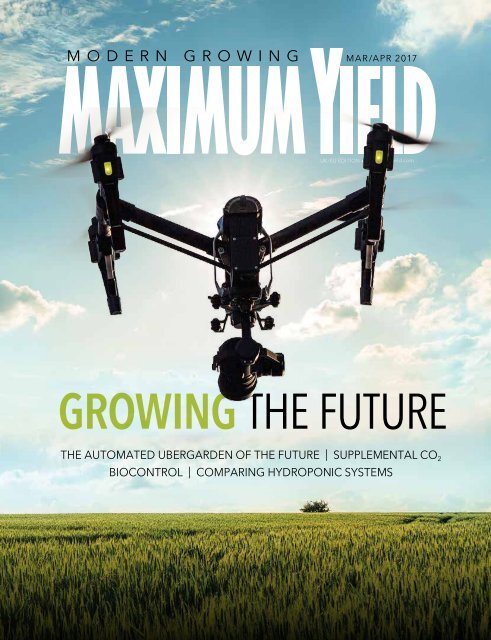

Maximum Yield Modern Growing | UK/EU Edition | March/April 2017

In this issue of Maximum Yield, we explore the changing face of agriculture and its emerging technology. Cory Hughes provides us with a 10,000-foot view of some of the new advancements in traditional agriculture, including automated agriculture, artificial intelligence, and the rise of agbots.

In this issue of Maximum Yield, we explore the changing face of agriculture and its emerging technology. Cory Hughes provides us with a 10,000-foot view of some of the new advancements in traditional agriculture, including automated agriculture, artificial intelligence, and the rise of agbots.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MODERN GROWING<br />

MAR/APR <strong>2017</strong><br />

<strong>UK</strong>/<strong>EU</strong> EDITION • maximumyield.com<br />

GROWING THE FUTURE<br />

THE AUTOMATED UBERGARDEN OF THE FUTURE | SUPPLEMENTAL CO 2<br />

BIOCONTROL | COMPARING HYDROPONIC SYSTEMS

MODERN GROWING<br />

MAR/APR <strong>2017</strong><br />

FEATURES<br />

22<br />

Supplemental CO2: The<br />

Next Step to Ridiculously<br />

Good Plants<br />

by Eric Hopper<br />

Your crops are on a killer nutrition<br />

regimen and living in an indoor<br />

growroom with on-point lighting,<br />

temperature, and humidity. What’s the<br />

next step towards getting ridiculously<br />

good-looking and well-performing<br />

plants? Bring on the CO2.<br />

28<br />

Ready, Tech, Grow:<br />

Emerging Technology<br />

in Agriculture<br />

by Cory Hughes<br />

Technology has created a new kind<br />

of farm and a new kind of farmer.<br />

Utilising automation, artificial<br />

intelligence, and agbots, the role of<br />

the grower is evolving.<br />

6 first feed

first feed<br />

8 from the editor<br />

10 contributors<br />

tapped in<br />

12 ask the experts<br />

14 max facts<br />

18 good to grow<br />

grow cycle<br />

32 Comparing Various Water Culture<br />

Hydroponic Systems<br />

by Frank Rauscher<br />

38 Conduct Yourself Accordingly:<br />

Measuring Electrical Conductivity<br />

for Bigger and Healthier Plants<br />

by Austin Yeany<br />

42 Wintertime Greenhouse Gardening<br />

by Kent Gruetzmacher<br />

46 The Light that Binds: Lighting for Young Plants<br />

by Eric Hopper<br />

52 Biocontrol: A New Age of Pest Management<br />

by Lacey Macri<br />

groundbreakers<br />

you tell us<br />

54 DryGair Energies Ltd.<br />

movers & shakers<br />

56 P.L. Light Systems Inc.<br />

10 facts on... Acid<br />

58 by Philip McIntosh<br />

62 max mart<br />

64 distributors<br />

first feed<br />

7

first feed<br />

from the editor<br />

No matter where you<br />

live, the city or country,<br />

the practice of growing<br />

food is changing in<br />

many exciting ways.”<br />

For the 75-plus per cent of Europeans who reside in<br />

urban areas, it is easy to believe that technology<br />

is reserved only for those who live in the city. Our<br />

city lives, after all, are immersed in technology.<br />

We’re connected by smartphones, transported along<br />

our roads by vehicles with sophisticated computer<br />

systems, and we rely on myriad apps that automate<br />

virtually everything we do. This technological<br />

revolution isn’t reserved just for urbanites, however.<br />

Technology in the field of agriculture is also moving<br />

swiftly forward.<br />

While the modern farmer still maintains his or her<br />

stereotypical elements—they still rise at ungodly<br />

hours—the tools they use are as sophisticated as<br />

any employed in the city. In this issue of <strong>Maximum</strong><br />

<strong>Yield</strong>, we explore the changing face of agriculture<br />

and its emerging technology. Cory Hughes provides<br />

us with a 10,000-foot view of some of the new<br />

advancements in traditional agriculture, including<br />

automated agriculture, artificial intelligence, and<br />

the rise of agbots.<br />

Of course, not everybody is a techie. For many, the<br />

pursuit of growing still means getting their hands<br />

dirty in some soil or maintaining an indoor hydro<br />

system. We’ve got those individuals covered too<br />

with Lacey Macri’s piece on biocontrol and Frank<br />

Rauscher’s comparison between deep water and<br />

NTF systems.<br />

No matter where you live, the city or country, the<br />

practice of growing food is changing in many exciting<br />

ways. As always, thanks for reading <strong>Maximum</strong> <strong>Yield</strong><br />

and if you have any questions or comments, feel free<br />

to email us at editor@maximumyield.com.<br />

<strong>March</strong>/<strong>April</strong> <strong>2017</strong><br />

GENERAL MANAGER<br />

Ilona Hawser<br />

EDITORIAL<br />

editor@maximumyield.com<br />

Toby Gorman<br />

Jessica Skelton<br />

Julie Chadwick<br />

ADVERTISING SALES<br />

250.729.2677<br />

SALES MANAGER<br />

Katie Rey - katie.rey@maximumyield.com<br />

ACCOUNT EXECUTIVES<br />

Jed Walker - jed.walker@maximumyield.com<br />

Michelle Fraser - michelle.fraser@maximumyield.com<br />

Erik Duivenvoorde - erik@maximumyield.com<br />

Courtenay Althouse - courtenay@maximumyield.com<br />

Hailey Woolgar - hailey@maximumyield.com<br />

DESIGN & PRODUCTION<br />

ads@maximumyield.com<br />

ART DIRECTOR<br />

Alice Joe<br />

GRAPHIC DESIGNERS<br />

Jennifer Everts<br />

Dionne Hurd<br />

Jesslyn Dubyna<br />

Holly Anderson<br />

Samira Saoud<br />

ACCOUNTING<br />

Tracy Greeno - accounting@maximumyield.com<br />

Katie LaFrance - ar@maximumyield.com<br />

<strong>Maximum</strong> <strong>Yield</strong> is published monthly by <strong>Maximum</strong> <strong>Yield</strong><br />

Inc. No part of this magazine may be reproduced without<br />

permission from the publisher. If undeliverable please<br />

return to the address below. The views expressed by<br />

columnists are personal opinions and do not necessarily<br />

reflect those of <strong>Maximum</strong> <strong>Yield</strong> or the editor.<br />

