You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

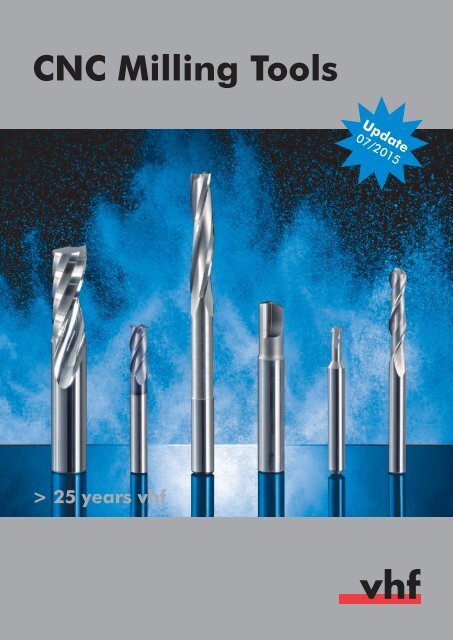

<strong>CNC</strong> Milling Tools<br />

Update<br />

07/2015<br />

> 25 years vhf

vhf tools for...<br />

v Milling<br />

Tools from one to six cutting edges made of carbide<br />

or diamond – uncoated or coated in more<br />

than 700 variants in total!<br />

v Engraving<br />

Universal gravers and engraver’s milling cutters<br />

as well as special tools for engraving acrylic glass,<br />

stainless steel and pressed paper sheets.<br />

v Deburring | chamfering | countersinking<br />

Removing burrs or chamfering edges with special<br />

tools from vhf. Countersinks for screws in wood,<br />

plastics, non-ferrous metals or steel.<br />

v Polishing<br />

Our special diamond polishing tools bring your<br />

milled edges or engravings in acrylic glass to a high<br />

gloss.<br />

v Thread cutting<br />

Cut your threads either with thread whirling cutters<br />

or with combined circular thread cutters which<br />

drill the tapping hole at the same time.<br />

As of: July 2015<br />

v Drilling<br />

Fine drills in 0.1 mm gradations with very good immersion<br />

characteristics for different kinds of materials.<br />

v Cutting<br />

Knifes and lances up to 70 mm length for straight<br />

cuts and diagonal cuts in all kinds of materials<br />

which can be better cut than milled.<br />

You will find many more production samples at www.vhf.de<br />

Picture credits: foliendesign GmbH, Essen (4 th from top).

Welcome to vhf!<br />

I want to thank you for your interest in our tools. With this issue, you have a much thicker<br />

catalogue in your hands than before. Compared with the previous issue more than 400<br />

new tools have been added. That means an extension of our range of tools by more than<br />

70 per cent.<br />

Quite much has happened concerning the composite cutters – we have added more than<br />

130 new tools in six categories. But also the selection of drills and diamond tools has<br />

become remarkably bigger. And we even have nearly doubled the quantity of single tooth<br />

cutters – a tool category which has already been well represented before. For reasons of<br />

clarity, we have marked all new tools with a red asterisk*. You will see that there are only<br />

very few pages without any asterisk in this new catalogue.<br />

We were able to extend our range of tools in such a way especially because we have invested<br />

heavily in our machinery and made our production more efficient during the past years.<br />

This leads also to the nice side benefit that we could reduce again many prices compared<br />

with the last issue of the catalogue.<br />

Our friendly and competent vhf tool team would be glad to answer all your questions.<br />

Please do not hesitate to contact them.<br />

Frank Benzinger<br />

Chief Executive Officer<br />

By using 100 % recovered paper for the complete edition of these catalogues, the following resources have been saved:<br />

Wood<br />

approx. 95,000 kg<br />

more than 3,000<br />

trees for fresh fibre<br />

paper<br />

Electricity<br />

approx 50.000 kWh<br />

consumption of a<br />

family of four in over<br />

10 years<br />

Water<br />

approx. 500,000 l<br />

consumption for<br />

more than 3,000<br />

full baths<br />

Waste<br />

approx. 25,000 kg<br />

amount of a family<br />

of four in over 10<br />

years<br />

100 %<br />

recycled

4<br />

Carbide Tools | Diamond Tools<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories<br />

Carbide milling cutters in more than<br />

700 variants – for most tools also available<br />

with coating. M Page 21<br />

For deburring, countersinking, chamfering<br />

of non-ferrous metals and plastics.<br />

M Page 81<br />

Using these tools you can cut threads<br />

in plastics, non-ferrous or ferrous metals<br />

and composites. M Page 95<br />

Lances and knives for the different<br />

cutting heads and the universal head.<br />

M Page 105<br />

A selection of tools for typical goldsmith<br />

works in materials like wax, metal<br />

and plastics. M Page 117<br />

Table of contents<br />

General information<br />

Development and production 6<br />

Special wishes? 7<br />

Order today, use it tomorrow... 7<br />

Comfortable search in the vhf Shop 8<br />

Tools live in the working process 8<br />

Why carbide tools? 9<br />

Why diamond tools? 10<br />

Hard coatings for carbide tools 11<br />

Overview of carbide and diamond tools 14<br />

Single tooth cutters<br />

Varius® cutters 22<br />

Cutters with polished flute 26<br />

Cutters with hawk beak profile 28<br />

Cutters with hawk beak and undercut 30<br />

Cutters with face radius 31<br />

Varius® cutters with left-hand twist 32<br />

Cutters, polished, with left-hand twist 33<br />

V-slot cutters for aluminium composites 34<br />

Double tooth cutters<br />

Varius® cutters 36<br />

Cutters with polished flute 37<br />

Cutters with fishtail 38<br />

HSC cutters 39<br />

Cutters for aluminium 40<br />

Cutters for aluminium profiles 41<br />

Cutters for stainless steel 42<br />

Cutters for wood 43<br />

Cutters with face radius 44<br />

Cutters with torus and undercut 45<br />

Cutters with face radius and undercut 46<br />

Rub out cutters 47<br />

Triple tooth cutters<br />

Varius® cutters 50<br />

Cutters for foam 51<br />

Cutters for stainless steel 52<br />

Four tooth cutters<br />

Varius® cutters 54<br />

Ratio cutters 55<br />

Roughing and finishing cutters<br />

Roughing cutters for copper 58<br />

Roughing cutters for graphite 59<br />

Finishing cutters for copper 60<br />

Composite cutters<br />

Finely toothed cutters 62<br />

Finely toothed cutters with chip breaker 63<br />

Medium toothed cutters 64<br />

Coarsely toothed cutters 65<br />

Straightly slotted honeycomb cutters 66<br />

Spiral-fluted honeycomb cutters 67<br />

PCB outline cutters, diamond-toothed 68<br />

PCB outline cutters, spiral-toothed 69<br />

Engraving tools<br />

Gravers 72<br />

Box gravers 74<br />

Engraver’s milling cutters for acrylic 75<br />

Engraver’s milling cutters for stainless steel 76<br />

Channel cutters 77<br />

Isolation engraving tool 78<br />

Semi-finished gravers 79

Impression<br />

Tools<br />

Carbide Tools | Diamond Tools 5<br />

Table of contents<br />

Deburring tools<br />

Deburring tools 82<br />

Deburring tools, quadrant 83<br />

Router bits<br />

V slot cutters 86<br />

Long hole slot cutters 87<br />

Slot cutters 88<br />

Character cutter 89<br />

Radius cutters 90<br />

Chamfering cutters 91<br />

Cutters with quadrant 92<br />

V slot cutters for aluminium composites 93<br />

Triple tooth surface milling cutters 94<br />

Thread cutters<br />

Thread whirling cutters 96<br />

Circular thread cutters 97<br />

Drills<br />

Drills with 3 mm shank 100<br />

Drills with 6 mm shank 102<br />

Lances and knives<br />

Lances 106<br />

Knives 107<br />

Diamond tools<br />

PCD single tooth cutters 110<br />

PCD double tooth cutters 111<br />

MCD polishing cutters 112<br />

MCD polishing gravers 113<br />

PCD polishing cutters 114<br />

PCD polishing gravers 115<br />

CVD cutters 116<br />

Impression tools<br />

Goldsmith tools 118<br />

Accessories<br />

Vacuum fleece 120<br />

Special adhesive film 120<br />

Stop rings 120<br />

Reducing bushes 121<br />

Coolants and lubricants 121<br />

Appendix<br />

Tips for the proper use of tools 122<br />

Hints for the right number of teeth 122<br />

Setting the machining parameters 123<br />

Choice of the milling direction 123<br />

Cooling/lubrication 124<br />

What to do in case of problems? 124<br />

Order form 125<br />

Your contacts 126<br />

vhf machine catalogue 127<br />

Engraver’s milling cutters and gravers<br />

for machining materials from plastics<br />

to stainless steel. M Page 71<br />

Massive steel body with integrated carbide<br />

cutting edges; for wood, plastics<br />

and composite plates. M Page 85<br />

For plastics, non-ferrous metals, PCBs<br />

or thermosetting plastics and thermoplastics.<br />

M Page 99<br />

A diamond instead of a carbide cutting<br />

edge improves the quality and endurance<br />

– without cooling. M Page 109<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

