African Petrochemicals- Mar/April Edition 15_2 {2018}

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IN THIS EDITION<br />

NEW THINMANAGER SOFTWARE RELEASE IMPROVES OPERATOR PRODUCTIVITY<br />

<strong>Edition</strong> <strong>15</strong>.2<br />

SLURRY PUMPS PUSH THE BOUNDARIES IF RELIABILITY <strong>Mar</strong>ch / <strong>April</strong> <strong>2018</strong><br />

Height safety | Welding Installations | Inspection & NDT | Confined spaces<br />

Maintenance protective coatings | Drones<br />

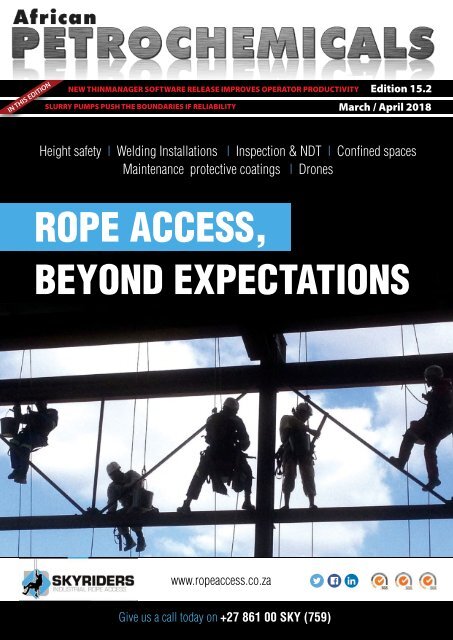

ROPE ACCESS,<br />

BEYOND EXPECTATIONS<br />

www.ropeaccess.co.za<br />

Give us a call today on +27 861 00 SKY (759)

Proudly hosted by<br />

The <strong>African</strong> Petrochemical Roadshow offers a diagonal slice of<br />

the industry, showcasing and highlighting multiple products,<br />

services and expertise available to the Petrochemical Industry,<br />

General Engineering, Mining and Power Generation sectors.<br />

Secunda<br />

28 June <strong>2018</strong><br />

Sasol Recreation Club<br />

Book your stand<br />

or pre-register to<br />

visit online.<br />

Upcoming <strong>2018</strong><br />

Roadshows<br />

Secunda Petrochemical<br />

Roadshow<br />

28 June <strong>2018</strong><br />

Sasol Recreation Club<br />

The Engineering, Procuremant<br />

& Construction Expo Gauteng<br />

30 August <strong>2018</strong><br />

Leeuwkop Golf Club, Kyalami<br />

Mosselbay Petrochemical<br />

Roadshow<br />

October <strong>2018</strong><br />

Mosselbay Civic Centre<br />

Germiston Independent Power<br />

Providers 4.0 Africa<br />

Roadshow<br />

25 October <strong>2018</strong><br />

Victoria Lake Club<br />

Durban Petrochemical<br />

Roadshow<br />

1 November <strong>2018</strong><br />

Amanzimtoti Civic Centre<br />

Dates are subject to change<br />

30 August <strong>2018</strong><br />

THE ENGINEERING,<br />

PROCUREMENT &<br />

CONSTRUCTION EXPO<br />

The Engineering, Procurement and Construction Expo<br />

This is the only expo hosted specifically for the Engineering Procurement and Construction (EPC) Industries in<br />

Gauteng. The show is an ideal business to business networking opportunity.<br />

2<br />

Please contact us for further information<br />

011 083 5125 • sales@africanpetrochemicals.co.za • www.africanpetrochemicals.co.za

<strong>African</strong> <strong>Petrochemicals</strong> is published bi-monthly by Direct Publications cc<br />

<strong>Edition</strong> <strong>15</strong>.2 <strong>Mar</strong>ch / <strong>April</strong> <strong>2018</strong><br />

Direct Publications<br />

Publisher<br />

Richard Scott<br />

richard@africanpetrochemicals.co.za<br />

Accounts and Admin<br />

Ashni Padiachie<br />

accounts@africanpetrochemicals.co.za<br />

Sales<br />

Sales Team<br />

sales@africanpetrochemicals.co.za<br />

Graphic Designer<br />

Linda Graae<br />

production@africanpetrochemicals.co.za<br />

The views and opinions expressed in this<br />

magazine are those of the respective authors<br />

and do not necessarily express the views and<br />

opinions of Direct Publications cc. We do not<br />

endorse any of the products , services or<br />

expertise offered by any of our advertisers or<br />

contributors. No liability will be accepted for<br />

artwork supplied incorrectly or slight colour<br />

deviations. Editorial contributions relevant<br />

to any section of the magazine are more than<br />

welcome. Email submissions to<br />

production@africanpetrochemicals.co.za<br />

Direct Publications reserves the right to cut and<br />

alter editorials received for publication.<br />

Reproduction<br />

No part of this magazine may be reproduced<br />

without written permission from the editor or<br />

publisher.<br />

Subscription Service<br />

For address changes, subscriptions or missed<br />

issues, please call 011 083 5125 or<br />

email: accounts@africanpetrochemicals.co.za<br />

CONTENTS<br />

Emerson’s new Magnetic Flow Meter<br />

Transmitter simplifies installation,<br />

maintenance and operation 4<br />

Skyriders progresses with five-year<br />

contract at major petchem producer 5<br />

Slurry pumps push the boundaries of<br />

reliability 6<br />

One-touch, advanced power quality<br />

analysis 8<br />

Facts about Watermist as a fire<br />

suppression solution 10<br />

New ThinManager Software Release<br />

Improves Operator Productivity 12<br />

Engen’s Theart is all Heart 13<br />

New orders for RTS Africa principal Nel’s<br />

hydrogen filling stations internationally<br />

‘fuelling’ hydrogen-powered vehicle<br />

trend 14<br />

BBF Safety Group donated footwear to<br />

Mhlaba Skills Centre <strong>15</strong><br />

‘Clamping’ down on safety: Vital<br />

Engineering’s Vitaclamps enhance safety<br />

in the power generation and other<br />

industrial sectors 16<br />

Schroeder SHP - A pump protection valve<br />

for Power Generation high pressures<br />

under all load conditions 17<br />

Waco Africa is now a 52% Black Owned<br />

Business 17<br />

Sasolburg Petrochemical Roadshow, <strong>15</strong><br />

<strong>Mar</strong>ch <strong>2018</strong> 18<br />

Engen’s Youth Development Programme<br />

shortlisted for the <strong>2018</strong> Sport Industry<br />

Awards 20<br />

Sulzer at ACHEMA <strong>2018</strong> 22<br />

Afraid a digital world means less human<br />

intelligence? Don’t be 24<br />

Rockwell Automation Named a <strong>2018</strong><br />

World’s Most Ethical Company for the<br />

Tenth Year 25<br />

Afrox welding facility at POPUP centre<br />

provides skills to those who need it the<br />

most 26<br />

Tech advances mean datacenters need<br />

more cooling – does yours? 27<br />

FactoryTalk Network Manager Software<br />

Simplifies Network Operations and<br />

Maintenance 28<br />

Zwick Triple Eccentric Valve with Superior<br />

Operating Characteristics 29<br />

Next Generation Wifi Fibre Optic<br />

Connector Inspection System 29<br />

Backup power - why site surveys are a<br />

win-win 30<br />

Added reliability in triple offset valves 31<br />

Visit <strong>African</strong> <strong>Petrochemicals</strong> online:<br />

www.africanpetrochemicals.co.za<br />

Visit our e-paper section to view the<br />

magazine archive:<br />

epaper.africanpetrochemicals.co.za<br />

(No Log-in details required)<br />

3

EMERSON’S NEW MAGNETIC FLOW METER TRANSMITTER SIMPLIFIES<br />

INSTALLATION, MAINTENANCE AND OPERATION<br />

Rosemount 8712EM wall mount transmitter provides easy navigation in the field and additional protocols for increased<br />

