Eastern Automotive Warehousing/Auto Machinery - Autosphere

Eastern Automotive Warehousing/Auto Machinery - Autosphere

Eastern Automotive Warehousing/Auto Machinery - Autosphere

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

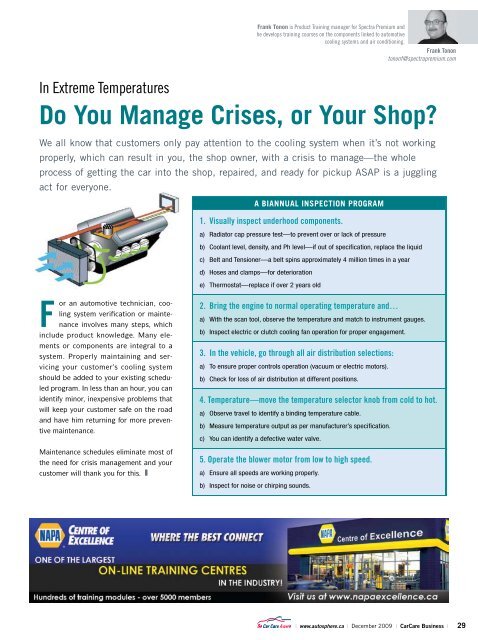

In Extreme Temperatures<br />

Do You Manage Crises, or Your Shop?<br />

We all know that customers only pay attention to the cooling system when it’s not working<br />

properly, which can result in you, the shop owner, with a crisis to manage—the whole<br />

process of getting the car into the shop, repaired, and ready for pickup ASAP is a juggling<br />

act for everyone.<br />

For an automotive technician, cooling<br />

system verifi cation or maintenance<br />

involves many steps, which<br />

include product knowledge. Many elements<br />

or components are integral to a<br />

system. Properly maintaining and servicing<br />

your customer’s cooling system<br />

should be added to your existing scheduled<br />

program. In less than an hour, you can<br />

identify minor, inexpensive problems that<br />

will keep your customer safe on the road<br />

and have him returning for more preventive<br />

maintenance.<br />

Maintenance schedules eliminate most of<br />

the need for crisis management and your<br />

customer will thank you for this.<br />

Frank Tonon is Product Training manager for Spectra Premium and<br />

he develops training courses on the components linked to automotive<br />

cooling systems and air conditioning.<br />

Frank Tonon<br />

tononf@spectrapremium.com<br />

A BIANNUAL INSPECTION PROGRAM<br />

1. Visually inspect underhood components.<br />

a) Radiator cap pressure test—to prevent over or lack of pressure<br />

b) Coolant level, density, and Ph level—if out of specifi cation, replace the liquid<br />

c) Belt and Tensioner—a belt spins approximately 4 million times in a year<br />

d) Hoses and clamps—for deterioration<br />

e) Thermostat—replace if over 2 years old<br />

2. Bring the engine to normal operating temperature and…<br />

a) With the scan tool, observe the temperature and match to instrument gauges.<br />

b) Inspect electric or clutch cooling fan operation for proper engagement.<br />

3. In the vehicle, go through all air distribution selections:<br />

a) To ensure proper controls operation (vacuum or electric motors).<br />

b) Check for loss of air distribution at different positions.<br />

4. Temperature—move the temperature selector knob from cold to hot.<br />

a) Observe travel to identify a binding temperature cable.<br />

b) Measure temperature output as per manufacturer’s specifi cation.<br />

c) You can identify a defective water valve.<br />

5. Operate the blower motor from low to high speed.<br />

a) Ensure all speeds are working properly.<br />

b) Inspect for noise or chirping sounds.<br />

| www.autosphere.ca | December 2009 | CarCare Business | 29