You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CASTING &<br />

METALLURGY.<br />

THE QUALITY AND DESIGN OF A CASTING<br />

DEFINE THE POTENTIAL OF THE FINAL PART.<br />

Castings made with mediocre materials will never be able to support<br />

the heat and power that a casting made from premium alloys will.<br />

Castings poured without the utmost attention to detail can suffer<br />

crippling structural flaws that lower the bar for the performance of<br />

the end product in ways that no amount of machining can alleviate.<br />

Because it’s important to build on a solid foundation, <strong>Dart</strong> takes<br />

the casting process very seriously. Every single <strong>Dart</strong> casting is<br />

100% made in the United States from start to finish. Many of our<br />

Aluminum castings employ aerospace quality alloy, the best in<br />

the industry for the high temperature, high pressure demands<br />

of performance engine operation. Our Iron castings use a selection<br />

of premium alloys, carefully chosen to meet the needs of<br />

each of our product lines. These Iron alloys offer excellent tensile<br />

strengths and Brinell hardness ratings from 200 to 250 or more,<br />

well above that of a “bargain” casting. This translates to blocks<br />

and heads that have longer life spans and can be built to more<br />

demanding specifications.<br />

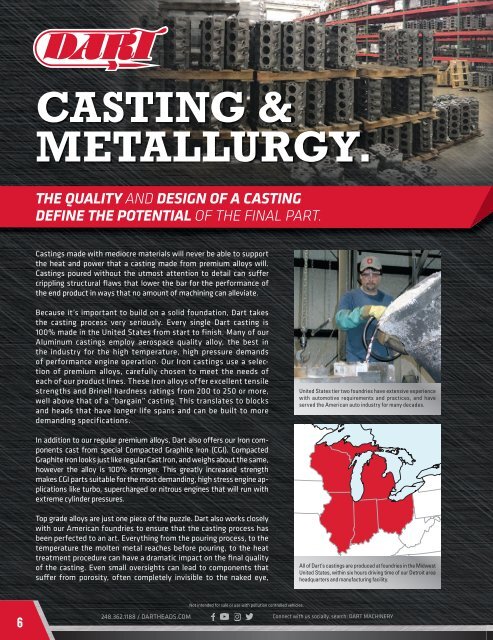

United States tier two foundries have extensive experience<br />

with automotive requirements and practices, and have<br />

served the American auto industry for many decades.<br />

In addition to our regular premium alloys, <strong>Dart</strong> also offers our Iron components<br />

cast from special Compacted Graphite Iron (CGI). Compacted<br />

Graphite Iron looks just like regular Cast Iron, and weighs about the same,<br />

however the alloy is 100% stronger. This greatly increased strength<br />

makes CGI parts suitable for the most demanding, high stress engine applications<br />

like turbo, supercharged or nitrous engines that will run with<br />

extreme cylinder pressures.<br />

Top grade alloys are just one piece of the puzzle. <strong>Dart</strong> also works closely<br />

with our American foundries to ensure that the casting process has<br />

been perfected to an art. Everything from the pouring process, to the<br />

temperature the molten metal reaches before pouring, to the heat<br />

treatment procedure can have a dramatic impact on the final quality<br />

of the casting. Even small oversights can lead to components that<br />

suffer from porosity, often completely invisible to the naked eye,<br />

All of <strong>Dart</strong>’s castings are produced at foundries in the Midwest<br />

United States, within six hours driving time of our Detroit area<br />

headquarters and manufacturing facility.<br />

Not intended for sale or use with pollution controlled vehicles.<br />

6<br />

248.362.1188 / DARTHEADS.COM Connect with us socially, search: DART MACHINERY