measurement confidence<br />

Emerson has introduced the Rosemount 8712EM Wall Mount<br />

Magnetic Flow Meter Transmitter with additional protocols, powerful<br />

diagnostic capabilities and usability features to help users in the water<br />

and wastewater, metals and mining, and other industries gain quick<br />

and easy insight into their processes.<br />

The meter’s local operator interface was designed using human<br />

centered design concepts, making it easier and faster for technicians<br />

to navigate in the field. According to Scott Dudek, product manager<br />

for Rosemount magnetic flow meters, “The Rosemount 8712EM melds<br />

usability pioneered by Emerson’s Human Centered Design Group with<br />

the quality, capabilities, and reliability that customers have come to<br />

trust from Emerson.”<br />

The Rosemount 8712EM’s diagnostic suite includes high process noise<br />

detection and ground fault detection. The electrode coating diagnostic<br />

offers two set points to alert when coating is present and when it is<br />

affecting flow measurement, enabling preventative maintenance.<br />

Smart Meter Verification continuously monitors the health and<br />

performance of the meter for ultimate measurement confidence.<br />

Universal transmitter capability allows the 8712EM to operate with<br />

any existing magnetic flow meter sensor and allows backwards<br />

compatibility with all Rosemount magnetic sensors. This feature not<br />

only makes the transmitter easier to integrate with older units, but it<br />

also enables the use of the 8712EM’s advanced diagnostic features.<br />

The Rosemount 8712EM supports HART 7 for 32-character-long tag<br />

capability for reduced start up time, as well as options for intrinsically<br />

safe HART outputs and Modbus RS-485.<br />

For more information, visit www.Emerson.com/Magnetic.<br />

About Emerson<br />

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a<br />

global technology and engineering company providing innovative<br />

solutions for customers in industrial, commercial, and residential<br />

markets. Our Emerson Automation Solutions business helps process,<br />

hybrid, and discrete manufacturers maximize production, protect<br />

personnel and the environment while optimizing their energy and<br />

operating costs. Our Emerson Commercial and Residential Solutions<br />

business helps ensure human comfort and health, protect food<br />

quality and safety, advance energy efficiency, and create sustainable<br />

infrastructure. For more information visit: Emerson.com.<br />

Further information is available from:<br />

Rob Smith<br />

Sales Manager, South & East Africa Emerson Automation Solutions<br />

Tel: 011 451 3700<br />

Email: Rob.Smith@emerson.com www.Emerson.com<br />

Rosemount 8712EM magnetic flowmeter.<br />

Online<br />

epaper.africanpetrochemicals.co.za<br />

VIEW THE BACK EDITIONS ONLINE<br />

(No opt in or log in details required)<br />

4

Skyriders progresses<br />

with five-year<br />

contract at major<br />

petchem producer<br />

From work at tank farms to power station<br />

boiler inspection, Skyriders’ five-year<br />

contract at a major petrochemical<br />

(petchem) producer in South Africa has<br />

progressed in leaps and bounds.<br />

FRONT COVER STORY<br />

The access specialist began its association<br />

with the company by carrying out<br />

maintenance and inspection work on its fire<br />

water systems. “Over the years, our scope of<br />

work has branched out to include inspection<br />

in power station boilers,” Skyriders <strong>Mar</strong>keting<br />

Manager Mike Zinn reveals. He adds that this<br />

is a good indication of not only the scope<br />

and size of the company in question, but<br />

the total value-add that a specialist service<br />

provider such as Skyriders can add to its<br />

operations.<br />

While the tank-farm portion of Skyriders’<br />

scope of work has a dedicated team allocated<br />

to it, any other requirements are assigned the<br />

necessary resources as and when needed.<br />

Apart from rope-access skills, the tank-farm<br />

team also has expert knowledge of deluge<br />

systems and general plumbing, especially as<br />

they are often required to join piping.<br />

Bolting and rigging skills are also included in<br />

the mix of services that Skyriders provides.<br />

The latest development is that an Elios<br />

collision-tolerant drone from Flyability of<br />

Switzerland has been deployed for confinedspace<br />

inspection at the petchem producer.<br />

“These areas are quite treacherous and<br />

dangerous, and pose a major health and<br />

safety risk,” Zinn highlights.<br />

The drone technology represents the latest<br />

innovation in inspection systems from<br />

Skyriders, which always strives to be at the<br />

top of its game in the industry, and thereby<br />

set itself as a benchmark for the rest of Africa.<br />

For example, during its association with<br />

the petchem producer, it has managed to<br />

achieve ISO9001, OHSAS 18001 Occupational<br />

Health and Safety, and ISO 14001<br />

Environmental Management.<br />

“It is important for us to align ourselves with<br />

exactly the same standards as our client<br />

in terms of quality, health and safety, and<br />

environmental management,” Zinn adds.<br />

“We often find that our clients have specific<br />

processes and procedures that we are<br />

required to follow, and therefore it helps if we<br />

are all on the same page from the get go.”<br />

The fact that the petchem producer is so<br />

safety-conscious and process-driven filters<br />

through to its entire supply chain and all of<br />

the specialist companies and service providers<br />

it deals with, which has the added benefit of<br />

raising standards in the industry as a whole.<br />

“This is a perfect example of the kind of<br />

partnership we like to enter into with our<br />

longstanding clients, which is testament<br />

to our proven capabilities. In this particular<br />

contract, we have seen a traditional client<br />

committed to scaffolding advance to rope<br />

access and ultimately our latest drone<br />

technology,” Zinn concludes.<br />

Connect with Skyriders on Social Media<br />

to receive the company’s latest news<br />

• Facebook: www.facebook.com/<br />

SkyridersIndustrialRopeAccess<br />

• Twitter: twitter.com/SkyridersZA<br />

About Skyriders<br />

Skyriders (Pty) Ltd, established in 1998, is<br />

a leader in the South <strong>African</strong> rope access<br />

industry, providing cost- and time-saving<br />

solutions to clients in the power generation<br />

and petrochemical industries who require<br />

rope access aided inspection, NDT and<br />

maintenance work to be done in difficult to<br />

reach, high-up locations.<br />

Skyriders Contact<br />

Mike Zinn<br />

Skyriders <strong>Mar</strong>keting Manager<br />

Phone: (011) 312 1418<br />

Email: mike@ropeaccess.co.za<br />

Web: www.ropeaccess.co.za<br />

5

The residue pump where KSB proved it is a myth that slurry pumps have short lifespans.<br />

Slurry pumps push the boundaries of reliability<br />

du Preez Calitz, projects engineer of<br />

QKR Namibia .<br />

KSB Pumps and Valves has busted the ‘slurry pumps have short lifespans’ myth with<br />

the ongoing success of its Navachab Gold Mine installation in Namibia, where 10 of its<br />

LSA slurry pumps have operated for nearly a year without incident.<br />

6<br />

AK Roux is the projects and<br />

asset management manager for<br />

QKR Namibia.<br />

This is in stark contrast to the previous pump<br />

sets at the mine, which operated a mere 4-6<br />

weeks between breakdowns in the aggressive<br />

wear environment of the mine. Resultant<br />

stoppages and production losses had<br />

resulted in the mine’s management seeking<br />

alternative solutions from new suppliers.<br />

KSB Pumps and Valves’ Andreas Gremels says<br />

the company was able to convince the mine<br />

of LSA technical superiority, and now has<br />

backed up the recommendation with actual<br />

on-the-job proof. “Our pumps have proven<br />

that they can work reliably and efficiently<br />

where others simply cannot.”<br />

Technical solution<br />

He continues that the hard metal design<br />

and additional high-pressure gland water<br />

system is less prone to component wear.<br />

The KSB LSA pumps make use of a unique<br />

high-pressure gland water system and gland<br />

service package that pressurizes the stuffingbox<br />

with non-slurry laden water to prevent<br />

particle ingress that can cause wear of<br />

components. Hard metal linings and specially<br />

designed impellers further contribute to the<br />

hard-wearing nature of the pumps.<br />

“This just goes to show that specifying the<br />

right pump for a technical application is<br />

critical to the success of pumping operations.<br />

In the case of the Navachab Gold Mine, the<br />

additional performance gains and reliability<br />

were complimented by the outstanding work<br />

done by owners, QKR Namibia’s technical<br />

teams. They designed and managed the<br />

installation of the entire project including<br />

monitoring systems etc and worked closely<br />

with our technical team to ensure optimal<br />

performance and longevity of the pumps<br />

and the entire installation,” says Andreas.<br />

QKR Namibia Projects Engineer, du Preez<br />

Calitz, confirms the success of the project.<br />

“The pumps were selected based on the<br />

long term wear simulations done by KSB and<br />

full life cycle cost analysis during the tender<br />

evaluation process. We have not looked back<br />

since then! In fact, an open inspection of<br />

the pumps recently revealed a much lower<br />

wear rate than initially expected which has

Host<br />

One global industry. One city. One meeting place.<br />

12 - <strong>15</strong> November <strong>2018</strong><br />

ADIPEC FAST FACTS<br />

135,000<br />

Gross sqm<br />

102,601<br />

Attendees<br />

2,109<br />

Exhibiting Companies<br />

THE DRIVING FORCE<br />

BEHIND TOMORROW’S<br />

OIL & GAS PARTNERSHIPS<br />

Over 80% of exhibition space at ADIPEC <strong>2018</strong> is now sold out.<br />

