Intelligent logistics for the automotive industry Logistics ... - SDV Geis

Intelligent logistics for the automotive industry Logistics ... - SDV Geis

Intelligent logistics for the automotive industry Logistics ... - SDV Geis

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

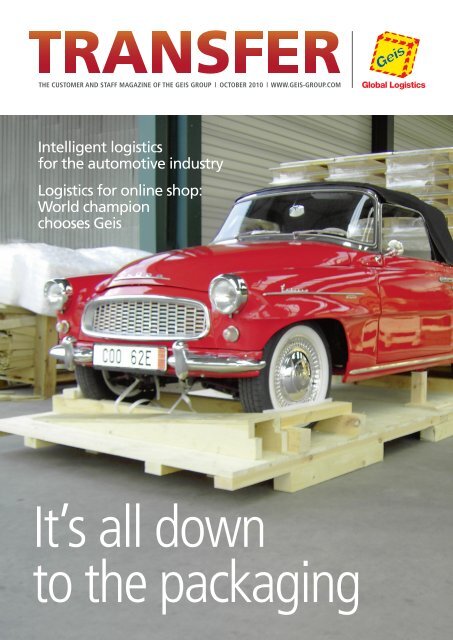

THE CUSTOMER AND STAFF MAGAZINE OF THE GEIS GROUP OCTOBER 2010 WWW.GEIS-GROUP.COM<br />

<strong>Intelligent</strong> <strong>logistics</strong><br />

<strong>for</strong> <strong>the</strong> <strong>automotive</strong> <strong>industry</strong><br />

<strong>Logistics</strong> <strong>for</strong> online shop:<br />

World champion<br />

chooses <strong>Geis</strong><br />

It’s all down<br />

to <strong>the</strong> packaging

2 | EDITORIAL<br />

Dear readers,<br />

Recent studies have shown that <strong>logistics</strong> remains one<br />

of <strong>the</strong> growth sectors in Germany and Europe – despite<br />

<strong>the</strong> short-term collapse in demand resulting<br />

from <strong>the</strong> economic downturn. The Shell HGV Survey<br />

thus <strong>for</strong>ecasts “continued high dynamic growth”<br />

in road haulage. In Germany alone, <strong>the</strong> volume of<br />

traffi c in <strong>the</strong> next 20 years will rise from 670 billion<br />

• In 2010 we also expect work to be completed on<br />

<strong>the</strong> expansion of our <strong>logistics</strong> centre in Ejpovice/<br />

Plzeň in <strong>the</strong> Czech Republic. Once complete, <strong>the</strong><br />

centre will have an additional 7,800 square metres<br />

of <strong>logistics</strong> area in addition to <strong>the</strong> existing 15,500<br />

square metres.<br />

• Also in <strong>the</strong> Czech Republic, we have acquired a<br />

10,000 square metres property that we are currently<br />

converting <strong>for</strong> combined use as a <strong>for</strong>warding and <strong>logistics</strong><br />

terminal. This building is situated in Prostějov<br />

in <strong>the</strong> east of <strong>the</strong> country and will probably replace<br />

our existing site in Olomouc at <strong>the</strong> end of <strong>the</strong> year.<br />

• Work on our latest new-build project has just<br />

started in Kürnach near Würzburg – a <strong>logistics</strong> centre<br />

with almost 8,000 square metres of space and a<br />

clear ceiling height of 10.5 metres, to be built alongside<br />

our existing <strong>for</strong>warding terminal. Our aim is to<br />

have it ready <strong>for</strong> use at <strong>the</strong> start of next year.<br />

• And last year we started our work at <strong>the</strong> comprehensive<br />

6,500 square metres expansion of our site in<br />

Salz near Bad Neustadt.<br />

As you can see <strong>the</strong>re<strong>for</strong>e, <strong>the</strong>re’s a lot happening at<br />

<strong>the</strong> <strong>Geis</strong> Group! Such <strong>for</strong>ward-thinking investments<br />

will enable us to have <strong>the</strong> capacity we need <strong>for</strong> <strong>the</strong><br />

continued development of our company. We are ex-<br />

INVESTMENTS INTO THE FUTURE<br />

tonne-kilometres to more than 1,000 billion tonnekilometres.<br />

Experts expect to see similar growth<br />

levels in contract <strong>logistics</strong>, a sector that has already<br />

grown disproportionately in recent years, with <strong>the</strong><br />

trend set to continue in <strong>the</strong> future. After all, many<br />

<strong>industry</strong> sectors are only now discovering <strong>the</strong> advantages<br />

of professional <strong>logistics</strong> outsourcing.<br />

For this reason, we as a <strong>logistics</strong> provider are continuing<br />

to drive <strong>for</strong>ward <strong>the</strong> development of <strong>the</strong> <strong>Geis</strong><br />

Group and equip our company <strong>for</strong> future growth.<br />

Thus we are investing massively in <strong>the</strong> expansion of<br />

our technologies, such as a centralized server architecture<br />

and new hand scanners <strong>for</strong> <strong>the</strong> road division<br />

by <strong>the</strong> end of this year, as well as in additional resources,<br />

such as our fl eet and multifunctional realestate.<br />

Here are fi ve examples:<br />

• This year at <strong>the</strong> Frauenaurach Industrial Park<br />

in Erlangen we have taken into operation a 30,000<br />

square metres <strong>logistics</strong> and technology centre as a<br />

multi-user site (see page 11). We will use it <strong>for</strong> contract<br />

<strong>logistics</strong>, assembly work and packing services<br />

<strong>for</strong> a number of diff erent customers. The 15 hectare<br />

site also has space <strong>for</strong> ano<strong>the</strong>r two fur<strong>the</strong>r <strong>logistics</strong><br />

terminals should <strong>the</strong> need arise.<br />

tremely selective in our choice of projects, and carefully<br />

take into consideration market requirements.<br />

We <strong>the</strong>reby ensure that our services and facilities<br />

precisely match <strong>the</strong> requirements of our customers.<br />

More news about our company can be found on <strong>the</strong><br />

following pages. We hope you enjoy reading it!<br />

Yours sincerely,<br />

Hans-Georg <strong>Geis</strong> and Wolfgang <strong>Geis</strong>,<br />

Managing Partners of <strong>the</strong> <strong>Geis</strong> Group

04<br />

08<br />

10<br />

12<br />

Photo: Daimler AG<br />

TOP STORY<br />

04 It’s all down to <strong>the</strong> packaging<br />

06 The packing experts<br />

ROAD SERVICES<br />

08 <strong>Intelligent</strong> procurement <strong>logistics</strong><br />

<strong>for</strong> <strong>the</strong> <strong>automotive</strong> <strong>industry</strong><br />

