stahlmarkt European Edition 01.2013

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

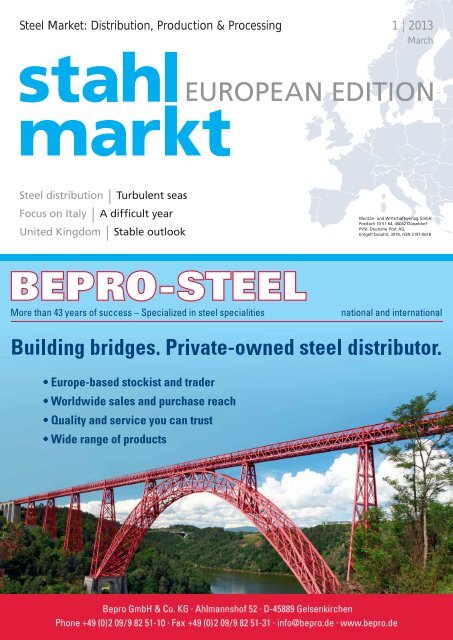

Steel Market: Distribution, Production & Processing 1 | 2013<br />

March<br />

EUROPEAN EDITION<br />

Steel distribution | Turbulent seas<br />

Focus on Italy | A dicult year<br />

United Kingdom | Stable outlook<br />

Montan- und Wirtschaftsverlag GmbH.<br />

Postfach 10 51 64, 40042 Düsseldorf<br />

PVSt, Deutsche Post AG,<br />

Entgelt bezahlt, 3018, ISSN 2191-0618

Editorial K 3<br />

Sabbatical Year 2013<br />

Dr.-Ing. Wiebke Sanders<br />

Editor-in-Chief<br />

Tel. +49 211 69936-131<br />

<strong>stahlmarkt</strong>@stahleisen.de<br />

WW K This is how some sector experts describe Europe’s<br />

steel market in the present year. The phrase originates<br />

from the word »Shabbat« (meaning rest or cessation in<br />

Hebrew) and many believe that the prospects for 2013<br />

will remain bleak. »The EU steel market in 2013 looks<br />

set to remain fragile. There is continued risk of supply<br />

and demand distortions,« according to Gordon Moffat,<br />

Director-General of Eurofer, the umbrella organisation<br />

of the <strong>European</strong> steel industry.<br />

WW K Steel demand in the EU fell almost 10 %, to about<br />

143 million tonnes, in 2012 and is set to fall a further<br />

1 % in 2013 (to roughly 141 million tonnes) according<br />

to estimates by Eurofer. A slight recovery is expected on<br />

the <strong>European</strong> steel market in 2014, though demand still<br />

remains about 30 % below the high level of the boom<br />

year of 2008.<br />

WW K Whereby the situation differs greatly in the various<br />

regions of Europe: while the economic crisis is still having<br />

a major effect in southern Europe, the steel market in<br />

central eastern Europe is comparatively robust. But: »The<br />

intensity of competition on international markets has<br />

risen considerably again,« as Hans Jürgen Kerkhoff,<br />

President of the German Steel Federation, recently<br />

pointed out at a steel conference in Germany. Europe’s<br />

steel sector is contending with high raw material and<br />

energy costs, emissions trading, trade barriers, and<br />

current or imminent adaptive processes. »Unprofitable<br />

locations must not be kept alive artificially by means of<br />

government support. Temporary surplus capacities must<br />

not become permanent overcapacities,« he continued.<br />

WW K There is, however, light at the end of the tunnel<br />

and circumstances will improve in 2014 according to<br />

Gordon Moffat: »We do expect a more supportive<br />

economic environment towards the end of the year. But<br />

it will take most of 2013 before our customers in<br />

industry and the steel distribution chain will notice any<br />

improvement in business conditions.«<br />

Steel market in Europe<br />

Economic indicator euro-zone<br />

Market supply, EU 27 (in million tonnes)<br />

65<br />

120<br />

250<br />

60<br />

55<br />

50<br />

45<br />

40<br />

35<br />

30<br />

Purchasing Managers Inde left side<br />

Economic condence<br />

right side<br />

Indepoints, latest value, Jan. 13<br />

07 08 09 10 11 12<br />

13<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

200<br />

150<br />

100<br />

50<br />

0<br />

192<br />

2006<br />

201<br />

2007<br />

185<br />

2008<br />

121<br />

2009<br />

148<br />

2010<br />

157<br />

2011<br />

142 141 146<br />

2012 p 2013 f 2014 f<br />

Source: Markit Economics, EU-Kommission, Eurofer, WV Stahl<br />

p<br />

Prognosis, f Forecast<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

4 K<br />

CONTENT 1.2013<br />

STEEL INTERNATIONAL<br />

6 Contentious issue: shale gas<br />

8 Emerging markets – the future for German SME?<br />

10 Russian steel producers react to market changes<br />

12 The steel industry: China continues to set the pace<br />

UK Quarterly Balance of Trade<br />

in million tonnes<br />

3<br />

2<br />

1<br />

All steel products Q3 2008 – Q2 2012<br />

Exports<br />

Imports<br />

2.2 2.1<br />

1.8<br />

1.9<br />

1.8 2.0 2.0<br />

2.0 2.0<br />

1.8<br />

1.6 1.7 1.6 1.6 1.7 1.6<br />

1.7<br />

1.5 1.5<br />

1.5<br />

1.5<br />

1.4<br />

1.3 1.4 1.4<br />

1.4<br />

1.3<br />

1.3 1.3<br />

1.0 1.1<br />

1.0<br />

SPECIAL: NORTHERN EUROPE/UK<br />

14 Stable outlook<br />

18 New solution for mould, tool and die makers<br />

20 Tata Steel restructures to improve competitiveness<br />

of UK operations<br />

SPECIAL: ITALY<br />

22 Looking ahead, Italy faces a difficult 2013<br />

26 Shaping the quality<br />

14<br />

0<br />

2008 2009 2010 2011 2012<br />

photo: ISSB<br />

Stable outlook<br />

British steel stockholders and service centres are<br />

looking forward to a virtual repeat of 2012 in terms<br />

of business growth and turnover.<br />

SPECIAL: STEEL DISTRIBUTION<br />

28 Steel distribution in turbulent seas<br />

32 Steel distribution in Poland<br />

34 A tool for optimizing steel stock<br />

35 Robust 4-way trucks for bright steel handling<br />

SPECIAL: TUBE & PIPE<br />

36 New solution combines electrical and hydraulic systems<br />

38 New tube production line in central Russia<br />

INDUSTRY<br />

39 Lightweight solutions for a wide range<br />

of car components<br />

27<br />

Looking ahead<br />

photo: Marcegaglia<br />

Italy faces a difficult year 2013. Nonetheless some steel<br />

companies have invested in their plants.<br />

41 New company brochures<br />

42 Steel Events<br />

43 Advertisers‘ index, preview next issue, Impressum<br />

33<br />

photo: WS<br />

Turbulent seas<br />

How can <strong>European</strong> steel distributors be successful<br />

today? This was a main question at the Central and<br />

Eastern <strong>European</strong> steel market conference 2012, hosted<br />

by the Polish steel distributors’ association PUDS.<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

