CPT International 04/2016

The leading technical journal for the global foundry industry – Das führende Fachmagazin für die weltweite Gießerei-Industrie

The leading technical journal for the

global foundry industry – Das führende Fachmagazin für die

weltweite Gießerei-Industrie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

K MELTING SHOP<br />

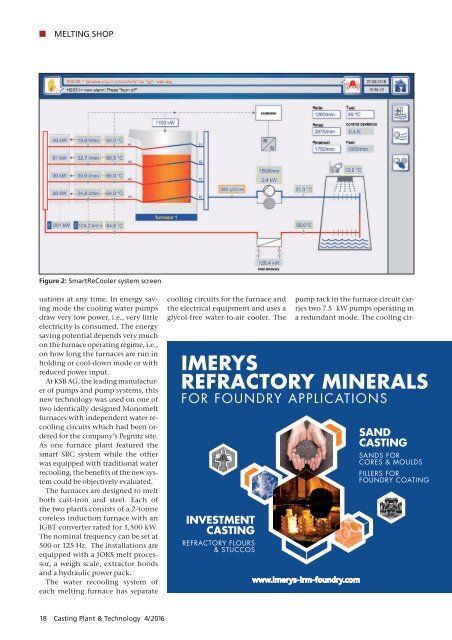

Figure 2: SmartReCooler system screen<br />

uations at any time. In energy saving<br />

mode the cooling water pumps<br />

draw very low power, i.e., very little<br />

electricity is consumed. The energy<br />

saving potential depends very much<br />

on the furnace operating regime, i.e.,<br />

on how long the furnaces are run in<br />

holding or cool-down mode or with<br />

reduced power input.<br />

At KSB AG, the leading manufacturer<br />

of pumps and pump systems, this<br />

new technology was used on one of<br />

two identically designed Monomelt<br />

furnaces with independent water recooling<br />

circuits which had been ordered<br />

for the company’s Pegnitz site.<br />

As one furnace plant featured the<br />

smart SRC system while the other<br />

was equipped with traditional water<br />

recooling, the benefits of the new system<br />

could be objectively evaluated.<br />

The furnaces are designed to melt<br />

both cast-iron and steel. Each of<br />

the two plants consists of a 2-tonne<br />

coreless induction furnace with an<br />

IGBT converter rated for 1,500 kW.<br />

The nominal frequency can be set at<br />

500 or 125 Hz. The installations are<br />

equipped with a JOKS melt processor,<br />

a weigh scale, extractor hoods<br />

and a hydraulic power pack.<br />

The water recooling system of<br />

each melting furnace has separate<br />

cooling circuits for the furnace and<br />

the electrical equipment and uses a<br />

glycol-free water-to-air cooler. The<br />

pump rack in the furnace circuit carries<br />

two 7.5 kW pumps operating in<br />

a redundant mode. The cooling cir-<br />

IMERYS<br />

REFRACTORY MINERALS<br />

FOR FOUNDRY APPLICATIONS<br />

INVESTMENT<br />

CASTING<br />

REFRACTORY FLOURS<br />

& STUCCOS<br />

SAND<br />

CASTING<br />

SANDS FOR<br />

CORES & MOULDS<br />

FILLERS FOR<br />

FOUNDRY COATING<br />

PUB IRM FFA EXE OK.indd 1 05/01/<strong>2016</strong> 11:58:36<br />

18 Casting Plant & Technology 4/<strong>2016</strong>