LOGISTICS SERVICES<br />

CONTENTS | 3<br />

10 <strong>Logistics</strong> <strong>for</strong> online shop:<br />

World champion chooses <strong>Geis</strong><br />

11 Contract with Rewe extended:<br />

From Hof to all four corners of <strong>the</strong> world<br />

11 New <strong>logistics</strong> centre: Coming along in leaps and bounds<br />

AIR + SEA SERVICES<br />

12 ‘Birth assistance’ <strong>for</strong> <strong>the</strong> Airbus A 400 M<br />

12 <strong>Geis</strong> at <strong>the</strong> Aircraft Interiors Expo 2010<br />

12 New: <strong>Logistics</strong> <strong>for</strong> ISOTRONIC<br />

13 Helicopter from India transported safely<br />

13 Assignment in Somalia<br />

GENERAL NEWS<br />

14 New apprentices<br />

14 New: Head of Key Account Management<br />

15 More safety at <strong>the</strong> wheel<br />

15 Successfully reaudited<br />

15 <strong>Geis</strong> meets <strong>the</strong> OHRIS standard<br />

15 Anniversaries<br />

Published by<br />

Hans <strong>Geis</strong> GmbH + Co Internationale Spedition<br />

Rudolf-Diesel-Ring 24, 97616 Bad Neustadt/Saale<br />

Phone: +49 9771 603-0, Fax: +49 9771 603-109<br />

www.geis-group.com<br />

Responsible <strong>for</strong> <strong>the</strong> contents<br />

Management of <strong>the</strong> <strong>Geis</strong> Group<br />

Editorial<br />

STROOMER PR | Concept GmbH<br />

Christian Stephan, Sonja Objartel.<br />

Kristine Wegner, Christoph Goldammer (Design)<br />

Rellinger Straße 64a, 20257 Hamburg<br />

Phone: +49 40 853133 0, Fax +49 40 853133 22<br />

E-Mail: mail@stroomer-pr.de

4 | TOP STORY<br />

It’s all down<br />

to <strong>the</strong> packaging<br />

“It‘s what‘s inside that counts” – a person packing a parcel at home might be able to get<br />

away with saying this, but what goes <strong>for</strong> <strong>the</strong>m would be unthinkable <strong>for</strong> <strong>the</strong> <strong>logistics</strong> sector.<br />

Packing today is a highly specialized service.<br />

Even if Germany wasn‘t world champion in<br />

South Africa this year, it still remains <strong>the</strong><br />

world champion when it comes to packing.<br />

The Federal Republic is one of <strong>the</strong> world‘s<br />

largest manufacturers of packaging, pallets and<br />

wooden packaging materials, making up a sector of<br />

<strong>the</strong> economy that is worth billions. The turnover of<br />

<strong>the</strong> German corrugated cardboard <strong>industry</strong> alone in<br />

2009 was 3.8 billion euros. Corrugated cardboard<br />

is <strong>the</strong> clear market leader when it comes to packaging<br />

materials, followed by wood, with 70 million<br />

wooden pallets manufactured in Germany in 2009.<br />

Sheeting comes third.<br />

Toys, cars, machinery parts, televisions and even entire<br />

production lines have to be moved around <strong>the</strong><br />

world and all have to be securely packed be<strong>for</strong>ehand.<br />

This is in order to retain <strong>the</strong> value of <strong>the</strong> products<br />

and also avoid costly time delays. In recent decades,<br />

selecting <strong>the</strong> right packaging has become a core task<br />

in distribution <strong>logistics</strong> and has developed into a<br />

highly specialized discipline.

OFTEN NEGLECTED. Alongside product packaging,<br />

transport packaging also plays an important role, and<br />

both infl uence on each o<strong>the</strong>r. Containers currently<br />

still reign supreme throughout <strong>the</strong> world, leading<br />

to pallets and wooden boxes often being neglected<br />

– wrongly, and ultimately at <strong>the</strong> cost of a smooth supply<br />

chain. Innovative <strong>logistics</strong> service providers recognised<br />

this problem years ago and today in addition<br />

to taking care of transportation and <strong>logistics</strong> <strong>for</strong> <strong>the</strong>ir<br />

customers, also advise on packing matters. <strong>Logistics</strong><br />

experts have long since become indispensable to <strong>industry</strong><br />

and commerce. After all, individual packing<br />

requirements only become visible and comprehensible<br />

as a part of <strong>the</strong> entire <strong>logistics</strong> chain. Thanks<br />

to <strong>the</strong> valuable experience ga<strong>the</strong>red by <strong>the</strong>se experts,<br />

customers can avoid having to repack goods and<br />

<strong>the</strong>reby ultimately save time and money.<br />

Talking of time, clever packing professionals don‘t<br />

just think about how goods are packed but also about<br />

how <strong>the</strong>y will subsequently be unpacked. For example,<br />

if just-in-time delivery is being used <strong>for</strong> a production<br />

line, <strong>the</strong> absence of packaging or <strong>the</strong> use of<br />

partial-packaging combined with modular loading<br />

can result in signifi cant time-savings.<br />

JUST AS IMPORTANT is <strong>the</strong> cost factor – especially<br />

since <strong>the</strong> economic crisis. No wonder: packaging<br />

usually accounts <strong>for</strong> between two and fi fty per cent<br />

of <strong>the</strong> product price. Skilled specialist packing fi rms<br />

can <strong>the</strong>re<strong>for</strong>e uncover interesting savings opportunities<br />

<strong>for</strong> <strong>the</strong>ir clients. The economic crisis has<br />

<strong>the</strong>re<strong>for</strong>e clearly also left its mark on <strong>the</strong> packing<br />

<strong>industry</strong>.<br />

Besides wanting cost-reducing solutions, customers<br />

are also keen on making savings with respect to<br />

packaging, energy effi ciency and environmentallyfriendly<br />

production. Sustainability is nowadays part<br />

of every packing concept. Experts reckon that by<br />

2014 around one third of all packaging will be environmentally<br />

friendly. Reusable or disposable? Wood<br />

or plastic? While <strong>logistics</strong> professionals usually use<br />

reusable packaging <strong>for</strong> small items, special packaging<br />

is often used <strong>for</strong> air and sea freight due to <strong>the</strong><br />

individual challenges involved.<br />

The majority of materials are recycled, with snap<br />

locks and tight straps being used <strong>for</strong> <strong>the</strong> most part<br />

ra<strong>the</strong>r than nails. Saving on materials also means<br />

saving on weight – something that is not only environmentally<br />

but also commercially sound, especially<br />

<strong>for</strong> air freight. Recycling makes obvious sense <strong>for</strong><br />

trade fair items, <strong>for</strong> example, with one trade fair following<br />

<strong>the</strong> next, and everything having to be packed<br />

anew each time. —<br />

Wood – <strong>the</strong> renewable packaging material<br />

Wood is CO 2 -neutral. Compared to a plastic pallet, its energy balance<br />

is signifi cantly more positive. With a plastic pallet, <strong>the</strong>re is more<br />

than double <strong>the</strong> amount of industrial waste. While German packers<br />

mostly use corrugated cardboard <strong>for</strong> transporting goods, wood is <strong>the</strong><br />

preferred packing material <strong>for</strong> transporting large machinery parts.<br />