Advertisement

6 K Steel International<br />

Contentious issue: shale gas<br />

U. S. steel industry with firm conviction<br />

New York (bln). The prospect of a shale gas revolution in the United<br />

States that promises to empower domestic manufacturing and, along with<br />

drilling for plentiful shale oil, assures the country’s eventual energy<br />

self-sufficiency, is questioned and attacked by show business celebrities.<br />

WW K Premiering in movie houses across the<br />

country early in the New Year, the Hollywood<br />

film »Promised Land« stirs the controversy<br />

over allegedly harmful environmental consequences<br />

of massive natural gas production<br />

from the vast shale rock formations from<br />

Texas to Pennsylvania and New York. John<br />

Lennon’s widow Yoko Ono organized the<br />

»Artists Against Fracking« Lobby recruiting<br />

some 140 well-known pop stars, among<br />

them Lady Gaga, Paul McCartney, Ringo<br />

Starr, Anne Hathaway, Hugh Jackman,<br />

Julianne Moore and Gwyneth Paltrow. The<br />

question is whether the star power of wellheeled<br />

pop idols can prevent the production<br />

of shale gas in regions that have not yet<br />

cashed in on the lucrative shale gas and<br />

slow down the natural gas boom in other<br />

states, among them Pennsylvania, Texas,<br />

Colorado, and Ohio.<br />

Steel producers hope<br />

for better margins<br />

The steel industry has considerable interest<br />

in the outcome of the shale exploration<br />

debate and its consequences for pertinent<br />

policies and regulations. To begin with, the<br />

healthy demand for pipe and tube products<br />

used in the production and transportation<br />

of shale gas has been the bright spot for the<br />

steel industry during a time of slow economic<br />

recovery.<br />

But those benefits dwarf the prospect of<br />

significantly reducing the cost of producing<br />

steel by using cheap gas instead of coal to<br />

purify iron ore, the main raw material in the<br />

production of steel. While the technology<br />

for using gas instead of coal is not new, it<br />

was simply not feasible in the past when gas<br />

prices were very high. Although not all shale<br />

rich states allow natural gas drilling through<br />

the controversial hydraulic fracturing pro–<br />

cess or fracking, the price for natural gas is<br />

at an all-time low.<br />

Not surprisingly, steelmakers are poised to<br />

exploit the changing market conditions in<br />

the hope of boosting their meager profit<br />

ranges. Nucor Corporation, the financially<br />

sound mini-mill giant, leads the competition<br />

for switching as soon as possible to gas as<br />

main energy source. The company’s new<br />

750 million dollars facility in Louisiana that<br />

will use gas instead of coal is set to open<br />

later this year. Steel analysts expect Nucor to<br />

soon disclose plans for a second plant using<br />

direct-reduced iron or DRI technology. Nucor<br />

has calculated that at today’s natural gas<br />

prices, it would decrease the production<br />

costs for a tonne of steel by 20 %.<br />

Betting on the future of DRI plants and<br />

production, Nucor agreed last year to a joint<br />

venture with Encana Oil & Gas that will<br />

assure the steel company a long-term,<br />

reliable supply of its growing need for gas.<br />

Encana will expand its operations in<br />

Colorado by several thousand additional<br />

drilling wells over the next two decades.<br />

Nucor will invest 542 million dollars in the<br />

first three years of the joint venture and a<br />

total of 3.6 billion dollars over the partnership’s<br />

contracted period.<br />

Steel companies abroad consider<br />

taking advantage<br />

Foreign steel companies, too, ponder plans<br />

to take advantage of the shale gas bonanza<br />

in the United States and prices that are<br />

merely half of those two or three years ago.<br />

According to various steel analysts, India’s<br />

Essar Global Ltd. considers a DRI project in<br />

Minnesota and Australian Bluescope Steel a<br />

DRI plant in Ohio.<br />

While more than a dozen shale-rich U.S.<br />

states allow fracking technology for the<br />

drilling of shale oil, others, like Vermont and<br />

New Jersey and New York banned this<br />

method because of environmental concerns.<br />

The state of New York is considering<br />

lifting the ban and participating in the<br />

economic opportunities of the shale gas and<br />

oil sector that have already created several<br />

hundred thousand jobs in several shale-rich<br />

states. But as the decision drew close in late<br />

2012 and early this year, Yoko Ono and her<br />

stepson Sean Lennon went to the state’s<br />

capitol Albany to press their passionate antifracking<br />

campaign on the home court of the<br />

state’s legislature and governor.<br />

To begin with, they delivered 50 boxes of<br />

what they said were more than 200,000<br />

anti-drilling petitions to the state’s Department<br />

of Environmental Conservation. In an<br />

op-ed article that was published in several<br />

newspapers, Ono wrote: »My husband John<br />

Lennon and I bought a beautiful farm in<br />

rural New York more than 30 years ago. Like<br />

the rest of the state, this peaceful farming<br />

community is threatened by fracking for<br />

gas. Governor Cuomo, please don’t frack<br />

New York. Don’t allow our beautiful landscapes<br />

to be ruined, or our precious and<br />

famous clean water be dirtied.« But Ono<br />

did not just plead, she also threatened if<br />

hydraulic fracture were to be approved.<br />

»There will be class action, and the class<br />

action is going to hit everybody who is<br />

doing this«, she said. »It’s going to go on<br />

and on and on…«<br />

Will »Promised Land« change<br />

public opinion?<br />

Apart from people in the shale-rich regions,<br />

gas companies, and environmentalists,<br />

there has not been a broad knowledge<br />

about the new source of energy. Indeed,<br />

opinion polls revealed that the majority of<br />

Americans had not heard or read anything<br />

about fracking. A solid majority had no<br />

opinion or was undecided whether to<br />

support or oppose the use of controversial<br />

fracking technology to produce huge<br />

quantities of natural gas. But when told by<br />

pollsters that critics link hydraulic fracturing<br />

or fracking to »tainted water supplies<br />

and earthquakes«, nearly three of five<br />

respondents opted for the »more regulation«<br />

response category.<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

The question is whether public opinion will change significantly as<br />

a result of »Promised Land«, a Hollywood movie that has been<br />

hailed as helping a noble environ mental protection cause and<br />

condemned as misinformation and anti-fracking propa ganda.<br />

Written by and starring Matt Damon and John Krasinski, the film<br />

focuses on the ways small town landowners are pressured by clever<br />

gas company salesmen to cash in on their shale rock properties –<br />

regardless of the environmental impact on their communities.<br />

Playing more on the emotions of people in an economically deprived<br />

Pennsylvania town than on a scientific exploration of what is known<br />

about fracking technology, the movie was harshly criticized by the<br />

energy lobby. »Energy In Depth«, an industry public rations group,<br />

launched a web site »The Real Promised Land« with what are called<br />

the real stories about real Americans in shale-rich regions. And the<br />

pro-fracking Marcellus Shale Coalition ran ads in movie houses in<br />

Pennsylvania to counter »Promised Land« by inviting audi ences to<br />

get answers about the shale controversy on its web site.<br />

As »Promised Land« was shown in hundreds of movie houses<br />

across America, a documentary titled »FrackNation« had a single<br />

showing in a single New York City cinema. Written and co-directed<br />

by inves tigative journalist Pelim McAlleer, the low-cost »FrackNation«<br />

challenges the argu ments of anti-fracking environmentalists as<br />

»misinformation and misrepresentation« about the true nature of<br />

hydraulic fracturing.<br />

Ultimately, the economic self-interest of New York and other<br />

states may follow the example of the shale oil boom elsewhere and<br />

trump the concerns of environmentalists and the star power of Matt<br />

Damon and Yoko Ono and their peers.<br />

(EE 130104858) K<br />

L STEEL IN BRIEF<br />

THYSSENKRUPP NIROSTA NOW<br />

OUTOKUMPU NIROSTA<br />

Krefeld. ThyssenKrupp Nirosta GmbH is now operating under the name<br />

Outokumpu Nirosta GmbH. Outokumpu announced the completion of the<br />

Inoxum transaction and resulting merger with the former ThyssenKrupp<br />

division, which also included ThyssenKrupp Nirosta, on 28 December 2012.<br />

Adding Outokumpu to the name clearly highlights the affiliation to the<br />

Finnish company. The retention of the Nirosta name symbolises the origins<br />

of the Krefeld-based stainless steel manufacturer. The abbreviation stands<br />

for »nichtrostender Stahl« (or stainless steel in English) and was registered<br />

as a trademark over 90 years ago. »There are better market opportunities<br />

for the long-established company Nirosta within the new combined<br />

Outokumpu Group«, explained Dr. Ulrich Albrecht-Früh, President of the<br />

Stainless Coil EMEA business area. »For example, we will be able to offer<br />

our customers an even broader range of product qualities, dimensions and<br />

surfaces«, he added.<br />

Within the new group, Outokumpu Nirosta will be part of the Stainless<br />

Coil EMEA business area. This covers activities for stainless steel products<br />

in the Europe, Middle East and Africa and ferrochrome activities worldwide.<br />