All prices exclude VAT, customs duties and transportation/packaging<br />

fees • Deliveries are always subject to<br />

our Terms of Sale; we would be glad to send them to<br />

you on request and you will find them on the internet<br />

at download.vhf.de • All trade and product names<br />

mentioned in this catalogue belong to their owners •<br />

Technical modifications and errors excepted.<br />

Stop rings and reducing bushes; vacuum<br />

fleece and adhesive film; lubricants<br />

for cooling. Page 119<br />

Accessories

Thread<br />

Cutters<br />

Diamond<br />

Tools<br />

6<br />

Carbide Tools | Diamond Tools<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Development and<br />

production<br />

Our tool experts develop sophisticated<br />

cutting edge geometries in order to exactly<br />

adjust the tools to different materials<br />

and machining strategies.<br />

These standard and special tools will be<br />

manufactured on most modern six and<br />

seven axis precision grinding centres.<br />

vhf exclusively uses ultra finest grain or<br />

super finest grain carbides of German origin.<br />

Finished tools will be checked by a<br />

<strong>CNC</strong> measuring machine with four axes<br />

and a resolution of the measured values of<br />

0.25 µm. Thus highest quality is guaranteed.<br />

The own production facilities enable us<br />

to flexibly manufacture variants of existing<br />

types. So the range of tools will be<br />

further extended also during the period of<br />

validity of this catalogue. Just check in our<br />

tool section on the internet (tools.vhf.de)<br />

the tool news from time to time.<br />

Drills<br />

Everything from a single source: Beginning with the development of the cutting<br />

edge geometry over the production of the carbide tools on a 6 or 7 axis grinding<br />

centre up to a contact-free complete measuring with a 4 axis machine.<br />

Lances and<br />

Knives<br />

All vhf tools are exclusively<br />

manufactured with certified<br />

green power of 100 %<br />

hydroelectricity.<br />

Impression<br />

Tools<br />

Accessories<br />

7 axis grinding machine with integrated<br />

robot loader for producing tools with diameters<br />

from 0.5 to 12 mm.<br />

A part of the vhf machinery for producing<br />

tools: 5 axis cylindrical grinding machine<br />

(right), several six axis grinding machines<br />

for producing tools with diameters from<br />

0.1 to 16 mm, in the background left a 4<br />

axis measuring machine.

Thread<br />

Cutters<br />

Carbide Tools | Diamond Tools 9<br />

Why carbide tools?<br />

Due to its extraordinary features, tools made of carbide<br />

metal are far superior to those made of high speed steel<br />

(HSS). For high speed cutting, HSS is not suitable anymore.<br />

All tools from vhf are carbide tools – either<br />

completely or partly. Most of the tools are solid carbide<br />

tools. The diamond tools consist of a carbide shank with<br />

an attached diamond and the router bits have carbide<br />

cutting edges.<br />

Sintered from finest powders<br />

under high pressure<br />

Carbide metal is a sintered material and consists mainly<br />

of the hard material tungsten carbide (WC). For a<br />

targeted optimization small amounts of other carbide<br />

phases may additionally be used. Mainly these are titanium<br />

carbides (TiC), tantalum carbides (TaC), niobium<br />

carbides (NbC) or chromium carbides (CrC). The second<br />

main component is the binder phase which mainly consists<br />

of cobalt (Co) and may partly be complemented by<br />

nickel (Ni), iron (Fe) and nickel chromium (NiCr). This<br />

mixture of originally powdery ingredients will finally be<br />

sintered under high pressure and high temperatures until<br />

it becomes a solid object.<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

It’s all the mix<br />

Micrograph of the carbide type DK460UF with 1,000 times<br />

magnification. With kind permission of Gühring KG.<br />

Result: detail view of the cutting edge geometry of a single<br />

tooth cutter manufactured from the carbide type DK460UF.<br />

Hardness, resistance to wear and ductility of the carbide<br />

are significantly influenced by the combination of<br />

its ingredients and the grain size of the hard material.<br />

An increasing proportion of tungsten carbide leads to increased<br />

hardness and ductility and higher resistance to<br />

wear. Milling tools mostly have a tungsten carbide proportion<br />

of 90 %. Relevant grain sizes range from less than<br />

0.2 microns (nano) to over 1.3 microns (fine/medium<br />

grains) – smaller grain sizes result in a greater hardness<br />

and bending strength. The material becomes<br />

more resistant to wear. If the proportion of the binder<br />

phase increases (especially cobalt of about 10 %), the<br />

bending strength, tensile strength and impact strength<br />

can be improved. The material becomes “tougher”.<br />

Generally vhf uses different kinds of carbide substrates for<br />

their tools – always with the aim to create the best possible<br />

tool with the most benefit for the user. When<br />

choosing our technology partners, we always put great<br />

emphasis on the fact that they are renowned companies<br />

with a high quality awareness.<br />

For example, many vhf single tooth cutters are manufactured<br />

from the carbide type DK460UF, which consists<br />

of 90 % tungsten carbide and 10 % cobalt; the average<br />

tungsten carbide grain size in this case is 0.5 microns.<br />

Thus it offers a balanced mix of wear resistance and<br />

toughness.<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories

10<br />

Carbide Tools | Diamond Tools<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Why diamond tools?<br />

Diamond is even much harder than carbide. The carbide<br />

tools with diamond attachment which are offered by vhf<br />

have a multiple of the endurance of carbide tools. We<br />

use three sorts of diamonds:<br />

Our monocrystalline diamonds (MCD) consist of pure<br />

carbon and are extremely resistant to wear. Although<br />

they have been produced synthetically, they have the<br />

same characteristics as natural diamonds. This ultra-hard<br />

material ensures glassy polishing edges. MCD tools are<br />

excellent for polishing acrylic glass to a high gloss.<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Polishing graver with monocrystalline diamond.<br />

Polycrystalline diamonds (PCD) will be sintered from<br />

numerous single crystals at high temperatures and pressures<br />

to a solid plate. This production process is comparable<br />

to that of carbide. Depending on the grade, they<br />

are suitable for milling and polishing tasks.<br />

The PCD polishing plates have a very fine grain size and<br />

will be finished by grinding in a separate step after laser<br />

cutting respectively eroding. Thus, there are only slight<br />

differences in polishing quality compared with the results<br />

of MCD tools. However, in most cases they are more than<br />

compensated by the effect of the longer cutting edges.<br />

Single tooth cutter with polycrystalline diamond.<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Double tooth cutter with two CVD thick layer plates.<br />

Despite their higher cost price, diamond tools are the<br />

more economic alternative for many processing tasks<br />

– last but not least due to the possibility that they can be<br />

regrind for several times.<br />

CVD thick film plates are built up in thin layers by<br />

Chemical Vapour Deposition (CVD). Afterwards they<br />

are cut into shape by a laser beam. The result is a very<br />

homogeneous diamond structure and an extremely<br />

smooth and sharp cutting edge for highest surface qualities.<br />

Compared with the already very good results of PCD<br />

tools, the CVD tools distinguish themselves by an even<br />

greater hardness and resistance to wear which can lead<br />

to an even longer endurance. In contrast to PCD, CVD<br />

has no metallic binder phase, so the bending strength<br />

and the impact resistance are a bit lower. So, by its features,<br />

it can be regarded as an ideal completion to PCD<br />

and MCD.<br />

Accessories

Diamond<br />

Tools<br />

Carbide Tools | Diamond Tools 11<br />

Hard coatings for carbide tools<br />

Nowadays, carbide milling tools are often additionally coated with hard material. By the proper choice of the coating, the<br />

tool endurance will be considerably extended. The range of possible coating alternatives is wide:<br />

