– The Approach and Experiences in ICC - Department of Building ...

– The Approach and Experiences in ICC - Department of Building ...

– The Approach and Experiences in ICC - Department of Building ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CPD Technical Sem<strong>in</strong>ar, CIBSE (Hong Kong Branch), ASHRAE<br />

(Hong Kong Chapter) <strong>and</strong> HKIE (BS division)<br />

17, March 2010, Hong Kong<br />

Build<strong>in</strong>g Energy Sav<strong>in</strong>g through Optimization<br />

<strong>and</strong> Life-cycle Commission<strong>in</strong>g<br />

<strong>–</strong> <strong>The</strong> <strong>Approach</strong> <strong>and</strong> <strong>Experiences</strong> <strong>in</strong> <strong>ICC</strong><br />

Shengwei Wang (王盛衛 王盛衛 王盛衛) 王盛衛<br />

Chair Pr<strong>of</strong>essor <strong>of</strong> Build<strong>in</strong>g Services Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Department</strong> <strong>of</strong> Build<strong>in</strong>g Services Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>The</strong> Hong Kong Polytechnic University<br />

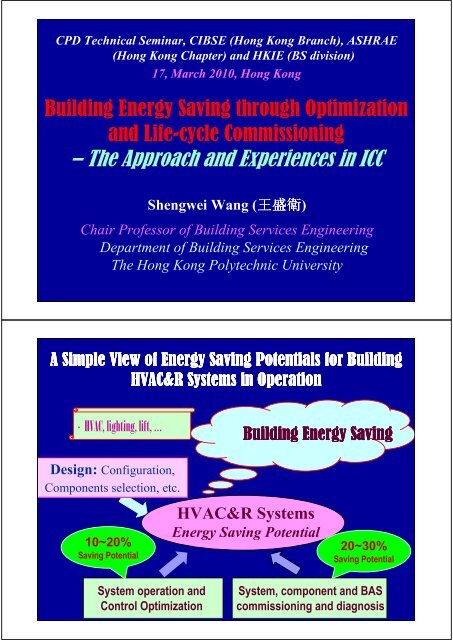

A A Simple Simple View View <strong>of</strong> <strong>of</strong> Energy Energy Sav<strong>in</strong>g Sav<strong>in</strong>g Potentials Potentials for for Build<strong>in</strong>g<br />

Build<strong>in</strong>g<br />

HVAC&R HVAC&R Systems Systems <strong>in</strong> <strong>in</strong> Operation<br />

Operation<br />

- HVAC, light<strong>in</strong>g, lift, …<br />

Design: Configuration,<br />

Components selection, etc.<br />

10~20%<br />

Sav<strong>in</strong>g Potential<br />

System operation <strong>and</strong><br />

Control Optimization<br />

Build<strong>in</strong>g Build<strong>in</strong>g Build<strong>in</strong>g Energy Energy Sav<strong>in</strong>g<br />

Sav<strong>in</strong>g<br />

HVAC&R Systems<br />

Energy Sav<strong>in</strong>g Potential<br />

20~30%<br />

Sav<strong>in</strong>g Potential<br />

System, component <strong>and</strong> BAS<br />

commission<strong>in</strong>g <strong>and</strong> diagnosis

Outl<strong>in</strong>e <strong>of</strong> Presentation<br />

• Introduction to <strong>ICC</strong> build<strong>in</strong>g systems;<br />

• Our roles <strong>in</strong> <strong>ICC</strong> project;<br />

• <strong>The</strong> concept <strong>of</strong> “commission<strong>in</strong>g”<br />

• Examples <strong>of</strong> commission<strong>in</strong>g efforts at design,<br />

<strong>in</strong>stallation, T&C <strong>and</strong> operation stages;<br />

• Sav<strong>in</strong>g Energy through Control Optimization<br />

control strategies implemented<br />

examples <strong>of</strong> control strategies<br />

• Summary <strong>of</strong> energy benefits<br />

• Summary <strong>of</strong> experiences <strong>in</strong> <strong>ICC</strong><br />

International F<strong>in</strong>ance Centre (<strong>ICC</strong>)<br />

Floor Area:<br />

Hotel 70,000 (m 2 )<br />

Office 286,000 (m 2 )<br />

Commercial center<br />

67,000 (m 2 )<br />

Gross 440,000 (m 2 )<br />

Six-star Hotel<br />

High-rank<br />

commercial<br />

<strong>of</strong>fice<br />

Commercial center <strong>and</strong><br />

basement<br />

490 m<br />

118 F

A<br />

D<br />

E<br />

F<br />

G<br />

PCHWP-06-01<br />

EVAPORAROR<br />

WCC-06a-01<br />

(2040 Ton)<br />

COOLING<br />

TOWER 1<br />

FROM PODIUM & BASEMENT<br />

TO PODIUM & BASEMENT<br />

HX HX<br />

(S-B) (S-B)<br />

SCHWP-06-10 to 12<br />

SCHWP-06-01 to 02<br />

COOLING<br />

TOWER 2<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

EVAPORATOR<br />

COOLING<br />

TOWER 3<br />

B<br />

COOLING<br />

TOWER 4<br />

FROM OFF<strong>ICC</strong>E FLOORS(7-41)<br />

TO OFFICE FLOORS(7-41)<br />

EVAPORATOR EVAPORATOR EVAPORATOR EVAPORATOR<br />

COOLING<br />

TOWER 5<br />

COOLING<br />

TOWER 6<br />

HX HX HX HX HX HX HX<br />

PCHWP-06-02 PCHWP-06-03 PCHWP-06-04 PCHWP-06-05 PCHWP-06-06<br />

WCC-06a-02<br />

(2040 Ton)<br />

Secondary water circuit for Zone 1<br />

Secondary water circuit for Zone 2<br />

Secondary water circuit for Zone<br />

3 <strong>and</strong> Zone 4<br />

Primary water circuit<br />

Chiller circuit<br />

Cool<strong>in</strong>g water circuit<br />

Cool<strong>in</strong>g tower circuit<br />

(S-B)<br />

WCC-06a-03<br />

(2040 Ton)<br />

WCC-06a-04<br />

(2040 Ton)<br />

COOLING<br />

TOWER 7<br />

COOLING<br />

TOWER 8<br />

WCC-06a-05<br />

(2040 Ton)<br />

CDWP-06-01 CDWP-06-02 CDWP-06-03 CDWP-06-04<br />

CDWP-06-05 CDWP-06-06<br />

C<br />

COOLING<br />

TOWER 9<br />

FROM OFFICE FLOORS (43-77)<br />

COOLING<br />

TOWER 10<br />

TO OFFICE FLOORS (43-77)<br />

WCC-06a-06<br />

(2040 Ton)<br />

CONDENSER CONDENSER CONDENSER CONDENSER CONDENSER CONDENSER<br />

CT-06a-01 CT-06a-02 CT-06a-03 CT-06a-04 CT-06a-05 CT-06a-06 CTA-06a-01 CTA-06a-02 CTA-06a-03 CTA-06a-04 CTA-06a-05<br />

CTA Towers (without heat<strong>in</strong>g coil)<br />

SCHWP-06-03 to 05<br />

HX<br />

SCHWP-78-01 to 03<br />

PCHWP-78-01 PCHWP-78-02<br />

HX<br />

SCHWP-42-04 to 06<br />

FROM OFFICE FLOORS (79-98)<br />

TO OFFICE FLOORSS (79-98)<br />

PCHWP-78-03<br />

HX<br />

(S-B)<br />

(S-B)<br />

(S-B)<br />

(S-B)<br />

SCHWP-42-01 to 03<br />

PCHWP-42-01 PCHWP-42-02 PCHWP-42-03 PCHWP-42-04 PCHWP-42-05 PCHWP-42-06 PCHWP-42-07<br />

SCHWP-06-06 to 09<br />

CTB Towers (with heat<strong>in</strong>g coil)<br />

Our Our Our Our Our Roles Roles Roles Roles <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>ICC</strong> <strong>ICC</strong> <strong>ICC</strong> <strong>ICC</strong> Project<br />

Project<br />

Project<br />

Project<br />

� Independent Energy Consultant<br />

(Independent Commission<strong>in</strong>g<br />

Agent)<br />

� Developer <strong>of</strong> HVAC Energy<br />

Optimization System (EOS)<br />

<strong>and</strong> Energy Performance<br />

Diagnosis System (EPDS)<br />

COOLING<br />

TOWER 11

� Summary <strong>of</strong> design power load <strong>of</strong> ma<strong>in</strong> HVAC<br />

equipments<br />

Chiller Pump Cool<strong>in</strong>g Tower Fan PAU Fan AHU Fan Total<br />

Number 6 36 11 29 152 234<br />

Rated Power (kW ) 1346 152<br />

Total load (kW ) 8076 4374 1672 513 4600 19235<br />

Percentage 41.99% 22.74% 8.69% 2.67% 23.91%<br />

� Annual electricity consumption <strong>of</strong> the central<br />

air-condition<strong>in</strong>g system is about 50,000,000 kWh<br />

Pr<strong>in</strong>ciple <strong>of</strong> Commission<strong>in</strong>g<br />

(校核 校核 校核/校校 校核 校核 校核 校核 校核 校校 校校及及及及及及及及改進<br />

校校 校校 校校 校校 校校 改進) 改進 改進 改進 改進 改進 改進<br />

� Commission<strong>in</strong>g is the process throughout the<br />

whole build<strong>in</strong>g lifecycle rather that one-<strong>of</strong>f task.<br />

� Commission<strong>in</strong>g is a valid means for<br />

improv<strong>in</strong>g energy performance <strong>of</strong><br />

build<strong>in</strong>gs <strong>and</strong> HVAC systems<br />

throughout the build<strong>in</strong>g life cycle.

