Precision Cultivator The Cultivation King

Precision Cultivator The Cultivation King

Precision Cultivator The Cultivation King

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> sowing and tillage specialists<br />

<strong>Precision</strong> <strong>Cultivator</strong>

<strong>Precision</strong> <strong>Cultivator</strong><br />

<strong>The</strong> <strong>Cultivation</strong> <strong>King</strong><br />

1 | <strong>Precision</strong> <strong>Cultivator</strong><br />

adaptability<br />

<strong>The</strong> <strong>Precision</strong> <strong>Cultivator</strong> can be<br />

equipped with alternate points<br />

130mm and 60mm. This allows<br />

different working results and<br />

depths. Likewise the double STS<br />

rollers can be removed and the<br />

cultivated ground can be left in<br />

ridges to allow the weather to<br />

work.<br />

2 | Tine Penetration in dry<br />

hard conditions<br />

<strong>The</strong> <strong>Precision</strong> <strong>Cultivator</strong> is<br />

equipped with 16mm heavy-duty<br />

leaf spring tines. <strong>The</strong> reversible<br />

point is 100mm wide and offers<br />

four wear possibilities. In hard dry<br />

conditions the leaf spring allows<br />

the point angle to become steeper<br />

giving a more aggressive soil entry<br />

angle. <strong>The</strong> tine vibration breaks<br />

the soil and the straw/soil mixing<br />

commences. <strong>The</strong> heavy-duty leaf<br />

spring is extremely robust and long<br />

lasting.<br />

3 | Precise working<br />

depth selection<br />

<strong>The</strong> working depth is selected<br />

hydraulically using 2 (4on 6.60<br />

& 7.5m models) depth wheels at<br />

the front of the machine. <strong>The</strong>se<br />

depth wheels are linked to the rear<br />

reconsolidation roller. This way the<br />

precise working depth is even over<br />

the whole width and length of the<br />

machine.<br />

<strong>The</strong> high tine density, 23 on the 3m<br />

<strong>Precision</strong> <strong>Cultivator</strong>, ensures all the<br />

soil is moved. <strong>The</strong> tines are spread<br />

over 8 tine bars ensuring block<br />

free work. Any unevenly spread<br />

straw has the opportunity to be<br />

re-distributed evenly through the<br />

working depth.<br />

1 <strong>Precision</strong> <strong>Cultivator</strong><br />

adaptability<br />

3 Precise working<br />

depth selection<br />

2 Tine Penetration in dry<br />

hard conditions<br />

5 Optimum<br />

Reconsoli

dation<br />

Even straw distribution: <strong>The</strong> aim is to mix the post harvest residues<br />

evenly in the top 50-150mm. This way nature, through the microbiological<br />

activity and the actions of worms, degrades the straw. This increases<br />

the humus content and significantly improves the soil quality. Having<br />

mixed the straw the soil needs reconsolidating to give weed, seeds and<br />

volunteers good soil contact and to reduce the ability of slugs to thrive.<br />

When good straw mixing takes place, the danger of fungal disease and<br />

damage to the capillary structure is reduced.<br />

<strong>The</strong> Köckerling <strong>Precision</strong><strong>Cultivator</strong> has been developed to work at an<br />

overall shallow depth mixing the post harvest residue evenly levelling<br />

the work and reconsolidating the cultivated ground.<br />

6 Diagonal Working<br />

7 Fast road transport<br />

Optimum Straw Mixing<br />

8 Block fre

e working<br />

<strong>The</strong> high weight of the <strong>Precision</strong><br />

<strong>Cultivator</strong> aids penetration even<br />

in hard, dry conditions. <strong>The</strong> angle<br />

of heavy spring tine changes in<br />

hard conditions bringing a more<br />

aggressive working angle.<br />

4 | Cost reduction<br />

<strong>The</strong> target of reducing crop<br />

establishment costs, reducing the<br />

time taken and to improve the<br />

humus content in the soil have<br />

meant that stubble cultivations have<br />

become much more important.<br />

Even harvest residue incorporation<br />

at shallow depth and reconsolidation<br />

of the worked ground to produce<br />

the best possible chit therefore<br />

making chemical elimination<br />

more effective are also important.<br />

Improving soil quality by increasing<br />

the humus content in the upper soil<br />

strata, by creating an environment<br />

where worms flourish, all combine<br />

to meet the demanding targets of<br />

modern cereals growing.<br />

5 | Optimum Reconsolidation<br />

Having moved all the soil and evenly<br />

mixed the post harvest residues it<br />

is crucial that the moved ground is<br />

reconsolidated.<br />

Reconsolidation creates good<br />

weed, seed and volunteer soil<br />

contact, moisture is retained and<br />

slug control is aided.<br />

<strong>The</strong> <strong>Precision</strong> <strong>Cultivator</strong> incorporates<br />