2339 A Delinea Place, Nanaimo, BC V9T 5L9<br />

Phone: 250.729.2677; Fax 250.729.2687<br />

<strong>UK</strong> DISTRIBUTION<br />

Century Grow Systems • Easy Grow Ltd.<br />

Erith Horticulture • Nutriculture <strong>UK</strong> • Dutchpro<br />

AUSTRALIAN DISTRIBUTION<br />

Dome Garden Supply • Holland Forge<br />

House N’ Garden • Hydroponic Generations<br />

Growlush • Way to Grow • Nutrifield<br />

USA DISTRIBUTION<br />

BWGS • Florida Hydroponics<br />

General Hydroponics • Humbolt Wholesale<br />

Hydrofarm National Garden Wholesale/Sunlight Supply<br />

Nickel City Wholesale Garden Supply<br />

Tradewinds • Urban Agricultural<br />

CANADIAN DISTRIBUTION<br />

Brite-Lite Group • Biofloral Hydrotek<br />

Eddis Wholesale • Green Planet Wholesale<br />

Greenstar Plant Products Inc. • Growers Paradise<br />

8<br />

first feed

first feed<br />

#maximumyield<br />

Win CANNABOOST!<br />

Enter to win with CANNA! Some<br />

lucky fans will get the chance to win a<br />

0.25-liter, 1-liter or 5-liter bottle of their<br />

incredible bloom stimulant. Simply visit<br />

cannagardening.com/boost and enter<br />

your email address to be entered to<br />

win. Invite a few friends to increase your<br />

chances of winning!<br />

Competition ends Feb. 28, <strong>2017</strong>.<br />

contributors<br />

ERIC HOPPER’S past<br />

experiences within<br />

the indoor gardening<br />

industry include being<br />

a hydroponic retail store<br />

manager and owner.<br />

Currently, he works as<br />

a writer, consultant, and product tester for<br />

various indoor horticulture companies. His<br />

inquisitive nature keeps him busy seeking<br />

new technologies and methods that could<br />

help maximise a garden’s performance.<br />

CORY HUGHES<br />

is a former police<br />

officer turned full-time<br />

commercial grower in<br />

Denver, Colorado.<br />

Grand Prize Winner<br />

Getting your feet wet in hydroponics<br />

is not easy. However, when my local<br />

shop gave me a copy of your informative<br />

magazine, it answered a lot of questions<br />

on how to get started and what I needed. I<br />

am hopelessly hooked on <strong>Maximum</strong> <strong>Yield</strong><br />

now. I'm totally pumped about winning the<br />

grand prize and will most likely use it to<br />

upgrade my old magnetic ballast grow light<br />

with a more energy efficient unit. Thanks!<br />

Michael Forsberg<br />

Editor’s Note: Michael has won <strong>Maximum</strong><br />

<strong>Yield</strong>’s 2016 I’m a Fan grand prize of<br />

$1,000 to spend at his favourite indoor<br />

gardening shop, St. Louis Hydroponic<br />

Company, in St. Louis, Missouri, for telling<br />

us why he loves <strong>Maximum</strong> <strong>Yield</strong>.<br />

Why I love doing what I do...<br />

@austinyeany<br />

LACEY MARCI works<br />

as head of sales at<br />

CleanGrow Ltd., focusing<br />

her time on business<br />

development within the<br />

company. She received<br />

a bachelor’s degree in<br />

communications and psychology from the<br />

University of California, Davis in 2011,<br />

where she worked at the California Aggie<br />

student newspaper on campus.<br />

FRANK RAUSCHER is<br />

a certified horticulturist<br />

and consultant for<br />

the hydroponic and<br />

landscape industry<br />

with a background in<br />

product development.<br />

Frank is a member of the Southern Nevada<br />

Landscape Association and active in the<br />

Southern California green industry, where<br />

his focus is drought-tolerant xeriscapes. He<br />

specialises in discovering the “root-cause”<br />

of plant stress.<br />

While we were on vacation our<br />

window garden plants were quite<br />

busy! @Max_<strong>Yield</strong><br />

@RHoskieWMES<br />

AUSTIN YEANY has<br />

been professionally<br />

involved in the<br />

agriculture and<br />

hydroponics industry for<br />

five years. He operates<br />

a business known<br />

as VGSorganic, where he engineers<br />

custom-made gardens. He is also currently<br />

studying agricultural science.<br />

#ScienceSunday - Healthy roots =<br />

healthy plants = happy farmer.<br />

“Maintaining Healthy Hydroponic Root<br />

Systems” by Dr. Lynette Morgan. Article can<br />

be found on the @maximumyield website.<br />

@nomad.farms<br />

editor@maximumyield.com<br />

@maximumyield<br />

@max_yield<br />

@maximumyield<br />

@maximumyield<br />

maximumyield<br />

KENT GRUETZMACHER<br />

is a California-based<br />

freelance writer and the<br />

west coast director of<br />

business development at<br />

Mac & Fulton Executive<br />

Search and Consulting, an<br />

employment recruiting firm dedicated to the<br />

indoor gardening and hydroponics industries.<br />

He is interested in utilising his Master of Arts<br />

in humanities to explore the many cultural<br />

and business facets of this emerging industry<br />

by way of his entrepreneurial projects.<br />

10 first feed

tapped in<br />

ask the experts<br />

Q<br />

I am growing several types of lettuce in my indoor vertical farm. I<br />

am interested in switching to organic fertilisers so that I can become<br />

Certified Organic. Along with several sources of organic micronutrients,<br />

I have the following organic sources of N-P-K on hand already: Sodium<br />

Nitrate Allganic (16-0-0), Tennessee Brown Phosphate (23 per cent P 2<br />

0 5<br />

),<br />

and Potassium Sulfate Soluble Fines GSL (0-0-50). All of these ingredients<br />

are OMRI approved. How would I go about mixing them to the correct N-P-K<br />

ratios? I have a 20-gallon tank and I am using LED lights and coco coir. I<br />

only want to use plant-based or mined minerals—no animal products—and<br />

I want my homemade hydroponic liquid fertiliser be 8-15-36. If my N-P-K<br />

percentages need to be changed, I am not opposed.<br />

Page<br />

Hello, Page. Thanks for<br />

the detailed information.<br />

Unfortunately, it’s not just<br />

a case of simply switching<br />

A<br />

from normal hydroponic<br />

fertiliser salts to organic<br />

products in a recirculating<br />

system; there are many<br />

factors to consider.<br />

First, although you have the N-P-K<br />

information for the organic products<br />

you want to use, check to see if they<br />

contain the other essential macro<br />

elements required for plant growth,<br />

mainly calcium and magnesium.<br />

Calcium in particular is difficult to<br />

obtain in a readily soluble form for use<br />

in organic hydroponics; most organic<br />

calcium fertilisers are slow release.<br />

So, the organic fertilisers you have<br />

might provide sufficient N-P-K, but<br />

the plants may still not thrive due to a<br />

lack of calcium and magnesium. Also,<br />

without knowing the composition of the<br />

liquid micronutrient products, it’s not<br />

possible to say if these provide all the<br />

trace elements in the correct levels. For<br />

example, iron can be difficult to obtain<br />

in sufficient amounts and in the correct<br />

form for hydroponics.<br />

Second, the sodium nitrate product you<br />

have, while it may be considered organic,<br />

would be fairly toxic in a recirculating<br />

system growing lettuce. It not only<br />

provides nitrate, but also a considerable<br />

amount of sodium that would build<br />

up rapidly in the recirculating system,<br />

eventually causing major growth issues.<br />

Sodium nitrate typically contains 16<br />

per cent nitrogen and 27 per cent sodium,<br />

which is why there are restrictions on<br />

the use of sodium nitrate in organic<br />

production. Often, organic regulations for<br />

producers only allow 20 per cent of total<br />

nitrogen to come from sodium nitrate, so<br />

another source of nitrogen is required.<br />

Next, the phosphate product you have<br />

is unlikely to be very water soluble<br />

and is likely to originate from rock<br />

phosphate. While rock phosphate is<br />

organically allowable, it isn’t intended<br />

to be a slow-release form of potassium<br />

and is usually not soluble enough for<br />

use in recirculating, NFT-type systems.<br />

Potassium sulphate, however, is<br />

soluble and is also used in non-organic<br />

hydroponics, so it can be used as a<br />

potassium and sulphur source.<br />

The ratio of the three organic<br />

products you have listed would be<br />

required, theoretically, at the following<br />

percentages to give the approximate<br />

N-P-K you requested:<br />

• sodium nitrate – 28 per cent<br />

• phosphate – 36 per cent<br />

• potassium sulphate – 36 per cent<br />

This would give an N-P-K of 4-8-18 (as<br />

elements) and 200 grams dissolved into<br />

100 litres of water would give 90 ppm N,<br />

166 ppm P, and 360 ppm K. However, as<br />

pointed out above, it would also give a<br />

toxic level of sodium, and the phosphate<br />

is unlikely to be readily available for<br />

plant uptake due to insolubility.<br />

To make a usable organic nutrient<br />

formulation for hydroponics with a source<br />

of nitrogen that is not sodium nitrate,<br />

many growers start with an organic<br />

liquid base nutrient that is based on fish,<br />

blood, bone, or similar materials because<br />

they contain amino acids/proteins that<br />

are organic sources of nitrogen. The<br />

microbial actions in the substrate or soil<br />

break them down into nitrates for plant<br />

uptake. Alternatively, there are commercial<br />

organic liquid nutrient concentrates<br />

already on the market that could experimented<br />

with in an organic lettuce system.<br />

Kind Regards,<br />

Lynette Morgan<br />