Due to unprecedented demand ADIPEC <strong>2018</strong> has increased exhibition space.*<br />

BOOK YOUR STAND NOW<br />

adipec.com/bookastand<br />

*The new Grandstand Hall 14 will be located next to the Atrium.<br />

26<br />

Country Pavilions<br />

189<br />

Conference Sessions<br />

959<br />

Expert Speakers<br />

10,1<strong>15</strong>*<br />

Conference Delegates<br />

17<br />

National<br />

Oil Companies<br />

*repeat delegate numbers<br />

16<br />

International<br />

Oil Companies<br />

Supported By<br />

Host City Knowledge Partner<br />

Official Broadcast Partner<br />

Official Media Partner ADIPEC Organised By

esulted in lower operating and maintenance<br />

costs as foreseen over the total lifecycle of<br />

the pumps. The pumps have certainly met<br />

and exceeded our expectations and the solid<br />

technical input and support of the company<br />

has been superb from the outset.”<br />

All-round solution<br />

Echoing the sentiment, AK Roux, projects<br />

and asset management manager for QKR<br />

Namibia, adds that the new pump station<br />

has now run more than 5000 hours without a<br />

single breakdown. He added that the project<br />

team placed specific focus on the evaluation<br />

of the full life cycle cost of the operation<br />

and maintenance of the pumps during the<br />

design of the new pump station and the<br />

selection of equipment. This resulted in<br />

pump installation which consume 18% less<br />

power under similar operation conditions<br />

than the previously installation, while the<br />

maintenance requirements over the first<br />

5000 hours of operations was limited to the<br />

repacking of the glands and the checking of<br />

bearing assembly oil levels.<br />

Vital statistics of the ten 6x8 LSA 25.HVHP for the Navachab Gold Mine owned by QKR<br />

Owners<br />

Mine Name<br />

Location<br />

QKR<br />

Navachab<br />

Karibib Namibia<br />

Date Installed 2017/05/10<br />

Date Final Commissioning 2017/05/23<br />

Operating time<br />

Application<br />

Pump Operating Duty<br />

from 2017/05/23 to present (24 hour operation)<br />

Tailings pumps<br />

Flow rate 500 m³/hr, SG= 1.5<br />

important making it essential to work with<br />

the best technical teams available, such as<br />

those of KSB Pumps and Valves.<br />

5 pumps in series (2 trains), pressure final stage 30 bar<br />

to become a multi-faceted solutions provider<br />

to the industry in Namibia and elsewhere in<br />

southern Africa,” he says<br />

KSB Pumps and Valves slurry pumps<br />

manager, Rob Bond, says the rural nature of<br />

this, and other mines in Namibia, makes it<br />

imperative that the pumps are manufactured<br />

from the highest quality materials and<br />

manufactured to the highest international<br />

standards. Correct pump selection is<br />

“The success of our slurry pumps in tough<br />

Namibian conditions is important to us as<br />

it gives us leverage to introduce our slurry<br />

pumps to other mines in the region. We are<br />

already one of the top suppliers of water<br />

pumps to mines in Namibia and the addition<br />

of our ultra-reliable slurry pumps enables us<br />

Contact:<br />

Annett Kriel,<br />

KSB Pumps and Valves,<br />

Tel: (011) 876 5600<br />

Fax: (011) 822 1746<br />

Email: Annett.Kriel@ksb.com<br />

Web: www.ksbpumps.co.za<br />

Petrochemical_Ad_AWC.indd 1 <strong>2018</strong>/01/27 13:42<br />

7

One-touch, advanced power quality analysis<br />

Troubleshoot, quantify energy usage and perform quality of service<br />

COMTEST is pleased to announce the availability of Fluke’s range of<br />

Three-Phase Power Quality Loggers - 1742, 1746 and 1748 - giving<br />

users fast, easy access to the data they need to make critical power<br />

quality and energy decisions in real-time.<br />

Compact and rugged, these Three-Phase Power Quality Loggers are<br />

designed specifically for technicians and engineers who need the<br />

flexibility to troubleshoot, quantify energy usage and analyze power<br />

distribution systems. Fully compliant with international power quality<br />

standards such as IEC 61000-4-30 and capable of simultaneously<br />

logging up to 500 parameters while also capturing events, the Fluke<br />

1740 Series helps uncover intermittent and hard-to-find power quality<br />

issues easily. The included Energy Analyze plus software quickly<br />

assesses the quality of power at the service entrance, substation, or<br />

at the load, according to national and international standards like EN<br />

50160 and IEEE 519.<br />

An optimized user interface, flexible current probes, and an intelligent<br />

measurement verification function allows for digital verification<br />

and correct connections make setup easier, considerably reducing<br />

measurement uncertainty. The devices also allow users to minimize<br />

time spent in potentially hazardous environments, while reducing the<br />

need to suit-up in PPE by using a wireless connection (WiFi) to view<br />

data directly in the field.<br />

Measures all power quality and power parameters<br />

The Fluke 1748 logs over 500 different parameters for each averaging<br />

period. This allows for the analysis of power quality in detail and<br />

the correlation of intermittent events with detailed waveform<br />

data, helping to identify the root cause of disturbances. For basic<br />

power quality logging, the Fluke 1746 captures all relevant power<br />

parameters for performing energy saving studies and electrical<br />

network planning with a full upgrade option to 1748 available.<br />

For simple load and energy studies the Fluke 1742 offers optimal<br />

performance in a rugged package and can be upgraded to 1746 or<br />

complete 1748 functionality.<br />

Calculates current harmonics limits<br />

When downloading data from the Fluke 1748 Power Quality Loggers,<br />

Energy Analyze Plus, can calculate the limits of current harmonics<br />

based on installation parameters to predict overload of the grid<br />

according to a wide range of international<br />

standards. This powerful predictive maintenance feature enables<br />

current harmonics to be observed before distortion appears in the<br />

voltage allowing users to prevent unexpected failures or noncompliance<br />

situations and increase system uptime.<br />

1746 Power Quality Logger.<br />

Rugged and reliable<br />

The 1740 series products are built to withstand tough working<br />

environments. The flexible current probes are IP65 rated and suitable<br />

for most installation situations; the optional IP65 voltage adapter<br />

ensures safe, reliable operation even in harsh conditions. Standard<br />

2m (6.6ft) leads simplify connection on difficult to access conductors,<br />

and optional 5m (16.5ft) leads are useful when installing in difficult<br />

locations. With the capability of powering the instruments from the<br />

power line up to 500 V, installation is simple.<br />

Thoughtful design<br />

The 1740 series power quality loggers include simple but effective<br />

accessories like the MA-C8 adapter making powering the instrument<br />

with a line cord easy when not in the field. Ports that aren’t always<br />

needed in the field are IP65 protected including the Ethernet, USB,<br />

AUX and I/O ports protecting for both moisture and dirt ingress. The<br />

status LEDs give a clear indication of what the instrument is doing<br />

without having to touch any controls. Its compact size means that in<br />

most cases it will fit into the available space easily.<br />

Contact COMTEST<br />

for more information on the Fluke 1740 series power quality loggers<br />

on<br />

Tel: 010 595 1821<br />

Email: sales@comtest.co.za<br />

Easy to use<br />

Fluke power quality loggers are designed with the technician in mind.<br />

The four current probes are each connected separately allowing<br />

flexibility and simplicity, the instrument automatically detects, scales<br />

and powers the probes so users don’t have to worry about ensuring<br />

the measurements are correct.<br />

8<br />

Analysis and reporting<br />

Capturing logged data is just one part of the task. Once you have the<br />

data, users need to create useful information and reports that can<br />

be easily shared and understood by their organization. Fluke Energy<br />

Analyze plus software makes that task as simple as possible. With<br />

powerful analysis tools and the ability to create customized reports<br />

in minutes users can communicate findings and solve problems<br />

to optimize system reliability and show savings. A range of built-in<br />

report templates for industry standards such as EN 50160, IEEE 519<br />

and GOST enable one-click reporting to create high quality reports at<br />

the touch of a button. Reports can be modified as standards evolve, or<br />

new versions become available.<br />

1748 Power<br />

Quality Logger.