Milling<br />

Cutters<br />

CC AluSpeed ®<br />

Type<br />

PVD coating<br />

Material TiB 2<br />

Micro hardness 4,000 VHN 0.05<br />

Coating thickness 2.0 µm ± 0.7<br />

Frictional value* –<br />

Max. application 900 °C<br />

temperature<br />

Coating colour silver grey<br />

vhf tools<br />

■■<br />

single tooth cutters with hawkbeak<br />

■■<br />

double tooth cutters for aluminium<br />

* dry against steel<br />

This coating has been especially designed<br />

for high performance milling<br />

of aluminium (alloys). Due to its low<br />

affinity to aluminium AluSpeed® effectively<br />

prevents the formation of built-up<br />

edges. Extremely smooth surfaces reduce<br />

the friction at the cutting face and<br />

facilitate the chip flow. Due to its great<br />

hardness also an excellent protection<br />

against wear is ensured.<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

An extremely hard and smooth, droplet-free<br />

coating due to its silicon doping.<br />

With best adhesive properties<br />

thanks to the new HiPIMS (High Power<br />

Impulse Magnetron Sputtering) technology.<br />

HARDLOX® is the first choice<br />

for machining stainless steel, materials<br />

which are difficult to machine such as<br />

titanium or chromium-cobalt-molybdenum<br />

alloys and hard machining up to<br />

70 HRC.<br />

HARDLOX ®<br />

Type<br />

PVD coating<br />

Material<br />

TiAlN/TiSiN<br />

Micro hardness 3,800 VHN 0.05<br />

Coating thickness 3.0 µm ± 1.0<br />

Frictional value* 0.30<br />

Max. application 1,100 °C<br />

temperature<br />

Coating colour coppery<br />

vhf tools<br />

■■<br />

triple tooth cutters for stainl. steel<br />

* dry against steel<br />

Thread<br />

Cutters<br />

Drills<br />

Lances and<br />

Knives<br />

HPN1<br />

Type<br />

PVD coating<br />

Material<br />

AlTiCrN<br />

Micro hardness 3,500 VHN 0.05<br />

Coating thickness 3.0 µm ± 1.0<br />

Frictional value* 0.30<br />

Max. application 1,100 °C<br />

temperature<br />

Coating colour grey<br />

vhf tools<br />

■■<br />

four tooth ratio cutters<br />

* dry against steel<br />

The HPN1 coating is also produced<br />

with the ultra-modern HiPIMS method.<br />

Thereby it is effectively fixed in the<br />

substrate. This facilitates a high hardness<br />

and exceptional toughness.<br />

The strengths of HPN1 lie in machining<br />

steel, cast iron, titanium and materials<br />

with hardness up to 55 – 60 HRC which<br />

are difficult to machine.<br />

Impression<br />

Tools<br />

Accessories

Milling<br />

Cutters<br />

12<br />

Carbide Tools | Diamond Tools<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Lances and<br />

Knives<br />

HYPERLOX ®<br />

Type<br />

PVD coating<br />

Material<br />

AlTiN<br />

Micro hardness 3,700 VHN 0.05<br />

Coating thickness 3.0 µm ± 1.0<br />

Frictional value* 0.30<br />

Max. application 1,100 °C<br />

temperature<br />

Coating colour black anthracite<br />

vhf tools<br />

■■<br />

four tooth cutters Varius®<br />

* dry against steel<br />

TINALOX® SN 2 is a proven all-round<br />

coating for all types of steel and cast<br />

iron up to 50 HRC. It has a wide application<br />

field for roughing and finishing<br />

tasks. Tools which are coating with this<br />

contour-close thin film are also perfectly<br />

suitable for engraving and/or for<br />

fine works in stainless steel.<br />

HYPERLOX® is characterized by being<br />

almost free from internal stress, having<br />

a high oxidation resistance and an additional<br />

extra of hardness. Due to the<br />

very wide range of applications (in alloyed<br />

and stainless steel, cast iron and<br />

materials with up to 60 HRC which<br />

are difficult to machine), this layer is<br />

an all-round coating which shows its<br />

strengths especially in roughing.<br />

TINALOX ® SN 2<br />

Type<br />

PVD coating<br />

Material<br />

TiAlN<br />

Micro hardness 3,500 VHN 0.05<br />

Coating thickness 3.0 µm ± 1.0 (1.5 µm ± 0.5)<br />

Frictional value* 0.30<br />

Max. application 1,000 °C<br />

temperature<br />

Coating colour black anthracite<br />

vhf tools<br />

■■<br />

engraver's milling cutters and double<br />

tooth cutters for stainless steel<br />

* dry against steel<br />

■■<br />

■■<br />

■■<br />

double, triple and four tooth cutters<br />

Varius®<br />

deburring tools<br />

thread whirling cutters<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories<br />

SHC ®<br />

Type<br />

DLC coating<br />

Material<br />

ta-C<br />

Micro hardness > 4,000 VHN 0.02<br />

Coating thickness 2.0 µm ± 0.2<br />

Frictional value* 0.10<br />

Max. application 400 °C<br />

temperature<br />

Coating colour black<br />

vhf tools<br />

■■<br />

single tooth cutters Varius®<br />

* dry against steel<br />

■■<br />

■■<br />

■■<br />

V-slot cutters for aluminium composites<br />

double tooth cutters for wood<br />

roughing cutters for graphite<br />

This super hard carbon coating with<br />

tightest coating thickness tolerance is<br />

the first choice for all tasks that require<br />

an outstanding dry running. Due to<br />

its high hardness SHC® resists strong<br />

abrasive exposures, e. g. when machining<br />

CRP and GRP. Also ideal for machining<br />

solid wood and (wood-metal) laminates.<br />

It can be used as inexpensive<br />

alternative to diamond coatings at<br />

anytime.

Carbide Tools | Diamond Tools 13<br />

CCDia ® MultiSpeed Thin<br />

Type<br />

CVD coating<br />

Material<br />

diamond<br />

Micro hardness > 10,000 VHN 0.05<br />

Coating thickness 3.0 µm ± 1.0<br />

Frictional value* –<br />

Max. application 700 °C<br />

temperature<br />

Coating colour dark grey<br />

vhf tools<br />

■■<br />

single tooth cutters Varius®<br />

■■<br />

double tooth cutters with polished<br />

flute<br />

Please note: Diamond is an insulator, i. e. there is no measuring<br />

by means of electric contact possible.<br />

* dry against steel<br />

The high-end coating MultiSpeed<br />

combines an optimised coating adhesion<br />

with a smooth surface and an extremely<br />

high wear volume. This multilayer<br />

coating also has crack-stopping<br />

properties which lead to additional<br />

endurance. As it is a relatively thin diamond<br />

coating, the cutting edges will<br />

nearly not be rounded off. Thus it is<br />

especially suitable for all non-ferrous<br />

metals (also in combination with fibre<br />

materials) and wood.<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

FiberSpeed is a diamond coating<br />

which is optimised for the special requirements<br />

of machining fibre reinforced<br />

plastics (CRP, GRP) and has<br />

ideal adhesive properties. The high<br />

surface quality counteracts any possible<br />

adhesive tendencies of the machined<br />

materials. Due to its very thick multilayer<br />

composition with 9.0 µm it can<br />

be used extremely long.<br />

CCDia ® FiberSpeed<br />

Type<br />

CVD coating<br />

Material<br />

diamond<br />

Micro hardness > 10,000 VHN 0.05<br />

Coating thickness 9.0 µm ± 1.0<br />

Frictional value* –<br />

Max. application 700 °C<br />

temperature<br />

Coating colour dark grey<br />

vhf tools<br />

■■<br />

finely toothed composite cutters<br />

with chip breaker<br />

Please note: Diamond is an insulator, i. e. there is no measuring<br />

by means of electric contact possible.<br />

* dry against steel<br />

Thread<br />

Cutters<br />

Drills<br />

Lances and<br />

Knives<br />

MicroSpeed<br />

Type<br />

CVD coating<br />

Material<br />

diamond<br />

Micro hardness > 10,000 VHN 0.05<br />

Coating thickness 9.0 µm + 3.0<br />

Frictional value* –<br />

Max. application 700 °C<br />

temperature<br />

Coating colour dark grey<br />

vhf tools<br />

■■<br />

diamond-toothed PCB outline<br />

cutters<br />

■■<br />

spiral-toothed PCB outline cutters<br />

Please note: Diamond is an insulator, i. e. there is no measuring<br />

by means of electric contact possible.<br />

* dry against steel<br />

A multilayer coating with the best<br />

possible cost-performance ratio. It is<br />

optimised for nearly all tasks in the field<br />

of printed circuit board manufacturing.<br />

You get a considerably higher performance<br />

in machining FR4/FR5, halogen-free<br />

materials and laminates with<br />

and without ceramic fillers.<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories

14<br />

Carbide Tools | Diamond Tools<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Overview of carbide and diamond tools<br />