12 tapped in

Q<br />

Hello,<br />

I grew cucumbers the last two winters in my hydroponic<br />

set-up and noticed that the flavour more resembled water<br />

than cucumber. I suspect the temperature in my growing<br />

area is not warm enough. It’s around 24˚C. Any suggestions?<br />

Thanks,<br />

Scott<br />

Hello Scott,<br />

Unlike tomato fruit,<br />

cucumbers don’t tend to<br />

A<br />

develop a particularly<br />

strong flavour: however,<br />

they shouldn’t taste like<br />

water. There can be a<br />

number of causes for a<br />

lack of that distinctive cucumber-ness,<br />

and they are largely related to genetic<br />

and/or growing conditions and nutrition.<br />

Firstly, flavour strength—which is made<br />

up of sugars, acids, volatiles, and other<br />

compounds—varies somewhat between<br />

the different types of cucumbers. Older,<br />

open pollinated varieties and types tend<br />

to have a stronger flavour, but are prone<br />

to bitterness. Greenhouse, hydroponic<br />

hybrids, on the other hand, are milder<br />

in flavour, unlikely to become bitter,<br />

and higher yielding.<br />

<strong>Growing</strong> environment also plays a role<br />

in the development of flavour compounds.<br />

A temperature around 24˚C is fine<br />

(optimal temperatures are 22-28˚C) unless<br />

the nights are much colder than this.<br />

Nutrients play a significant part in<br />

cucumber quality, too, as the plant has a<br />

high requirement for potassium (K) in the<br />

fruiting stages. It’s recommended to use<br />

a K booster or high-K fruiting formulation<br />

during fruit development, along with some<br />

additional calcium. Also, run a higher<br />

EC in winter (around two to 2.2). Some<br />

growers have found the addition of silicon<br />

to the nutrient solution assists flavour and<br />

fruit quality in cucumbers, too. However,<br />

silicon supplements can push the pH of the<br />

nutrient solution up, so that requires extra<br />

monitoring and adjustment.<br />

Avoiding overwatering and saturation<br />

of the growing medium also assists with<br />

improving compositional fruit quality<br />

and flavour strength. Light may be<br />

another issue; cucumbers need a lot of<br />

light, and if sufficient light is not present<br />

for maximum photosynthesis, the fruit<br />

won’t get enough sugars. This can result<br />

in poor flavour. Similarly, if the plants<br />

are carrying a high fruit load, then the<br />

supply of sugars (assimilate) allotted to<br />

each individual fruit is restricted. In this<br />

case, pruning fruitlets to reduce numbers<br />

may be beneficial.<br />

Finally, the stage at which the<br />

cucumber fruit are harvested and<br />

how they might be stored also plays a<br />

role with flavour. Cucumbers that are<br />

harvested fairly immature tend to have<br />

a milder, less developed flavour, while<br />

those that are over mature develop a<br />

watery, sometimes bitter flavour. Once<br />

harvested, cucumbers should be eaten<br />

as soon as possible. They do store well<br />

under refrigeration wrapped in plastic,<br />

but if storage is more than a couple of<br />

days, this does reduce compositional<br />

quality. The cool conditions in the<br />

refrigerator are likely to effect volatiles<br />

that contribute significantly to that<br />

cucumber flavour.<br />

Hope that helps, and good luck<br />

with the next crop.<br />

Kind regards,<br />

Lynette Morgan<br />

Dr. Lynette Morgan holds a B. Hort. Tech. degree<br />

and a PhD in hydroponic greenhouse production from<br />

Massey University, New Zealand. Lynette is a partner<br />

with Suntec International Hydroponic Consultants and<br />

has authored several technical books on hydroponics.<br />

Visit suntec.co.nz for more information.<br />

tapped in<br />

13

tapped in<br />

maxfacts<br />

growing news, tips, & trivia<br />

Powdery Mildew Could Hitch Rides on Bamboo Stakes<br />

There is a body of anecdotal evidence that suggests it is possible to infect plants with powdery<br />

mildew transferred by bamboo stakes. Bamboo is known for disease resistance, but it is not<br />

exempt from carrying mold and mildew spores. The spores lie dormant in bamboo culms until<br />

growth is triggered by moisture, and bamboo stakes in soil are constantly exposed to moisture.<br />

Also, bamboo stakes often arrive at stores with active mildew growth from “cargo sweat”, the<br />

tropical damp climate created in a closed shipping container. It may be beneficial for a grower<br />

to weigh the risks of bamboo against other non-porous alternatives that might be slightly more<br />

expensive but not prone to fungus infections.<br />

- scrogger.com<br />

Learning to Farm on Mars<br />

Shipping food to Mars could cost nearly $1 billion per person per year—so<br />

if people want to live there, growing food on the planet is a necessary<br />

step. It’s a challenge that NASA and the European Space Agency are<br />

working on. However, a non-sanctioned group of urban farmers, food<br />

entrepreneurs, bio-hackers, etc. who call themselves the Mars Farm<br />

Odyssey thinks it can also help in the quest to figure out how space<br />

farming should work. “The collective hive of humanity has more ideas<br />

to offer than a research team buried in a bunker somewhere,” says<br />

member Karin Kloosterman. “And this know-how can be applied<br />

on Earth, too, so young researchers can employ the hive to start<br />

experimentation even without the gravity or resource limitations<br />

one would experience in space.” In a recent meeting in Tel Aviv, the<br />

group focused on developing a citizen science kit that will crowdsource<br />

how particular plants grow, making it possible to build controlled “food<br />

computers” that recreate the climate and nutrients that a crop needs.<br />

- fastcoexist.com<br />

New Research Links Poor Eating and Asthma<br />

Having plenty of fruit and vegetables in your diet could prevent you from<br />

developing asthma, scientists claim. Children living in an area with a lack<br />

of healthy options are 53 per cent more at risk of having the common<br />

condition, says new research from the American College of Allergy,<br />

Asthma, and Immunology. Experts say the findings are a worry as around<br />

one in 10 children live in ‘food deserts’—a poorer area with no fresh<br />

products for a mile. Around 21 per cent of children who lived in a food<br />

desert had asthma—compared to 17 per cent of youngsters living in areas<br />

with closer access to fresh goods. Figures suggest 5.4 million people<br />

in the <strong>UK</strong> suffer from asthma. Nutrient-rich foods help ward off the<br />

condition by boosting the immune system, it is believed.<br />

- dailymail.co.uk<br />

14 tapped in

Recycled Bottle Greenhouses are Helping<br />

Students Learn Lessons About Sustainability<br />

In Suffolk, students from Laxfield Primary School children have made a<br />

greenhouse out of recycled bottles. Under the school’s “food for life”<br />

program, pupils are encouraged to understand how food is grown and<br />

how a combination of good nutrition and physical activity contributes to<br />

a healthier life. Each child has their own space<br />

in the garden and they design their own<br />

planting schemes and then plant their<br />

chosen vegetables, which includes<br />

tomatoes, chillies and peppers.<br />

“Building the greenhouse was a real<br />

team effort,” says Lucy Hammond,<br />

head of school. “The parents<br />

collected hundreds of bottles<br />

for the school to build it. It was<br />

a fantastic recycling exercise for<br />

the children.” Produce from the<br />

school’s garden was recently<br />

served to parents and invited<br />

guests as part of the popular<br />

Aldeburgh Food and Drink Festival.<br />

Staff and pupils served pumpkin soup,<br />

vegetable curry, and apple crumble.<br />

- hydroponics.com.au<br />

Underground Garden in London<br />

to Sell to <strong>UK</strong> Supermarkets<br />

Enter the lift at 1 Carpenter’s Place, a few minutes’ walk from Clapham Common<br />

tube station, and descend 30 metres below London’s bustling streets and you<br />

will be transported to London’s first underground farm. Set in tunnels used<br />

during World War II as a bomb shelter for London<br />

residents, <strong>Growing</strong> Underground is a 2.4-acre,<br />

£1 million crowdfunded project launched<br />

in June 2015. Since its launch, it has<br />

undergone rapid growth and now uses<br />

a sophisticated lighting and irrigation<br />

system to grow a range of crops<br />

including pea shoots, radish,<br />

mustard, coriander, red Amaranth,<br />

mizuna, celery, parsley, and rocket.<br />

Owners Steven Dring and Richard<br />

Ballard started by selling to local<br />

restaurants and just announced their<br />

first venture into the retail market. “Now<br />

we supply various large food service<br />

distributors, including Compass and<br />

BaxterStorey,” says Dring, who spent several<br />

months in talks with <strong>UK</strong> supermarkets. “By May<br />

<strong>2017</strong>, we will be selling to all the major retailers.”<br />

- fginsight.com<br />

tapped in<br />

15

max facts<br />

Flying in Emergency Salads from US after Spanish Floods<br />

Severe flooding in Spain has led to shortages so bad in the <strong>UK</strong> that some supermarkets are<br />

flying produce in from the United States. If you live in the United Kingdom and have made<br />

a New Year’s resolution to eat more salad in <strong>2017</strong>, you might have to rethink your strategy.<br />