Categories <strong>of</strong> Commission<strong>in</strong>g<br />

� Initial commission<strong>in</strong>g: Applied to a production <strong>of</strong> a new<br />

build<strong>in</strong>g <strong>and</strong>/or an <strong>in</strong>stallation <strong>of</strong> new systems.<br />

� Retro-commission<strong>in</strong>g: <strong>The</strong> first time commission<strong>in</strong>g<br />

implemented <strong>in</strong> an exist<strong>in</strong>g build<strong>in</strong>g <strong>in</strong> which a documented<br />

commission<strong>in</strong>g was not implemented before.<br />

� Re-commission<strong>in</strong>g: Implemented after the <strong>in</strong>itial<br />

commission<strong>in</strong>g or the retro-commission<strong>in</strong>g when the owner hopes to<br />

verify, improve <strong>and</strong> document the performance <strong>of</strong> build<strong>in</strong>g systems.<br />

� On-go<strong>in</strong>g/cont<strong>in</strong>uous commission<strong>in</strong>g: Conducted<br />

cont<strong>in</strong>ually for the purposes <strong>of</strong> ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g, improv<strong>in</strong>g <strong>and</strong><br />

optimiz<strong>in</strong>g the performance <strong>of</strong> build<strong>in</strong>g systems after the <strong>in</strong>itial<br />

commission<strong>in</strong>g or the retro-commission<strong>in</strong>g.<br />

Life-Cycle Life ycle Commission<strong>in</strong>g<br />

ommission<strong>in</strong>g<br />

� <strong>The</strong> build<strong>in</strong>g pr<strong>of</strong>ession <strong>in</strong> Northern American <strong>and</strong><br />

European countries has been promot<strong>in</strong>g the new concept <strong>of</strong><br />

life-cycle “Commission<strong>in</strong>g” <strong>and</strong> role <strong>of</strong> “Independent<br />

Commission<strong>in</strong>g Agent” over the last few years.<br />

� Commission<strong>in</strong>g is the process throughout the whole<br />

build<strong>in</strong>g lifecycle rather that one-<strong>of</strong>f task as conventional<br />

“Test <strong>and</strong> Commission<strong>in</strong>g”.<br />

It is performed regularly throughout the whole build<strong>in</strong>g lifecycle from<br />

early plann<strong>in</strong>g, design, construction <strong>and</strong> <strong>in</strong>stallation to operation<br />

for ensur<strong>in</strong>g that systems are designed, <strong>in</strong>stalled, functionally tested<br />

<strong>and</strong> capable <strong>of</strong> be<strong>in</strong>g operated <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong>ed properly.<br />

� Commission<strong>in</strong>g is an effective means for improv<strong>in</strong>g<br />

energy performance <strong>of</strong> build<strong>in</strong>gs <strong>and</strong> HVAC systems<br />

throughout the build<strong>in</strong>g life cycle.<br />

• An average payback period for commission<strong>in</strong>g <strong>of</strong> new<br />

build<strong>in</strong>gs is 4.8 years <strong>in</strong> United States.<br />

• Average energy cost sav<strong>in</strong>g for periodical commission<strong>in</strong>g<br />

<strong>of</strong> exist<strong>in</strong>g build<strong>in</strong>g is 15%.

Life-Cycle Life ycle Commission<strong>in</strong>g<br />

ommission<strong>in</strong>g<br />

� <strong>The</strong> build<strong>in</strong>g pr<strong>of</strong>ession <strong>in</strong> Northern American <strong>and</strong><br />

European countries has been promot<strong>in</strong>g the new concept <strong>of</strong><br />

life-cycle “Commission<strong>in</strong>g” <strong>and</strong> role <strong>of</strong> “Independent<br />

Commission<strong>in</strong>g Agent” over the last few years.<br />

� Commission<strong>in</strong>g <strong>ICC</strong> project is the is one process <strong>of</strong> the throughout very first the whole full scale<br />

build<strong>in</strong>g trial lifecycle <strong>of</strong> the new rather concept that one-<strong>of</strong>f <strong>of</strong> “Commission<strong>in</strong>g”<br />

task as conventional<br />

“Test <strong>and</strong> Commission<strong>in</strong>g”.<br />

<strong>and</strong> “Independent Commission<strong>in</strong>g Agent” <strong>in</strong><br />

It is performed regularly throughout the whole build<strong>in</strong>g lifecycle from<br />

early very plann<strong>in</strong>g, large design, <strong>and</strong> construction complex <strong>and</strong> build<strong>in</strong>g <strong>in</strong>stallation system to operation <strong>in</strong><br />

for ensur<strong>in</strong>g that systems are designed, <strong>in</strong>stalled, functionally tested<br />

<strong>and</strong> Asia. capable It <strong>of</strong> be<strong>in</strong>g is a very operated attractive <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong>ed contribution properly. to the<br />

IEA Research programme Annex 47.<br />

� Commission<strong>in</strong>g is an effective means for improv<strong>in</strong>g<br />

energy performance <strong>of</strong> build<strong>in</strong>gs <strong>and</strong> HVAC systems<br />

throughout the build<strong>in</strong>g life cycle.<br />

• An average payback period for commission<strong>in</strong>g <strong>of</strong> new<br />

build<strong>in</strong>gs is 4.8 years <strong>in</strong> United States.<br />

• Average energy cost sav<strong>in</strong>g for periodical commission<strong>in</strong>g<br />

<strong>of</strong> exist<strong>in</strong>g build<strong>in</strong>g is 15%.<br />

Commission<strong>in</strong>g Commission<strong>in</strong>g <strong>and</strong> <strong>and</strong> <strong>and</strong> examples examples <strong>of</strong><br />

<strong>of</strong><br />

efforts efforts at at design, design, design, <strong>in</strong>stallation, <strong>in</strong>stallation, T&C<br />

T&C<br />

<strong>and</strong> <strong>and</strong> operation operation stages<br />

stages

Development <strong>of</strong> Virtual Build<strong>in</strong>g System - Dynamic<br />

simulation platform <strong>of</strong> the complex HVACR system<br />

Load & status <strong>of</strong> AHUs<br />

Zone airflow rates<br />

Load & status <strong>of</strong> AHUs<br />

On/Off<br />

<strong>of</strong> AHUs<br />

On/Off <strong>of</strong> AHUs<br />

TYPE 49<br />

Ma,i&Ta,<strong>in</strong><br />

On/Off <strong>of</strong> AHUs<br />

TYPE 35<br />

On/Off <strong>of</strong> AHUs Ma,i&Ta,<strong>in</strong><br />

On/Off <strong>of</strong> AHUs Ma,i&Ta,<strong>in</strong><br />

Pump & network Mw,i AHUs<br />

TYPE 17 TYPE 63<br />

Mw,i<br />

Pump & network AHUs<br />

TYPE 13 TYPE 21<br />

Freq<br />

Tao,i<br />

PID control PID control<br />

TYPE 43 TYPE 20<br />

VPi<br />

Pump sequence Npu PD<br />

optimizer<br />

TYPE 39<br />

TYPE 7<br />

PDset<br />

Mix<strong>in</strong>g<br />

TYPE 60<br />

Tw,<strong>in</strong> &Mw<br />

HX sequence Nhx HX model<strong>in</strong>g<br />

&mix<strong>in</strong>g<br />

TYPE 39<br />

TYPE 41<br />

Nhx<br />

Pump & network<br />

TYPE 14<br />

Freq Mw,meas<br />

Tw,out<br />

PID control Mw,set PID control<br />

TYPE 43 TYPE 43<br />

Zone 1 Zone 1<br />

Return pipe<br />

TYPE 31<br />

Pump & network Mw,i AHUs<br />

TYPE 12 TYPE 63<br />

Freq<br />

Tao,i<br />

PID control PID control<br />

TYPE 43 TYPE 42<br />

VPi<br />

Pump sequence Npu PD<br />

optimizer<br />

TYPE 39<br />

TYPE 6<br />

PDset<br />

Mix<strong>in</strong>g<br />

Zone 2<br />

TYPE 48<br />

Zone 2<br />

Mw & Tw,rtn Mw & Tw,rtn<br />

Mix<strong>in</strong>g<br />

TYPE 61<br />

Mw,tot & Tw,rtn<br />

Mw & Tw,rtn<br />

Tw,rtn & Mw,tot<br />

Mw,i<br />

Pump & network AHUs<br />

Freq<br />

Tao,i<br />

TYPE 18 TYPE 63<br />

PID control PID control<br />

Freq<br />

Tao,i<br />

TYPE 43 TYPE 42<br />

PID control PID control<br />

VPi<br />

TYPE 43 TYPE 42<br />

Pump sequence Npu PD<br />

VPi<br />

optimizer<br />

TYPE 39 TYPE 62<br />

Pump sequence Npu PD<br />

PDset<br />

optimizer<br />

TYPE 39<br />

TYPE 8<br />

HX sequence Mix<strong>in</strong>g<br />

Load<br />

PDset<br />

TYPE 39 TYPE 47<br />

Nhx<br />

HX sequence Mix<strong>in</strong>g<br />

Pump & network HX model<strong>in</strong>g<br />

Mw &mix<strong>in</strong>g<br />

TYPE 39 Nhx TYPE Zones 47 3&4 3&4<br />

TYPE 15<br />

TYPE 36<br />

Freq Mw,meas<br />

Tw,<strong>in</strong><br />

Pump sequence HX model<strong>in</strong>g<br />

&mix<strong>in</strong>g<br />

TYPE 39<br />

PID control<br />

TYPE 37<br />

TYPE 43<br />

Mw Npu<br />

Tw,sup<br />

Mw,set<br />

&Mw<br />

Pump & network<br />

PID control Mix<strong>in</strong>g &<br />

TYPE 16<br />

TYPE 43<br />

bypass<br />

Freq Mw,meas<br />

Tw,out<br />

TYPE 19<br />

PID control Mw,set PID control<br />

Pump sequence<br />

TYPE 43 TYPE 43<br />

TYPE 39<br />

Tw,rtn & Mw Mix<strong>in</strong>g & bypass<br />

Tw,sup & Mw TYPE 45 Zone 3&4<br />

Tsup Supply pipe<br />

TYPE 31<br />

Mix<strong>in</strong>g & Bypass<br />

TYPE XX: Component type number<br />

TYPE 67<br />

T: Temperature<br />

Tw,sup<br />

Mw & PDmeas<br />

Data Reader<br />

TYPE 9<br />

Twb&Tdb<br />

Mw,tot& Trtn<br />

Mw<br />

Ma,i&Ta,<strong>in</strong><br />

Tsup<br />

Chiller sequence controller<br />

TYPE 50<br />

Cool<strong>in</strong>g tower controller<br />

TYPE 3&54&55<br />

Tw,out,i On/Off,i&Freq,i<br />

On/Off<br />

<strong>of</strong> AHUs<br />

Tw,sup<br />

Mw & PDmeas<br />

Chiller One<br />

TYPE 23<br />

Chiller Two<br />

TYPE 23<br />

Chiller Three<br />

TYPE 23<br />

Chiller Four<br />

TYPE 23<br />

Mix<strong>in</strong>g after chiller condensers<br />

TYPE 4<br />

Chiller Five<br />

TYPE 23<br />

Chiller Six<br />

TYPE 23<br />

CTA One CTA Two CTA Three CTA Four CTA Five CTA Six CTB One CTB Two CTB Three CTB Four CTB Five<br />