Single tooth cutters<br />

These tools are mainly used for machining wood, plastics<br />

and non-ferrous metals.<br />

Varius® cutters<br />

This universal tool of our own brand Varius®<br />

has a favourable cost/performance<br />

ratio. It is also available with two kinds of<br />

coatings. M Page 22<br />

Cutters with hawk beak profile<br />

Ideal for milling aluminium due to a very<br />

sharp and exposed cutting edge with extreme<br />

grinding and large flute. Available<br />

with AluSpeed® coating. M Page 28<br />

Cutters with face radius<br />

The cutting edge of this tool is semi-circular<br />

rounded for optimum results in threedimensional<br />

moulds or models without<br />

disturbing steps. M Page 31<br />

Cutters, polished, with left-hand twist<br />

The single tooth cutter with polished flute<br />

is also available with a left-hand twist. Very<br />

handy for small workpieces and vacuum<br />

tables. M Page 33<br />

New<br />

New<br />

Cutters with polished flute<br />

This tool has a mirror finished polished<br />

flute, so the risk of clogging is very low.<br />

Thus this tool is ideal for milling extruded<br />

acrylic glass. Page 26<br />

Cutters with undercut<br />

Thanks to the extra long undercut of this<br />

hawk beak cutter you can mill very deep<br />

slots. Ideal for machining aluminium, also<br />

in form of profiles. M Page 30<br />

Varius® cutters with left-hand twist<br />

Our single tooth cutter Varius® is also available<br />

with a left-hand twist, i. e. the workpiece<br />

will be pressed downwards while it<br />

is being machined. M Page 32<br />

V-slot cutters for composites<br />

An extra balanced carbide tool for chamfering<br />

aluminium composites. It runs very<br />

smoothly and achieves especially high<br />

rates of feed. M Page 34<br />

Double tooth cutters<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Suitable for harder sorts of wood, plastics and non-ferrous<br />

metals and for softer sorts of ferrous metals.<br />

Varius® cutters<br />

With its two cutting edges, this version<br />

of our milling cutter Varius® is suitable for<br />

working on harder sorts of aluminium and<br />

softer ferrous metals. M Page 36<br />

New<br />

Cutters with polished flute<br />

25° spiral flute, extremely sharp polished<br />

cutting edges with radial relief grinding;<br />

due to its two cutting edges especially<br />

great running smoothness. M Page 37<br />

Impression<br />

Tools<br />

Accessories<br />

Cutters with fishtail<br />

Due to its fishtail grinding, this milling cutter<br />

can dip into hard materials quite easily.<br />

It has a cost/performance ratio which is<br />

nearly unbeatable. M Page 38<br />

Cutters for aluminium<br />

With its 45° spiral flute, this milling cutter<br />

creates especially smooth edges of cut;<br />

optionally it is available with AluSpeed®<br />

coating. M Page 40<br />

New<br />

HSC cutters<br />

With its especially steep spiral flute (15°),<br />

this milling cutter enables high rates of<br />

feed as the chips are removed very quickly.<br />

M Page 39<br />

Cutter for aluminium profiles<br />

A tool with very good immersion features<br />

and a short cutting edge for high feed<br />

rates. Especially suitable for window and<br />

door making. M Page 41

Carbide Tools | Diamond Tools 15<br />

New<br />

New<br />

Cutters for stainless steel<br />

This torus cutter has a small edge radius.<br />

Thus its wear resistance is increased and<br />

you will receive a very good surface quality.<br />

M Page 42<br />

Cutters with face radius<br />

This double tooth cutter with its semicircular<br />

face radius is suitable for machining<br />

harder materials three-dimensionally.<br />

M Page 44<br />

Cutters with radius and undercut<br />

The two cutters with undercut make up an<br />

ideally matching mould making duo. With<br />

its face radius, this one is the finishing specialist.<br />

M Page 46<br />

Triple tooth cutters<br />

New<br />

Cutters for wood<br />

This almost straightly slotted tool exerts<br />

only low drag forces on the workpiece;<br />

thus a fraying of the edges of cut will be<br />

prevented. M Page 43<br />

Cutters with torus and undercut<br />

The two cutters with undercut make up an<br />

ideally matching mould making duo. With<br />

its torus grinding, this one is the roughing<br />

specialist. M Page 45<br />

Rub out cutters<br />

Its shortened cutting edge and very sharp<br />

grinding make this cutter ideal for removing<br />

larger copper areas from printed circuit<br />

boards (rub out areas). M Page 47<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Suitable for machining harder sorts of materials, on top<br />

of that we have extra long triple tooth cutters for foam.<br />

Varius® cutters<br />

Our Varius® milling cutter with three cutting<br />

edges is especially suitable for steel.<br />

Its TiAlN coating facilitates an excellent endurance.<br />

M Page 50<br />

Cutters for foam<br />

The cutting edge geometry is optimised<br />

for milling foam without fringing its vertical<br />

edges and for achieving plain surfaces<br />

when milling pockets. M Page 51<br />

Thread<br />

Cutters<br />

Drills<br />

Cutters for stainless steel<br />

For milling stainless steel, this triple tooth<br />

cutter has an especially shaped and very<br />

short cutting edge as well as a HARDLOX®<br />

coating. M Page 52<br />

Lances and<br />

Knives<br />

Four tooth cutters<br />

Mainly suitable for machining ferrous metals and other<br />

sorts of material which are difficult to machine.<br />

Diamond<br />

Tools<br />

Varius® cutters<br />

The four-toothed Varius® is ideal for very<br />

hard materials, e. g. for milling tempered<br />

steel, cast and other sorts of material which<br />

are difficult to machine. M Page 54<br />

Ratio cutters<br />

Milling cutter with different lead angles of<br />

its four flutes. This asymmetry facilitates a<br />

vibration-free running and counteracts the<br />

“cork-screw effect”. M Page 55<br />

Impression<br />

Tools<br />

Accessories

16<br />

Carbide Tools | Diamond Tools<br />

Milling<br />

Cutters<br />

Roughing and finishing cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

New<br />

New<br />

For an especially efficient machining while roughing respectively<br />

extra low-vibration running while finishing.<br />

Roughing cutters for copper<br />

Centre-cutting tool with three cutting<br />

edges and chip splitter for an especially efficient<br />

machining; 30° spiral flute and additional<br />

edge chamfer. M Page 58<br />

Finishing cutters for copper<br />

Due to three different spiral angles and<br />

micro supporting chamfer at its perimeter<br />

especially smooth running characteristics;<br />

polished cutting edges. M Page 60<br />

Composite cutters<br />

New<br />

Roughing cutters for graphite<br />

Centre-cutting tool with three or four cutting<br />

edges and chip splitter; with SHC<br />

coating for an extra long endurance.<br />

M Page 59<br />

Thread<br />

Cutters<br />

Drills<br />

New<br />

With cross cut, diamond or spiral toothing; for highly<br />

abrasive materials like GRP or CRP.<br />

Finely toothed cutters<br />

Milling cutter with a fine-staggered tooth<br />

system of 10 – 14 micro-teeth rows. Due to<br />

its 30° right hand twist, the chips can be<br />

well removed. M Page 62<br />

New<br />

Finely toothed cutters, chip-breaker<br />

Milling cutter with a fine-staggered tooth<br />

system of 10 – 14 micro-teeth rows and<br />

an integrated chip breaker flute. So long<br />

chips will be chopped. M Page 63<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

New<br />

New<br />

Medium-toothed cutters<br />

Milling cutter with a medium-staggered<br />

tooth system of 8 – 12 micro-teeth rows<br />

and a 25° right hand twist. The fibres will<br />

be sheared off accurately. M Page 64<br />

Straightly slotted honeycomb cutters<br />

Five tooth cutter with opposed chip breakers.<br />

Due to its straight flute, the chips can<br />

be well removed and no tractive forces are<br />

exerted on the workpiece. M Page 66<br />

New<br />

New<br />

Coarsely toothed cutters<br />

Coarse-staggered tooth system of 6 – 8 micro-teeth<br />

rows and a 20° right hand twist.<br />

Like all toothed composite cutters with<br />

double-tooth face grinding. M Page 65<br />

Spiral-fluted honeycomb cutters<br />

Six tooth cutter with opposed chip breakers<br />

and a 10° right hand twist. So there is<br />

only a slight tractive force exerted on the<br />

workpiece. M Page 67<br />

Impression<br />

Tools<br />

PCB outline cutters, diamond-toothed<br />

This milling cutter is especially suitable<br />

for milling the outlines of printed circuit<br />

boards. Its diamond-toothing facilitates a<br />

high endurance. M Page 68<br />

PCB outline cutters, spiral-toothed<br />

Also suitable for milling the outlines of<br />

PCBs. Its spiral-toothing facilitates a better<br />

chip-clearance which leads to smoother<br />

surfaces. M Page 69<br />

Accessories

Carbide Tools | Diamond Tools 17<br />

New<br />

New<br />

Engraving tools<br />

Engraver’s milling cutters and gravers for machining<br />

materials from plastics to stainless steel.<br />

Gravers<br />

Our classic gravers for engraving plastics,<br />

wood and non-ferrous metals with top angles<br />

from 15° on (ideal for working without<br />

workpiece levelling). M Page 72<br />

Engraver’s milling cutters for acrylic<br />

This engraver’s milling cutter is equipped<br />

with a flute. So chips can be removed better<br />

and engravings in acrylic glass become<br />

clean-cut and burr-free. M Page 75<br />

Channel cutters<br />

Graver with 180° top angle, for milling die<br />

channels in pressed paper sheets or high<br />

pressure laminates, also suitable for usage<br />

in packaging industry. M Page 77<br />

Semi-finished gravers<br />

We can deliver our gravers also in a semifinished<br />

state with preground profile<br />

which you can finish according to your demands.<br />

M Page 79<br />

Box gravers<br />

A special kind of graver with a top angle of<br />

92°. This tool is very well suitable for tasks<br />

like edge bending, e. g. for cabinet makers.<br />

M Page 74<br />

Engraver’s milling cutters for steel<br />

Engraving stainless steel needs an engraver’s<br />

milling cutter with a special cutting<br />

edge to achieve clear results and a long<br />

endurance. M Page 76<br />

Isolation engraving tool<br />

Our special tool for engraving isolation<br />

channels on printed circuit boards and<br />

other hard materials. The results become<br />

burr-free and clean-cut. M Page 78<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Deburring tools<br />