Britain is experiencing a significant shortage of green vegetables in its grocery stores,<br />

including iceberg and gem lettuces, broccoli, celery, and citrus fruits like clementines and<br />

satsumas. At this time of year, these fresh foods are typically imported from Murcia, a key<br />

growing area in southeastern Spain that provides 80 per cent of Europe’s produce during<br />

winter months. Extreme flooding and incessant downpours, however, have reduced much of<br />

the harvest to 30 per cent of what it usually is. Celery is down by 40 per cent. Many seedlings<br />

have been lost in the flooding, which means that scheduled harvests in February and <strong>March</strong><br />

will not happen, leading to inevitable further shortages.<br />

- theguardian.com<br />

French Parks and Public Gardens<br />

Bid Adieu to Pesticides<br />

France has officially given the boot to harmful chemicals in outdoor places<br />

where young children, crucial pollinators, and the general public frequently<br />

gather. As reported by the Associated Press, France's pesticide ban<br />

applies to all public parks, gardens, and forests, including famed Parisian<br />

green spaces like Jardin des Tuileries, Bois de Vincennes, and Jardin de<br />

Luxembourg. For now, pesticides can still be freely used—but one would hope in<br />

respectful moderation—at French cemeteries. The manicured turf found at sports<br />

stadiums is also off the hook and can continue to be treated with pesticides. In 2019, the law will<br />

expand from public green spaces to private gardens when the over-the-counter sale of pesticides<br />

to non-professionals becomes a thing of the past. While private residential green spaces are<br />

generally more compact than their public brethren, instances of abuse and misuse of pesticides<br />

by amateur gardeners is common.<br />

- mnn.com<br />

Precision Farming Market to Reach $7.8 billion, by 2022<br />

The Precision Agriculture Market Report, published by Allied Market Research, forecasts that the global market is expected<br />

to garner $7.8 billion (£6.2 billion) by 2022, registering a compound annual growth<br />

rate of 14.9 per cent during the period of 2016 to 2022. Precision<br />

agriculture is a farming technique associated with application of<br />

different technologies and solutions to enable efficient farming<br />

and improve crop yield. Precision agriculture technologies include<br />

GPS, GIS, telematics, variable rate technology (VRT), and remote<br />

sensing. North America presently leads the market, on account of<br />

high investment in agriculture technologies, high awareness levels<br />

and wide internet penetration. Within North America, the US<br />

constitutes over 80 per cent of the market revenue. Furthermore,<br />

Asia-Pacific is likely to exhibit the highest growth, on account of<br />

the increasing adoption of advanced agriculture technologies<br />

such as VRT and drone, mainly in countries such as China and<br />

Japan. It presents significant potential in enhancing food<br />

productivity while at the same time providing sustainable<br />

management of resources.<br />

- whatech.com<br />

16 tapped in

Refugees Plant Roots in new<br />

Hydroponic Community<br />

Garden in Tel Aviv<br />

A new project in Neve Sha’anan,<br />

a neighbourhood of Tel Aviv, is<br />

attempting to connect people<br />

to their food traditions using<br />

a hydroponic community<br />

garden. The neighborhood is<br />

low-income and has attracted<br />

thousands of refugees and<br />

migrants from East Africa. The<br />

idea of the new project Rooftop<br />

Gardens, is to connect all the<br />

parts of this community to one<br />

common denominator: real food<br />

from home. Leading the project is urban farming<br />

consultant Lavi Kushelevich, who is leading more<br />

than a handful of projects to rejuvenate Tel Aviv<br />

and to turn it into a food-producing engine. “We<br />

have now given the residents tools to grow their<br />

own food,” says Kushelevich, “and taught them<br />

about hydroponics, while we bring them seedlings<br />

with tastes of flavours from all over the world where<br />

these people once called home.”<br />

- greenprophet.com<br />

Schools Urged to Go Green For <strong>2017</strong><br />

Schools across the county are being urged to ‘go green’ for <strong>2017</strong> to save<br />

energy, money, and cut carbon emissions. Bucks County Council (BCC) is<br />

offering schools a package of new lighting along with heating and energy<br />

controls as part of its Re:fit scheme—a three year programme launched<br />

in 2015 to reduce energy consumption and cut carbon emissions by 10<br />

per cent. Four schools in Great Harwood, Waddesdon, Hazlemere, and<br />

High Wycombe took part in a pilot scheme which saw an investment of<br />

£115,000. Annual energy cost reductions of more than £11,000 at the<br />

schools will save BCC around a quarter of a million pounds within 25<br />

years. The schools have LED lighting and sensors and Millbrook Combined<br />

School in High Wycombe has had efficient heat and pool pumps fitted.<br />

The RE:fit programme is now open to all schools and the up-front costs<br />

come from interest-free<br />

government-funded loans.<br />

- bucksfreepress.co.uk<br />

tapped in<br />

17

tapped in<br />

good to grow<br />

ask for these products at your local hydro shop<br />

Dewey Mister 14-Site Cloner<br />

Whether you are propagating from seed or cloning a cutting, Dewey Mister’s 14-Site Cloner<br />

outperforms other units on the market. The 14-Site Cloner is a two-gallon food-grade bucket<br />

topped with a specially designed, 14-site sturdy lid that’s fitted and has a built-in channel to<br />

allow the air tube to fit nicely with no crimping and no leaking. Each cloning site is recessed<br />

and sized to fit a MisterSert, which is made of flexible, food-grade material for easy cleaning<br />

and reuse. Say goodbye to neoprene inserts and net pots that make transplanting difficult.<br />

The Cloner is powered by a Dewey Mister, which means no water pumps or air stones are<br />

needed and there are no spray nozzles to ultimately get clogged. Use less water and less<br />

nutrient solution and get better air infusion and faster cloning with an easy-to-use, costeffective<br />

Dewey Mister Cloner.<br />

Dutchpro Starter Pack<br />

for Hydro/Coco<br />

The Dutchpro Starter Pack for<br />

Hydro/Coco provides all the<br />

nutrients and supplements<br />

growers need for grow and<br />

bloom in one box, including<br />

one large bottle of Original<br />

Grow Hydro/Coco, one large<br />

bottle of Original Bloom Hydro/<br />

Coco, and one small bottle<br />

each of Take Root, Explode, and<br />

Multi Total. Grow schedules and<br />

instructions are also included.<br />

This authentic, Amsterdamdesigned<br />

canal house starter<br />

pack is the perfect introduction<br />

to Dutchpro nutrients and additives and<br />

provides the opportunity to give the award-winning<br />

Dutchpro range a try at a significantly reduced price.<br />

ExHale CO 2 Bags<br />

ExHale produces CO 2 for a minimum<br />

of six months to offer a 20 to<br />

30 per cent increase in yield.<br />

Trusted by garden enthusiasts,<br />

ExHale costs only cents a day;<br />

a small investment to make for<br />

guaranteed results in your indoor<br />

garden. ExHale is maintenance-free,<br />

produces no heat, and doesn't<br />

require electricity. With their<br />

award-winning genetics, ExHale<br />

helps take your garden to the next<br />

level of success: healthier plants<br />

and a better finished product.<br />

Proudly made in the US by fellow<br />

gardeners, the staff at ExHale stand<br />

behind their products 100 per cent<br />

and think it’s time growers give their<br />

garden what it wants and needs.<br />

Florafelt Vertical Gardens and Living Walls<br />

Florafelt Vertical Gardens and Living Walls present a whole new way to think about<br />

gardening. Grow a living wall is easy with the Florafelt System. The handmade<br />

pocket planters and robust Pro Systems are designed to use the micro fibres in PET<br />

felt so that all the plants are watered equally. Florafelt is made from recycled plastic<br />

bottles, a nylon non-toxic fibre that is indestructible. This amazing material provides<br />

a safe growing medium that is pH neutral and non-reactive so you can garden<br />

organically right on your wall. It’s especially safe and suitable for vegetables and<br />

herbs. Roots grow right into the felt, which comes alive thanks to the microbiology<br />

in the soil. Planters also come with a customizable Root-Wrapping system that lets<br />

you change and arrange your living wall at will, while maintaining the integrity of<br />

every plant in its own soil.<br />

18 tapped in

AgroLED iSunlight T5 LED<br />

Repower your fixture with Sun System’s new iSUNLIGHT T5, a first in horticultural<br />

lighting. Using the T5 platform, you can easily upgrade your lighting from<br />

fluorescent to LED by switching lamps. The iSUNLIGHT T5 LED is a 41W, 5,500K,<br />