TYPE 1 TYPE 1 TYPE 1 TYPE 1 TYPE 1 TYPE 1 TYPE 2 TYPE 2 TYPE 2 TYPE 2 TYPE 2<br />

Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw<br />

Mix<strong>in</strong>g after cool<strong>in</strong>g towers<br />

TYPE 5<br />

Tw,sup<br />

On/Off<br />

<strong>of</strong> AHUs<br />

Tw,ch,out Tw,ch,out Tw,ch,out Tw,ch,out Tw,ch,out Tw,ch,out<br />

Nch On/Off On/Off On/Off On/Off On/Off On/Off<br />

Nch Tw,cd,out Tw,cd,out Tw,cd,out Tw,cd,out Tw,cd,out Tw,cd,out<br />

Mw,tot&Tw,ct,<strong>in</strong><br />

Mw,tot&Tw,ct,out<br />

Tw,cd,out<br />

Load<br />

Nhx<br />

Mw<br />

On/Off<br />

<strong>of</strong> AHUs<br />

Tw,cd,<strong>in</strong><br />

Tw,sup<br />

Mw & Tw,<strong>in</strong><br />

Mw & PDmeas<br />

Mw<br />

Npu<br />

M:<br />

Load:<br />

Freq:<br />

N:<br />

VP:<br />

PD:<br />

Subscript<br />

w:<br />

ao:<br />

<strong>in</strong>:<br />

rtn:<br />

cd:<br />

ct:<br />

hx:<br />

wb:<br />

Water<br />

Air outlet<br />

Inlet<br />

Return<br />

Nhx<br />

Tw,out<br />

Number<br />

Condenser<br />

Tw,rtn& Mw<br />

Water or air flow rate<br />

Cool<strong>in</strong>g load<br />

Frequency<br />

Valve position<br />

meas: Measurement<br />

Pressure differential<br />

Cool<strong>in</strong>g tower<br />

Heat exchanger<br />

Wet-bulb<br />

a:<br />

i:<br />

Air<br />

tot: Total<br />

pu: Pump<br />

sup: Supply<br />

Mw,&w,<strong>in</strong><br />

Tw,rtn& Mw<br />

Individual<br />

set: Set-po<strong>in</strong>t<br />

ch: Chiller<br />

out: Outlet<br />

db: Dry-bulb<br />

Development <strong>of</strong> Virtual Build<strong>in</strong>g System - Dynamic<br />

simulation platform <strong>of</strong> the complex HVACR system<br />

Load & status <strong>of</strong> AHUs<br />

Zone airflow rates<br />

Load & status <strong>of</strong> AHUs<br />

On/Off<br />

<strong>of</strong> AHUs<br />

On/Off <strong>of</strong> AHUs<br />

TYPE 49<br />

Ma,i&Ta,<strong>in</strong><br />

On/Off <strong>of</strong> AHUs<br />

Mw,i<br />

Pump & network AHUs<br />

Pump & network Mw,i<br />

TYPE 13 TYPE 21<br />

AHUs<br />

Freq<br />

Tao,i<br />

TYPE 12 TYPE 63<br />

PID control PID control<br />

Freq<br />

Tao,i<br />

TYPE 43 TYPE 20<br />

PID control PID control<br />

VPi<br />

TYPE 43 TYPE 42<br />

PD<br />

VPi<br />

Pump sequence Npu<br />

optimizer<br />

TYPE 39<br />

TYPE 7<br />

Pump sequence Npu PD<br />

optimizer<br />

PDset<br />

TYPE 39<br />

TYPE 6<br />

Mix<strong>in</strong>g<br />

PDset<br />

TYPE 60<br />

Tw,<strong>in</strong> &Mw<br />

Mix<strong>in</strong>g<br />

HX sequence Nhx HX model<strong>in</strong>g Zone 2<br />

&mix<strong>in</strong>g<br />

TYPE 48<br />

TYPE 39<br />

TYPE 41<br />

Nhx<br />

Zone Zone 2<br />

Pump & network<br />

Mw & Tw,rtn Mw & Tw,rtn<br />

TYPE 14<br />

Freq Mw,meas<br />

Tw,out<br />

PID control Mw,set PID control<br />

TYPE 43 TYPE 43<br />

Mix<strong>in</strong>g<br />

Zone 1<br />

TYPE 61<br />

Zone 1<br />

Mw,tot & Tw,rtn<br />

Mw & Tw,rtn<br />

Return pipe<br />

Tw,rtn & Mw,tot<br />

TYPE 31<br />

On/Off <strong>of</strong> AHUs Ma,i&Ta,<strong>in</strong><br />

TYPE 35<br />

Pump & network Mw,i AHUs<br />

On/Off <strong>of</strong> AHUs Ma,i&Ta,<strong>in</strong><br />

TYPE 17 TYPE 63<br />

Mw,i<br />

Pump & network AHUs<br />

Freq<br />

Tao,i<br />

TYPE 18 TYPE 63<br />

PID control PID control<br />

Freq<br />

Tao,i<br />

TYPE 43 TYPE 42<br />

PID control PID Virtual<br />

control<br />

VPi<br />

TYPE 43 TYPE 42<br />

Pump sequence Npu PD<br />

VPi<br />

optimizer<br />

TYPE 39 TYPE 62<br />

Pump sequence Npu PD<br />

PDset<br />

optimizer<br />

TYPE 39<br />

TYPE 8<br />

HX sequence Mix<strong>in</strong>g<br />

Load<br />

PDset<br />

TYPE 39 TYPE 47<br />

Nhx<br />

HX sequence Mix<strong>in</strong>g<br />

Pump & network HX model<strong>in</strong>g Build<strong>in</strong>g Mw &mix<strong>in</strong>g<br />

TYPE 39 Nhx TYPE Zones 47 3&4<br />

TYPE 15<br />

TYPE 36<br />

Freq Mw,meas<br />

Tw,<strong>in</strong><br />

Pump sequence HX model<strong>in</strong>g<br />

&mix<strong>in</strong>g<br />

TYPE 39<br />

PID control<br />

TYPE 37<br />

TYPE 43<br />

Mw Npu<br />

Tw,sup<br />

Mw,set<br />

&Mw<br />

Pump & network<br />

PID control Mix<strong>in</strong>g &<br />

TYPE 16<br />

TYPE 43<br />

bypass<br />

Freq Mw,meas<br />

Tw,out<br />

TYPE 19 System<br />

PID control Mw,set PID control<br />

Pump sequence<br />

TYPE 43 TYPE 43<br />

TYPE 39<br />

Tw,rtn & Mw Mix<strong>in</strong>g & bypass<br />

Tw,sup & Mw TYPE 45 Zone 3&4<br />

Tsup Supply pipe<br />

TYPE 31<br />

Mix<strong>in</strong>g & Bypass<br />

TYPE XX: Component type number<br />

TYPE 67<br />

T: Temperature<br />

Tw,sup<br />

Mw & PDmeas<br />

Mw,tot& Trtn<br />

Mw<br />

Ma,i&Ta,<strong>in</strong><br />

Tsup<br />

On/Off<br />

<strong>of</strong> AHUs<br />

Tw,sup<br />

Mw & PDmeas<br />

Tw,sup<br />

On/Off<br />

<strong>of</strong> AHUs<br />

Data Reader<br />

Tw,ch,out Tw,ch,out Tw,ch,out Tw,ch,out Tw,ch,out Tw,ch,out<br />

M: Water or air flow rate<br />

TYPE 9<br />

Chiller sequence controller Nch<br />

TYPE 50<br />

Nch<br />

Cool<strong>in</strong>g tower controller<br />

TYPE 3&54&55<br />

Tw,out,i On/Off,i&Freq,i<br />

Chiller One Chiller Two Chiller Three Chiller Four Chiller Five Chiller Six<br />

Load: Cool<strong>in</strong>g load<br />

TYPE 23 TYPE 23 TYPE 23 TYPE 23 TYPE 23 TYPE 23<br />

Freq: Frequency<br />

On/Off On/Off On/Off On/Off On/Off On/Off<br />

N: Number<br />

Tw,cd,<strong>in</strong> VP: Valve position<br />

Tw,cd,out Tw,cd,out Tw,cd,out Tw,cd,out Tw,cd,out Tw,cd,out<br />

PD: Pressure differential<br />

Mix<strong>in</strong>g after chiller condensers (updated throughout<br />

Subscript<br />

TYPE 4<br />

Mw,tot&Tw,ct,<strong>in</strong><br />

Tw,cd,out<br />

w: Water<br />

a: Air<br />

meas: Measurement i: Individual<br />

ao: Air outlet tot: Total<br />

<strong>in</strong>: Inlet<br />

pu: Pump<br />

CTA One CTA Two CTA Three CTA Four CTA Five CTA Six CTB One CTB Two CTB Three the CTB Fourentire<br />