(EE 130104866) K<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

8 K Steel International<br />

Emerging markets –<br />

the future for German SME?<br />

A critical look at China and India<br />

Frankfurt (us). As the mature economies increasingly face changing<br />

demographics and slower growth, many small- and medium sized<br />

companies (SME) are looking towards new possibilities in emerging<br />

markets. During the Dow Jones Steel Day last year, Ralf Maier, Managing<br />

Director of MADEMA group, analyzed the opportunities and threats that<br />

steel companies are about to encounter in China and India – and the<br />

impact the two countries have on Europe.<br />

WW K »China and India have nearly the<br />

same population. Apart from that, the two<br />

countries share hardly any common traits«,<br />

Maier said at the start of his presentation.<br />

He then started with a view on China and<br />

discarded the idea that we may soon be<br />

overrun by Chinese steel imports. »About<br />

90 % of Chinese steel production is needed<br />

within China to fuel further growth«, Maier<br />

stated. However, Chinese steel producers<br />

also have problems as they are facing higher<br />

costs for iron ore and energy that cannot be<br />

»<br />

We<br />

won‘t be overrun<br />

by Chinese steel.<br />

rolled over to domestic buyers. He added<br />

that the number of Chinese steel producers<br />

is bound to shrink from some 800 today to<br />

around 200 in the near future due to<br />

consolidation driven by the state.<br />

Maier also gave another reason why<br />

China as an exporter should not be feared<br />

too much. On the world market, a certain<br />

quality is automatically expected by the<br />

customer. Additionally, competition in a<br />

globalized market works mainly on price. In<br />

this respect, Chinese exports have suffered<br />

during the euro crisis, Maier explained.<br />

Furthermore, imports into the eurozone<br />

depend on exchange rates.<br />

Huge growth through Chinese<br />

urbanization<br />

Nearly half of the Chinese population, about<br />

600 million people, are already living in<br />

cities, Maier said. By 2030, the rate of<br />

urbanization in China could even reach<br />

more than 80 %. To achieve this goal, China<br />

has to double the number of cities with<br />

more than 1 million inhabitants from around<br />

120 to more than 240. New cities will be<br />

predominantly built as greenfield developments<br />

within the country, to take pressure<br />

from the agglomerations at the coastline,<br />

according to Maier‘s analysis. As urban<br />

population needs significantly more steelbased<br />

products than rural population, the<br />

growth opportunities are enormous.<br />

India is in a different league<br />

India‘s GDP growth is lower than that of<br />

China, but its population growth is much<br />

higher. As a result, the overall development<br />

in India moves at a significantly slower pace.<br />

Nevertheless, there are huge opportunities<br />

for steel-using companies, Maier said. For<br />

example, India still has the lowest per-capita<br />

use of stainless steel in the world.<br />

Although India will experience a huge<br />

urbanization wave by 2030, the country‘s<br />

problems are completely different from<br />

those in China, Maier said. India suffers<br />

from a lack of infrastructure which means<br />

that many of its metropolitan areas are<br />

facing traffic collapse. The money that India<br />

wants to spend in the next few years to<br />

address these problems will hardly be<br />

enough. In this respect, there could be room<br />

for specialized products from mature<br />

economies, for example for innovative<br />

parking systems. However, in the Indian<br />

construction market only private projects are<br />

suitable for <strong>European</strong> companies, in Maier‘s<br />

view, due to the high price sensitivity of<br />

publicly funded projects.<br />

Strategies for success<br />

Basically, <strong>European</strong> companies have a good<br />

chance to be successful in emerging markets<br />

by offering a unique product which brings<br />

added value. Although India has severe<br />

development backlogs in some parts, it is on<br />

a <strong>European</strong> level in others – for example<br />

when it comes to environmental protection<br />

for newly built plants, even though old<br />

plants are often allowed to operate below<br />

these standards. On the other hand, the<br />

country is riddled with daily power cuts, a<br />

lack of sewer systems and inappropriate<br />

fresh water supply – good chances for<br />

»<br />

The<br />

companies active in components for these<br />

kinds of infrastructure. And the demand is<br />

huge: Maier estimated the yearly public<br />

investment need for communal fresh water<br />

supply in India at some 2.5 billion euros.<br />

However, a <strong>European</strong> company should be<br />

aware that it can only catch a small fraction<br />

of the highly-priced market with high-end<br />

products. To gain access to a bigger market,<br />

companies from mature economies have to<br />

downgrade their products and to tailor<br />

them to local needs. Lower steel grades for<br />

kitchenware are one example, Maier said.<br />

Another one would be washing machines in<br />

which the water can be filled by hand – for<br />

areas where no water line is available. The<br />

market opportunities are there. »China and<br />

India will be the export drivers for steelusing<br />

SMEs in the future«, Maier drew his<br />

conclusion.<br />

www.madema-group.com<br />

/<br />

Indian elephant<br />

is not running, it is moving.<br />

(EE 130104382) K<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

Steel International K 9<br />

Continued success in 2012<br />

Gelsenkirchen. BEPRO Blech und Profilstahl Handelsgesellschaft mbH & Co. KG, based in Gelsenkirchen,<br />

succeeded in sustaining its position in spite of the difficult market environment in 2012. The company achieved<br />

good operational results despite the current problems and uncertainties on the market.<br />

WWK In those markets that BEPRO considered<br />

posed special risks in view of their development<br />

it reduced its business activities and<br />

put security and risk procurement before<br />

further business volume.<br />

BEPRO sold its premises in Essen this year,<br />

and will concentrate its stock capacities in<br />

Gelsenkirchen-Bismarck. After completion<br />

of construction work, BEPRO will have more<br />

than 30,000 m² for storage purposes and<br />

about 900 m² of office space. Customers<br />

will therefore be offered improved operating<br />

efficiency, service, customer orientation and<br />

material availability.<br />

In order to maintain its excellent reputation<br />

as a flexible expert in steel specialities,<br />

BEPRO is planning to enlarge its product<br />

and storage range by adding additional<br />

products. Customers will be able to obtain<br />

materials from BEPRO that would otherwise<br />

be difficult, or even impossible, to find<br />

elsewhere.<br />

The economic slowdown and falling<br />

prices may result in a structural change in<br />

production or trade sectors. Nevertheless,<br />

despite the restricted economy, BEPRO<br />

remains optimistic regarding its own<br />

national and international opportunities as<br />

a medium-sized company in coming years.<br />

The company remains well positioned, and<br />

will grow further when the steel trade and<br />

market recover. BEPRO will then be able to<br />

achieve its target of selling over 100,000<br />

tonnes of steel products a year.<br />

2013 started better than expected for<br />

BEPRO. Nevertheless, it is currently impossible<br />

to predict future developments.<br />

Increasing financial insecurities, the euro<br />

crisis, poor steel demand, insufficient prices<br />

and a flagging worldwide economy could<br />

lead to poor prospects.<br />

/<br />

BEPRO Blech und Profilstahl<br />

Handelsges. mbH & Co. KG<br />

Ahlmannshof 5<br />

45889 Gelsenkirchen<br />

Germany<br />

phone +49 209 98251-10<br />

www.bepro.de<br />

(EE 130104880) K<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

10 K Steel International<br />

Russian steel producers react<br />

to market changes<br />

By Vladimir Kovalev (VK)<br />

In reaction to falling steel demand on international markets, and<br />

particularly in Europe, Russian producers started suspending their <strong>European</strong><br />

production facilities at the end of last year, a trend that is likely to persist<br />