This is not as simple as it sounds, however.<br />

According to <strong>the</strong> Bundesverband Holzpackmittel, Paletten und<br />

Exportverpackung (HPE) e. V. (Federal Association of Wooden Packing<br />

Material, Pallets and Export Packaging), over 50 countries,<br />

ranging from Egypt to Vietnam,<br />

currently impose import restrictions<br />

on packaging and pallets made of<br />

wood, with packing companies required<br />

to provide proof of different types<br />

of treatment.<br />

The international ISPM 15 standard,<br />

<strong>for</strong> example, states that wood must be<br />

free of bark, soil and pest infestation,<br />

which in turn calls <strong>for</strong> drying<br />

and fumigation.<br />

TOP STORY |<br />

5

6 | TOP STORY<br />

THE PACKING EXPERTS<br />

The <strong>Geis</strong> Group has more than 40 years‘ experience of packing goods, and <strong>for</strong> <strong>the</strong> last 20 years has<br />

off ered special packing services. Georg Lechner GmbH, which has belonged to <strong>the</strong> <strong>Geis</strong> Group since<br />

last year, is totally specialized in packing. In total around 120 <strong>Geis</strong> employees in Germany and<br />

<strong>the</strong> Czech Republic focus on packing, including trained woodworkers, carpenters and packing engineers.<br />

Not all<br />

packaging can<br />

be planned<br />

in advance<br />

ADVANTAGES FOR THE CUSTOMER. As an<br />

international <strong>logistics</strong> services provider,<br />

<strong>the</strong> <strong>Geis</strong> Group off ers its customers comprehensive<br />

one-source packing services. “There<br />

are so many things to consider, from <strong>the</strong> selection<br />

of sustainable materials and <strong>the</strong> development of an<br />

optimal packing concept to customs processing and<br />

safety precautions at international airports,” says<br />

Erik Lassen, Managing Director of <strong>Geis</strong> Industry<br />

Service GmbH and Georg Lechner GmbH. Several<br />

years ago <strong>Geis</strong> <strong>SDV</strong> <strong>the</strong>re<strong>for</strong>e set up its own packing<br />

operation at Munich Airport especially <strong>for</strong> air and<br />

sea freight.<br />

In <strong>the</strong> future, <strong>Geis</strong> will integrate <strong>Geis</strong> <strong>SDV</strong>‘s Munich<br />

packing services department into <strong>the</strong> organization<br />

of Lechner. “By pooling our services, we can<br />

fulfi l <strong>the</strong> needs of our customers more effi ciently<br />

and fl exibly,” says Dr. Johannes Söllner, Managing<br />

Director of <strong>Geis</strong> Holding <strong>for</strong> <strong>the</strong> business area <strong>Logistics</strong><br />

Services. “Not all packaging can be planned<br />

in advance; often our employees can only create <strong>the</strong><br />

fi nal packaging when <strong>the</strong> manufacturer has fi nished<br />

producing <strong>the</strong> goods. If production is delayed, we<br />

need to be fl exible.”

A COMPUTER INSTEAD OF A DRAWING BOARD. “We<br />

use <strong>the</strong> very latest technology in our work, whe<strong>the</strong>r<br />

it be standardized recording apparatus <strong>for</strong> packaging<br />

and material testing, or hygrometers,” explains<br />

Erik Lassen. “Computer-aided CAD applications<br />

have replaced <strong>the</strong> drawing board, and are today<br />

an everyday component of packing engineering.”<br />

<strong>Geis</strong> Group packers regularly attend specialist<br />

packer courses as part of ongoing training –<br />

at <strong>the</strong> renowned Wood Working Technical School at<br />

Bad Wildungen in Hesse, <strong>for</strong> example. Top-quality<br />

packaging calls <strong>for</strong> <strong>the</strong> manufacture of customized<br />

means of transport, use of container goods storage,<br />

and <strong>the</strong> resolution of any issues that arise relating to<br />

static, corrosion protection and load-securing.<br />

FLOATING PACKAGING. There are almost no limits<br />

on <strong>the</strong> weight or size of goods that can be packed<br />

by <strong>Geis</strong> and Lechner, with <strong>the</strong> range extending from<br />

medical engineering products to industrial goods.<br />

Larger or heavier items weighing over ten tonnes are<br />

packed by mobile teams at <strong>the</strong> customers‘ premises<br />

because <strong>the</strong> equipment required to move <strong>the</strong> items is<br />

usually already <strong>the</strong>re. Often <strong>the</strong> team from Lechner<br />

has to pack an entire production plant.<br />

It is precisely such projects, consisting of several hundred<br />

individual components, such as switch cabinets,<br />

steel parts, plat<strong>for</strong>ms and machinery, etc., that call<br />

<strong>for</strong> <strong>the</strong> experts‘ experience and total concentration.<br />

“In addition, we always have to ensure compliance<br />

with, <strong>for</strong> example, HPE guidelines, DIN standards<br />

and, of course, customer specifi cations. Even <strong>the</strong><br />

shape of wood chips in chipboard can be crucial<br />

in determining bending strength and <strong>the</strong>re<strong>for</strong>e its<br />

suitability as packing material,” says Robert Saxer,<br />

Site Manager in Oberhaching. “And if goods are extremely<br />

sensitive to impact, we use so-called fl oating<br />

packaging.”<br />

Lechner‘s specialist packers mostly pack classic industrial<br />

products manufactured, <strong>for</strong> example, by<br />

<strong>the</strong> engineering sector and generally exported by sea<br />

freight. In addition, <strong>the</strong>y develop and produce special<br />

packaging <strong>for</strong> goods weighing up to 15 tonnes,<br />

as well as <strong>for</strong> highly sensitive, climate-sensitive<br />

goods such as art objects and high-tech products.<br />

The company‘s customers include Siemens and<br />

Giesecke & Devrient.<br />

THE FUTURE BEGAN YESTERDAY. The <strong>Geis</strong> Group‘s<br />

new, almost 30,000 square metres large <strong>logistics</strong><br />

and technology centre, currently being built in <strong>the</strong><br />

Frauenaurach Industrial Park in Erlangen, will also<br />

have plenty of space <strong>for</strong> packing services. The centre,<br />

which will cover 5,000 square metres, will include<br />

ground-level access and two crane systems with a<br />

20-tonne hoisting capacity, enabling <strong>Geis</strong> in future<br />

to also pack extremely heavy goods such as machinery<br />

parts. —<br />

<strong>Geis</strong> at<br />

FachPack<br />

<strong>Geis</strong> Industrie Service<br />

this year showcased<br />

its various packing<br />

solutions <strong>for</strong> <strong>the</strong> fi rst<br />

time at <strong>the</strong> “FachPack”<br />

trade fair from 28 to 30<br />

September in Nuremberg.<br />

TOP STORY | 7<br />

INTERVIEW WITH AN EXPERT<br />

“Tailor-made suits”<br />

that provide optimal<br />

protection<br />

<strong>Geis</strong> subsidiary Georg Lechner GmbH<br />

specializes in customized packaging<br />

<strong>for</strong> unusual items. Site Manager Robert Saxer<br />

is interviewed below:<br />

What do you consider <strong>the</strong> most important<br />

aspect of packing?<br />

Robert Saxer: The most important aspect is that any<br />

high-value goods handed over to us by a customer<br />

arrive securely and above all undamaged at <strong>the</strong>ir destination.<br />