For deburring, countersinking, chamfering of non-ferrous<br />

metals and plastics.<br />

Router bits<br />

Deburring tools<br />

This tool is used for deburring, countersinking,<br />

chamfering of non-ferrous metals<br />

and plastics; available with 60° to 120° top<br />

angle. M Page 82<br />

Massive steel body with integrated carbide cutting<br />

edges; for wood, plastics and composite plates.<br />

V slot cutters<br />

Available with 60° or 90° top angle and<br />

two or three cutting edges; for milling<br />

(decoration) slots as well as for chamfering<br />

and engraving. M Page 86<br />

Deburring tools, quadrant<br />

The quadrant grinding of this tool creates<br />

smooth round chamferings on your workpieces<br />

of plastics or non-ferrous metals.<br />

M Page 83<br />

Long hole slot cutters<br />

Straightly slotted tool with negative cutting<br />

angle for perfectly even surfaces; For<br />

producing tongue and groove or mortice<br />

and tenon joints. M Page 87<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories

18<br />

Carbide Tools | Diamond Tools<br />

Milling<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

New<br />

New<br />

Slot cutters<br />

A straightly slotted tool which is radially<br />

ground for perfect surfaces; for milling<br />

plane surfaces, notches, tongue and<br />

groove joints etc. M Page 88<br />

Radius cutters<br />

Double-toothed cutter (partly made of solid<br />

carbide) with semi-circular tool tip for<br />

milling rounded slots and for mould making.<br />

M Page 90<br />

Cutters with quadrant<br />

A double tooth cutter with quadrant<br />

grinding for milling accurately rounded<br />

edges or appropriate internal profiles<br />

M Page 92<br />

Triple tooth surface milling cutters<br />

Massive steel shank with a carbide head<br />

soldered on it; for an efficient surface milling<br />

of larger areas of wood, MDF, plastics<br />

or aluminium. M Page 94<br />

Character cutter<br />

Special cutter with a top angle of 60° and<br />

a top radius; suitable for effectively removing<br />

the material around free standing letters.<br />

M Page 89<br />

Chamfering cutters<br />

Straightly slotted tool with two cutting<br />

edges for chamfering accurately. The tool<br />

is available with three different chamfering<br />

angles. M Page 91<br />

Cutters for aluminium composites<br />

These V slot cutters are used for bending<br />

aluminium composites with a thickness of<br />

3 mm to 6 mm. They are available with two<br />

different top angles. M Page 93<br />

Thread cutters<br />

Drills<br />

Using these tools you can cut threads in plastics, nonferrous<br />

or ferrous metals and composites.<br />

Lances and<br />

Knives<br />

Thread whirling cutters<br />

These tools are suitable for tiny threads<br />

from M 1 on. They will be machined down<br />

to the bottom of the pre-drilled (tapped<br />

blind) hole. M Page 96<br />

Circular thread cutters<br />

A special tool which offers the possibility<br />

to drill the hole and to cut the thread in<br />

one working cycle. You save the time of<br />

the tool changing process. M Page 97<br />

Drills<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

For plastics, non-ferrous metals, printed circuit boards<br />

or thermosetting plastics and thermoplastics.<br />

Drills with 3 mm shank<br />

These drills with diameters from 0.2 mm<br />

to 6 mm are optimally suited for plastics<br />

and printed circuit boards, also well suitable<br />

for non-ferrous metals. M Page 100<br />

New<br />

Drills with 6 mm shank<br />

A drill with a top angle of 130° for machining<br />

non-ferrous metals or thermoplastics,<br />

but also suitable for wood or composites.<br />

M Page 102<br />

Accessories

Carbide Tools | Diamond Tools 19<br />

Lances and knives<br />

Milling<br />

Cutters<br />

Lances and knives for the different cutting heads and<br />

the universal head.<br />

Diamond tools<br />

Lances<br />

We offer different kinds of lances for the<br />

use in tangential cutting heads. The largest<br />

choice is available for the oscillating<br />

tangential cutting head. M Page 106<br />

Knives<br />

Here you will find several replacement<br />

knives for the drag knife unit and for the<br />

various attachments of the universal head.<br />

M Page 107<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

A diamond instead of a carbide cutting edge improves<br />

the quality and endurance – without cooling.<br />

PCD single tooth cutters<br />

Centre-cutting tool with a polycrystalline<br />

diamond; suitable for machining softer<br />

sorts of plastics, non-ferrous metals and<br />

wood. M Page 110<br />

MCD polishing cutters<br />

You can produce polished acrylic glass letters<br />

or logos of any shape completely on<br />

your milling system. Polishing machines<br />

become dispensable. M Page 112<br />

PCD double tooth cutters<br />

The second cutting edge again extends<br />

the endurance and enables a slightly improved<br />

smoothness. This milling cutter is<br />

ideal for harder materials. M Page 111<br />

MCD polishing gravers<br />

With its diamond, it polishes engravings<br />

on sophisticated acrylic glass signboards<br />

to a high gloss. It is available with a top angle<br />

of 60° and 90°. M Page 113<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

New<br />

New<br />

PCD polishing cutters<br />

Thanks to its less expensive polycrystalline<br />

diamond cutting edge suitable for much<br />

thicker materials than the monocrystalline<br />

diamond tools. M Page 114<br />

CVD cutters<br />

Milling cutter with one or two cutting edges<br />

which distinguish themselves by their<br />

especially great hardness and endurance;<br />

ideal for abrasive materials. M Page 116<br />

New<br />

PCD polishing gravers<br />

Due to its extra long cutting edge, this tool<br />

is also suitable for very deep engravings. It<br />

is available with either 60° or 90° top angle.<br />

M Page 115<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression tools<br />

New<br />

With appropriate shank and stop ring for use in the milling<br />

machines of the Impression line.<br />

Goldsmith tools<br />

A selection of tools from the vhf product<br />

range which are suitable for typical goldsmith<br />

works in materials like wax, metal<br />

and plastics. M Page 118<br />

Impression<br />

Tools<br />

Accessories

Deburring<br />

Tools<br />

Engraving<br />

Tools<br />

Milling<br />

Cutters<br />

20<br />

Carbide Tools | Diamond Tools<br />

Accessories<br />

Drills<br />

Router Bits<br />

Impression<br />

Tools<br />

Diamond<br />

Tools<br />

Lances and<br />

Knives<br />

Thread<br />

Cutters

22<br />

Carbide Tools | Diamond Tools<br />

Single Milling Tooth<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

All-rounders: single tooth cutters of finest grain carbide.<br />

Single tooth cutters Varius ®<br />

Description:<br />

With our own brand Varius® we have developed a series<br />

of milling cutters with one to four cutting edges. They<br />

distinguish themselves by a universal applicability and<br />

a long endurance. This type is made of finest grain carbide<br />

and it has a 30° spiral flute.<br />

Coating:<br />

Many of these milling cutters are available with an SHC®<br />

coating which consists of super-hard carbon (see page<br />

12). On top of that, some diameters are available with<br />

the diamond coating CCDia® MultiSpeed Thin (see<br />

page 13).<br />

Fields of application:<br />

This universal single tooth cutter is suitable for milling<br />

aluminium (also aluminium composite plates), copper,<br />

zinc, brass, cast acrylic glass and plastics which do not<br />

tend to smear. With SHC® coating it is especially suitable<br />

for (composite) materials with a considerable part of<br />

glue/resin (e. g. MDF, multiplex panels, chipboards) or<br />

thermosetting plastics (Bakelite®, Pertinax, HPL, ...).<br />

27<br />

new<br />

tools<br />

Thread<br />

Cutters<br />

Dimensions and prices<br />

D2<br />

L1<br />

L2<br />

D1<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

Price –5%<br />

–10%<br />

–15%<br />

–20%<br />

Article no.<br />

in € 2 – 4 5 – 9 10 – 19 20 – 49<br />

ES-SC-0020-3-006-40 0.20 mm 3 mm 0.6 mm 40 mm 25.00 23.75 22.50 21.25 20.00<br />

