The Trucker Newspaper - April 15, 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Features<br />

<strong>April</strong> <strong>15</strong>-30, <strong>2018</strong> • 37<br />

Goodyear honors 3 drivers at annual<br />

Highway Heroes award presentation<br />

Klint Lowry<br />

klint.lowry@thetrucker.com<br />

LOUISVILLE, Ky. — Brian Bucenell hails<br />

from Richmond, Virginia. Ryan Moody calls<br />

Tacoma, Washington, home. And Frank Vieira<br />

resides in Ancaster, Ontario, about 55 miles (or<br />

89.5 kilometers, as he would say), southwest<br />

of Toronto.<br />

You would imagine fate would have to put<br />

in some overtime to ever bring these three veteran<br />

drivers together for any reason, much less<br />

to share a spotlight in Louisville, Kentucky.<br />

Yet there they were. On March 22, immediately<br />

after the first day of the Mid-America<br />

Trucking Show, a crowd gathered at the nearby<br />

Crowne Plaza Louisville Airport Expo Center<br />

hotel to celebrate serendipity’s fait accompli,<br />

and three standup guys, as the Goodyear Tire<br />

and Rubber Company marked the 35th anniversary<br />

of its Highway Hero Award.<br />

Each year since 1983, Goodyear has honored<br />

professional truck drivers who perform<br />

extraordinary acts of heroism, often at risk to<br />

themselves. This year, Bucenell, Moody and<br />

Vieira were the three finalists for the award.<br />

Gary Medalis, marketing director for<br />

Goodyear, said that over the years, the Highway<br />

Heroes award has honored drivers who<br />

have saved children’s lives, come to the aid of<br />

police officers and have performed numerous<br />

other feats of bravery. He added that the three<br />

drivers selected as finalists this year are all fine<br />

Virginia ‘Hackathon’ to pit techies against one another to invent way to thwart trafficking<br />

Dorothy Cox<br />

dlcox@thetrucker.com<br />

Around<br />

the Bend<br />

When you read or hear the word, “hacking,”<br />

what do you think of? I think of some<br />

tech-savvy person breaking into an individual’s<br />

or business’s computer system. Or, using<br />

a machete to cut down heavy undergrowth<br />

in a jungle somewhere. Or, not being able to<br />

cope with something, as in, “he wasn’t able<br />

to hack it, so he quit his job.”<br />

Hacking comes from an old English word,<br />

haccian, meaning to ‘cut in pieces’ and is related<br />

to Dutch hakken and German hacken.<br />

So when I heard about a “hackathon” in<br />

Arlington, Virginia, <strong>April</strong> 14-<strong>15</strong> I wrongly<br />