CTB Five process)<br />

rtn: Return set: Set-po<strong>in</strong>t<br />

TYPE 1 TYPE 1 TYPE 1 TYPE 1 TYPE 1 TYPE 1 TYPE 2 TYPE 2 TYPE 2 TYPE 2 TYPE 2<br />

cd: Condenser ch: Chiller<br />

Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw Tw,out & Mw<br />

ct: Cool<strong>in</strong>g tower out: Outlet<br />

Mix<strong>in</strong>g after cool<strong>in</strong>g towers<br />

hx: Heat exchanger sup: Supply<br />

TYPE 5<br />

Mw,tot&Tw,ct,out<br />

wb: Wet-bulb db: Dry-bulb<br />

Twb&Tdb<br />

Load<br />

Nhx<br />

Mw<br />

On/Off<br />

<strong>of</strong> AHUs<br />

Tw,sup<br />

Mw & Tw,<strong>in</strong><br />

Mw & PDmeas<br />

Mw<br />

Simulated<br />

Npu<br />

Nhx<br />

Tw,out<br />

Tw,rtn& Mw<br />

Mw,&w,<strong>in</strong><br />

Tw,rtn& Mw<br />

Tw,sup<br />

Tw,sup

A<br />

D<br />

E<br />

F<br />

Design Commission<strong>in</strong>g<br />

<strong>The</strong> design commission<strong>in</strong>g ma<strong>in</strong>ly concerns the<br />

future operation <strong>and</strong> control performance <strong>of</strong> HVAC<br />

systems, <strong>and</strong> <strong>in</strong>cludes:<br />

• Verification the system configuration <strong>and</strong> component<br />

selection <strong>in</strong>clud<strong>in</strong>g the chiller system, water system<br />

(primary/secondary system), heat rejection system<br />

(cool<strong>in</strong>g towers), fresh air system etc.<br />

• Verification <strong>of</strong> the meter<strong>in</strong>g system for proper local<br />

control, <strong>and</strong> the orig<strong>in</strong>al proposed control logics at the<br />

design stage.<br />

• Proposal <strong>of</strong> additional meter<strong>in</strong>g system for implement<strong>in</strong>g<br />

supervisory control strategies <strong>and</strong> diagnosis strategies<br />

<strong>and</strong> related facilities for implement<strong>in</strong>g these strategies<br />

( This is a typical energy-sav<strong>in</strong>g implementation from<br />

the earlier design <strong>and</strong> <strong>in</strong>stallation phase)<br />

HX-06<br />

PCHWP-06-01<br />

EVAPORAROR<br />

WCC-06a-01<br />

(2040 Ton)<br />

FROM PODIUM & BASEMENT<br />

TO PODIUM & BASEMENT<br />

HX-06<br />

(S-B) (S-B)<br />

A Secondary water circuit for Zone 1 C<br />

B Secondary water circuit for Zone 2<br />

C<br />

D Primary water circuit<br />

E Chiller circuit<br />

F Cool<strong>in</strong>g water circuit<br />

B<br />

EVAPORATOR<br />

FROM OFF<strong>ICC</strong>E FLOORS(7-41)<br />

TO OFFICE FLOORS(7-41)<br />

HX-42<br />

PCHWP-06-02 PCHWP-06-03 PCHWP-06-04 PCHWP-06-05 PCHWP-06-06<br />

WCC-06a-02<br />

(2040 Ton)<br />

Secondary water circuit for Zone<br />

3 <strong>and</strong> Zone 4<br />

(S-B)<br />

EVAPORATOR EVAPORATOR EVAPORATOR EVAPORATOR<br />

WCC-06a-03<br />

(2040 Ton)<br />

WCC-06a-04<br />

(2040 Ton)<br />

WCC-06a-05<br />

(2040 Ton)<br />

FROM OFFICE FLOORS (43-77)<br />

TO OFFICE FLOORS (43-77)<br />

CDWP-06-01 CDWP-06-02 CDWP-06-03 CDWP-06-04<br />

CDWP-06-05 CDWP-06-06<br />

(S-B)<br />

WCC-06a-06<br />

(2040 Ton)<br />

CONDENSER CONDENSER CONDENSER CONDENSER CONDENSER CONDENSER<br />

From cool<strong>in</strong>g towers<br />

SCHWP-06-10 to 12<br />

SCHWP-06-01 to 02<br />

System Design Verification -<br />

Secondary water loop systems <strong>of</strong> 3rd <strong>and</strong> 4 th zones<br />

SCHWP-06-03 to 05<br />

HX-78<br />

SCHWP-78-01 to 03<br />

PCHWP-78-01 PCHWP-78-02<br />

HX-78<br />

SCHWP-42-04 to 06<br />

FROM OFFICE FLOORS (79-98)<br />

TO OFFICE FLOORSS (79-98)<br />

PCHWP-78-03<br />

HX-78<br />

(S-B)<br />

(S-B)<br />

(S-B)<br />

SCHWP-42-01 to 03<br />

PCHWP-42-01 PCHWP-42-02 PCHWP-42-03 PCHWP-42-04 PCHWP-42-05 PCHWP-42-06 PCHWP-42-07<br />

HX-42 HX-42 HX-42 HX-42 HX-42 HX-42<br />

SCHWP-06-06 to 09<br />

Orig<strong>in</strong>al Orig<strong>in</strong>al Orig<strong>in</strong>al Orig<strong>in</strong>al System System System System<br />

HX-78<br />

SCHWP-78-01 to 03<br />

HX-78<br />

SCHWP-42-04 to 06<br />

HX-78<br />

FROM OFFICE FLOORS (79-98)<br />

(S-B)<br />

TO OFFICE FLOORSS (79-98)<br />

HX-42 HX-42 HX-42 HX-42 HX-42 HX-42 HX-42<br />

From Zone 3&4<br />

SCHWP-06-06 to 09<br />

To cool<strong>in</strong>g towers<br />

Primary pumps are omitted<br />

(S-B)<br />

To Zone 3&4<br />

(S-B)<br />

FROM OFFICE FLOORS (43-77)<br />

(S-B)<br />

TO OFFICE FLOORS (43-77)<br />

SCHWP-42-01 to 03<br />

Revised Revised Revised Revised System System System System<br />

(operation (operation (operation (operation mode) mode) mode) mode)<br />

Flow meter<br />

Bypass valve

Pump power (kW )<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Comparison between Two systems<br />

Orig<strong>in</strong>al design<br />

Alternative design<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24<br />

Time (h )<br />

Typical sunnysummer<br />

day<br />

Annual Pump<br />

Energy Sav<strong>in</strong>g is<br />

1M kWh<br />

System Design Verification-<br />

Verification<br />

Cool<strong>in</strong>g tower system<br />

• A very special cool<strong>in</strong>g tower with large heat rejection<br />

capacity <strong>and</strong> a very large dimension (4*10*9)<br />

• High pressure drop through fill pack<strong>in</strong>g <strong>and</strong> silencer<br />

• Energy consumption is about 3.6 million a year with<br />

<strong>in</strong>tended two-stage control<br />

Annual sav<strong>in</strong>g potential <strong>of</strong> us<strong>in</strong>g variable speed<br />

cool<strong>in</strong>g towers is 2.4M compared with that<br />

us<strong>in</strong>g constant speed towers. It is 1.4M<br />

compared with that us<strong>in</strong>g two speed towers.<br />

• Energy consumption is about 2.6<br />

million a year with <strong>in</strong>tended<br />

VFD control from PolyU<br />

• However, energy consumption<br />

will <strong>in</strong>crease greatly to about 5.0<br />

million when s<strong>in</strong>gle-stage is used<br />

Silencer<br />

100 Pa<br />

Fill pack<strong>in</strong>g<br />

300 Pa 50 Pa<br />

Pressure drop<br />

From chiller<br />

To chiller

Example <strong>of</strong> CO 2 Sensor<br />

Installation<br />

Morgan<br />

Stanley<br />

CO CO22<br />

CO CO22<br />

CO CO22<br />

CO CO22<br />

CO CO22<br />

CO CO22<br />

AHU<br />

Flow stations<br />

CO CO2 2<br />

CO CO22<br />

CO CO22<br />

CO CO22<br />

CO CO22<br />

AHU<br />

CO CO22<br />

CO CO22<br />

CO CO22 CO2 CO2<br />

Kaish<strong>in</strong>g<br />

� CO 2 sensor calibration <strong>and</strong> commission<strong>in</strong>g<br />

CO2 concentration (ppm)<br />

Measurement accuracy <strong>of</strong> CO 2 sensors directly affects<br />

<strong>in</strong>door air quality <strong>and</strong> energy performance <strong>of</strong> air side<br />

system, which is therefore essential for implement<strong>in</strong>g<br />

optimal ventilation control strategy.<br />

700<br />

650<br />

600<br />

550<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

Before calibration<br />

Fresh air (Measured) Return air (Measured)<br />

Supply air (Measured) Supply air (Calculated)<br />

200<br />

9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00<br />

Simple time (h)<br />

CO2 concentration (ppm)<br />

700<br />

650<br />

600<br />

550<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

Empty<br />

IC<br />

After calibration<br />

CO CO22<br />

CO CO22<br />

Fresh air (Measured) Return air (Measured)<br />

Supply air (Measured) Supply air (Calculated)<br />

CO CO22<br />

BB<br />

CO CO22<br />

CO CO22<br />

Empty<br />

Empty<br />

9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00<br />

Sample time (h)

∆P<br />

Q = A ⋅ v = A ⋅ 2∆P<br />

Example <strong>of</strong> air flow<br />

station Installation<br />

Cool<strong>in</strong>g Cool<strong>in</strong>g tower tower site site operation operation issue issue<br />

• We suggest all the cool<strong>in</strong>g tower fans are equipped with<br />

VFD for significant energy sav<strong>in</strong>gs, <strong>and</strong> the variable<br />

frequency range is from 50 Hz to 25 Hz at least.<br />

• At the test stage, the manufacture<br />

stated the m<strong>in</strong>imum frequency is 37<br />

Hz for cool<strong>in</strong>g requirement <strong>of</strong> the<br />

<strong>in</strong>side motor.<br />

• <strong>The</strong> manufacture f<strong>in</strong>ally confirmed the<br />

m<strong>in</strong>imum frequency is 20 Hz ensur<strong>in</strong>g<br />

the normal operation <strong>of</strong> the fan.<br />

This This This This low low low low frequency frequency frequency frequency <strong>in</strong>creases <strong>in</strong>creases <strong>in</strong>creases <strong>in</strong>creases the the the the<br />

energy energy energy energy sav<strong>in</strong>g sav<strong>in</strong>g sav<strong>in</strong>g sav<strong>in</strong>g potential potential potential potential greatly greatly greatly greatly<br />

at at at at partial partial partial partial load load load load conditions conditions conditions conditions !<br />

! ! !