ES-SC-0050-3-015-40 0.50 mm 3 mm 1.5 mm 40 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0060-3-030-40 0.60 mm 3 mm 3.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0070-3-040-40* 0.70 mm 3 mm 4.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0080-3-040-40 0.80 mm 3 mm 4.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0100-3-030-40* 1.00 mm 3 mm 3.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0100-3-050-40 1.00 mm 3 mm 5.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0100-6-050-40 1.00 mm 6 mm 5.0 mm 40 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0120-3-050-40* 1.20 mm 3 mm 5.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0150-3-050-40 1.50 mm 3 mm 5.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0150-6-050-40* 1.50 mm 6 mm 5.0 mm 40 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0160-3-060-40 1.60 mm 3 mm 6.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0180-3-070-40 1.80 mm 3 mm 7.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0200-3-050-40* 2.00 mm 3 mm 5.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0200-3-080-40 2.00 mm 3 mm 8.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0200-4-070-40 2.00 mm 4 mm 7.0 mm 40 mm 19.00 18.05 17.10 16.15 15.20<br />

ES-SC-0200-6-050-40* 2.00 mm 6 mm 5.0 mm 40 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0200-6-070-40 2.00 mm 6 mm 7.0 mm 40 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-SC-0250-3-100-40 2.50 mm 3 mm 10.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0250-6-100-50* 2.50 mm 6 mm 10.0 mm 50 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-SC-0300-3-050-40 3.00 mm 3 mm 5.0 mm 40 mm 13.00 12.35 11.70 11.05 10.40<br />

ES-SC-0300-3-100-30* 3.00 mm 3 mm 10.0 mm 30 mm 14.00 13.30 12.60 11.90 11.20<br />

ES-SC-0300-3-100-40 3.00 mm 3 mm 10.0 mm 40 mm 14.00 13.30 12.60 11.90 11.20<br />

ES-SC-0300-3-120-40* 3.00 mm 3 mm 12.0 mm 40 mm 15.00 14.25 13.50 12.75 12.00<br />

ES-SC-0300-4-100-40 3.00 mm 4 mm 10.0 mm 40 mm 19.00 18.05 17.10 16.15 15.20<br />

ES-SC-0300-6-050-40 3.00 mm 6 mm 5.0 mm 40 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-SC-0300-6-080-50* 3.00 mm 6 mm 8.0 mm 50 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0300-6-100-50 3.00 mm 6 mm 10.0 mm 50 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-SC-0300-6-120-50* 3.00 mm 6 mm 12.0 mm 50 mm 23.00 21.85 20.70 19.55 18.40<br />

...<br />

L1<br />

Total<br />

length

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Carbide Tools | Diamond Tools 23<br />

Continuation<br />

D2<br />

L1<br />

L2<br />

D1<br />

Single Milling Tooth<br />

Cutters<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

Price –5%<br />

–10%<br />

–15%<br />

–20%<br />

Article no.<br />

in € 2 – 4 5 – 9 10 – 19 20 – 49<br />

ES-SC-0330-6-160-50* 3.30 mm 6 mm 16.0 mm 50 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0350-6-140-50* 3.50 mm 6 mm 14.0 mm 50 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0400-4-060-40 4.00 mm 4 mm 6.0 mm 40 mm 16.00 15.20 14.40 13.60 12.80<br />

ES-SC-0400-4-100-40 4.00 mm 4 mm 10.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-SC-0400-4-140-50 4.00 mm 4 mm 14.0 mm 50 mm 18.00 17.10 16.20 15.30 14.40<br />

ES-SC-0400-4-220-60* 4.00 mm 4 mm 22.0 mm 60 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-SC-0400-6-060-40 4.00 mm 6 mm 6.0 mm 40 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0400-6-120-50 4.00 mm 6 mm 12.0 mm 50 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-SC-0400-6-180-60* 4.00 mm 6 mm 18.0 mm 60 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0420-6-160-50* 4.20 mm 6 mm 16.0 mm 50 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0450-6-140-50* 4.50 mm 6 mm 14.0 mm 50 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0500-5-120-50* 5.00 mm 5 mm 12.0 mm 50 mm 19.00 18.05 17.10 16.15 15.20<br />

ES-SC-0500-5-160-60 5.00 mm 5 mm 16.0 mm 60 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-SC-0500-6-070-40* 5.00 mm 6 mm 7.0 mm 40 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0500-6-140-50 5.00 mm 6 mm 14.0 mm 50 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-SC-0550-6-140-50* 5.50 mm 6 mm 14.0 mm 50 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0600-6-050-40* 6.00 mm 6 mm 5.0 mm 40 mm 19.00 18.05 17.10 16.15 15.20<br />

ES-SC-0600-6-080-40 6.00 mm 6 mm 8.0 mm 40 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-SC-0600-6-140-50 6.00 mm 6 mm 14.0 mm 50 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-SC-0600-6-200-60 6.00 mm 6 mm 20.0 mm 60 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-SC-0600-6-250-60 6.00 mm 6 mm 25.0 mm 60 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0600-6-350-75* 6.00 mm 6 mm 35.0 mm 75 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0800-8-140-50* 8.00 mm 8 mm 14.0 mm 50 mm 25.00 23.75 22.50 21.25 20.00<br />

ES-SC-0800-8-200-60* 8.00 mm 8 mm 20.0 mm 60 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0800-8-250-75 8.00 mm 8 mm 25.0 mm 75 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0800-8-350-85* 8.00 mm 8 mm 35.0 mm 85 mm 39.00 37.05 35.10 33.15 31.20<br />

ES-SC-1000-10-140-50* 10.00 mm 10 mm 14.0 mm 50 mm 34.00 32.30 30.60 28.90 27.20<br />

ES-SC-1000-10-250-75 10.00 mm 10 mm 25.0 mm 75 mm 39.00 37.05 35.10 33.15 31.20<br />

ES-SC-1000-10-280-75* 10.00 mm 10 mm 28.0 mm 75 mm 41.00 38.95 36.90 34.85 32.80<br />

ES-SC-1200-12-250-75 12.00 mm 12 mm 25.0 mm 75 mm 49.00 46.55 44.10 41.65 39.20<br />

* new tool in this printed issue | * new tool in this PDF update<br />

Coated tools on the next double page...<br />

L1<br />

Total<br />

length<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Wood<br />

Plastics<br />

Rigid<br />

Foam<br />

Non-ferr.<br />

Metals<br />

Accessories

24<br />

Carbide Tools | Diamond Tools<br />

Single Milling Tooth<br />

Cutters<br />

Engraving Single Tooth<br />

Tools Cutters<br />

Deburring<br />

Tools<br />

Router Bits<br />

Varius® cutters with SHC and diamond coating.<br />

Single tooth cutters Varius ®<br />

with coating<br />

Description:<br />

The coated Varius® types have a great dry running<br />

performance and do not tend to clog too easily. Their<br />

already long endurance will be prolonged considerably.<br />

Coating:<br />

Most of these milling cutters are available with an SHC®<br />

coating which consists of super-hard carbon (see page<br />

12). On top of that, some diameters are available with<br />

the diamond coating CCDia® MultiSpeed Thin (see<br />

page 13).<br />

Fields of application:<br />

Tools with SHC® coating it is especially suitable for (composite)<br />

materials with a considerable part of glue/resin<br />

(e. g. MDF, multiplex panels, chipboards) or thermosetting<br />

plastics (Bakelite®, Pertinax, HPL, ...). Tools coated<br />

with CCDia® MultiSpeed Thin are especially suitable for<br />

all non-ferrous metals (also in combination with fibre<br />

materials) and wood.<br />

20<br />

new<br />

tools<br />

Thread<br />

Cutters<br />

Dimensions and prices<br />

D2<br />

L1<br />

L2<br />

D1<br />

Article no.<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

L1<br />

Total<br />

length<br />

Price<br />

in €<br />

–5 %<br />

2 – 4<br />

–10 %<br />

5 – 9<br />

–15 %<br />

10 – 19<br />

–20 %<br />

20 – 49<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories<br />

with SHC® coating, thickness 2.0 µm ± 0.2<br />

ES-SC-0100-3-030-40-SHC* 1.00 mm 3 mm 3.0 mm 40 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-SC-0100-6-050-40-SHC* 1.00 mm 6 mm 5.0 mm 40 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0150-6-050-40-SHC* 1.50 mm 6 mm 5.0 mm 40 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0200-6-050-40-SHC* 2.00 mm 6 mm 5.0 mm 40 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0200-6-070-40-SHC 2.00 mm 6 mm 7.0 mm 40 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0300-3-100-40-SHC 3.00 mm 3 mm 10.0 mm 40 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-SC-0300-6-050-40-SHC 3.00 mm 6 mm 5.0 mm 40 mm 26.00 24.70 23.40 22.10 20.80<br />