The Information Revolution<br />

the smart process.<br />

We believe access to information should be simple!<br />

The Connected Enterprise makes it effortless.<br />

The ‘Internet of Things’ is driving the convergence of integrated control<br />

and information technologies. The Connected Enterprise helps advanced<br />

industrial operations be more productive, reliable, secure and sustainable, and<br />

respond competitively to dynamic demands within the oil and gas industry.<br />

Simplifying integrated process automation<br />

• Integrated control<br />

• Deterministic network<br />

• Secure infrastructure<br />

• Enhanced safety<br />

• Actionable information<br />

• Scalable dimensions<br />

• Future-proof networks<br />

• Operational efficiency<br />

From upstream to downstream, The Connected Enterprise<br />

helps ensure your informational connectivity, the smart way.<br />

Discover the right integrated control solution for your business.<br />

Tel: +27 11 654 9700<br />

Find out more about The Connected Enterprise:<br />

http://www.rockwellautomation.com/en_ZA/capabilities/<br />

connected-enterprise/overview.page?<br />

Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. Integrated Architecture is a registered trademark of Rockwell Automation, Inc.<br />

9

FACTS ABOUT WATERMIST AS A<br />

FIRE SUPPRESSION SOLUTION<br />

10<br />

Sperosens, a Danfoss-Semco partner, has<br />

recently embarked on introducing and<br />

developing High-Pressure water mist<br />

into the Southern <strong>African</strong> market. During<br />

experimental tests and demos, the<br />

effectiveness of water mist was clearly<br />

seen. During a test of the cooling effect<br />

of water mist on a petrol and diesel pan<br />

fire (1m by 1m) was started inside a 6m<br />

container. A pre-burn period was used<br />

for the fire and heat to fully develop. A<br />

sprinkler system with four sprinklers<br />

operating at a total flow rate of 1000<br />

liters per minute, was compared to one<br />

water mist nozzle operating at 40 bar and<br />

9 liters per minute. The sprinkler system<br />

did not manage to supress or extinguish<br />

the fire, while the mist nozzle was able<br />

to effectively extinguish the fire within<br />

8 seconds. Using a thermal camera to<br />

visualise the heat release and reduction<br />

rates, it was seen that after activation<br />

of the mist system, the ambient<br />

temperature inside the container<br />

drastically reduced form in excess of<br />

<strong>15</strong>0 °C to under 45°C after the mist was<br />

activated, proving and demonstrating<br />

the unique properties and life safety<br />

benefits that water mist has to offer.<br />

Over the past two decades, interest in water<br />

mist as a fire suppression systems technology<br />

significantly increased. As technology<br />

grew, the capability and understanding of<br />

water mist grew. By 1996, there were over<br />

50 agencies around the world who were<br />

involved in research and development<br />

of water mist, ranging from theoretical<br />

investigations of the extinguishing<br />

mechanisms to testing and development of<br />

mist generating equipment and hardware.<br />

The major focus of this development was<br />

to show that water mist has the potential to<br />

replace current fire protection techniques<br />

that are not environmentally acceptable and<br />

to find solutions to inefficiencies that current<br />

traditional technologies cannot answer.<br />

Before we focus on the fire supressing<br />

properties we first look at how water mist is<br />

defined. Water mist, according to NFPA 750,<br />

the Standard on Water Mist Fire Protection<br />

Systems defines water mist as a fine mist/fog<br />

spray were the Dv99 (99% of the distributive<br />

summation) of all the droplets is less than<br />

1000µm in diameter. The standard also<br />

defines that low-pressure systems operate<br />

at less than 12.1 bar, intermediate-systems<br />

between 12.1 bar and 34.5 bar with highpressure<br />

systems operating at 34.5 bar and<br />

greater. The focus is to break the water into<br />

extremely fine water particles and distribute<br />

a tested and proven amount of water mist<br />

flux into the risk area.<br />

Water mist has extremely favourable<br />

properties that make it such a favourable<br />

fire suppression system compared to other<br />

technologies. When considering the fire<br />

triangle, current fire technologies attack only

one side of the triangle, mainly heat in the<br />

case of water based systems, and oxygen in<br />

the case of gas based systems. Water mist has<br />

the advantage that due to the small particle<br />

size and distribution means, it beaves like a<br />

gas suppression agent and has the cooling<br />

properties of a water suppression system.<br />

Water mist is divided into primary and<br />

secondary extinguishing mechanisms.<br />

Primary Mechanisms:<br />

Heat extraction<br />

• Cooling of the fire plume<br />

• Wetting and cooling of the fuel surface<br />

Displacement<br />

• Displacement of oxygen at the flame front<br />

• Dilution of fuel vapour<br />

Secondary Mechanisms:<br />

Radiation attenuation<br />

Kinetic effects<br />

When comparing water mist particle size<br />

to traditional sprinkler and spray systems,<br />

the heat extraction effect that mist presents<br />

is magnitudes larger than conventional<br />

systems. As the water particle decreases,<br />

the surface area exposed for heat transfer<br />

increases. Water mist is therefore able to<br />

absorb/remove more heat per volume of<br />

water than conventional systems. Water has<br />

a sensible heat capacity of 4.2 kJ/kg.K and<br />

a latent heat of vaporization of 2442 kJ/kg.<br />

As the surface area of the droplet increases,<br />

more area is exposed for vaporization and<br />

therefore optimal heat extraction. Water<br />

mist therefore drastically cools the fire<br />

plume, primary mechanism, and prevents<br />

escape of radiation to other fuel sources,<br />

radiation attenuation which is a secondary<br />

mechanism.<br />

As the fine water droplets are rapidly<br />

converted to steam at the flame front, the<br />

oxygen and fuel vapour is displaced due<br />

to the volumetric expansion ratio of water<br />

to steam, the primary mechanism. Water<br />

expands 1700 times when it evaporates to<br />

steam. This expansion effect is seen as the<br />

secondary mechanism and enables the fire to<br />

“suck” in more water mist. These properties<br />

enable mist to be extremely effective on fires,<br />

especially Class, A, B, C and F fires.<br />

The Danfoss-Semco SEM-SAFE® water<br />

mist system is a high-pressure water mist<br />

system that comprises of state of the art<br />

technology. Water mist has many advantages<br />

compared to conventional sprinklers. One<br />

of the key benefits is that it often uses only<br />

one tenth as much water as traditional<br />

sprinklers. In addition, the majority of the<br />

water evaporates, causing much less water<br />

damage to buildings, furniture, electrical<br />

installations, etc. In industrial applications,<br />

the dramatic reduction in direct damage is<br />

of great value, but it is usually even more<br />

important that the production line or factory<br />

will be able to resume manufacturing<br />

very quickly after the fire. A long period of<br />

down-time in production means a high risk<br />

of losing market share, which often results<br />

in a dramatic long-term negative economic<br />

effect, far in excess of the original fire<br />

damage. Statistics show that only 4 out of<br />

10 industries are able to start manufacturing<br />

goods again after a major fire.<br />

Fire catastrophes are a threat to human<br />

life, cultural and industrial assets, private<br />

and corporate property and even our<br />

environment. From complex fire suppression<br />

systems for museums and heritage sites, to<br />

industrial applications over office buildings,<br />

universities and wind turbines, Danfoss<br />

Semco has a successful track record within<br />

commercial and industrial applications using<br />

the SEMSAFE® water mist system. Why?<br />

Because the SEM-SAFE® system provides<br />

better protection than existing water systems<br />

while being 100% environmentally friendly,<br />

harmless to users and with far less impact<br />

on buildings and interiors. It significantly<br />

reduces lifecycle costs, asset damage and<br />

operational downtime in all ‘business critical’<br />

applications, and offers the best protection of<br />

irreplaceable valuables. This offers a greatly<br />

enhanced cost/benefit ratio when compared<br />

to traditional systems.<br />

For more info contact Sperosens<br />

Tel: +27 (086) 177 3767<br />

Fax: +27 (086) 562 6511<br />

E-mail: marihette.hattingh@spero.co.za<br />

Web: www.spero.co.za<br />

It’s all good<br />

when your process<br />

is efficient<br />

Every project is unique and therefore deserves a unique<br />

approach. Afrox offers tailor-made process solutions for<br />

its customers. This is supported by a range of industrial<br />

gases as well as a team of dedicated specialists<br />

addressing the need for safer and more efficient<br />

operations.<br />

Africa’s leading gases and welding solutions partner.<br />

Customer Service Centre: 0860 020202 Shop online: www.afroxshop.co.za www.afrox.co.za<br />