Cool<strong>in</strong>g Cool<strong>in</strong>g tower tower site site operation operation issue issue<br />

• We suggest all the cool<strong>in</strong>g tower fans are equipped with<br />

VFD for significant energy sav<strong>in</strong>gs, <strong>and</strong> the variable<br />

frequency range is from 50 Hz to 25 Hz at least.<br />

• At the test stage, the manufacture<br />

stated the m<strong>in</strong>imum frequency is 37<br />

Hz <strong>The</strong> for cool<strong>in</strong>g sav<strong>in</strong>gs requirement is about 607,000 <strong>of</strong> the kWh , 2.86% <strong>of</strong><br />

<strong>in</strong>side motor.<br />

annual energy consumption <strong>of</strong> chillers <strong>and</strong><br />

cool<strong>in</strong>g towers due to the lower frequency limit.<br />

• <strong>The</strong> manufacture f<strong>in</strong>ally confirmed the<br />

m<strong>in</strong>imum frequency is 20 Hz ensur<strong>in</strong>g<br />

the normal operation <strong>of</strong> the fan.<br />

This This This This low low low low frequency frequency frequency frequency <strong>in</strong>creases <strong>in</strong>creases <strong>in</strong>creases <strong>in</strong>creases the the the the<br />

energy energy energy energy sav<strong>in</strong>g sav<strong>in</strong>g sav<strong>in</strong>g sav<strong>in</strong>g potential potential potential potential greatly greatly greatly greatly<br />

at at at at partial partial partial partial load load load load conditions conditions conditions conditions ! ! ! !<br />

Low Delta-T Central Plant Syndrome<br />

� Nearly all large primary-secondary chilled water<br />

systems suffer from low chilled water temperature<br />

difference, known as low delta-T central plant<br />

syndrome, result<strong>in</strong>g <strong>in</strong> <strong>in</strong>efficient operation.<br />

� When the low delta-T syndrome exists, a series <strong>of</strong><br />

operation problems will be resulted<br />

� <strong>The</strong> <strong>in</strong>ability to sufficiently<br />

load chillers;<br />

� Excess water flow dem<strong>and</strong>;<br />

� An <strong>in</strong>crease <strong>in</strong> pump energy;<br />

� Either an <strong>in</strong>crease <strong>in</strong> chiller<br />

energy or a failure to meet<br />

cool<strong>in</strong>g load; etc.<br />

Water flow rate (L/s)<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

-100<br />

-200<br />

-300<br />

-400<br />

-500<br />

Temp. difference after decouple<br />

Water flow<br />

Chiller operat<strong>in</strong>g number<br />

0 12 24 36 48 60 72 84 96 108 120 132 144 156<br />

0<br />

168<br />

Sample time (hour)<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Chiller number <strong>and</strong> Temp. difference

Low Delta-T Central Plant Syndrome<br />

� Nearly all large primary-secondary chilled water<br />

systems suffer from low chilled water temperature<br />

difference, known as low delta-T central plant<br />

syndrome, result<strong>in</strong>g <strong>in</strong> <strong>in</strong>efficient operation.<br />

Each phase <strong>in</strong> the life cycle <strong>of</strong> air-condition<strong>in</strong>g<br />

systems, <strong>in</strong>clud<strong>in</strong>g design, equipment selection,<br />

commission<strong>in</strong>g, operation <strong>and</strong> ma<strong>in</strong>tenance,<br />

may result <strong>in</strong> low delta-T problems.<br />

� When the low delta-T syndrome exists, a series <strong>of</strong><br />

operation problems will be resulted<br />

� <strong>The</strong> <strong>in</strong>ability to sufficiently<br />

load chillers;<br />

� Excess water flow dem<strong>and</strong>;<br />

� An <strong>in</strong>crease <strong>in</strong> pump energy;<br />

� applications.<br />

Either an <strong>in</strong>crease <strong>in</strong> chiller<br />

energy or a failure to meet<br />

cool<strong>in</strong>g load; etc.<br />

Temp. difference after decouple<br />

400<br />

300<br />

Water flow<br />

Some causes can be avoided, 200 but some<br />

100<br />

0<br />

<strong>of</strong> them cannot be avoided <strong>in</strong> some<br />

-100<br />

� Potential solutions<br />

Water flow rate (L/s)<br />

500<br />

-200<br />

-300<br />

-400<br />

-500<br />

Chiller operat<strong>in</strong>g number<br />

0 12 24 36 48 60 72 84 96 108 120 132 144 156<br />

0<br />

168<br />

Sample time (hour)<br />

� <strong>The</strong> use <strong>of</strong> variable primary-only systems;<br />

� <strong>The</strong> use <strong>of</strong> pressure-<strong>in</strong>dependent modulat<strong>in</strong>g<br />

control valves;<br />

� <strong>The</strong> use <strong>of</strong> bypass check valves;<br />

� Advanced control <strong>and</strong> operation strategies.<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Chiller number <strong>and</strong> Temp. difference

System Improvement by us<strong>in</strong>g a Check Valve<br />

Check valve<br />

Primary<br />

pumps 01-06<br />

CHILLER 01<br />

CHILLER 02<br />

CHILLER 03<br />

CHILLER 04<br />

CHILLER 05<br />

CHILLER 06<br />

FM<br />

Secondary water<br />

circuit for Zone 1<br />

AHU<br />

AHU<br />

AHU<br />

Secondary<br />

Pumps 01-02<br />

Secondary water<br />

circuit for Zone 2<br />

Secondary water<br />

circuit for Zone 3&4<br />

� Experimental validation prior to a check valve is really<br />

<strong>in</strong>stalled<br />

� by us<strong>in</strong>g a ‘conceptual’ check valve <strong>in</strong> the chiller<br />

decouple ---- through fully clos<strong>in</strong>g down one <strong>of</strong> the<br />

isolation valves <strong>in</strong> the chiller decouple when the<br />

deficit flow was observed.<br />

AHU<br />

AHU<br />

AHU<br />

Secondary<br />

pumps 03-05<br />

� Summary <strong>of</strong> experimental results<br />

Outlet air temp. <strong>of</strong> AHU 1 <strong>in</strong> L15 (°C)<br />

Deficit flow (L/S)<br />

12.5<br />

12<br />

50<br />

0<br />

-50<br />

-100<br />

-150<br />

-200<br />

-250<br />

10:09:59<br />

10:24:58<br />

10:42:56<br />

10:58:57<br />

10:00:58<br />

10:17:58<br />

Clos<strong>in</strong>g the valve <strong>in</strong><br />

the decouple<br />

10:36:58<br />

10:51:59<br />

11:10:59<br />

11:06:59<br />

11:19:04<br />

5.5 °C set-po<strong>in</strong>t<br />

11:23:01<br />

11:39:01<br />

12:03:03<br />

12:21:03<br />

12:35:00<br />

13:00:01<br />

11:32:56<br />

11:54:58<br />

12:14:56<br />

12:29:58<br />

13:14:04<br />

12:48:56<br />

13:07:58<br />

Reopen the valve<br />

<strong>in</strong> the decouple<br />

5.0 °C set-po<strong>in</strong>t<br />

13:29:01<br />

13:43:58<br />

13:56:59<br />

14:13:58<br />

14:38:58<br />

14:52:04<br />

15:02:58<br />

15:16:57<br />

15:33:04<br />

15:47:59<br />

16:06:59<br />

16:23:01<br />

13:24:59<br />

Time<br />

13:37:59<br />

13:50:59<br />

14:08:59<br />

14:34:00<br />

14:44:56<br />

14:58:58<br />

15:10:56<br />

15:29:01<br />

15:39:00<br />

15:57:59<br />

16:15:58<br />

Cool<strong>in</strong>g load <strong>of</strong> chiller(kW)<br />

7000<br />

6500<br />

6000<br />

5500<br />

5000<br />

4500<br />

4000<br />

200<br />

0<br />

10:17:58<br />

10:36:58<br />

Clos<strong>in</strong>g the valve<br />

<strong>in</strong> the decouple<br />

10:51:59<br />

11:06:59<br />

11:19:04<br />

11:32:56<br />

11:54:58<br />

12:14:56<br />

12:29:58<br />

12:48:56<br />

Reset supply water<br />

temp. set po<strong>in</strong>t from<br />

5.5°C to 5 °C<br />

13:07:58<br />

13:24:59<br />

13:37:59<br />

13:50:59<br />

AHU<br />

AHU<br />

AHU<br />

Secondary<br />

pumps 06-08<br />

14:08:59<br />

14:34:00<br />

Reopen the valve <strong>in</strong><br />

the decouple<br />

Time<br />

Time<br />

Test procedure Cool<strong>in</strong>g energy <strong>of</strong> chillers<br />

