rPET Quality Report

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7.0 Analysing the effects of contaminants on <strong>rPET</strong> discolouration<br />

Recycled PET has classically been more yellow or brown when compared to virgin PET. The<br />

factors that cause discolouration of <strong>rPET</strong> include:<br />

• Presence of PVC particles;<br />

• Coloured particles from PET and other polymers;<br />

• Adhesive residues;<br />

• Processing of residual <strong>rPET</strong> fines and dust with PET flake; and<br />

• Thermal and oxidative history.<br />

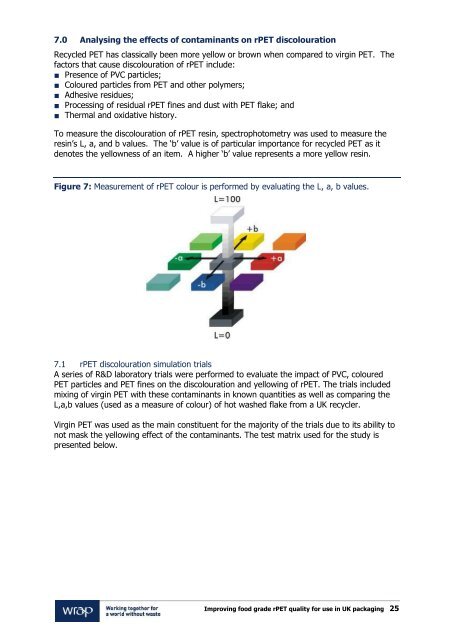

To measure the discolouration of <strong>rPET</strong> resin, spectrophotometry was used to measure the<br />

resin‟s L, a, and b values. The „b‟ value is of particular importance for recycled PET as it<br />

denotes the yellowness of an item. A higher „b‟ value represents a more yellow resin.<br />

Figure 7: Measurement of <strong>rPET</strong> colour is performed by evaluating the L, a, b values.<br />

7.1 <strong>rPET</strong> discolouration simulation trials<br />

A series of R&D laboratory trials were performed to evaluate the impact of PVC, coloured<br />

PET particles and PET fines on the discolouration and yellowing of <strong>rPET</strong>. The trials included<br />

mixing of virgin PET with these contaminants in known quantities as well as comparing the<br />

L,a,b values (used as a measure of colour) of hot washed flake from a UK recycler.<br />

Virgin PET was used as the main constituent for the majority of the trials due to its ability to<br />

not mask the yellowing effect of the contaminants. The test matrix used for the study is<br />

presented below.<br />

Improving food grade <strong>rPET</strong> quality for use in UK packaging 25