We have more than 40 years experience in<br />

packing goods <strong>for</strong> <strong>the</strong> exporting and high-tech industries,<br />

and use this experience to create ‘tailor-made<br />

suits’ that fi t each item perfectly and provide <strong>the</strong>m<br />

with optimal protection.<br />

Lechner packs 14,000 different items<br />

each year. Has any of <strong>the</strong>m been a particular<br />

challenge recently?<br />

Robert Saxer: Every item we pack presents a certain<br />

challenge – especially goods weighing more than<br />

15-20 tonnes. And we did indeed have one particular<br />

challenging item recently – a simulator <strong>for</strong> a special<br />

vehicle, about <strong>the</strong> size of a 20-foot container and<br />

jam-packed with high-tech equipment. Two of my<br />

colleagues spent two days packing it.<br />

You and your team also develop and<br />

produce special packaging.<br />

Robert Saxer: That’s right - often used to transport<br />

goods worth millions. For example, we recently produced<br />

cases <strong>for</strong> <strong>the</strong> ‘Der Blaue Reiter’ art collection.<br />

82 cases <strong>for</strong> 82 paintings, each one air-conditioned<br />

and insulated to provide optimal protection.<br />

Thank you very much <strong>for</strong><br />

talking to us!<br />

Robert Saxer, Site Manager <strong>for</strong> Georg Lechner GmbH,<br />

Unterhaching

8<br />

Photo: Daimler AG

ROAD SERVICES | 9<br />

INTELLIGENT LOGISTICS FOR<br />

THE AUTOMOTIVE INDUSTRY<br />

For decades <strong>the</strong> <strong>Geis</strong> Group has been providing <strong>logistics</strong> services to <strong>the</strong> <strong>automotive</strong> <strong>industry</strong><br />

and its suppliers. Now one of its large area freight <strong>for</strong>warder contracts has been extended and expanded.<br />

Did you know? A car nowadays consists of<br />

no less than 12,000 individual parts. And<br />

because car manufacturers have <strong>for</strong> years<br />

focused on core manufacturing, <strong>the</strong> remaining production<br />

processes are increasingly handed over to<br />

suppliers. As a result, around 80 per cent of all car<br />

parts, from airbags to spark plugs, are today produced<br />

by external suppliers. As an area contract<br />

freight <strong>for</strong>warder <strong>the</strong> <strong>Geis</strong> Group ensures that <strong>the</strong>se<br />

are transported securely and on time to <strong>the</strong> respective<br />

manufacturer‘s production facility.<br />

“We have been active as an area contract freight <strong>for</strong>warder<br />

in <strong>the</strong> <strong>automotive</strong> sector and taking care of<br />

procurement <strong>logistics</strong> <strong>for</strong> renowned car manufacturers<br />

<strong>for</strong> almost 20 years,” says Klaus Stäblein, Managing<br />

Director of Hans <strong>Geis</strong> GmbH + Co. “Screws,<br />

engine components, driver’s cabs – we supply plants<br />

and external warehouses throughout Germany with<br />

products such as <strong>the</strong>se, on time and from a clearly<br />

defi ned area.” On time in this case means that <strong>the</strong><br />

<strong>Geis</strong> Group supplies <strong>the</strong> goods on <strong>the</strong> day after <strong>the</strong><br />

order is placed.<br />

GROUPAGE, MILK RUNS AND DIRECT SERVICES. <strong>Geis</strong>‘<br />

service begins with <strong>the</strong> punctual collection of <strong>the</strong><br />

goods from <strong>the</strong> supplier – usually between 10am and<br />

8pm. The way in which delivery is subsequently carried<br />

out depends on <strong>the</strong> cargo volume: “First of all<br />

we consolidate classic groupage consignments up to<br />

around 2,500 kg – as well as based on volume – at<br />

our hubs in Bad Neustadt and Nuremberg, be<strong>for</strong>e<br />

<strong>for</strong>warding <strong>the</strong>m to <strong>the</strong> plants,” explains Klaus Stäblein.<br />

“Exceptions include directly-driven partial<br />

consignments, so-called milk runs, and container<br />

loads, which our drivers take directly from <strong>the</strong> suppliers<br />

to <strong>the</strong> respective car plants.”<br />

Delivery takes place on <strong>the</strong> day following pickup,<br />

and in <strong>the</strong> case of just-in-time delivery within <strong>the</strong><br />

timeframe agreed with <strong>the</strong> plant. Klaus Stäblein:<br />

“Generally <strong>the</strong> timeframe <strong>for</strong> receipt of goods is between<br />

5am and 8pm. The individual timeframes <strong>for</strong><br />

our shipments are usually between 30 and 60 minutes<br />

– <strong>the</strong>re‘s no room <strong>for</strong> hitches of any kind.”<br />

<strong>Geis</strong> utilises all types of commercial vehicles to<br />

transport goods – from short-haul trucks to megatrailers.<br />

“The choice of truck is determined entirely<br />

by requirements,” says Klaus Stäblein. “What collec-<br />

tion facilities does a supplier have? Which sites are<br />

to be supplied? Are we transporting bulky or heavy<br />

goods?” Successful area contract freight <strong>for</strong>warding<br />

<strong>the</strong>re<strong>for</strong>e calls <strong>for</strong> intelligent planning.<br />

CONTRACT EXTENDED. One example of a well-run<br />

area freight <strong>for</strong>warder contract is <strong>the</strong> <strong>Geis</strong> Group‘s<br />

long-standing collaboration with Daimler AG. On<br />

1 July this year this contract was extended and expanded,<br />

so that <strong>the</strong> <strong>Geis</strong> Group now covers an even<br />

larger area <strong>for</strong> Daimler.<br />

Additional suppliers in Thuringia, Hesse and Lower<br />

Saxony are now serviced from Bad Neustadt, with<br />

Nuremberg servicing additional suppliers in Upper<br />

and Lower Franconia. A total of around 560 suppliers<br />

now belong to <strong>the</strong> <strong>Geis</strong> area. Klaus Stäblein: “We are<br />