Industrial gases ad 190x130.indd 1<br />

<strong>2018</strong>/02/<strong>15</strong> 2:41 PM<br />

11

New ThinManager Software Release Improves Operator Productivity<br />

Updated thin client software from Rockwell Automation gives workers better access to production<br />

information with improved visualisation and mobility.<br />

12<br />

Industrial workers can get better access<br />

to the information they need, where<br />

they need it, with the new ThinManager<br />

v10.0 software platform from Rockwell<br />

Automation. New visualisation, mobility<br />

and security features can help operators<br />

and technicians produce more with<br />

less downtime using the Rockwell<br />

Automation software portfolio and<br />

industrial-grade thin clients.<br />

With a new virtual-screening capability, users<br />

can customise how they see applications<br />

and data from multiple sources, all without<br />

rewriting a single line of code. This capability<br />

can help them view the information that is<br />

most relevant to their job. New support for<br />

wearable technology can also revolutionise<br />

how workers access information. For<br />

example, a maintenance technician could<br />

diagnose and troubleshoot a machine just by<br />

looking at it through a Microsoft HoloLens<br />

mixed-reality headset.<br />

“ThinManager software is helping<br />

industrial companies build their Connected<br />

Enterprise environments through improved<br />

visualisation and mobility,” said Tom Jordan,<br />

marketing lead, ThinManager, Rockwell<br />

Automation. “The software can visualise data<br />

and disperse content to any combination of<br />

device, user or location within an industrial<br />

facility. This ability can provide greater insight<br />

into and management of a user’s operations.”<br />

The updated software introduces<br />

authentication pass-through to help improve<br />

productivity. In the past, users had to log in to<br />

ThinManager and other software applications<br />

separately, adding time onto costly<br />

operations. Now the software can natively<br />

pass users’ credentials to supported HMI<br />

products like FactoryTalk View Site <strong>Edition</strong>.<br />

Improved authentication features reduce<br />

operator maintenance and improve security<br />

by simplifying the management of all devices<br />

and users. Version 10.0 allows operators to<br />

configure multiple forms of authentication<br />

such as RFID badges and biometrics.<br />

New password-caching capabilities allow<br />

administrators to configure time periods for<br />

PIN authentication during a shift.<br />

With its built-in mobility solution, Relevance,<br />

the platform can deliver supported software<br />

components directly to mobile devices<br />

at specific locations within a facility.<br />

Relevance uses location resolvers such as<br />

Bluetooth beacons and Wi-Fi so mobile<br />

users and devices can only receive content<br />

in authorised areas. This capability can help<br />

users achieve greater connectivity with<br />

better operational security.<br />

ThinManager delivers content where it is<br />

needed and presents it to operators how<br />

they want to view it. It is the only thin client<br />

management and mobility solution made<br />

specifically for industrial application delivery<br />

and management. ThinManager is applicable<br />

across many industrial vertical markets such<br />

as food and beverage and water/wastewater.<br />

For more information, visit rok.auto/<br />

thinmanager.<br />

About Rockwell Automation<br />

Rockwell Automation Inc. (NYSE: ROK),<br />

the world’s largest company dedicated to<br />

industrial automation and information,<br />

makes its customers more productive and<br />

the world more sustainable. Headquartered<br />

in Milwaukee, Wis., Rockwell Automation<br />

employs approximately 22,000 people<br />

serving customers in more than 80 countries.<br />

Enquiries:<br />

Christo Buys<br />

Business Manager – Control Systems<br />

Rockwell Automation Sub-Saharan Africa<br />

Tel: 011 654 9700<br />

Email: cbuys@ra.rockwell.com<br />

Website: www.rockwellautomation.com

Engen’s Theart is all<br />

Heart<br />

The social upliftment of the<br />

communities living around the Engen<br />

Klawer 1Stop is close to the heart of<br />

owner Don Theart.<br />

Engen Klawer 1Stop is located on<br />

the N7 approximately 25km south of<br />

Vanrhynsdorp in the northern reaches of<br />

the Western Cape.<br />

Believing it is crucial to give back to<br />

the community in which he operates,<br />

Theart has chosen to focus his efforts on<br />

education.<br />

“When we heard that Smurfie pre-primary<br />

and the two primary schools in our area,<br />

Nieuwoudt and Klawer were short on basic<br />

supplies, we collected and handed over<br />

large packs of printing paper, colouring in<br />

books, play activities and other goodies<br />

from our Quickshop and toys from the<br />

Wimpy,” says Theart.<br />

Klawer 1Stop donates activity booklets, carry bags, toys and drawing paper to Smurfie<br />

Pre-Primary School in the Klawer area. From left to right <strong>Mar</strong>ius Makatees from Engen.<br />

This is also not the first time Engen Klawer<br />

1Stop have assisted the local community.<br />

In 2017, Theart and his team sponsored<br />

a number of ad hoc school sports such<br />

as rugby, netball, athletics and karate<br />

with both fuel donations and financial<br />

contributions for sports gear.<br />

Another issue close to Theart’s heart is<br />

water conservation and the drive for<br />

drought relief.<br />

“Engen Klawer and our customers are<br />

strong supporters of Burre Burger’s<br />

drought aid project which is wholly<br />

funded by the public and businesses to<br />

provide assistance to drought stricken<br />

areas. We have a large donations box on<br />

our forecourt where our customers can<br />

help support this drive,” says Theart.<br />

<strong>Mar</strong>ius Makatees and Kelly Kellerman from Engen with Sharon Cloete, school Secretary<br />

and Noldy Ockhuis Klawer 1 Stop supervisor donate play activities and paper to Nieuwou.<br />

Theart recently met with the principals<br />

from both Nieuwoudt and Klawer primary<br />

schools to find out what their pressing<br />

needs were.<br />

“We have got some exciting plans in<br />

the works for later this year which we<br />

hope will go a long way in uplifting the<br />

community of Klawer,” adds Theart.<br />

Engen’s Corporate Social Investment<br />

Manager, Adhila Hamdulay says the<br />

company views its responsibility to society<br />

as being as important as its responsibility<br />

towards its shareholders and employees.<br />

“As Engen, we are conscious of our need<br />

to build and maintain a credible profile<br />

as a responsible corporate citizen. We<br />

are therefore committed to conducting<br />

business in a manner that uplifts the<br />

economic, social and environmental needs<br />

of the communities in which we operate.”<br />

Don Theart with Burre Burger helping with DROOGTEHULP in Namaqualand and the<br />

