was established<br />

as the sole successor<br />

organization. Several countries<br />

reacted to this by boycotting<br />

Mexican petroleum.<br />

But despite this, Mexico developed<br />

into one of the largest<br />

petroleum exporters in the world.<br />

As Mexico’s largest franchise<br />

company, PEMEX runs an exhaustive<br />

network of gas stations.<br />

Mexico’s most important<br />

branch of industry.<br />

PEMEX became one of the<br />

most competitive companies in<br />

the world. The company operation<br />

is modern, transparent, efficient<br />

<strong>and</strong> effective. PEMEX feels<br />

committed to high st<strong>and</strong>ards of<br />

performance <strong>and</strong> honesty.<br />

There were great changes to<br />

the Mexican economy, which<br />

developed positively. PEMEX is<br />

now the most important company<br />

in Mexico. A considerable<br />

part of the state budget, around<br />

40%, is financed from oil revenue.<br />

PEMEX uses its cooperation<br />

with the industry to influence<br />

the <strong>development</strong> of the<br />

country <strong>and</strong> ensure a high employment<br />

rate.<br />

28 Inside

PEMEX Tower.<br />

INSIDE<br />

29

Partner<br />

Gas storage tanks.<br />

Thanks to its use of advanced<br />

technologies, PEMEX has succeeded<br />

in increasing its oil reserves<br />

<strong>and</strong> improving its export<br />

know-how. PEMEX sells highquality<br />

petroleum abroad <strong>and</strong> can<br />

supply its own natural gas, independently.<br />

Raw materials, products<br />

<strong>and</strong> top-quality service are<br />

offered at competitive prices.<br />

The petrochemical industry is<br />

modern <strong>and</strong> steadily growing.<br />

Operating groups.<br />

Five operating groups make up<br />

the PEMEX company, PEMEX<br />

Exploración y Producción (PEP),<br />

PEMEX Gas y Petroquímica<br />

Básica, PEMEX Petroquímica,<br />

PEMEX Refinación <strong>and</strong> PMI Comercio<br />

Internacional, S.A. de C.V.<br />

tion <strong>and</strong> exploitation of petroleum<br />

<strong>and</strong> natural gas, its transportation,<br />

storage <strong>and</strong> marketing.<br />

PEMEX Gas y Petroquímica<br />

Básica.<br />

PEMEX Gas y Petroquímica<br />

Básica occupies a strategic position<br />

within the petroleum production<br />

chain. PEMEX Gas y<br />

Petroquímica Básica is responsiblefor<br />

processing the natural<br />

gas, <strong>and</strong> for transporting, mar-<br />

keting <strong>and</strong> storing the products.<br />

PEMEX Gas y Petroquímica<br />

Básica is one of the ten largest<br />

companies in Mexico, with<br />

around 12.000 employees.<br />

PEMEX Petroquímica.<br />

PEMEX Petroquímica manufactures<br />

diverse products <strong>and</strong><br />

sells fertilizers, plastics, synthetic<br />

fibers <strong>and</strong> rubber, medicines<br />

<strong>and</strong> coolants to Mexican<br />

businesses.<br />

PEMEX Refinación.<br />

The essential task of PEMEX Refinación<br />

is the industrial refinery<br />

process for processing the petroleum<br />

products.<br />

PMI Comercio Internacional,<br />

S.A. de C.V.<br />

PMI is PEMEX’s trading company<br />

on the international market.<br />

PMI h<strong>and</strong>les the import<br />

<strong>and</strong> export of PEMEX’s petroleum<br />

<strong>and</strong> petroleum products<br />

Exploración y<br />

Producción (PEP).<br />

It is the task of PEMEX Exploración<br />

y Producción (PEP) to<br />

maximize the economic value of<br />

the country’s petroleum <strong>and</strong> natural<br />

gas reserves over the long<br />

term. The security of installations<br />

<strong>and</strong> employees is consistent<br />

with the environment. The<br />

main activities are the explora-<br />

Gas station.<br />

30 Inside

Platform complex in Cantarell.<br />

in many countries throughout<br />

the world.<br />

The right fuel balance in<br />

multi-engine systems.<br />

O.S.P (Obras Y Servicios Petroleros,<br />

S.A. De C.V.) delivers<br />

high-precision KRAL systems<br />

to PEMEX to measure fuel consumption.<br />

On the oil platforms<br />

<strong>and</strong> in l<strong>and</strong>-based production<br />

systems, power is generated by<br />

diesel engines. Although enormous<br />

quantities of oil are produced<br />

<strong>and</strong> processed, PEMEX<br />

h<strong>and</strong>les the valuable <strong>and</strong> scarce<br />

resource very carefully.<br />

They run the diesel engines at<br />

their optimum operating point,<br />

to ensure low fuel consumption.<br />

They also re-measure the diesel<br />

fuel that is delivered themselves,<br />

using KRAL Volumeter.<br />

KRAL Volumeter also measure<br />

the extraction flow from the<br />

storage tanks. All the measurements<br />

together, that is the engine-related<br />

fuel consumption<br />

measurement, the quantity in<br />

the tank <strong>and</strong> the quantity extracted<br />

from the tank, give the<br />

fuel balance. Nowadays, not a<br />

drop is wasted.<br />

What PEMEX really appreciates<br />

about the KRAL system is the<br />

centralized display of the fuel<br />

consumption of all the engines<br />

of a multi-engine system, as well<br />

as the opportunity for a customized<br />

expansion, in accordance<br />

with PEMEX st<strong>and</strong>ards. This is<br />

because KRAL can integrate individual<br />

KRAL flowmeters into<br />

the fuel consumption measurement,<br />

making it possible to carry<br />

out complex measuring tasks.<br />

All the data is stored on the data<br />

logger, which allows PEMEX to<br />

later evaluate the data as they<br />

choose.<br />

With the kind assistance of<br />

the Communicación Social de<br />

PEMEX division<br />

KRAL fuel consumption measurement of a PEMEX multi-engine system.<br />

INSIDE<br />

31

Partner<br />

The Corus Group.<br />

Europe’s second largest steel producer.<br />