MEATing POINT Magazine: #12 / 2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PROCESSING<br />

cost-effective option for mixing shafts<br />

design. With this configuration, the<br />

mixture takes place over the entire<br />

length of the trough. Likewise, narrow<br />

and long-built mixers have a positive<br />

influence upon the effectiveness (short<br />

mixing time for a homogeneous<br />

mixture) because the paddles sit<br />

close to the shaft and thus no dead<br />

spaces are caused by long paddle<br />

arms. Through novel special trough<br />

and paddle geometry, the weak<br />

point “emptying of stiff and viscous<br />

mass” of this mixer geometry is<br />

significantly optimized.<br />

In order to work continuously with<br />

the subsequent cutter, two mixers<br />

can be used: a mixer is filled or<br />

emptied, and a mixer mixes the<br />

composite. The alternative is a large<br />

buffer tank with a conveyor pump<br />

next to the mixer so that it can be<br />

emptied quickly and it is available<br />

for a new batch.<br />

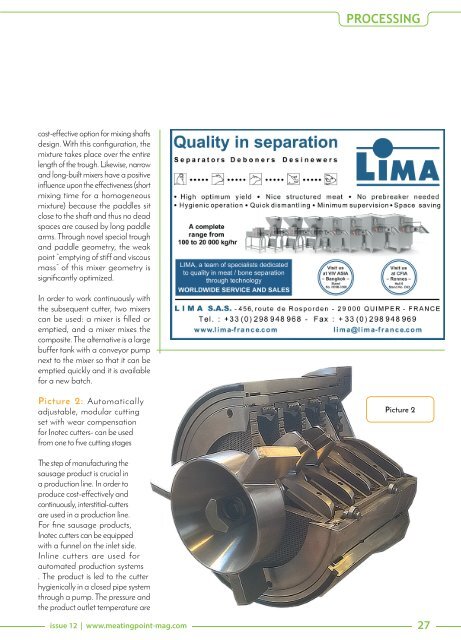

Picture 2: Automatically<br />

adjustable, modular cutting<br />

set with wear compensation<br />

for Inotec cutters- can be used<br />

from one to five cutting stages<br />

The step of manufacturing the<br />

sausage product is crucial in<br />

a production line. In order to<br />

produce cost-effectively and<br />

continuously, interstitial-cutters<br />

are used in a production line.<br />

For fine sausage products,<br />

Inotec cutters can be equipped<br />

with a funnel on the inlet side.<br />

Inline cutters are used for<br />

automated production systems<br />

. The product is led to the cutter<br />

hygienically in a closed pipe system<br />

through a pump. The pressure and<br />

the product outlet temperature are<br />

issue 12 | www.meatingpoint-mag.com<br />

Picture 2<br />

27