very pleased that <strong>the</strong> areas have been extended and<br />

volumes increased. 14 employees now work on this<br />

contract at Bad Neustadt, and twelve at Nuremberg.”<br />

A THOUSAND TONNES EACH DAY. <strong>Geis</strong> now supplies<br />

vehicle, truck and bus parts to 14 Daimler sites from<br />

Bad Neustadt and Nuremberg, as well as to various<br />

warehouses and affi liated companies. Freight volumes<br />

currently stand at 1,000 tons a day, requiring<br />

<strong>the</strong> use of around 65 vehicles on a daily basis.<br />

A project of this scale has certain challenges. Klaus<br />

Stäblein: “The widening of <strong>the</strong> area means that distances<br />

to suppliers inevitably increase. Of course<br />

what we have to do is to comprehensively process<br />

customer orders as economically and as environmentally-friendly<br />

as possible, whilst also taking into<br />

account time and quality parameters. Daimler have<br />

<strong>for</strong> years put <strong>the</strong>ir trust in us, and we aim to live up<br />

to it each and every day – it’s no good resting on our<br />

laurels.” —

10 | LOGISTICS SERVICES<br />

WORLD CHAMPION<br />

CHOOSES GEIS<br />

Amplid, a company belonging to <strong>the</strong> many-times snowboarding world champion Peter Bauer,<br />

is a successful manufacturer of snowboards and skis. <strong>Geis</strong> now manages <strong>the</strong> <strong>logistics</strong> of <strong>the</strong><br />

Amplid online shop.<br />

Photo: Amplid<br />

Peter Bauer and skier Anian Thrainer<br />

founded Amplid six years ago, and bucking<br />

<strong>the</strong> trend in <strong>the</strong> skiing and snowboarding<br />

market are enjoying great success. Sales of<br />

Amplid‘s snowboards and freestyle skis <strong>for</strong> discerning<br />

customers are doubling each year. Sales via <strong>the</strong><br />

Amplid online shop are also on <strong>the</strong> increase, and no<br />

wonder in view of Amplid‘s young and young-a<strong>the</strong>art<br />

customer base.<br />

Until last year, Amplid organized <strong>the</strong> warehousing<br />

and shipping of its online orders itself – from an outbuilding<br />

at its headquarters in Fischbachau, Upper<br />

Bavaria. Now <strong>the</strong> young company has chosen <strong>the</strong><br />

<strong>Geis</strong> Group to carry out <strong>the</strong> work. “The chemistry<br />

was <strong>the</strong>re right from <strong>the</strong> start,” says Peter Bauer.<br />

“And as we had thoroughly prepared everything –<br />

EAN codes <strong>for</strong> all <strong>the</strong> products, <strong>for</strong> example, and<br />

special boxes <strong>for</strong> <strong>the</strong> skis – everything went smoothly<br />

right from day one.”<br />

<strong>Geis</strong> integrated <strong>the</strong> online shop <strong>logistics</strong> into <strong>the</strong><br />

warehouse at Seubtendorf. “We pick, pack and send<br />

orders at <strong>the</strong> click of a mouse throughout <strong>the</strong> whole<br />

of Europe,” explains Hans-Peter Schneider, responsible<br />

<strong>for</strong> transregional sales activities in <strong>the</strong> <strong>Geis</strong><br />

Group. “Fur<strong>the</strong>rmore we off er Amplid an important<br />

additional service: our employees mount fi ttings individually<br />

onto skis according to customer specifi cations,<br />

enabling <strong>the</strong>m to head straight <strong>for</strong> <strong>the</strong> slopes.”<br />

<strong>Geis</strong> delivers orders on time even at peak times in<br />

<strong>the</strong> winter: “Thanks to our fl exible team, we can<br />

easily absorb seasonal peaks and provide immediate<br />

delivery even in winter,” says Schneider. Peter Bauer<br />

also appreciates <strong>the</strong> <strong>Geis</strong> Group‘s fl exibility: “Even<br />

though we‘re just a small online shop, <strong>Geis</strong> gives us<br />

a totally professional service. To date not one single<br />

product has been delivered incorrectly. What more<br />

could we ask <strong>for</strong>?!” —<br />

Amplid co-founder Peter Bauer

From Hof to all four corners of <strong>the</strong> world<br />

In Upper Franconia, <strong>Geis</strong> operates a 34,000 square metres European central warehouse <strong>for</strong> <strong>the</strong> trading and <strong>logistics</strong><br />

concern REWE Group. Here speed, precision and fl exibility are of <strong>the</strong> essence.<br />

Coming along in leaps and bounds<br />

Following preparatory ground and foundation works,<br />

construction work began in earnest at <strong>the</strong> beginning<br />

of July. First, precast concrete components were delivered<br />

<strong>for</strong> <strong>the</strong> building structure, with assembly work<br />

beginning immediately afterwards. “Work is visibly<br />

progressing almost on an hourly basis,” says Martin<br />

Vonderau, <strong>the</strong> <strong>Geis</strong> Group‘s construction project<br />

manager. “Two large mobile cranes are assembling<br />

<strong>the</strong> parts in quick succession. Everything is on schedule<br />

and <strong>the</strong> rail link is already coming in useful, even<br />

during <strong>the</strong> construction phase.”<br />

ENVIRONMENTALLY-FRIENDLY STEP BY STEP. Thanks<br />

to <strong>the</strong> rail link, <strong>the</strong> entire shell structure can be delivered<br />

directly to <strong>the</strong> site by rail from Bremer AG in<br />

Paderborn, where <strong>the</strong> general contractor has its own<br />

large prefabrication factory. The around 880 fi nished<br />

components manufactured at <strong>the</strong> factory <strong>for</strong> <strong>Geis</strong>‘ <strong>logistics</strong><br />

centre will be delivered to <strong>the</strong> site on around<br />

150 rail cars. This corresponds to a building mass of almost<br />

4,000 cubic metres and a weight of around 10,000<br />

tonnes. At <strong>the</strong> end of July, roof and facade works began<br />

where rough assembly had been completed. <strong>Geis</strong>‘<br />

largest <strong>logistics</strong> centre will be taken into operation in<br />

October. Of <strong>the</strong> approximately 30,000 square metres<br />

of space, a third will be used by Siemens Enterprise<br />

Communications GmbH & Co. KG. 5,000 square<br />

metres will be occupied by <strong>Geis</strong>’ own packaging plant<br />

<strong>for</strong> large machinery and industrial components, which<br />

will include ground level access entrance and two crane<br />

systems with a 20 tonne hoisting capacity. “In <strong>the</strong> future<br />

<strong>the</strong>re<strong>for</strong>e, we will be capable of lifting real heavyweights,”<br />

says Martin Vonderau delightedly. —<br />

Autumn: days grow shorter, <strong>the</strong> wea<strong>the</strong>r worsens, and<br />

shoes get dirtier. Cue <strong>the</strong> start of Rewe’s Europe-wide<br />

‘doormat’ campaign. So what is <strong>the</strong> best method of getting<br />

50,000 doormats to Rewe’s 4,500 <strong>for</strong>eign<br />

stores in 15 European countries as quickly as<br />

possible? “The packaging must be perfect and<br />

<strong>the</strong> pallets need to be labelled with country,<br />

goods and customer in<strong>for</strong>mation,” says Erik<br />

Lassen, Managing Director of <strong>Geis</strong> <strong>Logistics</strong><br />