ES-SC-0300-6-080-50-SHC* 3.00 mm 6 mm 8.0 mm 50 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0300-6-100-50-SHC 3.00 mm 6 mm 10.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0300-6-120-50-SHC* 3.00 mm 6 mm 12.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0330-6-160-50-SHC* 3.30 mm 6 mm 16.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0350-6-140-50-SHC* 3.50 mm 6 mm 14.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0400-4-140-50-SHC 4.00 mm 4 mm 14.0 mm 50 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-SC-0400-6-060-40-SHC 4.00 mm 6 mm 6.0 mm 40 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0400-6-120-50-SHC 4.00 mm 6 mm 12.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0400-6-180-60-SHC* 4.00 mm 6 mm 18.0 mm 60 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0420-6-160-50-SHC* 4.20 mm 6 mm 16.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0450-6-140-50-SHC* 4.50 mm 6 mm 14.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-SC-0500-5-160-60-SHC* 5.00 mm 5 mm 16.0 mm 60 mm 26.00 24.70 23.40 22.10 20.80<br />

ES-SC-0500-6-070-40-SHC* 5.00 mm 6 mm 7.0 mm 40 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0500-6-140-50-SHC 5.00 mm 6 mm 14.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0600-6-050-40-SHC* 6.00 mm 6 mm 5.0 mm 40 mm 25.00 23.75 22.50 21.25 20.00<br />

ES-SC-0600-6-080-40-SHC 6.00 mm 6 mm 8.0 mm 40 mm 26.00 24.70 23.40 22.10 20.80<br />

ES-SC-0600-6-140-50-SHC 6.00 mm 6 mm 14.0 mm 50 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-SC-0600-6-200-60-SHC 6.00 mm 6 mm 20.0 mm 60 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0600-6-250-60-SHC 6.00 mm 6 mm 25.0 mm 60 mm 29.00 27.55 26.10 24.65 23.20<br />

...

Thread<br />

Cutters<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Carbide Tools | Diamond Tools 25<br />

Continuation<br />

D2<br />

L1<br />

L2<br />

D1<br />

Single Milling Tooth<br />

Cutters<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

Price –5%<br />

–10%<br />

–15%<br />

–20%<br />

Article no.<br />

in € 2 – 4 5 – 9 10 – 19 20 – 49<br />

ES-SC-0800-8-140-50-SHC* 8.00 mm 8 mm 14.0 mm 50 mm 33.00 31.35 29.70 28.05 26.40<br />

ES-SC-0800-8-200-60-SHC* 8.00 mm 8 mm 20.0 mm 60 mm 35.00 33.25 31.50 29.75 28.00<br />

ES-SC-0800-8-250-75-SHC 8.00 mm 8 mm 25.0 mm 75 mm 37.00 35.15 33.30 31.45 29.60<br />

ES-SC-1000-10-250-75-SHC 10.00 mm 10 mm 25.0 mm 75 mm 47.00 44.65 42.30 39.95 37.60<br />

with CCDia® MultiSpeed Thin, thickness 3.0 µm ± 1.0 1<br />

ES-SC-0300-3-100-40-MST* 3.00 mm 3 mm 10.0 mm 40 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-SC-0400-4-140-50-MST* 4.00 mm 4 mm 14.0 mm 50 mm 38.00 36.10 34.20 32.30 30.40<br />

ES-SC-0600-6-140-50-MST* 6.00 mm 6 mm 14.0 mm 50 mm 48.00 45.60 43.20 40.80 38.40<br />

ES-SC-0800-8-220-60-MST* 8.00 mm 8 mm 22.0 mm 60 mm 68.00 64.60 61.20 57.80 54.40<br />

* new tool in this printed issue | * new tool in this PDF update<br />

1<br />

as the diamond layer is an electrical isolator, these tools are not suitable for a measurement with the automatic z adjustment.<br />

Ask for an individual offer if you are interested in annual orders or single orders of quantities from 50 upwards.<br />

L1<br />

Total<br />

length<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Drills<br />

Wood<br />

Plastics<br />

Non-ferr.<br />

Metals<br />

Composites<br />

Accessories

26<br />

Carbide Tools | Diamond Tools<br />

Single Milling Tooth<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Single tooth cutters<br />

with polished flute<br />

Description:<br />

This single tooth cutter has a mirror finished polished<br />

flute with a lead angle of 25°. So the risk of clogging<br />

is low and the chip clearance is very good. The cutting<br />

edge of this tool is extremely sharp and faceted. So<br />

the results will become very smooth even at high rates<br />

of feed.<br />

Fields of application:<br />

This tool has been developed especially for working on<br />

extruded acrylic glass; however, it is also very well suitable<br />

for working on soft wood and thermoplastics.<br />

Router Bits<br />

The original – often copied, but still unmatched.<br />

45<br />

new<br />

tools<br />

Thread<br />

Cutters<br />

Dimensions and prices<br />

D2<br />

L1<br />

L2<br />

D1<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

Price –5%<br />

–10%<br />

–15%<br />

–20%<br />

Article no.<br />

Undercut<br />

in € 2 – 4 5 – 9 10 – 19 20 – 49<br />

ES-PS-0100-3-040-40 1.00 mm 3 mm 4.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0100-6-050-50* 1.00 mm 6 mm 5.0 mm 50 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-PS-0150-3-060-40 1.50 mm 3 mm 6.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0200-2-080-30 2.00 mm 2 mm 8.0 mm 30 mm 19.00 18.05 17.10 16.15 15.20<br />

ES-PS-0200-3-050-40* 2.00 mm 3 mm 5.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0200-3-080-30* 2.00 mm 3 mm 8.0 mm 30 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0200-3-080-40 2.00 mm 3 mm 8.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0200-3-090-40* 2.00 mm 3 mm 9.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0200-3-110-40* 2.00 mm 3 mm 11.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0200-6-050-50* 2.00 mm 6 mm 5.0 mm 50 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-PS-0200-6-080-50 2.00 mm 6 mm 8.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-PS-0250-3-100-40* 2.50 mm 3 mm 10.0 mm 40 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0300-3-080-40* 3.00 mm 3 mm 8.0 mm 40 mm 17.00 16.15 15.30 14.45 13.60<br />

ES-PS-0300-3-100-30 3.00 mm 3 mm 10.0 mm 30 mm 18.00 17.10 16.20 15.30 14.40<br />

ES-PS-0300-3-120-40 3.00 mm 3 mm 12.0 mm 40 mm 19.00 18.05 17.10 16.15 15.20<br />

ES-PS-0300-3-120-60 3.00 mm 3 mm 12.0 mm 60 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-PS-0300-3-160-50* 3.00 mm 3 mm 16.0 mm 50 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-PS-0300-3-220-60 3.00 mm 3 mm 22.0 mm 60 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-PS-0300-4-120-50* 3.00 mm 4 mm 12.0 mm 50 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0300-6-080-50* 3.00 mm 6 mm 8.0 mm 50 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-PS-0300-6-100-50 3.00 mm 6 mm 10.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-PS-0300-6-120-50 3.00 mm 6 mm 12.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0300-6-160-50* 3.00 mm 6 mm 16.0 mm 50 mm 30.00 28.50 27.00 25.50 24.00<br />

ES-PS-0300-6-220-60* 3.00 mm 6 mm 22.0 mm 60 mm 31.00 29.45 27.90 26.35 24.80<br />

ES-PS-0400-4-080-40* 4.00 mm 4 mm 8.0 mm 40 mm 18.00 17.10 16.20 15.30 14.40<br />

ES-PS-0400-4-120-50 4.00 mm 4 mm 12.0 mm 50 mm 20.00 19.00 18.00 17.00 16.00<br />

ES-PS-0400-4-160-50* 4.00 mm 4 mm 16.0 mm 50 mm 22.00 20.90 19.80 18.70 17.60<br />

...<br />

L3<br />

L1<br />

Total<br />

length<br />

Accessories

Carbide Tools | Diamond Tools 27<br />

Continuation<br />

D2<br />

L1<br />

L2<br />

D1<br />

Single Milling Tooth<br />

Cutters<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

Price –5%<br />

–10%<br />

–15%<br />

–20%<br />

Article no.<br />

Undercut<br />

in € 2 – 4 5 – 9 10 – 19 20 – 49<br />

ES-PS-0400-4-220-60 4.00 mm 4 mm 22.0 mm 60 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0400-4-320-70 4.00 mm 4 mm 32.0 mm 70 mm 26.00 24.70 23.40 22.10 20.80<br />

ES-PS-0400-6-060-50* 4.00 mm 6 mm 6.0 mm 50 mm 26.00 24.70 23.40 22.10 20.80<br />