thought people were going to learn how to be<br />

better computer hackers so they could break<br />

into computer systems for ill-gotten gain.<br />

It turns out that’s not what it’s about at<br />

all. But I bet you guessed that already.<br />

choices as the award — the oldest of its kind in<br />

trucking — marks this milestone year.<br />

<strong>The</strong> incidents that led to these three drivers<br />

being nominated for the Highway Hero Award<br />

were about as far-flung from one another as<br />

their hometowns, with one thing in common:<br />

<strong>The</strong>y all exhibited personal and professional<br />

cool under pressure.<br />

For Bucenell, an owner-operator, it all started<br />

just after he’d merged onto the Ohio Turnpike<br />

near Toledo. He heard chatter on the CB<br />

about a high-speed chase going on somewhere<br />

in the vicinity. Moments later, Bucenell saw<br />

several state troopers in his rearview mirror<br />

chasing a car and gaining on him fast.<br />

Just then, he came upon a construction<br />

zone. “We lost the far left lane,” he said. “It<br />

went from three lanes to two lanes. <strong>The</strong>y put up<br />

a concrete barrier, blocking it off.”<br />

When the car reached Bucenell’s truck another<br />

truck was running alongside. Bucenell<br />

said the car tried to pass him on the left, saw<br />

the barrier, then cut back behind him.<br />

From that point on, Bucenell said, the car<br />

kept trying to pass, to the left, to the right, between<br />

the two trucks. Every time he moved, Bucenell,<br />

who’s been driving professionally for 10<br />

years, moved over just enough to cut him off.<br />

“I know my truck pretty well,” Bucenell<br />

said. “It was a mixture of his lack of experience<br />

and my knowing my truck. I think that’s<br />

what let me be able to stop him.”<br />

In this case hack means to put pieces of<br />

something together in order to build something<br />

else, not hacking or breaking into<br />

something.<br />

It means that local computer programmers,<br />

college students, tech gurus, engineers,<br />

tech specialists and others — about 100 people<br />

so far — will be competing to come up<br />

with an algorithm or app or some such thing<br />

in order to thwart human traffickers.<br />

This hackathon is being held by Blue<br />

Compass, a tech development group which<br />

works with government agencies to help<br />

them use data to figure out answers to problems.<br />

And that is way over-simplifying what<br />

they do.<br />

OK. OK. Just for example, say an agency<br />

like the National Center for Missing and Exploited<br />

Children is trying to find out if traffickers<br />

go after a type of child, or they’re<br />

looking for a certain child who has been<br />

kidnapped. Instead of having a human go<br />

through miles of data and pictures of children,<br />

they use all this data to create an algorithm<br />

and feed that to a robot or some sort<br />

of artificial intelligence thing-a-ma-bob and<br />

have it come up with a pattern of what kind<br />

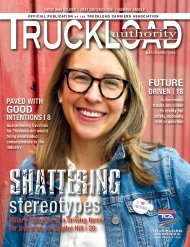

<strong>The</strong> <strong>Trucker</strong>: KLINT LOWRY<br />

From left are Goodyear Marketing Director Gary Medalis, <strong>2018</strong> Goodyear Highway Hero<br />

Award winner, Frank Vieira, and finalists Brian Bucenell and Ryan Moody.<br />

Finally, the driver tried to swerve on the<br />

shoulder again. “I just whipped it toward the<br />

guardrail and stopped,” Bucenell said. <strong>The</strong><br />

car was trapped, and the chase, which Bucenell<br />

later found out had reached 100 mph<br />

of children they’re looking for and what<br />

types of children are at risk of being trafficked.<br />

Or where a specific child might be.<br />

<strong>The</strong> idea, says Christine Jung, president<br />

and CEO of Blue Compass, is that technology<br />

can be used to say, predict the kinds of<br />

places where trafficking is more likely to occur.<br />

From data they have already, they’ve<br />

found it happens more in areas of the country<br />

or in nations that are unstable economically,<br />

where people are desperate and will take desperate<br />

measures to get money. Those areas<br />

are ripe for trafficking, Jung said. It could be<br />

a third-world country or an inner city or rual<br />

area in the U.S.<br />

<strong>The</strong> participants at the hackathon will be<br />

“everyday people,” she said, students from<br />

area schools, young professionals, computer<br />

techs, professors and also people who want<br />

to learn about the subject of human trafficking.<br />

In the trucking industry you hear about<br />

“big data” being generated from the truck engine,<br />

from on-cab cameras and other devices<br />

like the ELD. That data is being used to help<br />

carriers spot waste or garner proof it was the<br />

at one point, was over.<br />

“<strong>The</strong>re were 20 cop cars on him in the blink<br />

of an eye. I’ve never seen anything like it,” Bucenell<br />

said.<br />

See Hero on p38 m<br />

four-wheeler that hit the truck, not the other<br />

way around or, some say, to spy on drivers.<br />

One trucking company using trailertracking<br />

devices discovered their trailers<br />

were being used to move goods other than<br />

theirs. And it was causing a lot of unnecessary<br />

wear-and-tear to their equipment.<br />

<strong>The</strong> idea, said Jung, is to understand large<br />

volumes of data, the complexity behind the<br />

data and then figure out how to make sense<br />

of it and like the carrier whose trailers were<br />

being used illicitly, put a stop to it. Whatever<br />

“it” might be.<br />

In this case, it would be trafficking.<br />

Now, don’t ask me whether this will be an<br />

app or what. This is so not my area of expertise.<br />

Also invited to the “hackathon” will be<br />

people who know about human trafficking<br />

and the different ways traffickers use to victimize<br />

children and young adults, such as<br />

posing as a modeling agent or as someone<br />

looking for a “date.”<br />

I’ll keep you posted on what happens<br />

with the event and I hope they will explain<br />

it to me in plain English so that I can understand<br />

it. Just sayin.’<br />

Be safe out there and God bless. 8