+ Trade GmbH. “Moreover we‘re very<br />

fl exible, thanks to our strong pool of temporary staff ,<br />

which is available to us at short notice.” Speed and<br />

pooled manpower are also required <strong>for</strong> <strong>the</strong> processing<br />

LOGISTICS SERVICES | 11<br />

of returns. <strong>Geis</strong> returns goods that have not been sold<br />

or are defective to Hof, where <strong>the</strong>y are immediately<br />

sorted and categorized into goods that can be sold or<br />

need to be returned to <strong>the</strong> supplier.<br />

TOTALLY SATISFIED. “We coordinate all schedules <strong>for</strong><br />

Rewe, and toge<strong>the</strong>r with our sister company, Spedition<br />

Bischoff , take care of all transportation,” says<br />

Erik Lassen. Thanks to <strong>the</strong> centralized warehouse<br />

concept, only full truckloads go out on <strong>the</strong> road – this<br />

is both effi cient and environmentally friendly. Erik<br />

Lassen: “Rewe have just extended <strong>the</strong> contract, something<br />

we‘re naturally very pleased about.” —<br />

Since <strong>the</strong> ground-breaking ceremony on 14 June <strong>for</strong> <strong>Geis</strong>’ multi-user <strong>logistics</strong> and technology centre in Frauenaurach,<br />

construction has been proceeding at full speed.<br />

Breaking ground toge<strong>the</strong>r (from <strong>the</strong> left): Hans-Georg <strong>Geis</strong> (Managing Partner), Dr. Siegfried Balleis<br />

(Lord Mayor of Erlangen), Wolfgang <strong>Geis</strong> (Managing Partner), Josef Ellebracht (Bremer Bau Director),<br />

Dr. Johannes Söllner (Managing Director of <strong>Geis</strong> Holding) and Martin Vonderau<br />

(<strong>Geis</strong> Group Head of Construction+Facility Management)

12 | AIR + SEA SERVICES<br />

‘BIRTH ASSISTANCE‘ FOR<br />

THE AIRBUS A 400 M<br />

In January, Airbus transported <strong>the</strong> initial components of <strong>the</strong> A 400 M military<br />

transport aircraft to Dresden <strong>for</strong> load testing. <strong>Geis</strong> <strong>SDV</strong> helped load <strong>the</strong> cockpit<br />

and fuselage of <strong>the</strong> Airbus newcomer.<br />

At Dresden Airport in frosty temperatures,<br />

everything was ready <strong>for</strong> <strong>the</strong> unloading of<br />

<strong>the</strong> cockpit. The only thing left to be done<br />

was to de-ice <strong>the</strong> special mounting plat<strong>for</strong>m that <strong>Geis</strong><br />

<strong>SDV</strong> had brought in advance from Toulouse to Dresden<br />

and assembled in just four days. Once <strong>the</strong> de-icing<br />

had been completed, <strong>the</strong> unloading of <strong>the</strong> eight-tonne<br />

cockpit from <strong>the</strong> belly of <strong>the</strong> Airbus Beluga could begin.<br />

<strong>Geis</strong> at <strong>the</strong> Aircraft Interiors Expo 2010<br />

From 18 to 20 May 2010, <strong>Geis</strong> <strong>SDV</strong> attended <strong>the</strong><br />

world‘s leading trade fair <strong>for</strong> aircraft interiors, <strong>the</strong><br />

‘Aircraft Interiors Design & Cabin Systems Engineering<br />

Expo’ in Hamburg. Around 7,300 trade<br />

fair visitors visited <strong>the</strong> <strong>Geis</strong> <strong>SDV</strong> stand, where <strong>Geis</strong><br />

<strong>SDV</strong> and <strong>SDV</strong> experts in<strong>for</strong>med <strong>the</strong>m about <strong>the</strong><br />

various spare parts services off ered by <strong>the</strong> Aerospace<br />

Division. This was <strong>the</strong> third time <strong>for</strong> <strong>Geis</strong><br />

<strong>SDV</strong> to attend <strong>the</strong> fair, and it was <strong>the</strong> only <strong>logistics</strong><br />

services provider present. “As always, we made<br />

a large number of interesting contacts,” says Jan<br />

Kleine-Lasthues, Head of Sales Aerospace Division<br />

at <strong>Geis</strong> <strong>SDV</strong>. “We will certainly be <strong>the</strong>re again<br />

next year.” —<br />

“It was defi nitely ‘precision work’!” says project leader<br />

Tim Oliver Kramp. “But in <strong>the</strong> end, everything went<br />

to plan.” The next day, at <strong>the</strong> exact same place, <strong>Geis</strong><br />

<strong>SDV</strong> unloaded <strong>the</strong> 31-tonne fuselage of <strong>the</strong> A 400 M,<br />

which once again called <strong>for</strong> perfect visual judgement.<br />

According to Xavier Masson, Project Leader at Airbus<br />

Transport Industrie, everything again went well,<br />

thanks to <strong>the</strong> <strong>Geis</strong> <strong>SDV</strong> team. —<br />

The trade fair team (from <strong>the</strong> left): Hortense Eble, Konstanze<br />

Ahner, Jan Kleine-Lasthues and Thomas Pupp (all from <strong>Geis</strong> <strong>SDV</strong>),<br />

and Ling Jin and Lee Purdy from <strong>SDV</strong><br />

New: <strong>Logistics</strong> <strong>for</strong><br />

ISOTRONIC<br />

Since 1 March of this year,<br />

<strong>Geis</strong> <strong>SDV</strong> has been<br />

processing sea and air<br />

freight imports from <strong>the</strong><br />

Far East <strong>for</strong> ISOTRONIC.<br />

The team at <strong>the</strong> Hamburg<br />

<strong>logistics</strong> centre also takes<br />

care of warehousing and<br />

distribution of fi nished<br />

goods to traders.<br />

The products sold by<br />

ISOTRONIC Mezger KG,<br />

which is based in Horb<br />

am Neckar, range from<br />

energy-effi cient lighting<br />

and electronic insectprotection<br />

to clever<br />

technical gadgets <strong>for</strong> <strong>the</strong><br />

car, house and garden.<br />

All of <strong>the</strong>m are innovative<br />

and environmentally<br />

friendly. ISOTRONIC‘s<br />

largest customers include<br />

<strong>the</strong> national and international<br />

DIY chains, and<br />

supermarkets, which<br />

sell <strong>the</strong> goods in <strong>the</strong>ir<br />

non-food sections.<br />

„Particularly challenging<br />

in <strong>the</strong> case of ISOTRONIC<br />

are <strong>the</strong> just-in-time deliveries<br />

to DIY stores and<br />

supermarkets,“ says Reiner<br />

Riksen, Logistic Manager<br />

Germany at <strong>Geis</strong> <strong>SDV</strong>.<br />

At <strong>the</strong> end of March this<br />

year, <strong>Geis</strong> <strong>SDV</strong> distributed<br />

a total of 10,500 boxes<br />

of ISOTRONIC promotional<br />

items across Europe.<br />

“Spread across a total<br />

of 267 Euro pallets, <strong>the</strong><br />

boxes went to 64 different<br />

supermarkets in Italy,<br />

Spain, England and many<br />

o<strong>the</strong>r countries,“ explains<br />

Reiner Riksen. “Despite<br />

several shipments from<br />

<strong>the</strong> Far East being<br />

delayed, we managed<br />

to deliver everything<br />

‘just-in-time’.“ —

Helicopter from India<br />

transported safely<br />

At <strong>the</strong> beginning of May, <strong>Geis</strong> <strong>SDV</strong>,<br />