during 2013 given the continuing economic difficulties in the region.<br />

WW K At the same time, closure of selected<br />

steel production lines in Europe stimulates<br />

sales and maintains steel prices on the<br />

<strong>European</strong> markets, creating additional<br />

advantages for Russian producers, such as<br />

Severstal, whose attention could shift to<br />

Asian markets, currently gaining in<br />

importance.<br />

The Evraz Group was one of the first to<br />

cut back after suspending steel production<br />

at its Vitkovice steelworks in the Czech<br />

Republic in December 2012 for about two<br />

weeks, a decision that came shortly after<br />

Mechel stopped selected production lines in<br />

Romania in November. The market subsequently<br />

expected Russia’s NLMK to close<br />

its Belgian site at La Louviere after the<br />

company announced that it was involved in<br />

negotiations with local labour unions on<br />

proposals to restructure the plant.<br />

Evraz Vitkovice Steel (EVS) is the biggest<br />

steel producer in the Czech Republic. »We<br />

took the step in order to optimise steel<br />

stocks in response to low demand«,<br />

according to a statement in December by<br />

Yakomir Kirisica, head of EVS, quoted in the<br />

Russian business journal Expert.ru.<br />

The operations of Evraz’s plant in the<br />

Czech Republic have been affected by a<br />

number of factors, including lower demand.<br />

In late December, the company announced<br />

that it had reached an agreement with<br />

ArcelorMittal to resume deliveries of pig<br />

iron, enabling the site to resume production<br />

during the first half of January. This appears<br />

to have been the main reason for having<br />

suspended production. The plant is one of<br />

Europe’s biggest producers of thick rolled<br />

steel and the largest in the Czech Republic.<br />

»All EVS operations are running now«,<br />

Krisica told »<strong>stahlmarkt</strong>« shortly after the<br />

plant resumed operations in January. »The<br />

reason for the restart was an agreement on<br />

the supply of pig iron by ArcelorMittal<br />

Ostrava (AMO) for the period of January and<br />

February 2013.«<br />

At the same time, activity at the plant in<br />

Czech Republic could still be affected by<br />

complications over the receipt of the carbon<br />

credits required for operation from January<br />

1, 2013, according to remarks by Dimitry<br />

Scuka, the EVS Chairman, sent to »<strong>stahlmarkt</strong>«<br />

by the company’s press service.<br />

»Based on all the information available, the<br />

carbon credits have still not been received<br />

due to the refusal of individual EU institutions<br />

that insist on their specific way of<br />

solving the issue. The result, unfortunately,<br />

is that we are not entitled to what all the<br />

other companies are«, he said.<br />

Meanwhile, the general tendency for 2013<br />

is still considered bleak given the forecast by<br />

the World Steel Association regarding<br />

demand in Europe. International demand<br />

grew about 2.1 % in 2012, which is less than<br />

in 2011 when it was about 6.2 %. At the<br />

same time, <strong>European</strong> demand fell by about<br />

5.6 % compared to the previous year – to<br />

about 145 million tonnes – and would grow<br />

by only 2.4 % in 2013, according to statistics<br />

quoted by the daily. Most of reduction is<br />

expected to affect Italy and Spain.<br />

»We think that steel demand in Spain and<br />

Italy [in 2012] fell by 11.9 % and 12.6 %<br />

respectively. Germany, Europe’s most stable<br />

country, also experienced a reduction of<br />

4.7 % in 2012. In 2013 the situation should<br />

improve and steel demand in the EU-27<br />

could improve by 2.4 %«, the Russian<br />

analytical agency MinProm quoted Edwin<br />

Basson, Director General of the World Steel<br />

Association.<br />

Striving for asset optimization<br />

In conditions when some steel producers are<br />

starting to optimise their <strong>European</strong> assets<br />

by cutting production, others are taking<br />

advantage of this by filling the emptying<br />

niche. »The situation in the first quarter of<br />

2013 looks better than in the fourth quarter<br />

of 2012«, Vladimir Zaluzhsky, a Severstal<br />

spokesperson told »<strong>stahlmarkt</strong>«. Prices for<br />

products continue to rise in many regions of<br />

the world, especially in Asia. This is linked to<br />

the increase in iron ore prices and another<br />

cycle of restocking in China and South-East<br />

Asia, during which traders are buying up<br />

metal in advance for the spring construction<br />

season.«<br />

»Closure of <strong>European</strong> capacities has<br />

become an additional factor supporting<br />

higher steel prices. Thus positive dynamism<br />

will continue in the first quarter and,<br />

probably, in the second, after which there<br />

could be a correction on the market. But in<br />

general we do not expect a negative<br />

scenario«, Zaluzhsky added.<br />

NLMK’s Belgian plant in La Louviere is<br />

expected to face losses of up to 100 million<br />

euros as a result of its activities in 2012,<br />

according to sources in the industry quoted<br />

by the business newspaper RBC Daily. At the<br />

end of the year, the plant had to hold<br />

negotiations on the restructuring of its<br />

production lines in order to reduce the high<br />

production costs, which could involve<br />

significant redundancies at the plant in<br />

order to increase financial efficiency. The<br />

plant’s annual output is estimated at 2.4<br />

million tonnes.<br />

The situation at NLMK’s Belgian site is still<br />

not clear for the first quarter of 2013 and<br />

restructuring is on agenda, while the plant<br />

continues operating. »We are still in<br />

negotiations with the unions«, Caroline<br />

Marlair, La Louviere’s spokesperson told<br />

»<strong>stahlmarkt</strong>«.<br />

Veering from Europe to China?<br />

In a worse-case scenario, operators of metal<br />

plants in Europe could decide to close down<br />

even more production lines in 2013, as<br />

happened when the original economic crisis<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