Western Cape.<br />

13

New orders for RTS Africa principal Nel’s hydrogen filling stations<br />

internationally ‘fuelling’ hydrogen-powered vehicle trend<br />

14<br />

The era of fossil-fuelled transportation<br />

is drawing to a close. Climate change<br />

concerns and dwindling liquid<br />

hydrocarbon reserves will undoubtedly<br />

change the patterns of personal and<br />

commercial transportation in the future.<br />

While there are sound cases to be made<br />

for the adoption of transportation<br />

alternatives such as battery-powered<br />

electric vehicles (EVs) - as well as for<br />

hydrogen-powered fuel cell vehicles<br />

(FCVs) - the latter type holds the better<br />

potential for diminished environmental<br />

harm in the longer term.<br />

Managing Director of RTS Africa Engineering,<br />

Ian Fraser, explains that both battery-powered<br />

cars and hydrogen-powered cars run on<br />

electric motors. “So the issue is where the<br />

electricity comes from?” he asks. In both cases,<br />

the electricity can come from either clean or<br />

contaminating resources, either renewable<br />

energy or coal-burning power stations.<br />

A FCV converts hydrogen, which has been<br />

generated either by electricity or a steam<br />

reformer, into electrical energy. There are<br />

various methods of generating hydrogen,<br />

however the cleanest method splits water<br />

into hydrogen and oxygen, by passing an<br />

electric current through water. The hydrogen<br />

is then used in the FCV fuel cell to generate<br />

electrical power. The only emission from this<br />

process is water.<br />

Proponents of battery power maintain that<br />

there are no emissions from EVs either.<br />

“However, batteries have a limited life cycle,<br />

and spent batteries contain environmentally<br />

unfriendly chemicals such as lithium and<br />

cobalt. There are certain battery parts<br />

that can be reused but a large proportion<br />

of battery waste products will end up in<br />

landfills,” Fraser explains.<br />

In a fuel cell on the other hand, the only<br />

replaceable part is the catalytic membrane,<br />

which is made of a platinum group metal<br />

such as palladium or platinum, metals<br />

that can be recycled and used to build a<br />

new fuel cell. The result is that there is no<br />

environmental fallout from the process.<br />

Critics of EVs explain that while the EV does<br />

not itself burn fossil fuel, at present they are<br />

reliant on power sourced from coal-burning<br />

power stations. “In the long run, however,<br />

hydrogen cars are a very much cleaner<br />

option,” Fraser adds.<br />

Refuelling both FCVs and EVs has been an<br />

issue globally and certainly here in South<br />

Africa. Even overseas, at present, batterypowered<br />

vehicles have the advantage in that<br />

there are more EV charging stations then<br />

there are hydrogen refuelling stations. The<br />

major stumbling block that stands in the<br />

way of the use of both EVs and FCVs is the<br />

carrying capacity of national power grids.<br />

“In both cases, you are now converting the<br />

energy from the grid into energy to drive<br />

vehicles. Our local alternating current grids<br />

are not up to that at present,” Fraser asserts.<br />

“National electrical reticulation systems will<br />

have to be significantly upgraded to handle<br />

all this energy that is theoretically going to<br />

be pumped into alternative-energy-powered<br />

cars.”<br />

A factor that is making the proliferation of<br />

FCVs rather more remote at this stage in<br />

South Africa - and in comparison to the EV - is<br />

the matter of either refuelling or recharging<br />

the vehicle.<br />

To set up the charging system for a batterypowered<br />

car requires a simple charger -<br />

albeit a comparatively large one. Whereas,<br />

hydrogen filling stations require the creation<br />

of hydrogen by electrolysis on site, and the<br />

storage and the dispensing of hydrogen<br />

through pumps that closely resemble current<br />

petrol pumps.<br />

The alternative possibility to generating<br />

hydrogen at refuelling station sites is to<br />

deliver it in tankers to filling stations. To allay<br />

concerns about the safety of bulk hydrogen<br />

transport Fraser explains that hydrogen bulk<br />

transport is much safer than the current bulk<br />

transportation of petrol.<br />

“However, bulk transport would be more<br />

expensive, and the first prize would be<br />

to solve the grid problem and generate<br />

hydrogen at the dispensing point,” he adds.<br />

An exciting move in this direction has come<br />

from one of RTS Africa’s most long-standing<br />

international principals, Nel Hydrogen- a<br />

dedicated hydrogen company delivering<br />

solutions to produce, store and distribute<br />

hydrogen from renewable energy.<br />

Nel recently received an order from Nikola<br />

Motor Company for two demonstration<br />

refuelling stations to provide hydrogen to<br />

Nikola’s fleet of prototype hydrogen vehicles.<br />

“This order is the first part of an initiative<br />

aiming at developing low-cost renewable<br />

hydrogen production and fuelling sites, for<br />

the potential development of 16 largescale<br />

sites with a capacity up to 32 tons of<br />

hydrogen a day,” Fraser explains.<br />

The initial two demonstration stations will<br />

each provide one ton of hydrogen to Nikola<br />

Motor’s prototype trucks and serve as design<br />

verification for Nel’s mega-scale concept. This<br />

solution will be jointly developed and scaled<br />

into the world’s most efficient network of lowcost<br />

hydrogen production and fuelling sites.<br />

For the mega-stations, Nel will incorporate<br />

its clustering concept, where eight Nel A-485<br />

Ian Fraser, MD of RTS Africa Engineering.<br />

electrolysers are integrated into one unit,<br />

to achieve lower capex levels. Nikola has an<br />

initial target to build 16 of the mega-scale<br />

hydrogen stations between 2019 and 2021,<br />

with a minimum of eight units of the Nel<br />

A-485 electrolyser per site. The solution is<br />

scalable to a maximum of 32 units of the<br />

Nel A-485 electrolyser per site, equalling<br />

a production capacity of up to 32 tons<br />

of hydrogen per day. The delivery of the<br />

demonstration stations is intended to start in<br />

the second half of <strong>2018</strong>.<br />

The greater availability of hydrogen fuelling<br />

stations is key to unlocking the potential<br />

of FCVs. A FCV has a range of some 600 km<br />

and once at its destination refuelling takes<br />

a minute or two. EVs do not have the same<br />

range and to recharge them properly takes a<br />

couple of hours, Fraser explains.<br />

“With very rapid charging, an EV can be<br />

recharged in as little as <strong>15</strong> minutes, but that<br />

is not good for the batteries,” he adds.<br />

“I think it is optimistic to think that battery<br />

technology can be improved much further<br />

by making lighter and more efficient energy<br />

storage solutions,” he continues.<br />

Fraser points out that in South Africa,<br />

hydrogen transportation technology<br />

would be very useful in applications such<br />

as servicing the taxi industry and in large<br />

opencast mines, where a number of haul<br />

trucks operate in a limited radius. A single<br />

Nel filling station could, for example, serve<br />

the fuel needs of an entire fleet. With these<br />

applications, it would not be necessary to<br />

set up a massively dispersed suburban and<br />

urban filling station network.<br />

“These two applications alone could serve<br />

as a stepping stone to the realisation<br />

of the value of hydrogen technology in<br />

transportation and also serve to usher in<br />

a cleaner, more environmentally- friendly<br />

future,” Fraser concludes.

