Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

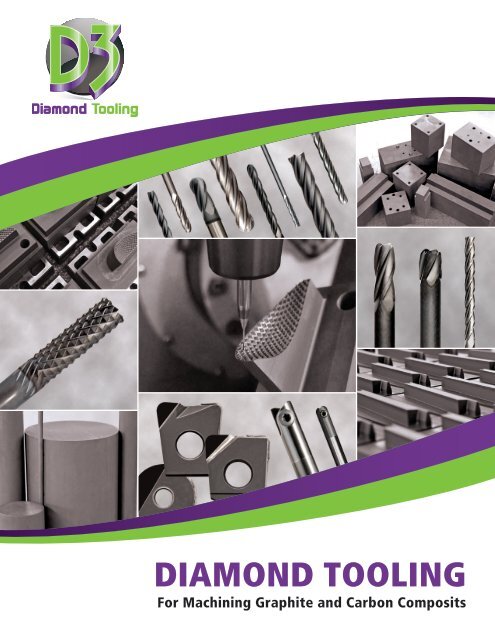

DIAMOND TOOLING<br />

For Machining Graphite and Carbon Composits

DIAMOND MILLS<br />

For Machining Graphite and Carbon Composits<br />

TABLE OF CONTENTS<br />

COATING TYPES<br />

Why Use a diamond coated tool?<br />

Diamond-coated tools last 10 - 20 times longer than bare<br />

tungsten carbide tools allowing almost any job to be<br />

done completely with one tool and with no change due<br />

to wear, no interruption, and no recalibration. Diamond<br />

tools can typically be run two to three times the surface<br />

speed of carbide tools.<br />

Below are the 3 types of diamond coatings used on our<br />

precision cutting tools.<br />

AD-100<br />

Amourphous Diamond<br />

AD-100 is a multi-layered, PVD, amorphous diamond<br />

coating that is designed for graphite machining<br />

with small diameter endmills. The abrasion resistant<br />

quality adds 5 -10 times the cutter life in comparison to<br />

uncoated endmills. AD -100 is a micron thick film that<br />

does not change the shape, size or tolerance. This thin<br />

coating also has an added advantage of a sharp cutting<br />

edge that results in less deflection, which gives better<br />

surface finishes.<br />

AD-100 Ball Mini Mills<br />

page 4<br />

AD-100 Flat and Radius Mini Mills<br />

page 5<br />

AD-100 End Mills<br />

page 6<br />

AD-100 Ball Mills<br />

page 7<br />

CVD-L Flat Mini Mills<br />

page 8<br />

CVD-L Ball Mini Mills<br />

page 9<br />

CVD Diamond End Mills<br />

page 10<br />

CVD<br />

Chemical Vapor Deposition<br />

CVD is a diamond coating that is grown directly<br />

onto carbide tools. This coating produces the highest<br />

degree of hardness and the lowest coefficient of<br />

friction. It has the longest life available for machining<br />

graphite electrodes. It will outlast non-coated end-mills<br />

by 20 - 30 times.<br />

CVD LIGHT<br />

Thin Chemical Vapor Deposition<br />

CVD Diamond Ball End Mills<br />

page 11<br />

CVD Diamond End Mills w/Corner Radius<br />

page 12<br />

CVD Metric Diamond Mills<br />

page 13<br />

PCD — Inserts<br />

page 14<br />

CVD LIGHT is the thinnest of the CVD coatings. You<br />

get the edge sharpness of a thin coating with the<br />

performance of a real diamond coating. This coating<br />

Solid Carbide Holders<br />

was specifically designed for small diameter, ball nose,<br />

page 15<br />

2 endmills with an extended reach.<br />

3