T5 HO replacement LED lamp, and a superior choice for the propagation and<br />

veg cycles of your plants. The iSUNLIGHT T5 lamp is an intelligent LED that is<br />

specifically designed to work with your existing T5 HO fluorescent fixture. The<br />

iSUNLIGHT T5 LED produces more than 5,100 lumens with only 41W of consumed<br />

power. These are environmentally friendly, mercury-free grow lights.<br />

Dutchpro pH- Grow<br />

Dutchpro pH- Grow reduces the pH value in a garden during the growth<br />

stage. This product contains 38 per cent nitric acid, so caution must be used<br />

while handling and storing. To use, growers add small amounts of pH- Grow<br />

during the growth stage until the desired pH level is reached, keeping in mind<br />

the recommended pH level for most plants during the<br />

bloom stage is around 5.8. Dutchpro pH- Grow comes in<br />

a wide variety of sizes and is compatible<br />

with many types of media.<br />

Titan Controls Apollo 18 Two Outlet<br />

Dual Schedule Timer<br />

Imagine running two different timing schedules<br />

from the same timer. Growers have been asking for<br />

this timer for some time and Titan has delivered,<br />

with their new Apollo 18 Dual Outlet Timer. The<br />

Apollo 18 has two separate timing schedules<br />

and can operate two different appliances<br />

simultaneously. This timer features up to eight<br />

total timing schedules. Easy-to-use, built Titanreliable,<br />

and affordably priced, this is a must-have,<br />

breakthrough product for indoor gardeners. The sturdy enclosure resists dust, rust,<br />

and moisture in the often-damp garden environment. This precision digital timer<br />

provides the grower with the perfect timing solution to operate cloning machines,<br />

CO 2 systems, pumps, fans, or other 120V appliances. 15A/60 hertz.<br />

tapped in<br />

19

good to grow<br />

Current Culture H 2 O Under Current and Cultured Solutions<br />

The Under Current systems and Cultured Solutions premium hydroponic nutrients<br />

have combined to create a proven production system. Designed for prolific yields,<br />

quality, and increased efficiency, the revolutionary Under Current system delivers your<br />

best harvest yet. The Under Current system adapts to all growing applications from the<br />

home grower to greenhouse and commercial operations. Made from the highest-grade<br />

greenhouse components, the Under Current system is expandable and accommodates<br />

multiple configurations. The revolutionary Sub-Current Culture technology delivers high levels of<br />

oxygenated nutrient solution throughout the root zone. This results in explosive growth rates and<br />

increased quality and yields. Current Culture's cup-winning Cultured Solutions premium hydroponic<br />

nutrients use the finest materials, resulting in one of the cleanest, pH stable, highly-soluble nutrient lines<br />

available. Cultured Solutions nutrients’ complete line up features VEG A & B, BLOOM A & B, UC ROOTS,<br />

BUD BOOSTERS, and COCO CAL. Cultured Solutions works in all types of applications.<br />

Dutchpro Leaf Green<br />

Dutchpro Leaf Green is used to<br />

achieve good leaf development<br />

in plants, giving them a healthy,<br />

vital look. It is especially<br />

recommended for plants that<br />

have noticeable difficulties<br />

with their development.<br />

Leaf Green also gives plants<br />

with a yellowish tinge a fresh<br />

green color. It’s also great at<br />

improving nutrient uptake. Leaf<br />

Green is non-ammonia-based<br />

and comes ready to use as a<br />

spray-on liquid. Apply at least<br />

three hours before the lights<br />

go on. Dutchpro nutrients are<br />

stable, clear, contain organic<br />

elements, and are available in a<br />

variety of sizes.<br />

Automation GrowSystems<br />

Automation GrowSystems is a technology company<br />

that uses patent-pending hardware, software, and<br />

process control to provide controlled environments for<br />

grow facilities. Its systems decrease costs and allow for<br />

repeatable and tracked growing processes. The system’s<br />

hardware consists of a programmable logic controller,<br />

with low voltage switching, and state-of-the-art sensors<br />

to report and control cycle management. The software<br />

consists of a program code developed specifically for<br />

the grow industry. It allows technology to process the<br />

complete growing cycle from start to finish. An HMI<br />

touchscreen user interface allows for precise control<br />

of adjustable parameters, complete reporting, and<br />

remote access. Automation GrowSystems—Profit Growth<br />

Through Automation.<br />

BudBox Grow Tents<br />

With 14 years of hydroponic engineering experience behind them, BudBox has been<br />

continuously innovating new products from the very start. The first to feature oversized<br />

air ports, electrical and irrigation ports, a flower-friendly green viewing window, militarygrade<br />

zippers, reinforced cover corners, micro mesh passive vents, a fully waterproof<br />

one-piece catchment tray, and a fully clear floor growing area puts BudBox at the top of<br />

the game. With super strong 25-millimetre tempered steel frames, the whole product<br />

range is available in four height options, 18 floor plan sizes, two weights of Mylar (210D<br />

and 600D) and two colours: pro white and silver, with seven per cent more PAR reflectivity<br />

than their nearest competitor. With unprecedented customer support, BudBox delivers<br />

the highest-quality tested, trusted, and certified grow tents. Exclusively available via a<br />

select group of authorised professional partner stores within Europe, the US, and Canada.<br />