Clos<strong>in</strong>g the valve<br />

Reset supply water<br />

Annual energy Reopen the valve <strong>in</strong><br />

<strong>in</strong> the decouple<br />

temp. set po<strong>in</strong>t from sav<strong>in</strong>g potential by us<strong>in</strong>g the check<br />

the decouple<br />

1800<br />

5.5°C to 5 °C<br />

16<br />

1600<br />

15.5 valve <strong>in</strong> <strong>ICC</strong> is about 325,800 1400kWh<br />

when compared<br />

15<br />

14.5<br />

1200<br />

1000<br />

to that without us<strong>in</strong>g the check valve.<br />

14<br />

800<br />

13.5<br />

600<br />

Us<strong>in</strong>g 'conceptual' check valve<br />

with similar weather condition<br />

by without us<strong>in</strong>g the check<br />

13<br />

400<br />

valve<br />

Total power (kW)<br />

14:44:56<br />

14:58:58<br />

15:10:56<br />

15:29:01<br />

15:39:00<br />

15:57:59<br />

16:15:58<br />

11:19:56<br />

11:30:02<br />

11:42:58<br />

11:52:59<br />

12:05:56<br />

12:16:58<br />

12:32:03<br />

12:46:56<br />

12:57:00<br />

13:07:04<br />

13:17:59<br />

13:31:59<br />

13:48:03<br />

13:56:01<br />

14:09:57<br />

14:28:03<br />

14:39:56<br />

14:48:00<br />

14:57:59<br />

Supply air temperature Energy consumptions<br />

Time

Onl<strong>in</strong>e performance test<strong>in</strong>g <strong>of</strong> control<br />

optimizers <strong>and</strong> diagnostic tools on the<br />

simulated virtual system<br />

Control optimizers <strong>and</strong> diagnostic tools should be tested on the virtual<br />

systems prior to site implementation<br />

Virtual Plants<br />

Simulated<br />

Communication<br />

Interfaces<br />

IBmanager<br />

Sav<strong>in</strong>g Energy through<br />

Control Optimization<br />

System Control Optimizer<br />

Simplified<br />

Models<br />

Optimization<br />

Strategies<br />

Performance<br />

Models<br />

Diagnosis<br />

Strategies<br />

Performance<br />

Prediction<br />

Diagnostic Tool<br />

Performance<br />

Prediction

Optimization for HVAC&R systems<br />

Optimization allows the <strong>of</strong> HVAC&R systems<br />

provide expected quality <strong>of</strong> services (comfort <strong>and</strong><br />

health environment) with reduced energy<br />

consumption by means <strong>of</strong> :<br />

• Optimiz<strong>in</strong>g design configuration;<br />

• Optimiz<strong>in</strong>g the selection <strong>and</strong> siz<strong>in</strong>g;<br />

• Optimal operation <strong>and</strong> control.<br />

Optimal control strategies for central<br />

air-condition<strong>in</strong>g air condition<strong>in</strong>g systems<br />

� Chiller sequence, optimal start<br />

Optimal chiller sequence - based on a more accurate cool<strong>in</strong>g load<br />

prediction us<strong>in</strong>g data fusion method, <strong>and</strong> consider<strong>in</strong>g dem<strong>and</strong> limit<strong>in</strong>g<br />

Adaptive onl<strong>in</strong>e strategy for optimal start - based on simplified subsystem<br />

dynamic models<br />

� Ventilation strategy for multi-zone air-condition<strong>in</strong>g<br />

system<br />

Optimal ventilation control strategy - based on ventilation needs <strong>of</strong><br />

<strong>in</strong>dividual zones <strong>and</strong> the energy benefits <strong>of</strong> fresh air <strong>in</strong>take<br />

� Peak dem<strong>and</strong> limit<strong>in</strong>g <strong>and</strong> global electricity cost<br />

management

Optimal control strategies for central<br />

air-condition<strong>in</strong>g air condition<strong>in</strong>g systems (cont’d) (cont d)<br />

� Chilled water system optimization<br />

Optimal pressure differential set po<strong>in</strong>t reset strategy<br />

Optimal pump sequence logic<br />

Optimal heat exchanger sequence logic<br />

Optimal control strategy for pumps <strong>in</strong> the cold water side <strong>of</strong> heat<br />

exchangers<br />

Optimal chilled water supply temperature set-po<strong>in</strong>t reset strategy<br />

� Cool<strong>in</strong>g water system optimization<br />

Optimal condenser <strong>in</strong>let water temperature set po<strong>in</strong>t reset strategy<br />

Optimal cool<strong>in</strong>g tower sequence<br />

Optimal control <strong>of</strong> condenser<br />

cool<strong>in</strong>g water systems

Optimal control <strong>of</strong> condenser cool<strong>in</strong>g water systems (cont’d) (cont d)<br />

� Formulation <strong>of</strong> the optimal control strategy<br />

It is designed us<strong>in</strong>g a model-based method<br />

• <strong>The</strong> overall structure <strong>of</strong> the optimal control strategy<br />

T wb, Q ev, N ch<br />

Def<strong>in</strong>e the search ranges<br />

for T w,cd,sup <strong>and</strong> N ct<br />

T w,cd,sup& N ct<br />

Onl<strong>in</strong>e measurements<br />

<strong>and</strong> control signals<br />

Measurement filter<br />

Simplified CTA <strong>and</strong><br />

Performance prediction<br />

CTB tower models<br />

Tw,cd,sup, NCTA, NCTB, Ma,, Pct , Freq<br />

Cost estimation & optimization algorithm<br />

Supervisory control strategy<br />

Simplified chiller<br />

model<br />

Optimal control sett<strong>in</strong>gs & cost<br />

(T w,cd,sup , N CTA , N CTB , Freq , P ch +P ct ) Optimization process<br />

N CTA<br />

T w,cd,sup<br />

N CTB<br />

Interface<br />

N ch &T wb<br />

T w,cd,sup<br />

Chiller plant control system<br />

(BAS)<br />

T w,cd,out<br />

P ch<br />

Freq<br />

Q ev , N ch , T w,ev,<strong>in</strong><br />

It consists <strong>of</strong> :<br />

Performance Performance predictor predictor<br />

predictor<br />

Cost Cost estimator estimator<br />

estimator<br />

Optimization Optimization tool<br />

tool<br />

Supervisory Supervisory strategy<br />

strategy<br />

• Objective function<br />

N ⎛ ch NCTA<br />

NCTB<br />

J = m<strong>in</strong>W<br />

= ⎜<br />

tot m<strong>in</strong>⎜∑<br />

Wch,<br />

k + ∑WCTA,<br />

i + ∑W<br />

Tw,<br />

cd , sup<br />

Tw,<br />

cd , sup ⎝ k=<br />

1 i=<br />

1<br />

j=<br />

1<br />

CTB,<br />

i<br />

Optimal control <strong>of</strong> condenser cool<strong>in</strong>g water systems (cont’d) (cont d)<br />

• Parameters to be optimized<br />

� <strong>The</strong> condenser water supply temperature set-po<strong>in</strong>t<br />

� <strong>The</strong> number <strong>of</strong> CTA towers operat<strong>in</strong>g<br />

� <strong>The</strong> number <strong>of</strong> CTB towers operat<strong>in</strong>g<br />

• Optimization tool ---HQS (hybrid quick search) method<br />

T<br />

T<br />

n,<br />

o<br />

w,<br />

cd , sup<br />

n,<br />

o<br />

w,<br />

cd,<br />

sup<br />

= h<br />

0<br />

+ h T<br />

1<br />

wb<br />

− ∆T<br />

≤ T<br />

⎛ Q<br />

+ h ⎜ 2 ⎜<br />

⎝ Qev,<br />

w,<br />

cd,<br />

sup<br />

ev<br />

≤ T<br />

des<br />

⎞<br />

⎟<br />

⎠<br />

n.<br />

o<br />

w,<br />

cd,<br />

sup<br />

• Operat<strong>in</strong>g constra<strong>in</strong>ts<br />

+ ∆T<br />

Control sett<strong>in</strong>g<br />

Upper limit<br />

Search range<br />

+Δx<br />

-Δx<br />

Low limit Search center (near optimal)<br />

� basic energy <strong>and</strong> mass balances (i.e., flow, heat, etc.)<br />

� mechanical limitations (i.e., fan speed, temperature, etc.)<br />

Time<br />

⎞<br />

⎟<br />

⎠

Temperature (°C )<br />

Optimal control <strong>of</strong> condenser cool<strong>in</strong>g water systems (cont’d) (cont d)<br />

� Performance tests <strong>and</strong> evaluation<br />

• Evaluation <strong>of</strong> control accuracy <strong>and</strong> computation performance<br />

32.00<br />

29.00<br />

26.00<br />

23.00<br />

20.00<br />

17.00<br />

14.00<br />

� Comparison between the HQS <strong>and</strong> GA-based strategies<br />

Items<br />

Seasons<br />

Spr<strong>in</strong>g Mild-summer Sunny-summer<br />

Typical work<strong>in</strong>g conditions<br />

Qload (kW) 25520.11 31213.61 37547.74<br />

Nch 4 5 6<br />

Tw,ev,<strong>in</strong> (°C) 9.92 9.82 9.83<br />

Tw,ev,out (°C) 5.50 5.50 5.50<br />

Tdb (°C) 22.55 27.76 33.66<br />

Twb (°C) 15.86 20.11 24.99<br />

Mw,cd (L/s) 410.10 410.10 410.10<br />

Items Tools<br />

HQS GA HQS GA HQS GA<br />

Optimization results<br />

Wch (kW) 3628.07 3644.90 5004.21 4994.37 6794.24 6799.59<br />

Wct (kW) 285.74 268.91 386.11 396.08 538.74 533.42<br />

Wch+Wct (kW) 3913.81 3913.81 5390.32 5390.45 7332.98 7333.01<br />

Optimal Tw,cd,sup (°C) 21.85 21.88 26.65 26.64 31.80 31.80<br />

NCTA 6 6 6 6 6 6<br />

NCTB 5 5 5 5 5 5<br />

Freq (Hz) 25.99 25.35 29.33 29.62 33.39 33.26<br />

Computational cost(s) 0.152 3.610 0.144 3.512 0.134 3.589<br />

<strong>The</strong> computational cost sav<strong>in</strong>g is 96.0%<br />

Dry-bulb Temp.<br />

Wet-bulb Temp.<br />

Optimal Temp. set-po<strong>in</strong>t<br />

Near optimal Temp. set-po<strong>in</strong>t<br />

Upper limit <strong>of</strong> set-po<strong>in</strong>t<br />

Low limit <strong>of</strong> set-po<strong>in</strong>t<br />

Optimal control <strong>of</strong> condenser cool<strong>in</strong>g water systems (cont’d) (cont d)<br />

• Evaluation <strong>of</strong> the Energy Performance<br />

� Comparison <strong>of</strong> condenser water supply temperature setpo<strong>in</strong>ts<br />

us<strong>in</strong>g HQS-based strategy <strong>and</strong> near optimal strategy<br />