BBF Safety Group<br />

BBF Safety Group is proud to have recently donated footwear to the<br />

students at Ray Mhlaba Skills Centre in Port Elizabeth. Ladies were<br />

provided with products from the Sisi Safety Footwear range, while<br />

Bova products were donated to the men.<br />

The Ray Mhlaba Skills Training Centre, an extension program of the<br />

EP Child & Youth Care Centre, offers skills training to vulnerable,<br />

underprivileged and displaced youth between the ages of 18-25. This<br />

includes those who come from children’s homes, have lost one or<br />

both parents, live in households with no formal income and/or come<br />

from child-headed households.<br />

The aim is to empower these young adults through skills and social<br />

development programs, thereby equipping them with the knowledge<br />

and ability to obtain formal employment or become entrepreneurs.<br />

On completion of the training, the centre also assists the youth with<br />

finding employment.<br />

A variety of SETA Accredited and Entrepreneurial Training Programs<br />

are offered to students, including Hospitality Studies, Bakery,<br />

Woodwork & Upholstery, Hairdressing, Early Childhood Development,<br />

Needlework & Crafts and HIV/AIDS & Palliative Care. In addition to<br />

these, all students are enrolled in a Personal Development Program.<br />

The centre is solely reliant on the support and generosity of corporate<br />

and private donors to continue their successful operation.<br />

“This is a huge cost saver, as the shoes form a vital part of the required<br />

safety standards uniform for our Hospitality Training Program<br />

students completing their NQF Level 4 in Professional Cookery<br />

qualification. We thank you again for making it possible for our<br />

students to have a complete professional workplace uniform, which<br />

will not only allow them to train professionally but prepare them for<br />

Recipients with Sabelani Hakula, Product Consultant for the Eastern Cape.<br />

formal employment within the Hospitality Industry”, said Caroline<br />

Ferreira, the centre’s Project Director.<br />

To date, in its 12th year of operation, the centre has successfully<br />

trained 1185 students across its vocational training programs, 82%<br />

of whom have gained formal employment or are earning a reliable<br />

income as entrepreneurs.<br />

“It brings us great pleasure to support the Ray Mhlaba Skills Centre<br />

in continuing their incredible work”, said Vanessa Ronald, BBF Senior<br />

Brand Manager.<br />

“BBF Safety Group is committed to having a positive impact on<br />

the communities in which we operate and contributing to the<br />

meaningful and impactful efforts of initiatives such as this. We wish<br />

all the students many successful steps in their new footwear as they<br />

complete their studies and enter into the professional world.”<br />

Sisi and Bova are two of the eight market-leading brands within the<br />

BBF Safety Group stable. BBF Safety Group is the largest manufacturer<br />

of safety footwear in Africa, operating out of four manufacturing<br />

plants in South Africa.<br />

For more information: www.bbfsafety.com.<br />

Safe, Cost-effective, Environmentally Friendly<br />

Fire Solutions for your Peace of Mind<br />

SPERO SOLUTIONS:<br />

• Fire Detection Solutions<br />

• Fire Suppression Solutions<br />

• Fire Extinguishing Products<br />

• Fire Equipment Monitoring<br />

• Temperature Measuring<br />

• Environmental Monitoring<br />

• Fire Safe Design<br />

Product Innovation & Service Excellence with each Fire Prevention Solution Supplied<br />

www.spero.co.za • info@spero.co.za • +27 12 665 0317<br />

5793 Sperosens Generic Advert <strong>Petrochemicals</strong> publications 190x130mm wide - REP.indd 1 2016/09/26 2:28 PM<br />

<strong>15</strong>

Clamping’ down on safety<br />

Vital Engineering’s Vitaclamps enhance safety in the power generation and other industrial sectors<br />

Vitaclamps from Vital Engineering.<br />

Vitaclamps are a patented, top-fixing grating panel<br />

unit intended to save installation time and costs.<br />

16<br />

When it comes to quality, reliability and<br />

safety, companies responsible for supplying<br />

the nation with power cannot afford to make<br />

mistakes. That is why Vital Engineering, a<br />

long-established manufacturer of gratings,<br />

stair treads, expanded metals, pressed floors<br />

and safety handrail, was selected to supply<br />

500 000 Vitaclamps as part of the largest<br />

gratings, handrail and stair tread supply<br />

contract in Africa.<br />

The contract included the supply of 250 000<br />

Vitaclamps to Medupi Power Station in the<br />

Limpopo Province and 250 000 to Kusile<br />

Power Station in Mpumalanga. As part of the<br />

project, Vital Engineering also supplied some<br />

200 000 m2 of grating panels and 70 km of<br />

handrailing and 8 000 stair treads.<br />

“After carefully assessing the quality and<br />

durability of our products, our superior<br />

fixing product was chosen because it suited<br />

the client’s particular requirements and<br />

application,” explains Glen Pringle, Technical<br />

Director of Vital Engineering. “Their decision<br />

shows that the market recognises our<br />

products as synonymous with high quality,<br />

performance and safety.”<br />

Vitaclamps are a patented, top-fixing grating<br />

panel unit intended to save installation<br />

time and costs, by improving installation<br />

turnaround times, reducing scaffold hire and<br />

improving overall operational safety in the<br />

mining, petrochemical and other industries.<br />

“Vitaclamps reduce costs while improving<br />

safety, by enabling a unit to be tightened<br />

from the top - unlike the traditional clip<br />

on the market which is fixed underneath,”<br />

explains Pringle.<br />

As always, safety was a key aspect in both<br />

the Eskom power station projects. Vital<br />

Engineering worked proactively with the<br />

principal contractor, MHPSA (Mitsubishi<br />

Hitachi Power Systems Africa) to meet and<br />

surpass specified quality and safety goals.<br />

As a strong advocate in the industry of<br />

the importance of making an informed<br />

choice when it comes to safety products,<br />

Vital Engineering is wary of the number of<br />

sub-standard products that are ‘passed off’<br />

as being equivalent to specified products<br />

by engineers or quantity surveyors. In<br />

comparison with other products on the<br />

market - including copies - Vitaclamps are:<br />

• Stronger: They can more securely and<br />

reliably fix grating panels/flooring to the<br />

steelwork for various applications.<br />

• Faster: They enable quicker fixing, easier<br />

maintenance and replacement of floor<br />

gratings.<br />

• Safer: In addition to the use of friction grip<br />

nuts for improved safety, they are more<br />

visible for safety checks and can even be<br />

colour-coded.<br />

• Easier to use: With better grip features and<br />

torque when tightening, they are simple<br />

and easy to fit.<br />

The three Vitaclamp ranges — light, medium<br />

and heavy — are suitable for various<br />

applications and environments within mines,<br />

petrochemical plants and other on other<br />

industrial sites.<br />

Vitaclamps are furthermore branded with<br />

the Vitagrid trademark — a sign of quality<br />

indicating a product is manufactured by an<br />

original equipment manufacturer (OEM).<br />

“For example, when mining and<br />

petrochemical companies use products<br />

with this quality trademark, they protect<br />

themselves from risks associated with the use<br />

of poor quality copies available from other<br />

companies,” says Pringle.<br />

He adds that Vitaclamps are an example of<br />

how the company continues to develop and<br />

produce innovative fixing solutions. With a<br />

proud history and track record of product<br />

innovation, Vital was the first square grating<br />

manufacturer on the market.<br />

“We also manufactured the first ball-type<br />

handrail in both tubular and solid forged<br />

handrails; and m the first serrated gratings<br />

and expanded metal conveyor walkways to<br />

reduce slippage.<br />

In addition, we have recently launched a<br />

distinctive channel clip, which clips onto<br />

the underside of the channel for faster<br />

installation,” he adds.<br />

“We see a constant demand for our fixing<br />

products. In addition to utilising our<br />

products for their maintenance-related<br />

requirements, clients are even using them<br />

to secure opposition products in place.<br />

This is the result of the market’s growing<br />

preference for improved safety in industries<br />

ranging from power generation, mining,<br />

and petrochemicals to commercial, food<br />

and beverage, and materials handling<br />

sectors.”<br />

In most if not all cases, Vitaclamps are<br />

sold with Vitagrid precision-made grating<br />

products and handrails.<br />

“We do find that demand for these and<br />

many of our other patented gratings, stair<br />

treads, pressed floors and safety handrails<br />

products within South Africa - and from the<br />

international market - is growing, thanks to<br />

their innovative design and safety features.<br />

Vitaclamps are a really excellent example<br />

thereof, as their selection at some of our<br />

country’s leading power stations signifies,”<br />

Pringle concludes.