20 tapped in

grow cycle<br />

supplemental CO 2<br />

SUPPLEMENTAL CO 2<br />

: THE<br />

NEXT STEP TO<br />

Ridiculously<br />

Good Plants<br />

Your crops are on a killer nutrition regimen and<br />

living in an indoor growroom with on-point lighting,<br />

temperature, and humidity. What’s the next step<br />

towards getting ridiculously good-looking and<br />

well-performing plants? BRING ON THE CO 2 .<br />

BY ERIC HOPPER<br />

22 grow cycle

supplemental CO 2<br />

The greatest advantage of indoor horticulture is having<br />

ultimate control over light cycles, nutrition, and<br />

atmospheric conditions. A grower should do everything in<br />

his or her power to make sure their growroom’s lighting,<br />

nutrition, temperature, and humidity are precise and<br />

consistent. After all, it is only when a plant has access to<br />

sufficient light and balanced nutrients, and is provided<br />

with the appropriate atmospheric conditions, that it will<br />

be able to achieve its full potential.<br />

Once an indoor horticulturist dials in these crucial factors,<br />

he or she can take the next step toward maximizing the<br />

garden’s productivity. This can be done by supplementing<br />

CO 2 into the garden’s atmosphere. Higher levels of CO 2 have<br />

been shown to significantly increase plants’ growth rates<br />

and, therefore, the garden’s yield. On average, ambient air<br />

has around 350-450 ppm of CO 2 (it can be greater in urban<br />

areas with more air pollution). A grower who wishes to<br />

gain all the benefits associated with enriched CO 2 levels<br />

will typically increase CO 2 levels to 1,000-1,500 ppm. This<br />

enrichment can be achieved by a few different methods<br />

combined with specialised CO 2 control devices.<br />

CO 2 AND PHOTOSYNTHESIS<br />

Plants are unique creatures because they can directly<br />

convert light energy into usable energy for growth. This<br />

phenomenon is known as photosynthesis, which can be<br />

using the chemical equation:<br />

6CO 2 + 6H 2 O + light energy = C 6 H 12 O 6 + 6O 2<br />

In the first part of the equation, there is CO 2 (carbon dioxide)<br />

and H 2O (water). When plants have access to these compounds<br />

in addition to light energy, they can produce the second part<br />

of the equation: C 6H 12O 6 (glucose) and O 2 (oxygen).<br />

A grower who<br />

wishes<br />

"<br />

to gain all the benefits associated<br />

with enriched CO 2 levels will typically<br />

increase CO 2 levels to 1,000-1,500 ppm.<br />

It may look and sound complicated, but don’t be alarmed;<br />

you do not need a degree in chemistry to be a successful<br />

grower. Still, it is important to note that photosynthesis is a<br />

chemical reaction. Like other chemical reactions, photosynthesis<br />

can be affected by factors like temperature and the<br />

proper chemical compounds.<br />

One of these crucial chemical compounds is CO 2. Plants<br />

absorb carbon dioxide through the open stomata on their<br />

leaves. Transpiration, which helps keep plants at an even<br />

temperature, occurs when the stomata are open. However,<br />

transpiration results in the loss of water (another significant<br />

chemical compound for photosynthesis); so, to conserve water,<br />

plants regulate the amount of time the stomata are open.<br />

When a grower enriches the environment with CO 2, the<br />

amount of CO 2 available for absorption increases for the<br />

length of time the stomata are open. In other words, the plant<br />

can absorb more CO 2 while still limiting water loss through<br />

24 grow cycle

transpiration. Some experiments have also shown that when<br />

provided with an increased amount of CO 2, plants will not<br />

open the stomata as wide, thus reducing the amount of transpiration.<br />

All in all, increased CO 2 levels will increase the efficiency<br />

of a plant’s water use. Assuming the plant has access<br />

to the necessary nutrients and light energy, the additional CO 2<br />

absorbed, combined with the increased efficiency of water<br />

use, will increase the plant’s rate of growth.<br />

METHODS USED FOR CO 2 ENRICHMENT<br />

There are a few different ways to increase the level of CO 2 in<br />

the garden. For large spaces, the preferred method is generally<br />

a burner. CO 2 burners are fueled by propane or natural<br />

gas. As the fuel is burned, CO 2 is created as a by-product of the<br />

combustion. There are many different burners available and<br />

the size required generally depends on how large of an area<br />

a gardener is trying to enrich. Unfortunately, these devices<br />

also create heat in addition to CO 2. This is usually viewed as a<br />

disadvantage of CO 2 burners because most growers work hard<br />

to remove unwanted heat that is created by the intense lighting<br />

systems. Still, in commercial gardens or in very large growing<br />

facilities, burners are the most effective way to produce the<br />

large amount of CO 2 necessary to enrich the environment.<br />

Another common way to increase CO 2 levels is to use<br />

pure CO 2 contained in a tank or cylinder. This method of<br />

enrichment utilises containers of compressed CO 2 teamed<br />

in commercial gardens or in very<br />

"<br />

large growing facilities, burners are the most<br />

effective way to produce the large amount of<br />

CO 2 necessary to enrich the environment.<br />

with a CO 2 emitter. The emitter regulates the rate at which<br />

the CO 2 is released from the tank and is normally combined<br />

with a timer or controller to determine when the CO 2 should<br />

be released. A compressed tank system is a great choice<br />

for many hobby growers because it is not only effective at<br />

increasing CO 2 levels, but also will not create additional<br />

heat in the garden’s environment.<br />

The final method of CO 2 enrichment commonly used by<br />

indoor horticulturists is mycelium-based CO 2 systems.<br />

These devices can be purchased in buckets, bags,<br />

bottles, boxes, or mats, all of which contain strains of<br />

fungus combined with a food source for that fungus. As<br />

the fungus creates its mycelium (its equivalent to the<br />

vegetative process), it releases CO 2 as a by-product. This<br />

type of CO 2 enrichment is great for small areas, such<br />

as closets or small bedrooms. They are also relatively<br />

inexpensive, which allows a grower to experiment with<br />

CO 2 enrichment without making a huge investment.<br />

grow cycle<br />

25

supplemental CO 2<br />

CONTROLLING CO 2 CONSISTENCY<br />

A grower should team a CO 2 device with some sort of<br />

controller so the emission rate of CO 2 can be regulated<br />

(mycelium-based CO 2 products are the exception as they can’t<br />

be controlled). Using automation devices that control the level<br />

of CO 2 within the room is imperative to both the efficiency<br />

and the effectiveness of the CO 2 system. Many atmospheric<br />

controllers come equipped with built-in CO 2 control systems.<br />

There are also stand-alone systems available.<br />

A good CO 2 controller will essentially automate the<br />

CO 2 system, controlling both the concentration (usually<br />

expressed in ppm) and the appropriate times for operation.<br />

Plants thrive in consistent environmental conditions<br />

and the concentration of CO 2 is no exception. The amount<br />

of CO 2 in the environment is detected by a ‘sniffer’, which<br />

will periodically sample the atmosphere’s concentration of<br />

CO 2 and send a signal to the controller. If the concentration<br />

falls below the system’s set-point, the controller will then<br />

trigger the CO 2 device to turn on. On the other hand, a good<br />

controller will stop the CO 2 unit when exhaust fans are in<br />

operation so the CO 2 is not being removed from the garden<br />

as soon as it is emitted. Newer, software-based control<br />

systems offer additional control features, such as remote<br />

access to the devices and data logging. Data logging of CO 2<br />

levels can provide valuable information over the course of<br />

a few garden cycles and can help a gardener determine the<br />

optimal concentration of CO 2 for their particular crop.<br />

IN GENERAL<br />

Increasing the amount of CO 2 in the atmosphere of an<br />

indoor garden or greenhouse can increase growth rates<br />

when all other factors are considered. This will not only<br />

equate to faster vegetative growth, but also larger yields.<br />

For some growers, increasing the rate of vegetative growth<br />

will allow them to start fruiting or flowering more quickly. A<br />

shorter vegetative cycle can mean more garden cycles per<br />

year and a more profitable garden.<br />

Growers who want to invest in CO 2 equipment should go<br />

all-in. In order to reach the full potential of a CO 2 enriched<br />

environment, growers will not only need equipment for<br />

creating the CO 2, but also the adequate control devices<br />

to automate the system for efficiency. Without the full<br />

package, CO 2 enrichment can be a disappointing venture<br />

with little gained in terms of overall financial investment.<br />

CO 2 enrichment should be viewed as icing on the cake. In<br />

other words, CO 2 systems should be something that growers<br />

add to an already fully functional and productive garden.<br />

The basics of lighting, ventilation, and nutrition should<br />

always be the first priorities for any indoor grower striving<br />

for success.<br />

an indoor garden<br />

enriched<br />

"<br />

with CO 2 will have a slightly<br />

higher optimal temperature range.<br />

TEMPERATURE AND NUTRIENT REQUIREMENTS<br />

As previously mentioned, photosynthesis is a chemical<br />

reaction and, like other chemical reactions, it can be<br />

affected by temperature. A typical indoor garden will have<br />

an optimal temperature range of 21-27°C. An indoor garden<br />

enriched with CO 2 will have a slightly higher optimal<br />

temperature range (usually around 24-29°C).<br />

It is also common for growers to increase the nutrient<br />

concentration in growrooms with increased CO 2 levels.<br />

This makes perfect sense because if the rate of growth<br />

increases, the nutrient requirements will increase as<br />

well. Since nutrient requirements vary, there is no perfect<br />

way to tell the exact nutrient concentration needed. That<br />

being said, a grower can expect to increase his or her<br />

garden’s nutrient concentration by five to 15 per cent when<br />

enriching the atmosphere with CO 2.<br />

26 grow cycle

grow cycle<br />

emerging technology in agriculture<br />

by Cory Hughes<br />

EADY, TECH, GROW:<br />

Emerging Technology in Agriculture<br />

Life on the farm isn’t what it used to be. Where there used to be farm hands and back-breaking<br />

labour, today there is automation, artificial intelligence, and agbots. Cory Hughes explains how<br />

today’s technology has created a new kind of farm and a new kind of farmer.<br />