toge<strong>the</strong>r with Indian colleagues<br />

from <strong>SDV</strong>, transported a Eurocopter<br />

EC 155 from Uttar Pradesh near<br />

Delhi to Kassel.<br />

Be<strong>for</strong>e being transported to Germany, <strong>the</strong><br />

helicopter, weighing almost fi ve tonnes,<br />

had fi rst to be dismantled and packed<br />

ready <strong>for</strong> transportation. Once all <strong>the</strong><br />

parts of <strong>the</strong> Eurocopter had been securely<br />

loaded onto aircraft pallets, everything<br />

was loaded onto three trucks and driven<br />

to <strong>the</strong> airport at Delhi. The 60km journey<br />

to <strong>the</strong> airport took six hours to complete.<br />

Why? Because of <strong>the</strong> diffi cult road conditions<br />

and <strong>the</strong> sensitive nature of <strong>the</strong> load.<br />

Having arrived safely at <strong>the</strong> airport, <strong>the</strong><br />

shipment was transferred onto a freighter<br />

aircraft and fl own directly to Frankfurt am<br />

Main in just eight hours. Two trucks <strong>the</strong>n<br />

delivered <strong>the</strong> helicopter parts to Kassel<br />

on time as <strong>the</strong> fi nal stage in <strong>the</strong> delivery<br />

process. —<br />

ASSIGNMENT IN<br />

SOMALIA<br />

AIR + SEA SERVICES | 13<br />

<strong>Geis</strong> <strong>SDV</strong> recently transported 22 machinery parts with a total<br />

weight of 52 tonnes from South Germany to Somalia.<br />

Somalia, lying at <strong>the</strong> easternmost tip of <strong>the</strong> African continent, is one of <strong>the</strong> socalled<br />

‘failed states’, and UN workers have been providing humanitarian aid in<br />

<strong>the</strong> war-torn region <strong>for</strong> years. A South German company that supports <strong>the</strong> UN<br />

with its mandates worldwide recently commissioned <strong>Geis</strong> <strong>SDV</strong> to deliver an urgently<br />

needed aid shipment on time to <strong>the</strong> UN troops in Mogadishu.<br />

STOPOVER IN UGANDA. From <strong>the</strong> south of Germany, <strong>Geis</strong> <strong>SDV</strong> transported <strong>the</strong> machinery<br />

parts in four low-loaders fi rst of all to Schiphol Airport in Amsterdam, and<br />

<strong>the</strong>n in a Boeing 747F to Entebbe in Uganda. There colleagues from <strong>SDV</strong> reloaded<br />

<strong>the</strong> freight, which weighed several tonnes, onto four Hercules-type charter aircrafts.<br />

Their destination: Mogadishu in Somalia. A technician oversaw <strong>the</strong> unloading and<br />

reloading of <strong>the</strong> consignment in Entebbe on <strong>the</strong> customer‘s behalf.<br />

ASSIGNMENT IN MOGADISHU. Now came <strong>the</strong> tricky part: The long-running civil<br />

war and <strong>the</strong> very diffi cult security situation in Somalia meant that <strong>the</strong> fl ight arrival<br />

time in Mogadishu needed to be precisely coordinated. “The fl ights from Entebbe<br />

to Mogadishu could only start once <strong>the</strong> ‘green light’ had been given by Mogadishu<br />

that <strong>the</strong> planes would be able to land and be unloaded without major problems,” says<br />

Stefan Reitzner, Manager Airfreight Pricing Germany. “In addition, our customer‘s<br />

technician needed to be present in Mogadishu to receive <strong>the</strong> consignment and assemble<br />

<strong>the</strong> machines.” In <strong>the</strong> end, everything went according to plan. The consignment<br />

arrived on time at <strong>the</strong> airport in Mogadishu and was unloaded without incident. —

14 | GENERAL NEWS<br />

New apprentices<br />

In August and September, 60 new apprentices began <strong>the</strong>ir training<br />

at <strong>Geis</strong> sites.<br />

Starting <strong>the</strong>ir <strong>logistics</strong> career at <strong>the</strong> <strong>Geis</strong> Group: <strong>the</strong> new apprentices at Bad Neustadt ...<br />

“We‘re delighted,” says Bernhard Hofmann,<br />

Freight Forwarding Careers Training Offi cer <strong>for</strong><br />

<strong>the</strong> Bad Neustadt head offi ce, Salz and Eichenzell.<br />

“Last year we had to cut down on <strong>the</strong> number of<br />

places off ered because of <strong>the</strong> economic crisis, but<br />

now we‘re back to normal again. Even if demographic<br />

trends and limited numbers of young people<br />

make it increasingly diffi cult to fi nd suitable<br />

apprentices, we‘ve always managed to fi ll all our<br />

training vacancies due to <strong>the</strong> renowned quality of<br />

our training.”<br />

The largest apprenticeship categories at <strong>Geis</strong> remain<br />

as be<strong>for</strong>e <strong>for</strong>warding and <strong>logistics</strong> service specialists,<br />

warehouse <strong>logistics</strong> specialists and warehouse<br />

specialists. O<strong>the</strong>r categories, depending on<br />

location, include professional drivers, offi ce communications<br />

specialists, offi ce administrators, IT<br />

administrators and IT specialists.<br />

Besides site-specifi c training, centralized training<br />

events, primarily <strong>for</strong> <strong>for</strong>warding and <strong>logistics</strong><br />

service specialists, are also increasingly being held.<br />

On 11 June in Kürnach near Würzburg, <strong>for</strong> example,<br />

38 second-year <strong>for</strong>warding and <strong>logistics</strong><br />

service specialist apprentices were taught about<br />

warehouse and transport liability regulations. Also<br />

included was in<strong>for</strong>mation on <strong>the</strong> central insurance<br />