ES-PS-0400-6-080-50* 4.00 mm 6 mm 8.0 mm 50 mm 27.00 25.65 24.30 22.95 21.60<br />

ES-PS-0400-6-100-50* 4.00 mm 6 mm 10.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-PS-0400-6-120-50 4.00 mm 6 mm 12.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0400-6-160-50* 4.00 mm 6 mm 16.0 mm 50 mm 30.00 28.50 27.00 25.50 24.00<br />

ES-PS-0400-6-220-60* 4.00 mm 6 mm 22.0 mm 60 mm 31.00 29.45 27.90 26.35 24.80<br />

ES-PS-0500-5-120-50* 5.00 mm 5 mm 12.0 mm 50 mm 21.00 19.95 18.90 17.85 16.80<br />

ES-PS-0500-5-160-60 5.00 mm 5 mm 16.0 mm 60 mm 23.00 21.85 20.70 19.55 18.40<br />

ES-PS-0500-5-320-70 5.00 mm 5 mm 32.0 mm 70 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0500-6-140-50 5.00 mm 6 mm 14.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-PS-0500-6-220-60* 5.00 mm 6 mm 22.0 mm 60 mm 31.00 29.45 27.90 26.35 24.80<br />

ES-PS-0540-6-140-50* 5.40 mm 6 mm 14.0 mm 50 mm 28.00 26.60 25.20 23.80 22.40<br />

ES-PS-0540-6-270-70* 5.40 mm 6 mm 27.0 mm 70 mm 31.00 29.45 27.90 26.35 24.80<br />

ES-PS-0600-6-100-50* 6.00 mm 6 mm 10.0 mm 50 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-PS-0600-6-140-50 6.00 mm 6 mm 14.0 mm 50 mm 24.00 22.80 21.60 20.40 19.20<br />

ES-PS-0600-6-220-60 6.00 mm 6 mm 22.0 mm 60 mm 26.00 24.70 23.40 22.10 20.80<br />

ES-PS-0600-6-320-70 6.00 mm 6 mm 32.0 mm 70 mm 31.00 29.45 27.90 26.35 24.80<br />

ES-PS-0600-6-420-80 6.00 mm 6 mm 42.0 mm 80 mm 36.00 34.20 32.40 30.60 28.80<br />

ES-PS-0800-8-140-50* 8.00 mm 8 mm 14.0 mm 50 mm 34.00 32.30 30.60 28.90 27.20<br />

ES-PS-0800-8-220-60 8.00 mm 8 mm 22.0 mm 60 mm 39.00 37.05 35.10 33.15 31.20<br />

ES-PS-0800-8-320-70* 8.00 mm 8 mm 32.0 mm 70 mm 44.00 41.80 39.60 37.40 35.20<br />

ES-PS-0800-8-420-80* 8.00 mm 8 mm 42.0 mm 80 mm 49.00 46.55 44.10 41.65 39.20<br />

ES-PS-1000-10-140-60* 10.00 mm 10 mm 14.0 mm 60 mm 39.00 37.05 35.10 33.15 31.20<br />

ES-PS-1000-10-220-70* 10.00 mm 10 mm 22.0 mm 70 mm 44.00 41.80 39.60 37.40 35.20<br />

ES-PS-1000-10-320-75 10.00 mm 10 mm 32.0 mm 75 mm 49.00 46.55 44.10 41.65 39.20<br />

ES-PS-1200-12-220-70* 12.00 mm 12 mm 22.0 mm 70 mm 54.00 51.30 48.60 45.90 43.20<br />

ES-PS-1200-12-300-75 12.00 mm 12 mm 30.0 mm 75 mm 59.00 56.05 53.10 50.15 47.20<br />

ES-PS-1200-12-420-100* 12.00 mm 12 mm 42.0 mm 100 mm 74.00 70.30 66.60 62.90 59.20<br />

with undercut<br />

ES-PS-0100-6-050-0120-50* 1.00 mm 6 mm 5.0 mm 12.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0200-6-080-0160-50* 2.00 mm 6 mm 8.0 mm 16.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0300-6-100-0220-50* 3.00 mm 6 mm 10.0 mm 22.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0400-6-120-0220-50* 4.00 mm 6 mm 12.0 mm 22.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0500-6-140-0220-50* 5.00 mm 6 mm 14.0 mm 22.0 mm 50 mm 29.00 27.55 26.10 24.65 23.20<br />

ES-PS-0600-6-140-0220-50* 6.00 mm 6 mm 14.0 mm 22.0 mm 50 mm 25.00 23.75 22.50 21.25 20.00<br />

ES-PS-0600-6-420-0650-100* 6.00 mm 6 mm 42.0 mm 65.0 mm 100 mm 49.00 46.55 44.10 41.65 39.20<br />

ES-PS-0800-8-140-0220-50* 8.00 mm 8 mm 14.0 mm 22.0 mm 50 mm 35.00 33.25 31.50 29.75 28.00<br />

ES-PS-0800-8-220-0420-75* 8.00 mm 8 mm 22.0 mm 42.0 mm 75 mm 42.00 39.90 37.80 35.70 33.60<br />

ES-PS-0800-8-220-0620-100* 8.00 mm 8 mm 22.0 mm 62.0 mm 100 mm 47.00 44.65 42.30 39.95 37.60<br />

ES-PS-1000-10-140-0220-60* 10.00 mm 10 mm 14.0 mm 22.0 mm 60 mm 40.00 38.00 36.00 34.00 32.00<br />

ES-PS-1000-10-220-0320-70* 10.00 mm 10 mm 22.0 mm 32.0 mm 70 mm 45.00 42.75 40.50 38.25 36.00<br />

ES-PS-1000-10-220-0420-75* 10.00 mm 10 mm 22.0 mm 42.0 mm 75 mm 47.00 44.65 42.30 39.95 37.60<br />

L3<br />

L1<br />

Total<br />

length<br />

* new tool in this printed issue | * new tool in this PDF update<br />

Ask for an individual offer if you are interested in annual orders or single orders of quantities from 50 upwards.<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

Thread<br />

Cutters<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Practical Tip<br />

If the tool has finished its lifetime and is no longer sharp enough<br />

for milling acrylic glass, you can still use it for machining aluminium<br />

composite plates or similar materials.<br />

Wood<br />

Plastics<br />

Rigid<br />

Foam<br />

Impression<br />

Tools<br />

Accessories

28<br />

Carbide Tools | Diamond Tools<br />

Single Milling Tooth<br />

Cutters<br />

Engraving<br />

Tools<br />

Deburring<br />

Tools<br />

Router Bits<br />

This hawk beak is especially keen on aluminium...<br />

Single tooth cutters<br />

with hawk beak<br />

Description:<br />

This single tooth cutter has a very sharp, exposed cutting<br />

edge (“hawk beak”) with an extreme grinding. The<br />

large flute with a lead angle of 30° enables a very good<br />

chip clearance. So the risk is low that the tool may clog<br />

during milling, also in softer sorts of aluminium.<br />

Coating:<br />

Many tools are optionally available with the high performance<br />

coating AluSpeed® (see page 11).<br />

Fields of application:<br />

Special milling cutter for aluminium; however, also very<br />

good results in plastics and wood. The coated tools are<br />

suitable for machining aluminium with a silicon part of<br />

up to 10 %, copper and other non-ferrous metals.<br />

Practical tip:<br />

Choose appropriately short cutting edges (ideal in combination<br />

with increased shanks) for milling works or feed<br />

rates in the threshold range.<br />

39<br />

new<br />

tools<br />

Thread<br />

Cutters<br />

Dimensions and prices<br />

D2<br />

L1<br />

L2<br />

D1<br />

Drills<br />

Lances and<br />

Knives<br />

Diamond<br />

Tools<br />

Impression<br />

Tools<br />

Accessories<br />

D1<br />

Cutting edge<br />

diameter<br />

D2<br />

Shank<br />

diameter<br />

L2<br />

Cutting edge<br />

length<br />

Price –5%<br />

–10%<br />

–15%<br />

–20%<br />

Article no.<br />

in € 2 – 4 5 – 9 10 – 19 20 – 49<br />

ES-HB-0100-3-030-40* 1.00 mm 3 mm 3.0 mm 40 mm 18.00 17.10 16.20 15.30 14.40<br />

ES-HB-0100-3-050-40* 1.00 mm 3 mm 5.0 mm 40 mm 18.00 17.10 16.20 15.30 14.40<br />

ES-HB-0100-6-050-40* 1.00 mm 6 mm 5.0 mm 40 mm 22.00 20.90 19.80 18.70 17.60<br />

ES-HB-0150-3-050-40* 1.50 mm 3 mm 5.0 mm 40 mm 18.00 17.10 16.20 15.30 14.40<br />