Climate Action 2012-2013

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AGRICULTURE, FOOD AND WATER<br />

About 1 million tonnes of CO 2<br />

is released when<br />

1 TWh of electricity is produced by using coal,<br />

gas or oil.<br />

Interest in using nuclear energy for producing<br />

potable water has been growing worldwide.<br />

This has been motivated by variety of factors,<br />

from the economic competitiveness of nuclear<br />

energy to energy supply diversification, from<br />

conservation of limited fossil fuel resources<br />

to environmental protection, and the spinoff<br />

effects of nuclear technology in industrial<br />

development. In a nuclear desalination facility,<br />

both the reactor and the desalination system are<br />

located on a common site, with some degree of<br />

shared facilities, services, staff, seawater intake<br />

and outfall structures. These nuclear plants can<br />

be dedicated to desalination, or combined with<br />

power production facilities.<br />

Co-location of desalination and power plants<br />

has the obvious benefit of sharing infrastructure<br />

resources such as a common intake and outfall<br />

of sea water. In recent years a number of projects<br />

have been carried through using the co-location<br />

concept. Dual purpose plant (power together with<br />

desalination) has inherent design advantages in<br />

optimising thermodynamic efficiency, in addition<br />

to its economic benefits.<br />

Pioneering thermal and hybrid nuclear<br />

desalination<br />

Development of thermal desalination<br />

technologies using low grade and waste heat for<br />

seawater desalination is well estabished at the<br />

Bhabha Atomic Research Centre (BARC) in<br />

India. Technology was evolved using a 15,000<br />

litres/day capacity three-stage multi-stage flash<br />

(MSF) system. A pilot plant of 425,000 litres/<br />

day capacity was setup in BARC Trombay. The<br />

experience helped in the design, installation<br />

and commissioning of a 4,500,000 litres/day<br />

(4.5 MLD) MSF system as a part of the Nuclear<br />

Desalination Demonstration Plant (NDDP) at<br />

Kalpakkam.<br />

The use of low grade waste heat as energy input<br />

for desalination was pioneered in the islands of<br />

Lakshadweep, producing 10,000 litres/day of<br />

distilled quality water using the waste heat of<br />

a diesel generator facility. Other value-added<br />

thermal desalination technologies are being<br />

developed, such as multi-effect distillation vapour<br />

compression (MED-VC) and low temperature<br />

evaporation (LTE).<br />

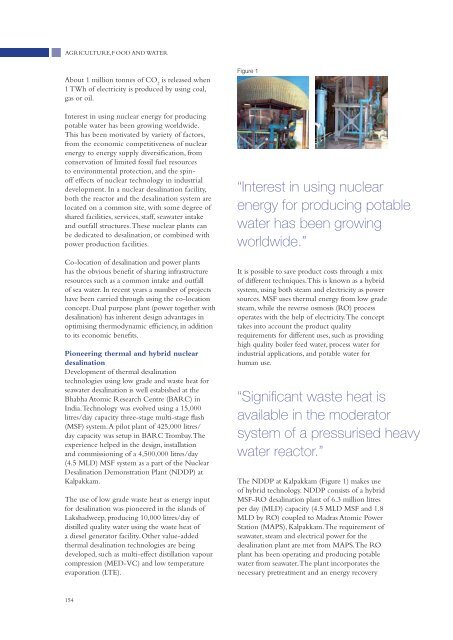

Figure 1<br />

“Interest in using nuclear<br />

energy for producing potable<br />

water has been growing<br />

worldwide.”<br />

It is possible to save product costs through a mix<br />

of different techniques. This is known as a hybrid<br />

system, using both steam and electricity as power<br />

sources. MSF uses thermal energy from low grade<br />

steam, while the reverse osmosis (RO) process<br />

operates with the help of electricity. The concept<br />

takes into account the product quality<br />

requirements for different uses, such as providing<br />

high quality boiler feed water, process water for<br />

industrial applications, and potable water for<br />

human use.<br />

“Significant waste heat is<br />

available in the moderator<br />

system of a pressurised heavy<br />

water reactor.”<br />

The NDDP at Kalpakkam (Figure 1) makes use<br />

of hybrid technology. NDDP consists of a hybrid<br />

MSF-RO desalination plant of 6.3 million litres<br />

per day (MLD) capacity (4.5 MLD MSF and 1.8<br />

MLD by RO) coupled to Madras Atomic Power<br />

Station (MAPS), Kalpakkam. The requirement of<br />

seawater, steam and electrical power for the<br />

desalination plant are met from MAPS. The RO<br />

plant has been operating and producing potable<br />

water from seawater. The plant incorporates the<br />

necessary pretreatment and an energy recovery<br />

154