Schroeder SHP - A pump protection valve for Power Generation high<br />

pressures under all load conditions<br />

Since the launch in 20<strong>15</strong>, Schroeder<br />

Valves have had success that exceeded<br />

their expectations.<br />

One of has been the supply of 36 large<br />

units to a power station in Egypt.<br />

Schroeder SHP.<br />

This automatic recirculation valve was<br />

developed for high and extremely high<br />

pressures and also works reliably under<br />

highly fluctuating load conditions. With<br />

this innovation, the specialist in protective<br />

pump fittings is responding to the<br />

requirements of its customers, primarily<br />

from the field of power plant and plant<br />

construction and the offshore industry.<br />

These valves are ideally suited for Eskom<br />

Power Stations where they need minimum<br />

flow protection on their steam driven and<br />

electrically driven feedwater pumps.<br />

The SHP builds on existing Schroeder Valves<br />

technology. The company already has years<br />

of operational experience with almost all<br />

of the effective principles and assemblies<br />

used. As such this can be considered<br />

‘Proven Equipment’. The individual<br />

system components have simply<br />

been modified and innovatively<br />

combined, as such that they enhance<br />

the dependable and low-wear area of<br />

application of the existing technology<br />

to meet the increased requirements.<br />

Thus, the new SHP-series automatic<br />

recirculation valve enables and promotes<br />

the energy-efficient operation of modern<br />

power plant facilities.<br />

“The SHP takes the general development<br />

of higher pressures and temperatures<br />

and the increased energy-efficiency<br />

requirements into account,” explained Axel<br />

Mücher, managing partner at Schroeder<br />

Valves. “Alongside this, the changing<br />

way in which plants work was also taken<br />

into consideration in the development<br />

of the SHP. Special load sequence power<br />

plants, such as modern combined cycle<br />

power plants and coal-fired power plants,<br />

are operated at partial load for a large<br />

proportion of their operating time, on<br />

account of the increasing high proportion<br />

of regenerative energy generation and<br />

highly fluctuating load conditions.”<br />

Schroeder Valves has each valve undergo<br />

a 100% pressure and functionality testing<br />

prior to delivery. To ensure this also with<br />

the SHP, the company is currently adding<br />

to their flow test center a test stand for<br />

pressures up to 400 bar.<br />

For more information contact:<br />

Desmond Delport<br />

Valve & Automation<br />

Tel: +27 (0)11 397 2833<br />

Email: desmond.delport@valve.co.za<br />

Web: www.valve.co.za<br />

Waco Africa is now a 52% Black Owned Business<br />

A learnership programme for 60 females<br />

from previously disadvantaged backgrounds,<br />

with disabilities, was recently implemented<br />

by Sanitech, a division of Waco Africa.<br />

The learners, who all reside in rural areas<br />

around South Africa, embarked on a General<br />

Education and Training Certificate in Hygiene<br />

and Cleaning.<br />

“This certificate is a level 1 certificate which<br />

allows the learner to work and study for<br />

a period of 12 months while receiving a<br />

stipend,” says Sanitech Managing Director<br />

Robert Erasmus. “Embarking on a level 1 roll<br />

out allows Sanitech to enrol youth that did<br />

not finish matric. Once they have successfully<br />

completed level 1 they can move on to level<br />

2 and 3 in the following year.<br />

“This process will give hope to youth who<br />

were not able to finish matric and are given a<br />

chance to pursue a career and stand a chance<br />

of attaining sustainable employment for the<br />

future. We are excited about this journey and<br />

look forward to watching it develop during<br />

the year ahead.”<br />

This latest learnership programme has<br />

also enabled Waco to move from a BBBEE<br />

contribution Level 4 to a Level 3, with a BEE<br />

Supplier Recognition of 110%, in addition<br />

Waco Africa is now 52 % black owned<br />

business.<br />

“The Waco Group continuously identifies<br />

talented individuals for promotion into<br />

positions that are strategically important or<br />

require unique skills. This is done through<br />

our Employee Development Programmes<br />

offered at different levels of the organisation<br />

and structured to achieve specific outcomes,<br />

contribute to the group’s management<br />

team and support leadership succession<br />

requirements,” concludes Erasmus.<br />

The Waco Group offers several Employee<br />

Development Programmes, including the<br />

Waco Africa Cadet Scheme, Supervisory<br />

Development Programme, Business<br />

Leadership Development Programme and<br />

Executive Development Programme.<br />

Once the learnerships are complete, the<br />

students will be absorbed into Sanitech’s<br />

business with their current 2 500 employees,<br />

and another cycle of learnerships will be<br />

rolled out.<br />

Sanitech is a leading provider of cleaning and<br />

hygiene services, operating in Sub-Saharan<br />

Africa. It prides itself on being the continent’s<br />

leader in toilet hire and technology,<br />

providing superior products and excellent<br />

customer service. Sanitech is a division of<br />

Waco Africa, a Level 3 BEE contributor.<br />

Waco Africa includes Sanitech, Form-Scaff,<br />

SGB-Cape, Skyjacks and Abacus Space<br />

Solutions. These businesses have been<br />

providing essential services in their markets<br />

for more than 60 years, and form an integral<br />

part of maintenance and infrastructure<br />

roll-out expenditure programmes including<br />

dams, bridges, power stations, petrochemical<br />

plants, mines, schools, hospitals, sanitation<br />

plants, shopping centres and office blocks.<br />

Waco Africa is a subsidiary of Waco<br />

International, a global provider of formwork,<br />

shoring, scaffolding, industrial maintenances<br />

services, hydraulic and suspended access<br />

platforms, relocatable modular buildings,<br />

portable sanitation, and hygiene solutions.<br />

The group operates out of more than<br />

100 locations in <strong>15</strong> countries across three<br />

continents.<br />

17

18 18<br />

The recent Sasolburg<br />

Petrochemical Roadshow

Supporting associations<br />

m3⁄h<br />

l/h<br />

fact<br />

m/s<br />

Liquid flow measurement<br />

up to 600 °C or 490 bar<br />

OPTISONIC 4400 –<br />

technology driven by KROHNE<br />

• Ultrasonic flowmeter for<br />

high temperature and high pressure<br />

liquids, e. g. in vacuum distillation,<br />

visbreaking or coker unit<br />

• HT version: 45…+600 °C,<br />

DN25…1000<br />

• HP version: ≤490 bar, DN25…200<br />

• Flow range 0,5…20 m/s,<br />

bi-directional<br />

• Communication options<br />

with NAMUR NE 107 diagnostics<br />

Flavius <strong>Mar</strong>eka College Hall<br />

<strong>15</strong> <strong>Mar</strong>ch <strong>2018</strong><br />

Thank you to all exhibitors<br />

KROHNE South Africa<br />

8 Bushbuck Close, Corporate Park South<br />

Randjiespark, Midrand, Tel.: +27 113141391<br />

Fax: +27 113141681, Clayton Duckworth,<br />

c.duckworth@krohne.com, www.za.krohne.com<br />

19

Engen’s Youth Development Programme shortlisted<br />

for the <strong>2018</strong> Sport Industry Awards.<br />

The Engen Youth<br />

Development Programme<br />

has been shortlisted for<br />

the <strong>2018</strong> Sport Industry<br />

Awards.<br />

Jabu Mahlangu - Supersport UTD<br />

Brand Ambassador.<br />

20<br />

Sport Industry Group brings the sport industry<br />

together through a series of world-class<br />

events, industry-leading editorial content and<br />

a genuinely unparalleled network of influential<br />

figures from across the international sporting<br />

landscape. They focus on three key pillars:<br />

Share, Connect and Celebrate.<br />

Through editorial content and a series of<br />

events analysing the business, the Sport<br />

Industry Group looks to scrutinise the bad<br />

and celebrate best, helping set the agenda<br />

for the world’s most dynamic industry.<br />

The official shortlist was selected through<br />

an extensive process - involving more than<br />

40 key industry figures across 8 days of<br />

intensive reviews; and will now go forward<br />

for consideration by the main judging panel<br />

who will decide the winners in each category.<br />

The winners will be unveiled at the Sport<br />

Industry Awards taking place in the final<br />

week of May or early in June.<br />

The Engen Youth Development Programme<br />

was nominated in the Development<br />

Programme of the Year category, amongst<br />

other competing brands. With higher entry<br />

numbers and an increasing quality of work<br />

year-on-year, reaching the shortlist for the<br />

Sport Industry Awards <strong>2018</strong> represents a<br />

stellar achievement.<br />

Brought to you by Engen, South Africa’s<br />

leading petroleum brand*, the Engen Youth<br />

Development Programme comprising of<br />

the Engen Knockout Challenge and Engen<br />

Soccer Laduma Media Workshop by Head of Digital, Gail Odgers II.<br />

Champ of Champs, are widely regarded<br />

as the most prestigious youth football<br />

tournaments in South Africa.<br />

The Engen Knockout Challenge has grown<br />

from humble beginnings and is played in<br />

five cities across South Africa, namely: Cape<br />

Town, Port Elizabeth, Durban, Bloemfontein<br />

and Johannesburg culminating with the<br />

regional champions playing-off for the<br />

national Championship at the Engen Champ<br />

of Champs.<br />

Since inception in 2003, more than 30,000<br />

aspiring young soccer players from all walks<br />

of life have participated in the Engen Youth<br />

Development Programme, with more than<br />

181 Engen Knockout Challenge Alumni<br />

having gone on to play professional soccer in<br />

the PSL and abroad.<br />

In 2017, the Engen Youth Development<br />

Programme secured an attendance of more<br />

than 20 local and international football scouts<br />

from as far as Holland, Belgium, France, Spain<br />

and Denmark thus providing a platform for<br />

the players to succeed, resulting in more than<br />