department, a practical presentation by <strong>the</strong> current<br />

<strong>for</strong>warding insurer, and progress checks by<br />

means of group work. Finally, <strong>the</strong> apprentices<br />

were given a tour of <strong>the</strong> Kürnach site. —<br />

... and at Kürnach<br />

New: Head of Key<br />

Account Management<br />

Road Services<br />

Since early 2010 Peter<br />

Gayer has been <strong>the</strong> <strong>Geis</strong><br />

Group‘s Head of Key<br />

Account Management<br />

Road Services. This newlycreated<br />

position will help<br />

<strong>the</strong> company bundle its<br />

tenders toge<strong>the</strong>r, <strong>the</strong><br />

number of which has<br />

increased considerably,<br />

and also manage <strong>the</strong>m<br />

centrally. “From Bad<br />

Neustadt I coordinate<br />

<strong>the</strong> regional and national<br />

tenders, as well as enquiries<br />

involving sales<br />

volumes of more than<br />

500,000 euros a year,”<br />

explains Peter Gayer.<br />

“Ano<strong>the</strong>r part of my new<br />

position is looking after<br />

existing large customers.”<br />

Peter Gayer has been<br />

employed by <strong>Geis</strong> since<br />

1989. After a short spell<br />

in <strong>the</strong> sales department,<br />

he became manager<br />

of <strong>the</strong> export department.<br />

In 1995 he went to Plzeň<br />

in <strong>the</strong> Czech Republic <strong>for</strong><br />

two years to work as<br />

<strong>Geis</strong> Transport‘s authorized<br />

representative.<br />

Until <strong>the</strong> end of 2009,<br />

Peter Gayer was National<br />

Forwarding Manager at<br />

Bad Neustadt. —

For more safety<br />

at <strong>the</strong> wheel<br />

Between mid May and <strong>the</strong> end of June, 20<br />

<strong>Geis</strong> drivers based at our Nuremberg site took<br />

part in risk management training. During a<br />

combination of both <strong>the</strong>oretical and practical<br />

seminars, <strong>the</strong> drivers learned how to avoid accidents<br />

and save fuel. Traffi c psychologists accompanied<br />

<strong>the</strong> drivers on <strong>the</strong>ir journeys – including<br />

over lengthier periods of time – and<br />

assessed previous damage. “The fi rst round of<br />

training was a complete success. We plan to<br />

expand <strong>the</strong> project to include o<strong>the</strong>r locations,”<br />

says Michael Deuter, Fleet Department Manager<br />

<strong>for</strong> <strong>Geis</strong> Eurocargo in Nuremberg. —<br />

Successfully reaudited<br />

From 12 to 16 July, TÜV Rheinland visited <strong>the</strong> Naila, Bad Neustadt and<br />

Salz sites, and successfully reaudited <strong>the</strong>m <strong>for</strong> compliance with <strong>the</strong> DIN EN<br />

ISO 9001:2008 quality standard.<br />

<strong>Geis</strong> sites have been selected by rotation <strong>for</strong> auditing each year <strong>for</strong> <strong>the</strong> past 15<br />

years. According to <strong>the</strong> TÜV audit report, in August <strong>Geis</strong>‘ quality management<br />

complied in full, without any aberrations, with <strong>the</strong> strict targets. The quality certifi cate was<br />

<strong>the</strong>re<strong>for</strong>e extended <strong>for</strong> ano<strong>the</strong>r three years. —<br />

In July of this year, all <strong>Geis</strong> Industrie Service<br />

GmbH sites in Bavaria were certifi ed as being<br />

OHRIS-compliant, i.e. having health and safety<br />

management systems that comply with <strong>the</strong><br />

OHRIS (Occupational Health and Risk Management<br />

System) standard. This means that<br />

<strong>the</strong> sites implement structured and uni<strong>for</strong>m<br />

health and safety procedures at work.<br />

“In Germany, OHRIS has up until now only<br />

been certifi able in Bavaria and Saxony despite<br />

being internationally recognised,” explains<br />

Christian Wild, Management Representative<br />

<strong>for</strong> <strong>Geis</strong> Industrie Service. “In <strong>the</strong> future, we<br />

will introduce <strong>the</strong> OHRIS standard at our<br />

non-Bavarian sites as well <strong>for</strong> corporate identity<br />

purposes.” The newly-acquired certifi cate<br />

is valid until June 2013. —<br />

<strong>Geis</strong> driver Daniela Zimmermann<br />

took part in <strong>the</strong> training<br />

<strong>Geis</strong> meets <strong>the</strong> OHRIS standard<br />

Dr. Thomas Bauer (right) presents <strong>the</strong> OHRIS Certifi cate<br />

to Ralf Lammering, GIS Managing Director (centre)<br />

and Christian Wild (GIS Management Representative)<br />

GENERAL NEWS | 15<br />

Anniversaries<br />

In recent months, four <strong>Geis</strong><br />

employees have celebrated<br />

<strong>the</strong>ir 25 th and 40 th anniversaries<br />

with <strong>the</strong> company.<br />

Roland Dressel has<br />

worked at our Forchheim<br />

site <strong>for</strong> 40 years.<br />

He started working<br />

<strong>for</strong> Siemens on 24 July<br />

1970, and following <strong>the</strong><br />

transfer of <strong>the</strong> operation to <strong>Geis</strong>, came<br />

to be employed by <strong>the</strong> company. He has<br />

been a valuable member of <strong>the</strong> packing<br />

department at <strong>Geis</strong> Industrie Service<br />

(GIS) GmbH since 1 September 1997.<br />

Reinhold Brückling<br />

too worked fi rst <strong>for</strong><br />

Siemens, followed by<br />

GIS. He has worked<br />

at Forchheim since<br />

1 July 1985, where he<br />

is responsible <strong>for</strong> daily scheduling in<br />

<strong>the</strong> scheduling department.<br />

Andreas Schmitt<br />

ensures that accounts<br />

are kept correctly in<br />

Bad Neustadt – and has<br />

done so <strong>for</strong> <strong>the</strong> past<br />

25 years. On 1 July 2010<br />

he celebrated his 25 th anniversary<br />

with <strong>the</strong> company.<br />

Walter Lamprecht‘s<br />

work at <strong>Geis</strong> <strong>logistics</strong><br />

& trade GmbH‘s<br />

warehouse in Hof<br />

encompasses everything<br />

from being<br />

a warehouse employee to being<br />

a <strong>for</strong>k-lift driver and an order picker.<br />

On 21 August 2010 he celebrated<br />

25 years with <strong>the</strong> company.<br />

Hildegard<br />

Kemmerth has<br />

worked at Forchheim<br />

since 23 September<br />

1985. Previously with<br />

Siemens, her work<br />

today includes packing and weighing<br />

individual parts and consignment goods.<br />

The <strong>Geis</strong> Group says a big thank you<br />

to all of <strong>the</strong>m!

<strong>Geis</strong> Industrie-Service GmbH<br />

Phone: +49 911 64178239<br />

E-mail: verpackungsspezialisten@geis-group.de<br />

Conception, production, packing<br />

– we provide tailor-made<br />

packing solutions!<br />

THE PACKING SPECIALISTS<br />

Georg Lechner GmbH<br />

Phone: +49 89 6651850<br />

E-mail: info@lechner-verpackungen.de