0 2 4 6 8 10 12 14 16 18 20 22 24<br />

Time (h )<br />

Optimal temperature set-po<strong>in</strong>t<br />

Spr<strong>in</strong>g Spr<strong>in</strong>g case case<br />

38.00 Dry-bulb Temp.<br />

Wet-bulb Temp. Sunny<br />

Optimal Temp. set-po<strong>in</strong>t<br />

35.00 Near optimal Temp. set-po<strong>in</strong>t<br />

Upper limit <strong>of</strong> set-po<strong>in</strong>t<br />

32.00 Low limit <strong>of</strong> set-po<strong>in</strong>t<br />

Temperature (°C)<br />

29.00<br />

26.00<br />

23.00<br />

20.00<br />

0 2 4 6 8 10 12 14 16 18 20 22 24<br />

Time (h )<br />

Near-optimal temperature set-po<strong>in</strong>t<br />

Sunny-summer summer case case<br />

case

Power difference ( kW )<br />

Optimal control <strong>of</strong> condenser cool<strong>in</strong>g water systems (cont’d) (cont d)<br />

� Comparison <strong>of</strong> the hourly-based power consumptions us<strong>in</strong>g<br />

different control methods<br />

40<br />

30<br />

20<br />

10<br />

0<br />

-10<br />

-20<br />

Optimal strategy<br />

Near optimal strategy<br />

Fixed approach<br />

-30<br />

0 2 4 6 8 10 12 14 16 18 20 22 24<br />

Time (h )<br />

HQS-based strategy<br />

Spr<strong>in</strong>g case<br />

Spr<strong>in</strong>g case 210<br />

Optimal strategy Sunny<br />

180 Near optimal strategy<br />

Power difference ( kW )<br />

150<br />

120<br />

90<br />

60<br />

30<br />

0<br />

-30<br />

Fixed<br />

approach<br />

0 2 4 6 8 10 12 14 16 18 20 22 24<br />

Time (h )<br />

Near optimal strategy<br />

Sunny-summer summer case<br />

case<br />

Optimal control <strong>of</strong> condenser cool<strong>in</strong>g water systems (cont’d) (cont d)<br />

� Comparison <strong>of</strong> daily <strong>and</strong> annual power consumptions <strong>of</strong> the<br />

condenser cool<strong>in</strong>g water system us<strong>in</strong>g different control methods<br />

• Daily power consumptions<br />

Operation<br />

Strategies<br />

Fixed approach<br />

Wct+Wch<br />

(kWh)<br />

Near optimal strategy<br />

Wct+Wch Sav<strong>in</strong>g Sav<strong>in</strong>g<br />

(kWh) (kWh) (%)<br />

HQS-based strategy<br />

Wct+Wch Sav<strong>in</strong>g Sav<strong>in</strong>g<br />

(kWh) (kWh) (%)<br />

Spr<strong>in</strong>g 51,738 51,623 114.53 0.221 51,404 334.30 0.646<br />

Mild-summer 71,289 70,668 621.49 0.872 70,560 729.36 1.023<br />

Sunnysummer<br />

91,653 90,878 775.44 0.846 90,356 1,297.50 1.416<br />

• Annual power consumptions<br />

Operation<br />

strategies<br />

Wch<br />

(kWh)<br />

Wct<br />

(kWh)<br />

Wcd,pu<br />

(kWh)<br />

Wtot<br />

(kWh)<br />

Sav<strong>in</strong>g<br />

(kWh)<br />

Sav<strong>in</strong>g<br />

(%)<br />

Fixed approach 18,464,812 1,882,583 4,210,690 24,558,085 --- ---<br />

Near optimal 18,715,458 1,501,701 4,210,690 24,427,849 130,236 0.530<br />

HQS-based 18,715,134 1,448,765 4,210,690 24,374,589 183,496 0.747

Operation modes<br />

Plume Control <strong>and</strong> Energy Benefits<br />

Decision<br />

maker<br />

Platform for predict<strong>in</strong>g<br />

plume occurr<strong>in</strong>g possibility<br />

Cool<strong>in</strong>g<br />

Water<br />

Temp Setpo<strong>in</strong>t<br />

Operat<strong>in</strong>g Condition Power Consumption<br />

Cool<strong>in</strong>g<br />

Tower<br />

Number<br />

Cool<strong>in</strong>g<br />

Tower<br />

Freq<br />

Normal operation when there is<br />

no predicted plume occurs<br />

At first-level warn<strong>in</strong>g, <strong>in</strong>crease airflow rate<br />

by 20% when plume potential is marg<strong>in</strong>al<br />

At second-level warn<strong>in</strong>g, <strong>in</strong>crease airflow<br />

by 40% when plume potential is high<br />

Start heat<strong>in</strong>g us<strong>in</strong>g heat pumps when<br />

visual plume is observed<br />

Chiller<br />

Power<br />

Cool<strong>in</strong>g<br />

Tower<br />

Power<br />

Additional energy consumption for<br />

plume control could be reduced from<br />

Total<br />

Power<br />

Difference<br />

°C - Hz kW kW kW kW %<br />

Reference<br />

First-level warn<strong>in</strong>g<br />

22.7 3 26.51 856.2 59.1 32.8% to 5.5% or 1.5% at low Load<br />

21.3 3 30.74 836.2 93.0<br />

915.35<br />

929.2<br />

--<br />

14.0<br />

--<br />

1.5<br />

Second-level warm<strong>in</strong>g 20.1 3 35.52 819.9 145.9 965.8 50.6 5.5<br />

Us<strong>in</strong>g heat pumps 22.7 3CT+1HP 26.51 856.2 59.1 1215.2 300 32.8<br />

Chiller Plant Sequenc<strong>in</strong>g Control<br />

<strong>of</strong> Enhanced Robustness<br />

Us<strong>in</strong>g Data Fusion Technique

Types <strong>of</strong> chiller sequenc<strong>in</strong>g control<br />

� Return chilled water temperature based sequenc<strong>in</strong>g<br />

control<br />

Background (1)<br />

Chiller sequenc<strong>in</strong>g control<br />

� Aims to determ<strong>in</strong>e how many <strong>and</strong> which chillers are to be<br />

put <strong>in</strong>to operation accord<strong>in</strong>g to build<strong>in</strong>g cool<strong>in</strong>g load<br />

� Plays a significant role for build<strong>in</strong>g energy efficiency<br />

� Bypass flow based sequenc<strong>in</strong>g control<br />

� Direct power based sequenc<strong>in</strong>g control<br />

� Total cool<strong>in</strong>g load based sequenc<strong>in</strong>g control<br />

Background (2)<br />

Total cool<strong>in</strong>g load based chiller sequenc<strong>in</strong>g control<br />

� Build<strong>in</strong>g cool<strong>in</strong>g load measurement<br />

� Maximum cool<strong>in</strong>g capacity<br />

� Optimal number <strong>of</strong> chillers to be put <strong>in</strong>to operation<br />

N c = φ(Q cl, Q max)<br />

Problems<br />

� Build<strong>in</strong>g cool<strong>in</strong>g load cannot be measured accurately<br />

� Chiller maximum cool<strong>in</strong>g capacity vary with the<br />

operat<strong>in</strong>g conditions

Fused Cool<strong>in</strong>g Load Measurement<br />

Cool<strong>in</strong>g load measurement<br />

� Direct measurement <strong>of</strong> build<strong>in</strong>g cool<strong>in</strong>g load<br />

Q dm = c pwρ wM w(T w,rtn-T w,sup)<br />

where c pw is the water specific thermal capacity; ρ w is the<br />

water density; M w is water flow rate; T w,rtn,T w,sup are<br />

chilled water return/supply temp.<br />

� Indirect measurement <strong>of</strong> build<strong>in</strong>g cool<strong>in</strong>g load<br />

Q im = f(P com,T cd,T ev)<br />

where f is the chiller <strong>in</strong>verse model; P com is chiller power<br />

consumption; T cd,T ev are chiller condens<strong>in</strong>g/evaporat<strong>in</strong>g<br />

temperature<br />

Robust build<strong>in</strong>g cool<strong>in</strong>g load measurement technique<br />

� Data fusion to merge “Direct measurement” <strong>and</strong><br />

“Indirect measurement” improv<strong>in</strong>g the accuracy <strong>and</strong><br />

reliability <strong>of</strong> build<strong>in</strong>g cool<strong>in</strong>g load measurement<br />

T sup<br />

Advanced s<strong>of</strong>t measurement system<br />

Q dm<br />

Direct<br />

measurement<br />

T rtn M w<br />

Chiller<br />

Model 1<br />

Chiller<br />

Model 1<br />

Q im,1<br />

P com,1 T ev,1 ,T cd,1<br />

Data Fusion<br />

Eng<strong>in</strong>e<br />

+<br />

…<br />

Q im,n<br />

P com,n,T ev,n,T cd,n<br />

Central Chill<strong>in</strong>g Plant<br />

Chiller<br />

Model n<br />

Chiller<br />

Model n<br />

Q f<br />

γ f

Robust Chiller Sequenc<strong>in</strong>g Control Build<strong>in</strong>g Cool<strong>in</strong>g Load<br />

Measurement Technique<br />

Direct<br />

measurement<br />

Parameters<br />

sett<strong>in</strong>g<br />

Periodical<br />

analysis<br />

Central chill<strong>in</strong>g<br />

plant<br />

Indirect<br />

Measurement<br />

Data Fusion<br />

Eng<strong>in</strong>e<br />

Robust Cool<strong>in</strong>g Load<br />

Measurement<br />

Build<strong>in</strong>g Automation<br />

System<br />

Alarm<strong>in</strong>g<br />

subsystem<br />

Chiller sequenc<strong>in</strong>g<br />

control<br />

Temperature<br />

set-po<strong>in</strong>t<br />

Database<br />

Optimal Control <strong>of</strong> Variable Speed Pumps<br />

� Speed control <strong>of</strong> pumps distribut<strong>in</strong>g water to<br />

