Insulate Magazine Issue 11 - October 2017

When is an Insulation Manufacturer not and Insulation Manufacturer headlines the October issue of Insulate Magazine. Possibly the best front cover for an Insulation publication EVER.

When is an Insulation Manufacturer not and Insulation Manufacturer headlines the October issue of Insulate Magazine. Possibly the best front cover for an Insulation publication EVER.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

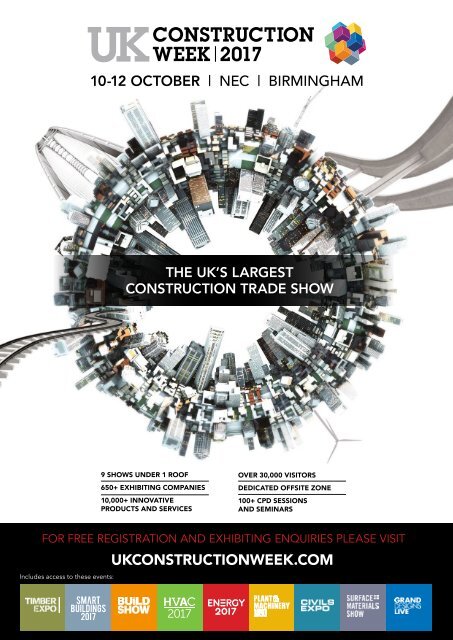

<strong>2017</strong><br />

10–12 NEC BIRMINGHAM<br />

10-12 OCTOBER | NEC | BIRMINGHAM<br />

THE UK’S LARGEST<br />

CONSTRUCTION TRADE SHOW<br />

9 SHOWS UNDER 1 ROOF<br />

650+ EXHIBITING COMPANIES<br />

10,000+ INNOVATIVE<br />

PRODUCTS AND SERVICES<br />

OVER 30,000 VISITORS<br />

DEDICATED OFFSITE ZONE<br />

100+ CPD SESSIONS<br />

AND SEMINARS<br />

FOR FREE REGISTRATION AND EXHIBITING ENQUIRIES PLEASE VISIT<br />

Includes access to these events:<br />

UKCONSTRUCTIONWEEK.COM<br />

<strong>2017</strong>