28 grow cycle

Technology has always been a major<br />

contributing factor in how our lives<br />

are led. It impacts how we communicate,<br />

how we travel, and even how we eat.<br />

Advancements in agricultural technology<br />

are changing how we grow our food and<br />

manage its production. The ultimate<br />

goal of technology in agriculture<br />

is to increase yields, slash harvest<br />

times, and ultimately reduce costs<br />

and environmental impact. Emerging<br />

technologies not only impact farming<br />

on a small scale, but have a drastic<br />

effect on the large-scale system of food<br />

distribution as well. As new technology<br />

becomes integrated with modern<br />

farming, it results in improved production<br />

and easier supply chain management.<br />

Automated Agriculture<br />

Automation is the true focus of<br />

technological advances in agriculture,<br />

and it is already employed on farms<br />

around the world. Automation has come<br />

a long way since the days of mechanical<br />

timers, as modern automation requires<br />

very little assistance from humans.<br />

Systems are being created that can<br />

monitor, feed, and harvest crops from<br />

seed through to sale. Automation<br />

combines the use of a wide array<br />

of sensors, computers, feeding<br />

mechanisms, and everybody’s favourite:<br />

robots. Complete automation is a nearly<br />

self-sustaining system that can handle<br />

all day-to-day activities on the farm.<br />

It all but removes the need for human<br />

staffing, which can be good or bad<br />

depending on how you look at it. One<br />

of the core resources of automation is a<br />

vast network of sensors.<br />

Crop, air, and soil sensors are expected<br />

to be the backbone of future automated<br />

farming. While sensors are currently<br />

able to determine basics like pH, the<br />

sensors of tomorrow will be able to do<br />

much more than that. Soil and crop<br />

sensors will not only be able to read<br />

nutrient levels and EC, they will be<br />

able to perform more detailed analysis<br />

using infrared, electromagnetic, and<br />

acoustic means. Having more data can<br />

save crop growers time and money by<br />

allowing them to break from strict feed<br />

schedules to take a more as-needed<br />

approach. Equipment sensors will also<br />

be used to relay information from smart<br />

technology to a central control unit in<br />

order to warn of potential machinery<br />

failures or malfunctions. Just about any<br />

metric that can be measured will have<br />

a sensor constantly communicating<br />

with a centrally controlled artificial<br />

intelligence system.<br />

“<br />

The ultimate goal of<br />

technology in agriculture is to<br />

increase yields, slash harvest<br />

times, and ultimately reduce costs<br />

and environmental impact.“<br />

Artificial Intelligence<br />

The use of artificial intelligence, or AI,<br />

will make automated systems more<br />

adaptable to shifting conditions. Not<br />

only that, AI agricultural systems will be<br />

able to analyse, diagnose, and prescribe<br />

proper treatment programs for crops at a<br />

level of efficiency unmatched by humans.<br />

Now, we’re not talking about The<br />

Terminator when we talk about AI. For<br />

the time being, AI is simply a complex<br />

computer system that has the ability<br />

to adapt to new stimuli. AI systems in<br />

agriculture work to better coordinate<br />

mechanical systems, create feed schedules,<br />

diagnose illness, and ultimately<br />

increase yields and productivity. How do<br />

they do this? One of the more exciting<br />

technologies that will be coordinated by<br />

AI in agriculture is that of drones.<br />

grow cycle<br />

29

emerging technology in agriculture<br />

Drones are popping up everywhere.<br />

They are cool and fun and seem to<br />

have way more practical uses than<br />

anyone could have imagined. Farmers<br />

can fly a surveillance drone over acres<br />

of crops and take real-time photos<br />

and video. They can also be fitted to<br />

monitor crop temperatures in the colder<br />

months. Currently, drones are being<br />

used on farms not only for surveillance,<br />

but application as well. Cropspraying<br />

drones are one of the latest<br />

iterations of unmanned aerial vehicles<br />

(UAVs) found on today’s modern<br />

farm. Crop-spraying drones can apply<br />

pesticides or fertilisers and are unimpeded<br />

by rough terrain. Aerial drones<br />

aren’t the only ones having all the fun.<br />

Autonomous robots are also having an<br />

impact on modern farming.<br />

“ Today, drone-like<br />

autonomous robots<br />

are starting to be used<br />

to perform tasks like<br />

planting seeds, tending<br />

crops, and harvesting.“<br />

The Rise of Agbots<br />

The farms of tomorrow may no longer<br />

need people to grow crops at all. Today,<br />

drone-like autonomous robots are being<br />

used to perform tasks like planting<br />

seeds, tending crops, and harvesting. A<br />

variety of drone farmhands are starting<br />

to hit the market. Micro-seed planters,<br />

drone tractors, and weed-eating robots<br />

are slowly creeping into the agricultural<br />

mainstream. The idea is to create<br />

a swarm of automated robots controlled<br />

by a central AI that removes the possibility<br />

of human error and adapts to<br />

conditions to maximise yields and<br />

drastically cut time and increase efficiency.<br />

Automated farming machines<br />

work much like driverless cars. They<br />

are coordinated by GPS technology that<br />

precisely controls their locations and<br />

functions. The use of GPS technology<br />

is part of a much larger<br />

trend in farming known<br />

as precision agriculture.<br />

Precision agriculture<br />

has a few different<br />

names, including satellite<br />

farming and sitespecific<br />

crop management<br />

(SSCM). Precision agriculture<br />

takes the most<br />

precise readings in<br />

topographic data<br />

and then combines<br />

it with sensor data<br />

on the ground<br />

to give a precise<br />

picture of crop needs. It is<br />

broken into four phases: data<br />

collection, analysis of variables, development<br />

of strategies, and implementation<br />

of practices. In the end, precision<br />

agriculture looks to maximise efficiency<br />

through precise data analysis using<br />

cutting-edge technology.<br />

Automation, however, does not solve<br />

the problem of space. Along with<br />

modern technology, new systems of<br />

agriculture, such as vertical farming,<br />

are gaining in popularity as ways<br />

to maximise yields in a fraction of<br />

the space that traditional farms<br />

take up. As technology progresses,<br />

its contribution to securing our<br />

food supply has been undeniable.<br />

New technology allows us to better<br />

understand our land, the soil, and<br />

ultimately, our crops. It is with this<br />

better understanding that we can<br />

refine our methods and techniques<br />

that will ultimately lead to more<br />

efficient systems of production.<br />

30 grow cycle

grow cycle<br />

water culture hydroponic systems<br />

by Frank Rauscher<br />

COMPARING VARIOUS WATER CULTURE<br />

HYDROPONIC SYSTEMS<br />

Water culture hydroponics is one<br />

of the fastest growing segments<br />

of hydroponics, but there are a<br />

number of factors to consider<br />

when choosing a system. Water<br />

culture expert Frank Rauscher goes<br />

deep to explain the differences<br />

and help determine which system<br />

may best suit your needs.<br />

32 grow cycle

water culture hydroponic systems<br />

Though the history of hydroponics<br />

goes back to the Hanging Gardens<br />

of Babylon, around 500 BC, this soilless<br />

plant growing technique was advanced<br />

by a number of distinguished individuals,<br />

including Francis Bacon and<br />

Wilhelm Knop. In 1929, a man named<br />

William Gericke at UC Berkeley created<br />

a more modern example: water culture<br />

hydroponics. This hydroponic method<br />

goes without growing media at all,<br />

simply immersing root systems into<br />

water with nutrients and added oxygen.<br />

Understanding Water<br />

Culture Systems<br />

Recirculating deep water culture<br />

(RDWC), static solution culture, and<br />

deep water culture (DWC) are all<br />

hydroponic systems classified as<br />

water culture. Within the RDWC<br />

group, there are a few primary<br />

recirculating systems: nutrient film<br />

technique (NFT), top feeding, and<br />

underflow RDWC systems.<br />

Static solution and DWC systems are<br />

similar to each other, but differ in key<br />

ways. Standard DWC uses a mesh<br />

pot to contain the roots and aggressive<br />

aeration of the nutrient water,<br />

but static solution does not require<br />

these techniques. Basic static solution<br />

systems are mostly used by hobbyists<br />

growing plants that do fine with<br />

minimal oxygen in the water—take<br />

the beta fish in a tank with a peace<br />

lily as an example.<br />

When the nutrient water can be<br />

recirculated and shared between<br />

larger quantities of plants, it is<br />

conveniently possible to control<br />

nutrient and oxygen levels for<br />

the whole crop. If each grow<br />

bucket is separate from the others<br />

for the crop, on the other hand,<br />

maintenance can be cumbersome,<br />

especially when there are a large<br />