To term<strong>in</strong>al<br />

units<br />

heat exchangers<br />

� Orig<strong>in</strong>al implemented<br />

strategy --- differential<br />

pressure controller by<br />

resort<strong>in</strong>g to the<br />

modulat<strong>in</strong>g valve<br />

Secondary side <strong>of</strong> HX Primary side <strong>of</strong> HX<br />

From term<strong>in</strong>al units<br />

Temperature<br />

set-po<strong>in</strong>t<br />

TM T<br />

Temperature<br />

controller<br />

HX<br />

HX<br />

Water flow<br />

set-po<strong>in</strong>t<br />

TM<br />

Water flow<br />

controller<br />

From cool<strong>in</strong>g<br />

source<br />

To cool<strong>in</strong>g<br />

source<br />

Temperature Temperature<br />

set-po<strong>in</strong>t controller<br />

Modulat<strong>in</strong>g<br />

valves<br />

Secondary side <strong>of</strong> HX Primary side <strong>of</strong> HX<br />

From term<strong>in</strong>al units<br />

To term<strong>in</strong>al<br />

units<br />

T<br />

T<br />

Temperature<br />

controller<br />

HX<br />

HX<br />

M<br />

M<br />

Pressure<br />

differential set-po<strong>in</strong>t<br />

ΔP<br />

Differential<br />

pressure<br />

controller<br />

From cool<strong>in</strong>g<br />

source<br />

To cool<strong>in</strong>g<br />

source<br />

� Proposed strategy<br />

--- cascade controller<br />

without us<strong>in</strong>g any<br />

modulat<strong>in</strong>g valve

� Performance test <strong>and</strong> evaluation<br />

� Site practically test showed that the proposed<br />

strategy can provide stable <strong>and</strong> reliable control.<br />

Compared to orig<strong>in</strong>al implemented strategy, about<br />

22.0% sav<strong>in</strong>gs for pumps before heat exchangers <strong>in</strong><br />

Zone 1 was achieved.<br />

� Due to the low load <strong>of</strong> Zone 1 <strong>in</strong> <strong>ICC</strong> at current<br />

stage, a simulation test <strong>of</strong> annual energy sav<strong>in</strong>gs by<br />

us<strong>in</strong>g PolyU strategy is performed.<br />

Pumps<br />

Number<br />

(st<strong>and</strong>by)<br />

Energy consumption (kWh)<br />

Orig<strong>in</strong>al<br />

strategy<br />

(kWh)<br />

Energy sav<strong>in</strong>g <strong>of</strong> primary pumps before<br />

heat exchanges due to the use <strong>of</strong><br />

PolyU strategy is about 250000 kWh.<br />

Alternative<br />

Strategy<br />

(kWh)<br />

Sav<strong>in</strong>g<br />

(kWh)<br />

Primary pumps <strong>in</strong> Zone 1 1(1) 528,008 456,132 71,876<br />

Primary pumps for Zones 3&4 3(1) 921,235 795,830 125,405<br />

Primary pumps <strong>in</strong> Zone 4 2(1) 401,008 346,420 54,588<br />

Total sav<strong>in</strong>g <strong>of</strong> the primary pumps 251,869<br />

Optimal Outdoor air Ventilation Control<br />

Static pressure<br />

set po<strong>in</strong>t<br />

Static pressure<br />

Static pressure<br />

controller<br />

P<br />

<strong>The</strong> 7 th floor<br />

………….<br />

<strong>The</strong> 1 st floor<br />

Outdoor air<br />

controller<br />

Set po<strong>in</strong>t<br />

Adaptive DCV<br />

strategy<br />

Model-based<br />

outdoor air flow rate<br />

Control strategy

W<br />

Energy-based outdoor air flow rate set-po<strong>in</strong>t<br />

resett<strong>in</strong>g scheme<br />

cost<br />

= W<br />

fan<br />

Q<br />

+<br />

COP<br />

outdoor<br />

Iterative<br />

algorithm<br />

= C<br />

k<br />

v<br />

⋅ M<br />

k<br />

out,<br />

set<br />

Outdoor Air Optimal Scheme<br />

+<br />

Least Square Algorithm<br />

Set po<strong>in</strong>t trails<br />

Cost function<br />

estimator<br />

Optimal set po<strong>in</strong>t Range <strong>of</strong> set po<strong>in</strong>t<br />

Supervisor Constra<strong>in</strong>s<br />

Parameter estimators<br />

Parameter identification <strong>of</strong> the fan model<br />

Real process <strong>of</strong> the multi-zone<br />

air condition<strong>in</strong>g system<br />

M<br />

Model-based<br />

predictor<br />

k<br />

out,<br />

set<br />

⋅(<br />

H<br />

k<br />

out<br />

COP<br />

− H<br />

� Site Implementation <strong>and</strong> Validation <strong>of</strong> Optimal<br />

Ventilation Strategy for Fresh Air Control<br />

� CO2-based occupancy detection<br />

Number <strong>of</strong> occupancy<br />

� Site count<strong>in</strong>g the number <strong>of</strong><br />

occupancy <strong>in</strong> the typical floor<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Dem<strong>and</strong>-controlled Ventilation control<br />

Counted<br />

Predicted<br />

0<br />

8:30 9:30 10:30 11:30 12:30 13:30 14:30 15:30 16:30 17:30 18:30<br />

Time (hour)<br />

k<br />

rtn<br />

� Comparison<br />

between counted<br />

<strong>and</strong> predicted<br />

occupancies<br />

)

� Practically test <strong>and</strong> validation <strong>of</strong> the ventilation<br />

control strategy<br />

Tests aimed at validat<strong>in</strong>g the actual operational performance <strong>of</strong> the<br />

ventilation control strategy <strong>and</strong> also for verify<strong>in</strong>g whether the control<br />

sett<strong>in</strong>gs provided by PolyU strategy can be properly sent to the ATC<br />

system <strong>and</strong> further be used <strong>in</strong> practical control.<br />

AHU1<br />

AHU2<br />

Study cases<br />

Control strategy<br />

Fixed flow PolyU Fixed flow PolyU<br />

About 662,000 Primary fan energy kWh consumption energy sav<strong>in</strong>gs can be<br />

612.29 607.99 794.60<br />

761.92<br />

Site test case<br />

(kWh)<br />

(PolyU strategy achieved only applied to by Primary us<strong>in</strong>g fan energy sav<strong>in</strong>g PolyU (%) - ventilation +0.70 - control +4.11<br />

typical floor)<br />

(Nov., 2009)<br />

Energy saved due to fresh air<br />

7.90 3.04 4.96<br />

2.81<br />

strategy for all cool<strong>in</strong>g floors (kWh) per year <strong>in</strong> Zone 2!<br />

Estimation case<br />

(PolyU strategy applied to all<br />

floors <strong>in</strong> Zone 2)<br />

Summer case<br />

(PolyU strategy applied to all<br />

floors <strong>in</strong> Zone 2)<br />

Primary fan energy consumption<br />

(kWh)<br />

Primary fan energy sav<strong>in</strong>g (%)<br />

Primary fan energy consumption<br />

(kWh)<br />

Fresh air cool<strong>in</strong>g energy<br />

consumption (kWh)<br />

Total energy consumption (kWh)<br />

Total energy sav<strong>in</strong>g (%)<br />

612.29<br />

-<br />

612.29<br />

4754.4<br />

5366.7<br />

-<br />

288.3<br />

+52.9<br />

288.3<br />

1915.2<br />

2203.5<br />

+58.9<br />

794.60<br />

-<br />

794.60<br />

2985.6<br />

3780.2<br />

Site Implementation <strong>of</strong> <strong>The</strong><br />

Control Strategies<br />

-<br />

324.5<br />

+59.2<br />

324.5<br />

1725.6<br />

2050.1<br />

+45.8

Implementation Strategy <strong>of</strong> Optimal Control <strong>and</strong> Diagnosis<br />

Tools <strong>in</strong> <strong>ICC</strong><br />

BACnet SDK<br />

Control<br />

Parameters<br />

Optimizer<br />

Control Sett<strong>in</strong>g<br />

from PolyU<br />

Diagnosis<br />

Control Sett<strong>in</strong>g<br />

from ATC<br />

Decision Supervisor<br />

ATC<br />

VAV Box<br />

Overall KVA, etc.<br />

Manual<br />

Control<br />

Chiller Plant Control Optimizer<br />

<strong>and</strong> Diagnosis<br />

LAN<br />

Supply air control<br />

optimizer<br />

IBmanager<br />

AHU PAU<br />

Build<strong>in</strong>g<br />

Management<br />

System<br />

Fresh air control<br />

optimizer<br />

Fresh air<br />

term<strong>in</strong>al<br />

Intelligent build<strong>in</strong>g management system<br />

-- based on IBmanager<br />

� IBmanager is an open <strong>and</strong> <strong>in</strong>tegrated management platform. It<br />

employs st<strong>and</strong>ard middleware <strong>and</strong> web-service technologies to<br />

support the <strong>in</strong>tegration <strong>and</strong> <strong>in</strong>teroperation among distributed BASs.

Summary <strong>of</strong> Energy Benefits<br />

• 1,000,000 kWh energy consumption is saved due to the<br />

modification on the secondary water loops <strong>of</strong> Zone 3 & 4;<br />

• 2,360,000 kWh , (about 5.1% <strong>of</strong> annual energy<br />

consumption <strong>of</strong> chillers <strong>and</strong> cool<strong>in</strong>g towers) <strong>of</strong> the cool<strong>in</strong>g<br />

system can be sav<strong>in</strong>g due to the change from s<strong>in</strong>gle speed<br />

to variable speed us<strong>in</strong>g VFD.<br />

• 607,000 kWh , (about 2.8% <strong>of</strong> annual energy consumption<br />

<strong>of</strong> chillers <strong>and</strong> cool<strong>in</strong>g towers) <strong>of</strong> the cool<strong>in</strong>g system will<br />

be wasted when the lowest frequency is limited at 37 Hz.<br />

• 3, 500,000 kWh (about 7%) <strong>of</strong> the total energy<br />

consumption <strong>of</strong> HVAC system) can be saved us<strong>in</strong>g PoyU<br />

control strategies based on the orig<strong>in</strong>al design;<br />

Summary <strong>of</strong> Energy Benefits<br />

• 1,000,000 Sav<strong>in</strong>g Sav<strong>in</strong>g Sav<strong>in</strong>g Sav<strong>in</strong>g by by by by kWh Commission<strong>in</strong>g Commission<strong>in</strong>g<br />

Commission<strong>in</strong>g<br />

Commission<strong>in</strong>g energy consumption (Improv<strong>in</strong>g (Improv<strong>in</strong>g (Improv<strong>in</strong>g (Improv<strong>in</strong>g is saved the the the the due system system system system to the<br />

modification on the secondary water loops <strong>of</strong> Zone 3 & 4;<br />