SPRING 2018

Distributor's Link Magazine Spring 2018 / Vol 41 No2

Distributor's Link Magazine Spring 2018 / Vol 41 No2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

138<br />

THE DISTRIBUTOR’S LINK<br />

VOGELSANG FASTENER SOLUTIONS LARGE DIAMETER SLOTTED TENSION PINS VS. ALTERNATIVE FASTENERS from page 56<br />

Large Diameter Pin Application Examples<br />

Agriculture attachments – large diameter 5/8”<br />

slotted tension pin can replace a bolt, two flat washers,<br />

lock washer and nut, saving material costs & labor.<br />

Agriculture Plow Joint – use M16, M18, and M20<br />

large slotted tension pins.<br />

Communication Dome – Slotted tension pins hold<br />

the pivot joints together. The size used was a 21mm<br />

diameter. The cost savings was in the fact that the<br />

tension pins not only acted as locating devices, but also<br />

secured the connection structure joints.<br />

Material handling equipment mines – M18<br />

pins are used to assemble the conveyor system. They<br />

replaced the bolt and nut application.<br />

Forestry Heavy Duty equipment – Slotted tension<br />

pins are used in booms and bucket applications.<br />

Construction bucket teeth – use slotted tension<br />

pins in ½” inch and metric M12 diameters.<br />

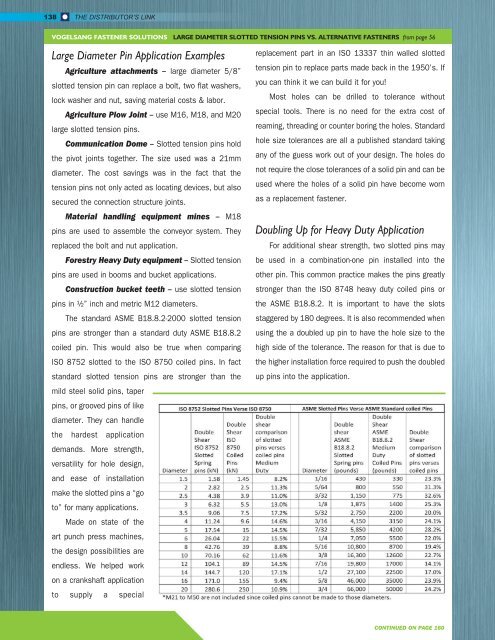

The standard ASME B18.8.2-2000 slotted tension<br />

pins are stronger than a standard duty ASME B18.8.2<br />

coiled pin. This would also be true when comparing<br />

ISO 8752 slotted to the ISO 8750 coiled pins. In fact<br />

standard slotted tension pins are stronger than the<br />

mild steel solid pins, taper<br />

pins, or grooved pins of like<br />

diameter. They can handle<br />

the hardest application<br />

demands. More strength,<br />

versatility for hole design,<br />

and ease of installation<br />

make the slotted pins a “go<br />

to” for many applications.<br />

Made on state of the<br />

art punch press machines,<br />

the design possibilities are<br />

endless. We helped work<br />

on a crankshaft application<br />

to supply a special<br />

replacement part in an ISO 13337 thin walled slotted<br />

tension pin to replace parts made back in the 1950’s. If<br />

you can think it we can build it for you!<br />

Most holes can be drilled to tolerance without<br />

special tools. There is no need for the extra cost of<br />

reaming, threading or counter boring the holes. Standard<br />

hole size tolerances are all a published standard taking<br />

any of the guess work out of your design. The holes do<br />

not require the close tolerances of a solid pin and can be<br />

used where the holes of a solid pin have become worn<br />

as a replacement fastener.<br />

Doubling Up for Heavy Duty Application<br />

For additional shear strength, two slotted pins may<br />

be used in a combination-one pin installed into the<br />

other pin. This common practice makes the pins greatly<br />

stronger than the ISO 8748 heavy duty coiled pins or<br />

the ASME B18.8.2. It is important to have the slots<br />

staggered by 180 degrees. It is also recommended when<br />

using the a doubled up pin to have the hole size to the<br />

high side of the tolerance. The reason for that is due to<br />

the higher installation force required to push the doubled<br />

up pins into the application.<br />

CONTINUED ON PAGE 160