number of plants. In standard DWC,<br />

each grow bucket is separate. This<br />

is primarily why more deep water<br />

systems are set up as RDWC.<br />

Nutrient film technique is an RDWC<br />

method where the tubing, channel,<br />

or trays holding the nutrient water is<br />

sloped at about a 2.5 per cent drop, and<br />

the water is pumped at a moderate rate<br />

of around 0.3 gallons per minute so that<br />

water runs across the roots at a very<br />

slight depth. Obviously, the feed rate<br />

and slope would be adjusted according<br />

to the thickness of the roots.<br />

This still leaves us with top feeding<br />

and underflow recirculating systems,<br />

as well as NFT systems, to look at. In<br />

a top feeding system, such as bubbleponics,<br />

the recirculated nutrient and<br />

oxygenated water is initially fed to<br />

the top of the root system. This is most<br />

often done with seedlings and younger<br />

plants whose roots do not yet extend<br />

deeply and, therefore, there is a desire<br />

to have the heaviest concentration of<br />

oxygen at the surface. As these plants<br />

mature, the roots will grow and search<br />

for additional water and nutrient.<br />

Usually within a couple weeks, they<br />

will become large enough to reach the<br />

reservoir and gain access to that larger<br />

source, so top feeding would be less<br />

advantageous.<br />

Often, there is a desire to recirculate<br />

nutrient water, though the<br />

input is not needed at the top as<br />

with more mature plants. The water<br />

is then infused at the bottom of the<br />

grow pots. This is known as underflow<br />

systems.<br />

There are several ways to connect this<br />

oxygen-rich water to multiple mesh<br />

pots. The size of the mesh pots holding<br />

a plant’s roots will determine whether<br />

that pot can be placed in a four-inch PVC<br />

tube or require a grow bucket. The large<br />

PVC tube can be used as the underflow<br />

connector with no need for a bucket when<br />

the smaller mesh pot size is sufficient<br />

for the type of plant to be grown. Buckets<br />

with underflow connector tubing are<br />

needed for larger plants.<br />

Production Advantages Within<br />

These Water Culture Systems<br />

It is due to the high concentration<br />

of oxygen in the nutrient water that<br />

most water culture systems exercise<br />

superiority over other systems using<br />

grow media. The roots are immersed<br />

in and saturated with nutrified and<br />

oxygenated water all the time. Properly<br />

balanced and maintained RDWC<br />

systems will provide maximum yield.<br />

With well-oxygenated root systems,<br />

the plant can convert sugars and<br />

starch into energy for plant vigour.<br />

Though photosynthesis occurs only<br />

during daylight hours for a plant,<br />

respiration occurs (and needs to<br />

occur) all the time. Therefore, it<br />

is the recirculating water culture<br />

systems that will typically dominate<br />

this category. It becomes easier<br />

to boost oxygen levels and keep<br />

it that way for a large number of<br />

plants. Root volume and water<br />

uptake requirements are primarily<br />

determined by plant transpiration<br />

demand. So, the amount of light<br />

“PROPERLY BALANCED<br />

and maintained RDWC<br />

systems will provide<br />

maximum yield.”<br />

34 grow cycle

provided is also a major contributor<br />

to obtaining greater production.<br />

So, which of these WC systems will<br />

be more productive than the other? It is<br />

clear that most static systems are going<br />

to be limited in the capacity to provide<br />

concentrated amounts of oxygen and<br />

nutrient continuously. The NFT and<br />

four-inch PVC recirculating systems<br />

are appropriate for smaller plants and,<br />

if designed properly, are capable of<br />

providing just as great a concentration<br />

of oxygen and nutrient as the other<br />

systems. The single-bucket DWC system<br />

can also provide these concentrations,<br />

but may be cumbersome to maintain<br />

proper levels if a large number of plants<br />

are involved. The RDWC underflow<br />

system would be the choice for a greater<br />

number of large mature plants, while<br />

the top feeding would be optimum for<br />

seedlings and younger plants. With<br />

all the DWC systems (except static), a<br />

well-designed and properly maintained<br />

system will be capable of producing<br />

maximum crop yield over basic grow<br />

media techniques.<br />

Trade-offs for the Various Types of<br />

WC Systems<br />

It is difficult to state which system<br />

outproduces the other. Success is not<br />

really that simple. There are many different<br />

viewpoints regarding how to succeed<br />

with your crop.<br />

DISEASE is a big concern when the<br />

root systems for one plant share the<br />

same water as others. This is true for<br />

most recirculating grow media systems,<br />

as well as DWC systems. When using a<br />

system where water is shared between<br />

several or many plants, greater care<br />

must be given towards cleanliness<br />

and the observation and interception<br />

of root disease. Various pathogens<br />

such as pythium, fusarium, phytophthora,<br />

botrytis, and rhizoctonia are<br />

common. Knowing and understanding<br />

the disease is key to preventing and<br />

controlling it.<br />

Fusarium is a fungus and thrives in<br />

very wet conditions. A symptom plants<br />

may exhibit when infested with fusarium<br />

is leaf wilt. An inspection of the roots<br />

will confirm their unhealthy nature by<br />

displaying a brownish or beige colour<br />

instead of the white observed on healthy<br />

roots. Botrytis, also a fungus, is found<br />

nearly everywhere, even the greenhouse<br />

and hydroponics. Commonly called gray<br />

mould, this disease must have some food<br />

source before it invades plants. Often,<br />

wounded or dying tissue can become<br />

this source.<br />

Rhizoctonia is also a fungus that often<br />

is responsible for root and stem rotting.<br />

Damping-off and leaf blight are two<br />

frequently seen symptoms.<br />

Pythium is often referred to as water<br />

mould because it thrives in watery<br />

places. Though sometimes called a<br />

fungus, it is not; rather, it’s an oomycete.<br />

It’s found in poor-draining, overwatered<br />

fields and greenhouses, as well<br />

as hydroponic systems. Phytophthera<br />

is also another oomycete like pythium.<br />

When a plant is infected by this disease,<br />

that plant will not be able to absorb<br />

nutrients or water due to extensive dead<br />

root tissue.<br />

CONTROLLING DISEASE and<br />

preventing root rot is vital with DWC<br />

systems. Fungicides are generally only<br />

effective for short-term applications,<br />

and do not have much impact on nonfungi<br />

infestations. There are a number<br />

of effective fungicides and other specific<br />

treatments available. Check the reference<br />

QR at the end of this article for<br />

more information. Phytophthera, not<br />

being a fungus, is very difficult to<br />

control. Often, if detected, it is best<br />

to discard and destroy all infected or<br />

contaminated plants and then sterilise<br />

the entire system before replanting.<br />

Maintain a high level of oxygen in the<br />

water for WC systems as this will reduce<br />

“THE AMOUNT OF light<br />

provided is also a major<br />

contributor to obtaining<br />

greater production.”<br />

grow cycle<br />

35

water culture hydroponic systems<br />

the opportunity for disease to start.<br />

Clean and disinfect between grows and<br />

anytime possible when sign of infestation<br />

might be visible.<br />

ENERGY COSTS are higher for continuously<br />

recirculating systems. The oxygen<br />

level in DWC systems drops off rapidly if<br />

circulation stops. This is not an issue for<br />

most grow media systems. There are also<br />

additional pieces of equipment to run,<br />

such as an air pump and water chiller,<br />

in addition to the water pump. Often, the<br />

air infused into the system will warm the<br />

nutrient solution and may then require<br />

chilling to allow the solution to retain the<br />

dissolved oxygen better.<br />

START-UP and maintenance costs can<br />

be higher for WC systems. Leaks can be<br />

a catastrophe. To have a reliable system,<br />

source and purchase only reputable<br />

components and accessories for your WC<br />

set-up. The more accessories that you<br />

incorporate into your system will add to<br />

maintenance, as well as improve how you<br />

can control the growing environment.<br />

SPACE UTILISATION AND FLEX-<br />

IBILITY is always valuable to most<br />

every grower. If overall yield is a goal,<br />

then you will want to be able to grow<br />

more plants in the same space. Being<br />

able to relocate plants as needed<br />

throughout the growth cycle is important<br />

to harvest or maintain the crop<br />

you have. Water culture systems can<br />

provide excellent space utilisation<br />

if designed properly as the focus is<br />

optimum production. Modular water<br />

culture systems are available and offer<br />

the flexibility of being able to relocate<br />

or remove specific plants while keeping<br />

the rest on the system.<br />

Water culture is capable of awesome<br />

crop production when designed and<br />

maintained correctly. As with most<br />

any grow technique, you will want to<br />