Steel International K 11<br />

hit Europe in 2008, according to Moscowbased<br />

analysts monitoring the situation on<br />

the <strong>European</strong> steel market. »We don’t<br />

expect the economic situation in Europe to<br />

improve within the next few months. This is<br />

based on industrial production statistics<br />

which indicate that the volume of industrial<br />

contracts fell by 3.5 % in 2012, compared<br />

to 2011. In practice, the eurozone is<br />

currently in recession. GDP is falling and it is<br />

still not clear when it will recover from the<br />

current position. Germany, which is an<br />

economic locomotive for Europe, could not<br />

drag the eurozone out of its economic crisis<br />

by itself«, Roman Tkachuk, an analyst at the<br />

Moscow-based Nord Capital investment<br />

company told »<strong>stahlmarkt</strong>«.<br />

Judging by the fact that the steel industry<br />

is traditionally more sensitive to economic<br />

slowdowns in crisis periods, steel demand is<br />

expected to maintain its low levels, the<br />

analyst said, and added that in such a<br />

situation: »it could not be ruled out that<br />

metallurgical companies would go for<br />

suspending blast furnaces, as was the case<br />

in 2008. This would be radical, because<br />

restarting a suspended blast furnace is a<br />

very expensive process.«<br />

The current negative trends in Europe<br />

could force Russian steel operators to<br />

redirect their attention to other markets. »A<br />

more positive scenario for Russian companies<br />

could be to reorient themselves<br />

towards the Chinese market. In late 2012,<br />

this market showed signs of recovery when,<br />

in December and January 2013, demand for<br />

steel products grew – the price of pig iron<br />

has gone up by 80 % during the last four<br />

months«, the analyst said, adding that some<br />

major Russian producers expect international<br />

growth of steel demand to be about 3 % in<br />

2013. (EE 130104823) K<br />

i<br />

The following article can<br />

be downloaded from the<br />

»<strong>stahlmarkt</strong>« website.<br />

Siberian steelmaker reorganises<br />

its production facilities<br />

The OAO Novosibirsk Metallurgical Plant<br />

(NMZ Kuzmina) intends to reorganise the<br />

production of welded medium-diameter tubes<br />

within the next two years with investments of<br />

about 750 million roubles (20 million euros).<br />

Read the article via QR<br />

Code. Go straight to the<br />

PDF using this QR Code<br />

on your smartphone or<br />

via our website.<br />

/www.<strong>stahlmarkt</strong>-magazin.de/<br />

crossmedia<br />

L STEEL IN BRIEF<br />

ENERGY-INTENSIVE INDUSTRIES<br />

WARN AGAINST INCREASE OF<br />

ENERGY COSTS<br />

Brussels. The Alliance of Energy-Intensive<br />

Industries has urged the <strong>European</strong> Commission<br />

to abandon its plans to amend the Emission<br />

Trading System (ETS) in a way that would<br />

increase energy costs for private and industrial<br />

consumers in Europe. In the face of recent plant<br />

closures, restructuring and lay-offs throughout<br />

the whole value chain of <strong>European</strong> manufacturing<br />

industry, the EU should avoid all political<br />

measures that would add to the cost burden of<br />

its economic base, the Alliance said.<br />

The <strong>European</strong> industry has been struggling for<br />

almost four years with recession conditions<br />

brought about by the financial and economic<br />

crisis. Unemployment has climbed to 25.3 million<br />

persons or 10.4 % in the EU 27 in September<br />

2012, a historically high level. Recent incidents<br />

in the manufacturing industries in France,<br />

Belgium or the UK represent but a few, though<br />

particularly striking examples of the critical state<br />

of Europe’s economy. The Alliance said that<br />

investments were much needed to reinvigorate<br />

industrial production and reestablish growth.<br />

The Commission‘s proposals now on the table<br />

to artificially increase the ETS carbon price would<br />

further undermine the competitiveness of the<br />

<strong>European</strong> manufacturing industry, in the view of<br />

the Alliance. According to the current planning,<br />

soaring carbon costs will be passed on by the<br />

power sector through higher power prices.<br />

However, the recent Industrial Policy Communication<br />

has highlighted that electricity costs in the<br />

EU are already twice as high as in competing<br />

regions such as the US, Korea or Canada.<br />

Increasing ETS costs in the EU would thus further<br />

add to this competitive disadvantage, the<br />

Alliance fears.<br />

(EE 130104549) K<br />

FURNACE FOR TATA STEEL<br />

SPECIALITY STEELS<br />

Düsseldorf. Tata Steel Speciality Steels, UK,<br />

has chosen SMS Mevac, Germany, to design a<br />

VIM X-eed ® vacuum induction melting furnace<br />

for its Stocksbridge site. The facility will produce<br />

high-purity steels and specialist alloys for the<br />

aerospace industry, a sector where Tata Steel is<br />

already established as a leading supplier. The<br />

project is currently in the design phase and is<br />

intended to go into production in 2014, pending<br />

final capital approval.<br />

(EE 130104722) K<br />

SMS CONCAST AND SMS MEER<br />

TO BUILD GREEN FIELD MINIMILL<br />

Düsseldorf. SIMEC Group from Apizaco,<br />

Mexico, has placed an order with SMS Concast,<br />

Switzerland, and SMS Meer, Germany, for a<br />

minimill. The plant for »GV do Brazil« will be<br />

tailored to the customer‘s requirements and<br />

offers high production flexibility. The minimill is<br />

to be erected near Pindamonhangaba in the<br />

Brazilian State of São Paulo. SMS Concast will<br />

supply the steelworks for the minimill, and SMS<br />

Meer the adjacent bar and wire rod mill. The<br />

plant is designed for an annual production<br />

capacity of 520,000 tonnes of billets and<br />

400,000 tonnes of bars and wire rod, which can<br />

be expanded to 560,000 tonnes per year.<br />

(EE 130104593) K<br />

MODERNISATION PROJECT<br />

AT ZENTRALKOKEREI SAAR<br />

COMPLETED<br />

Dillingen. Work has now been completed on<br />

the modernisation project of Zentralkokerei Saar<br />

GmbH (ZKS), a joint subsidiary of AG der Dillinger<br />

Hüttenwerke and Saarstahl AG. Optimisation of<br />

coke production and the reduction of emissions<br />

were the essential targets of the project that<br />

started in 2007. Following the construction of the<br />

new battery 3 and its commissioning in 2010, the<br />

totally renovated battery 1 has now also been<br />

successfully restarted. The modernisation of the<br />

batteries included the incorporation of the very<br />

latest pollution prevention technologies: a new<br />

charging-gas capture system and the installation<br />

of independent pressure control in each individual<br />

coke oven chamber have achieved a<br />

notable reduction in emissions.<br />

www.stahl-holding-saar.de<br />

/<br />

(EE 130104627) K<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

12 K Steel International<br />

The steel industry:<br />

China continues to set the pace<br />

Is ecological sustainability a successful strategy for steel producers?<br />

Düsseldorf (mh). The future of the steel industry is currently plagued by<br />

many uncertainties. Producers face major challenges despite enormous<br />

developments in recent decades. During the Second International Steel<br />

Trade Day at EUROMETAL, engineer Pierre Mangers MBA – Metals &<br />

Mining Leader at Ernst & Young – described the options available for<br />

producers to react to the changing market situation.<br />

WW K Considered on a global level, the<br />

material steel has been enjoying a boom<br />

for many years. Driven by the demand<br />

generated by major economies, such as<br />

China, India or Brazil, ever-greater quantities<br />

of steel are being produced. However, steel<br />

producers in the classic industrial nations,<br />

e.g. in Europe, Japan or the USA, face major<br />

challenges. No significant growth rates can<br />

be expected from their own domestic<br />

markets in the foreseeable future. In<br />

addition, growing demand has led to rising<br />

raw material and energy costs. With<br />

demand fluctuating, however, it is difficult<br />

to pass on these increased costs to customers,<br />

according to the Ernst & Young<br />

expert Mangers. This puts pressure on the<br />

margins.<br />

Profits under pressure<br />

The situation would not be so bad if it were<br />

only higher raw material and energy costs<br />

that affected the margins. Profits, however,<br />

are under pressure from a variety of sources,<br />

Mangers adds: lower steel prices, rising<br />

employment costs, and investor interests<br />

make life difficult for steel producers. It is<br />

also becoming increasingly hard to make<br />

stable predictions about future market<br />

... how sustainability leaders are responding to the challenge<br />

Innovating in energy<br />

effective products<br />

Sharing corporate<br />

responsibility values<br />

Customer<br />

Reach<br />

Prioritizing regional<br />

to global markets<br />

Enhancing exibility<br />

in supply chain<br />

Enhancing market<br />

volatility intelligence<br />

Increasing collaboration<br />

with external partners<br />

Operational<br />

Agility<br />

Leaders of<br />

Sustainable<br />

Steel<br />

Cost<br />

Competitiveness<br />

Sustaining material and<br />

energy effectiveness<br />

Implementing<br />

Lean Six Sigma<br />

Implementing lowcarbon<br />

cost sourcing<br />

Identifying and managing<br />

sustainability risks<br />

Stakeholder<br />

<br />

Improving transparency and frequency of<br />

nancial and non-nancial reporting on<br />

performance with stakeholders<br />

(EE 130104840/1)<br />

Anticipating regulatory<br />

changes<br />

Source: Ernst & Young Metals & Mining Analysis<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