a 530mm diameter soil-tosoil<br />

roller (STS) to reconsolidate<br />

the moved ground. <strong>The</strong> STS roller<br />

has two rows of self-cleaning rings.<br />

<strong>The</strong> rings are constructed from ‘U’<br />

channels.<br />

<strong>The</strong> open ‘U’ channel fills with soil<br />

and the friction between the soil in<br />

the ring and the ground keep the<br />

ring turning.<br />

A row of chisel scrapers limits the<br />

amount of soil in the U channel.<br />

<strong>The</strong> weight and strength of the STS<br />

gives a press effect even in stony<br />

conditions.<br />

6 | Diagonal Working<br />

Working at an angle to the tramlines<br />

gives the best elimination and<br />

the optimum straw mixing. Uneven<br />

straw lumps and concentrations<br />

are carried by the eight tine bars<br />

for some distance aiding the<br />

mixing effect. When working after<br />

sugar beet, maize and potatoes the<br />

levelling effect of the <strong>Precision</strong><br />

<strong>Cultivator</strong> is particularly beneficial.<br />

7 | Fast road transport<br />

<strong>The</strong> <strong>Precision</strong> <strong>Cultivator</strong> is a trailed<br />

machine using the tractors link<br />

arms. Being fully trailed, less<br />

ground pressure from the tractor<br />

wheels, compared to mounted<br />

implements is exerted particularly<br />

when turning on the headland.<br />

8 | Block free working<br />

By using eight tine bars the tine<br />

spacing side by side is 1m and<br />

80cm diagonally. At the same time<br />

the overall tine spacing leaves<br />

15mm between neighbouring<br />

points even though one point may<br />

be on the front tine bar and the<br />

neighbour on the rear tine bar. <strong>The</strong><br />

result is fast block free work.

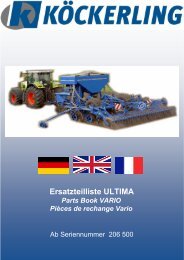

Technical Data VARIO<br />

Width m 3,00 4,00 4,80 5,70 6,60 7,50<br />

Weight kg 3500 4000 5120 5850 7000 7300<br />

hp 136 180 200 272 350 400<br />

No Tines 23 31 37 43 51 57<br />

Tine spacing 130 130 130 130 130 130<br />

mm<br />

Point 100x12 100x12 100x12 100x12 100x12 100x12<br />

Depth 15.0/ 15.0/ 15.0/ 15.0/ 4x15.0/ 4x15.0/<br />

Wheels 55-17" 55-17" 55-17" 55-17" 55-17" 55-17"<br />

Transport 500/ 500/ 500/ 500/ 500/ 500/<br />

Wheels 50-17" 50-17" 50-17" 50-17" 60-22,5" 60-22,5"<br />

Rear Roller Double STS<br />

Drawbar Cat Cat III Cat III Cat III Cat III Cat III Cat III

KÖCKERLING reserve the right to<br />

make technical changes and product<br />

development.<br />

in UK:<br />

Köckerling UK<br />

51 Leam Terrace, Leamington Spa<br />

Warwickshire, CV31 1DG<br />

Paddy Flynn<br />

Mob: +44 (0)7887 894828<br />

Office: +44 (0)1926 315079<br />

Point Wear<br />

In comparison with winged points, the<br />

wear on the 100mm reversible point<br />

is much lower. <strong>The</strong> soil boil effect from<br />

the heavy-duty leaf spring tine and the<br />

possibility to have four wear positions<br />

(as the point reduces in length) reduce<br />

the operating costs.<br />

This is particularly noticeable in a dry<br />

year such as 2003.<br />

Attachment to the tractor drawbar<br />

Standard equipment for the <strong>Precision</strong><br />

<strong>Cultivator</strong> is a cat 3 link drawbar, this<br />

gives the tightest turning circle possible.<br />

Your Dealer<br />

Seedbed preparation<br />

<strong>The</strong> <strong>Precision</strong> <strong>Cultivator</strong> is just as<br />

effective after the plough.<br />

One pass produces a level seedbed<br />

with a firm top to drill into.<br />

Again the on the move hydraulic depth<br />

adjustment takes care of varying<br />

conditions.<br />

For tractors such as articulated or<br />

tracked or without hydraulic linkage<br />

draw bar fitment is possible.<br />

This fitting retains the movement<br />

available in linkage fitment.<br />

in Germany:<br />

Köckerling GmbH & Co. KG<br />

Lindenstraße 11-13, D-33415 Verl<br />

Tel. +49 (0) 52 46 96 08-0<br />

Fax +49 (0) 52 46 96 08-21<br />

www.koeckerling.de<br />

info@koeckerling.de<br />

www.pmr-werbung.de 03/07/8577