Steel International K 13<br />

developments because the markets are<br />

simply changing too quickly. Thus stable<br />

planning – a necessary prerequisite for the<br />

long-term investments in large production<br />

plants typical in the steel industry – is<br />

becoming increasingly difficult to draw up<br />

and, above all, implement. Therefore, in<br />

Pierre Mangers’ opinion, it is becoming less<br />

and less important for steel companies to<br />

come up with highly detailed strategies, but<br />

instead to prepare for a variety of scenarios<br />

with extreme flexibility.<br />

The risk of overcapacities<br />

China is still of prime importance for the<br />

development of the worldwide steel industry,<br />

according to Mangers. The industrialisation<br />

there has had, and continues to have,<br />

enormous effects on the development of<br />

many industrial sectors worldwide,<br />

particularly the steel industry. China will also<br />

set the pace for future development.<br />

Steel demand in China will probably reach<br />

its peak in about seven years, in around<br />

2020. Chinese industrialisation will have<br />

reached its zenith then – a turning point<br />

that will have a major effect on the global<br />

steel industry. But on the way there, China’s<br />

already lower growth rates represent a<br />

major challenge for the steel industry.<br />

Overcapacities: the enormous demand for<br />

steel in China has led to massive ›green field‹<br />

investments in a range of large production<br />

capacities. Moreover, many existing production<br />

plants have been modernised. Obsolete<br />

capacities, however, have not been taken<br />

off the market. But falling steel use is<br />

releasing production capacities that are<br />

used for exports, if they are not closed<br />

down. According to Mangers, overcapacities<br />

in China amounted to about 30 % of<br />

demand in 2011. The imbalance between<br />

supply and demand will increase further if<br />

the Chinese government does not introduce<br />

clear regulations – and it is extraordinarily<br />

difficult to predict what that would mean<br />

for China’s various export markets<br />

worldwide, Mangers continues.<br />

Ecological and economic<br />

interests converge<br />

Energy and raw material costs decide on the<br />

profitability of production throughout the<br />

steel industry. In this situation the industry’s<br />

economic interests come up against<br />

ecological interests regarding the emission<br />

of lower quantities of greenhouse gases.<br />

Whereby, as one of the important energyintensive<br />

industries, the steel industry plays<br />

a decisive role. In China, for example, the<br />

steel industry is responsible for about 20 %<br />

of global energy consumption and roughly<br />

30 % of the world’s output of CO 2<br />

,<br />

according to the International Energy<br />

Agency, Mangers adds. Further political<br />

measures to reduce emissions can be<br />

expected in future. Even if regulation leads<br />

to increased burdens for steel-producing<br />

companies, the lower consump tion of<br />

»<br />

There<br />

is no planning security<br />

in the current market situation,<br />

but the freedom to plan<br />

for the future by means<br />

of scenarios – in order to be<br />

better able to limit the<br />

uncertainty of working<br />

hypotheses.<br />

Pierre Mangers<br />

energy would result in reduced costs. This<br />

would be the case, according to Mangers,<br />

when energy costs make up more than onethird<br />

of a company’s total costs. China, for<br />

example, could reduce its CO 2<br />

emissions<br />

by about 300 million tonnes by 2020 by<br />

installing modern production capacities<br />

designed for sustainability.<br />

Sustainable steel production<br />

as a strategic option<br />

In technical terms, there are various<br />

approaches for reducing emissions of<br />

greenhouse gases. Many modifications that<br />

cut greenhouse gas emissions could be<br />

made along the entire value-creation chain<br />

from producers to traders. While in Europe<br />

the minimisation potentials in production<br />

are relatively small – because state-of-theart<br />

plants are already being operated – the<br />

production side in other countries and<br />

regions, such as China, Russia and South<br />

America, offer great potentials.<br />

How does one successfully compete on<br />

the markets, in this situation, with steel<br />

production that is sustainable from both the<br />

ecological and economic points of view?<br />

Mangers advises examining the strategies<br />

used by other industries (e.g. the oil industry)<br />

that face, or have faced, similar challenges.<br />

Four strategic areas play a special role:<br />

Firstly, the customer base: The customer<br />

base is increased by innovations in energyefficient<br />

products, the preference of regional<br />

over global markets, and the successfully<br />

communicated (and shared) corporate<br />

responsibility for sustainable production.<br />

Secondly, operational agility: The only<br />

thing that can help combat increasing<br />

volatility is to function more flexibly and be<br />

able to adapt seamlessly to unforeseen<br />

events. This involves new concepts for<br />

organising the work steps in the valuecreation<br />

chain so that rapid adaptations to<br />

changing conditions are possible. New<br />

analytical methods for obtaining reliable<br />

information on volatile markets also play a<br />

role, as does greater collaboration with<br />

external partners.<br />

Thirdly, cost competitiveness: This involves<br />

material and energy efficiency as well as<br />

new management techniques already<br />

exploited in automobile and aircraft manufacture:<br />

lean manufacturing and Six Sigma.<br />

In addition, Pierre Mangers recommends a<br />

rethink regarding the low-cost-country<br />

sourcing approach and the gradual introduction<br />

of procurement strategies that are<br />

more CO 2<br />

-neutral.<br />

Fourthly, stakeholder confidence: Greater<br />

external transparency regarding corporate<br />

performance and particular attention to<br />

potential regulatory changes ensure and<br />

improve the position of the company vis-a-vis<br />

important external interest groups<br />

What strategies are therefore available to<br />

steel producers for successfully facing the<br />

future? Above all, the volatility of the<br />

markets should be taken into account,<br />

according to Mangers. At least until 2020,<br />

because then the saturated steel demand in<br />

China could lead to a turning point for the<br />

steel industry worldwide and dampen the<br />

heavy fluctuations in the markets. According<br />

to Mangers, the second important area is<br />

sustainable production, which steel producers<br />

are almost forced into as a result of<br />

rising energy and raw material costs.<br />

(EE 130104840) K<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

14 K Special: Northern Europe / UK<br />

Stable outlook<br />

British steel stockholders are facing 2013 with confidence<br />

In a changing supply scene, where an increasing amount of steel is<br />

imported into the UK, British steel stockholders and service centres are<br />

looking forward to a virtual repeat of 2012 in terms of business growth and<br />

turnover. »<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong>« visited the National Association of<br />

Steel Stockholders (NASS) and met Director General, Peter Corfield.<br />

(photo: NASS)<br />

Peter Corfield<br />

WW Stahlmarkt: When we spoke last in<br />

summer 2011, you quite rightly predicted a<br />

low but sustained growth for the UK steel<br />

trade sector. In the recent NASS News Update<br />

there were some cautiously positive views<br />

about the UK economy. Recent government<br />

figures bear this out, but will this trend<br />

continue and will it be uniform across the<br />

sector?<br />

WW Peter Corfield: In 2013, I think the<br />

automotive sector will continue to be quite<br />

strong. One of the advantages that the<br />

automotive sector in the UK has is that the<br />

vehicles produced are on a single model<br />

UK Quarterly Balance of Trade<br />

in million tonnes<br />

3<br />

2<br />

1<br />

0<br />

(EE 130104861/1)<br />

All steel products Q3 2008 – Q2 2012<br />

Exports<br />

production site basis. i.e. there is not<br />

another factory in Europe that is building<br />

the same model. These plants therefore rely<br />

on the demand for their specific product<br />

across Europe to absorb their output. The<br />

markets either want or don‘t want specific<br />

models. The models made in the UK seem<br />

to be popular, especially Jaguar and Land<br />

Rover, however all models being produced<br />

within the UK seem to have a positive<br />

response from the marketplace.<br />

You only have to look at the number of<br />

vehicle registrations in the UK and how<br />

much is exported to mainland Europe and<br />

Imports<br />

2.2 2.1<br />

1.8<br />

1.9<br />

1.8 2.0 2.0<br />

2.0 2.0<br />

1.8<br />

1.6 1.7 1.6 1.6 1.7 1.6<br />

1.7<br />

1.5 1.5<br />

1.5<br />

1.5<br />

1.4<br />

1.3 1.4 1.4<br />

1.4<br />

1.3<br />

1.3 1.3<br />

1.0 1.1<br />

1.0<br />

2008 2009 2010 2011 2012<br />

Source: ISSB<br />

other parts of the world – I think that the<br />

automotive sector is now approaching<br />

historical highs in terms of production units<br />

within the UK. And that is in contrast to<br />

what‘s happening elsewhere in Europe.<br />

Some parts of Europe are reporting that<br />

their automotive sector is not strong,<br />

because they are experiencing reduced<br />

demand. It is also important to note that the<br />

UK has started from a lower point and<br />

continues to grow. So we‘ve got the<br />

opposite sides of the spectrum here.<br />

WW But there will be some flexibility, as in the<br />

case of Honda, where the manufacturer is<br />

slowing down a facility. That‘s of course a<br />

drawback of the situation that if you are the<br />

maker of one specific model, you will also<br />

have to bear it if that model does not sell well.<br />

WW Yes, you will, if the model does not sell.<br />

Honda have always tried to align their<br />

production to supply and demand. They are<br />

usually quite good at forecasting.<br />

The next major sector, construction, has<br />

had a lot of publicity and media attention in<br />

the year. It has stalled, there‘s no doubt<br />

about it – obviously the consequences of<br />

what‘s happened as a result of government<br />

cuts has impacted. Nonetheless there was<br />

still something in excess of 900,000 tonnes<br />

of steel consumed in construction in 2012.<br />

And there is no reason why that situation<br />

should change in 2013. In fact, the latest<br />

forecast is that it is likely to be even better.<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

Special: Northern Europe / UK K 15<br />

UK: crude steel production 2001 – 2012<br />

16<br />

14<br />

13,54<br />

13,17 13,77 13,24 13,87 14,32 13,52<br />

in million tonnes<br />

12<br />

10<br />

8<br />

6<br />

11,67<br />

10,08<br />

9,71 9,48 9,70<br />

4<br />

2<br />

0<br />

2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012<br />

(EE 130104861/2)<br />

Source: worldsteel<br />

WW Is this influenced by the easier planning<br />

and execution of domestic house building?<br />

WW Domestic house building has an impact<br />

on steel, but it‘s not as great as industrial,<br />

commercial, retail, or in fact infrastructure<br />

development. Within domestic build, the<br />

main use of steel is on what we call »fitout«,<br />

i.e. components for ceilings, partition<br />

walls or purlins, which are all derived from<br />

flat products. Steel construction is normally<br />

a large consumer of long products which<br />

are processed by steel fabricators. There<br />

have been some casualties amongst the<br />

fabricators and it is still an area which is<br />

considered with concern by the risk<br />

underwriters. Having said that, there are<br />

also one or two success stories in there, with<br />

fabricators who have continued to flourish.<br />

But the important thing within construction<br />

is that there is relatively stable activity. And<br />

surprisingly, in the last couple of months,<br />

there has been a revival of some projects<br />

and increased activity.<br />

WW Another important steel sector involves<br />

the manufacture of earthmoving equipment,<br />

the »yellow goods sector«, as it is generally<br />

referred to. Demand has been good for the<br />

first three quarters of 2012. In the final<br />

quarter there was probably a similar situation<br />

to Honda, i.e. there was an alignment of<br />

units produced to meet demand. The latest<br />

view of 2013 is that it will replicate 2012. So<br />

it is not a case of the last quarter of 2012<br />

becoming the basis for expectations in 2013.<br />

These yellow goods, are they going to<br />

markets outside Europe?<br />

WW They‘re mainly going to the rest of the<br />

world markets. All major manufacturers are<br />

going to these markets and setting up<br />

appropriate facilities. JCB with their headquarters<br />

in the UK, are now operating plants<br />

in Brazil, China and India. And there are<br />

others that are pursuing similar activities,<br />

and they are supplying the goods.<br />

WW So whatever happens in the Eurozone<br />

will be relevant to them, but not decide their<br />

business?<br />

WW The majority of their activity is outside<br />

Europe and will increasingly be that way.<br />

There is no doubt about it. And obviously,<br />

with that in mind, hopefully they will<br />

maintain their plants in the UK for their<br />

<strong>European</strong> requirements.<br />

The other sector worthy of note at the<br />

present time is utilities, incorporating<br />

energy, power and gas production. This is a<br />

key area for our plate distributors/profilers,<br />

who are telling us that projects which were<br />

frozen or on hold are suddenly coming<br />

to fruition. These projects do not use<br />

commodity plate, but utilise specialised<br />

plate that has an extended lead time, and<br />

this has created some pressure in terms of<br />

availability. So there‘s no doubt that in that<br />

area of specialised plate, the suppliers are<br />

having quite a reasonable time.<br />

WW Will this plate come mostly from abroad?<br />

WW The sourcing of these higher quality<br />

grade plates is likely to be from Europe as<br />

opposed to the rest of the world. Some of<br />

these requirements will obviously be met by<br />

UK supply.<br />

In this context it is also worth noting that<br />

in the manufacturing supply chain the closer<br />

firms are to making things, the busier they<br />

appear to be. The majority of UK manufacturers<br />

have filled their capacities to<br />

acceptable levels throughout 2012. There<br />

are no indications of reduced activity in the<br />

short term, in fact I would argue that more<br />

and more companies are becoming very<br />

selective in the work they are undertaking<br />

to ensure they are in a position to optimise<br />

profitability from the capacity they have<br />

available.<br />

WW One of the trends in recent market<br />

figures was the confidence amongst steel<br />

stockholders who re-built the stocks which<br />

had been depleted in the difficult years up<br />

to 2011. Will the steel trade allow its stocks<br />

to run down again in view of the uncertain<br />

outlook, particularly in the Eurozone?<br />

WW I think that the economic outlook in the<br />

Eurozone is a factor, although steel distribution<br />

centres in mainland Europe are<br />

probably aligning their steel stocks in terms<br />

of supply and demand, and controlling<br />

inventory levels based on stock days. In the<br />

past mainland <strong>European</strong> service centres<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

16 K Special: Northern Europe / UK<br />

have operated with higher levels of stock or<br />

stock days. They are now adopting a similar<br />

stance to that taken in the UK whereby<br />

stock levels have been significantly reduced<br />

and maintained at levels which are considered<br />

to be sufficient. People are working<br />

more efficiently within their range. They are<br />

not speculating, and the majority of the<br />

material supplied to the market is now from<br />

imports, not from domestic supply. These<br />

imports tend to be more <strong>European</strong> as<br />

opposed to from the rest of the world,<br />

because availability, competitive pricing and<br />

in some cases, quality, is the deciding factor.<br />

So, what does it mean in practice? Steel<br />

service centres are operating with stock<br />

levels that may have some gaps within their<br />

range, but in the main they are operating<br />

with reduced levels of inventory. The key is<br />

that material is readily available. As a service<br />

centre you might therefore ask yourself:<br />

»Why do I want to keep this stock? It‘s<br />

taking up space, it‘s costing me money. I can<br />

buy it when I need it and in the amounts<br />

that I need and, in the main, I can bring it in<br />

from the UK or Europe at short notice.«<br />

WW Going by the ISSB‘s statistics, the ratio of<br />

imported to exported steel products has<br />

changed considerably. Imports of steel<br />

products are now much higher – more or less<br />

the same as in 2008 – while exports have<br />

consistently shrunk by about a quarter over<br />

the same period. Is the UK becoming even<br />

more dependent on foreign steel supplies?<br />

WW In the last four years imports of steel into<br />

the UK have gone from the mid 40 to the<br />

mid 50 % of supply. Overall, consumption<br />

is approximately 10 million tonnes per<br />

annum, of which NASS core products<br />

represent circa 6 million tonnes. Yes, imports<br />

have steadily increased and are likely to<br />

remain the major supply route to the UK<br />

steel market for the foreseeable future.<br />

WW Is another reason for imports increasing<br />

in the UK the fact that material from the rest<br />

of the world is being supplied to the UK<br />

market?<br />

WW Yes, steel does come from rest of world<br />

markets, with China, India, Russia and<br />

Turkey being the major sources of supply.<br />

There has however been a significant swing<br />

from RoW supply to <strong>European</strong> supply due to<br />

these sources normally involving longer lead<br />

NASS: new website<br />

NASS recently modernised its website www.nass.<br />

org.uk, which now offers an impressive range of<br />

facilities, including a secure members‘ area, a<br />

calendar of events and, of course, the extensive<br />

News Update.<br />

<br />

become the portal for our communication, with<br />

both the membership and the external world. We<br />

would like our website to be user-friendly, active<br />

and provide interest for everyone involved in steel<br />

processing and distribution. In terms of where we<br />

times, and the biggest danger with shipping<br />

any great volume is that by the time the<br />

steel arrives in the UK, it is no longer at the<br />

right price. Steel service centres may have<br />

thought they had concluded an advantageous<br />

transaction when ordering the steel,<br />

but upon arrival that might no longer be the<br />

case. That is why there is less being speculated<br />

and purchased from RoW markets.<br />

WW On the list of NASS members, there are<br />

now ten large groups active nationwide<br />

which seem to dominate the market. Is there<br />

a trend towards consolidation in the sector<br />

or could this be a situation where the large<br />

groups cover a wide range of general products,<br />

whereas the smaller companies act<br />

more like »boutique« suppliers with highly<br />

specialised products and services?<br />

WW There is no generic way of looking at it,<br />

but the last two major changes in the UK<br />

were Barclay & Mathieson being acquired by<br />

Stemcor, and Austin Truman exiting the<br />

heavy sections market when the Murray<br />

Group was re-structured. However, there<br />

have not been any casualties, the sector<br />

remains quite robust and this is confirmed in<br />

our discussions with the risk underwriters,<br />

who have developed an appetite for the<br />

sector. Yes, the bigger groups have got both<br />

specialisation and also have the opportunity<br />

to serve local markets. There have been<br />

announcements by some of the major<br />

groups to close or rationalise sites. They are<br />

undertaking these restructuring activities<br />

over a specified time scale. There is no doubt<br />

that there will always be a place for the small<br />

niche suppliers, the local service centres, and<br />

in actual fact, I think that this sector will<br />

<br />

facility is paramount as we seek to provide more<br />

links for members. We are already involved with<br />

the CBI, the Chamber of Commerce and the<br />

Health & Safety Executive. We want these links to<br />

create a knowledge share for both members<br />

<br />

continues to grow and will feature prominently to<br />

visitors to the website, whereby both professional<br />

and social activities can be clearly seen.«<br />

grow. The larger distributors are all now<br />

actively processing and distributing on a<br />

»hub and spoke« basis, whereby they have<br />

major facilities with smaller units feeding off<br />

them. Customers will then either buy directly<br />

from the central hub or buy locally,<br />

depending on what the products are, the<br />

frequency with which they‘re needed, the<br />

time restraint and so on. I don‘t think that<br />

there will be much further amalgam ation.<br />

In conclusion, I think that the existing<br />

groups are likely to stay in place. It may be<br />

that they acquire or that they rationalise, but<br />

that will be down to their own philosophy<br />

and their geographical approach to the UK<br />

market. In the long term, however, you<br />

might have fewer medium-sized groups<br />

going forward as the emphasis will be on<br />

having very large or small facilities processing<br />

and distributing steel products.<br />

WW One left-over from the financial crisis in<br />

2008 was the tight credit supply to the steel<br />

trade. NASS counteracted that by trying to<br />

improve mutual understanding between the<br />

stockholders, government and the finance<br />

industry. Have you been able to alleviate the<br />

situation, or are there, by now, alternative<br />

solutions?<br />

WW Discussions are on-going with all<br />

interested parties. NASS is delighted to have<br />

all the major players in the risk management<br />

sector as Associate Members, with whom we<br />

have regular dialogue and this has obviously<br />

improved communications and understanding.<br />

That is of particular relevance given<br />

that 2012 has probably produced a number<br />

of financial returns which were disappointing<br />

and gave potential cause for concern. If you<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

Special: Northern Europe / UK K 17<br />

go back in time, this would probably have started a ripple of credit<br />

withdrawals or led to a tightening of credit limits in the process. I<br />

think the regular dialogue and better understanding of the business<br />

scenario has certainly helped that situation. In addition we also meet<br />

on a quarterly basis with the Bank of England, whereby we represent<br />

the steel service centre sector and, in turn, ensure everyone has a<br />

better appreciation of what NASS members represent.<br />

In addition to all the things we have spoken about so far, another<br />

area NASS will be focusing on is that of aspects of the environment<br />

and climate change. In the past many people have not considered<br />

it relevant, but if they review the costs involved relating to the<br />

carbon tax they pay on their utility bills, then they might realise that<br />

there is an issue. So, one of our main objectives for 2013 will be to<br />

review the eligibility of our members to be embraced by umbrella<br />

arrangements which can significantly reduce carbon tax costs. This<br />

will not apply to all our membership, but we seek to maximise where<br />

opportunity presents.<br />

Finally, and with the above in mind, it is our intention to revamp<br />

our current motto »Safer Steel«. This has served the purpose of<br />

raising the awareness of handling and processing steel in a safe<br />

manner. In view of the advent of demand on the environment and<br />

the impact of recycling, climate change and sustainability, NASS is<br />

considering the introduction of a new motto which embraces these<br />

concepts. Hence a new motto of »Safe and Sustainable Steel« is<br />

currently under consideration by the gov erning body of NASS,<br />

namely the National Council. It is anticipated that the revised motto<br />

will be finalised and agreed at the AGM to be held in July 2013.<br />

Mr. Corfield, many thanks for answering these questions.<br />

(EE 130104861) K<br />

i<br />

The following article can be downloaded<br />

from the »<strong>stahlmarkt</strong>« website.<br />

Looking for a recovery<br />

After zero growth in 2012, the UK economy is expected to catch up<br />

again in the current year.<br />

Read the article via QR Code.<br />

Go straight to the PDF using<br />

this QR Code on your smartphone<br />

or via our website.<br />

/www.<strong>stahlmarkt</strong>-magazin.de/crossmedia<br />

<strong>stahlmarkt</strong> <strong>European</strong> <strong>Edition</strong> 1.2013

18 K Special: Northern Europe / UK<br />

New solution for mould, tool and die makers<br />

Vero Software release VISI 20 with many new features<br />

Cheltenham. Vero Software, a leading provider of CAD/CAM/CAE<br />

solutions for the tooling industry, has announced the release of their<br />

Mould & Die focused product VISI 20. Version 20 is a substantial release<br />

introducing many new features in all areas of the product with continued<br />

emphasis on solutions for mould, tool and die makers.<br />

WW K Major graphic enhancements include<br />

improved rendering, a programmable<br />

dynamic command widget and the ability to<br />

fast-view a file before opening to include<br />

pan and zoom functionality. Significant CAD<br />

enhancements include the ability to assign<br />

constraints to geometrical bodies (concentric,<br />

parallel, coincident, distance, etc)<br />

providing the tools to simulate the real<br />

movement of tooling, such as the ability to<br />

check for collisions with slides, cams, lifters,<br />

etc. A re-designed feature manager and 3D<br />

boring chart creates and edits complex holes<br />

and pockets as well as recognising features<br />

directly from the 3D model or 2D drawing<br />

for automated annotation.<br />

User efficiency continues to be a focus for<br />

product development, with the process<br />

workflow having been improved in a<br />

number of areas. This includes the ability to<br />

extract wireframe edges and also concatenate<br />

and simplify the extracted elements,<br />

remove knot points and split the geometry<br />

into correctly formatted curves based on<br />

angular deviation. Automating the process<br />

in this way significantly speeds up high<br />

quality surface creation when working with<br />

third-party data.<br />

VISI-Enhancements in detail<br />

VISI Progress developments include a new<br />

tool building engine, improved unfolding<br />

and new middle skin functionality for<br />

flanging and blanking operations. Other<br />

enhancements include a completely rewritten<br />

explode tool for 3D assemblies (with the<br />

ability to record the explode movements),<br />

improved standard component catalogues<br />

and continued collaboration with CADENAS.<br />

VISI Flow, for plastic flow analysis, is now<br />

64bit compatible, and therefore capable of<br />

benefiting from additional hardware performance.<br />

Other developments include new<br />

tools for the thermal analysis of conformal<br />

cooling.<br />