Envirotemp ® FR3 ® Fluid - Waukesha Electric

Envirotemp ® FR3 ® Fluid - Waukesha Electric

Envirotemp ® FR3 ® Fluid - Waukesha Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Envirotemp</strong> <strong>®</strong> <strong>FR3</strong> <strong>®</strong> <strong>Fluid</strong><br />

6 June 2007<br />

Cooper Power Systems Cooper Power Systems<br />

McGraw-Edison Development Corporation 1900 East North Street<br />

19, Mykinon Street <strong>Waukesha</strong>, Wisconsin 53188-3899<br />

GR-166 74 Glyfada, Athens USA<br />

GREECE<br />

telephone: +30 210 964 6332 telephone: +01 262 524 3300<br />

email: cps-athens@cooperpower.com<br />

<strong>®</strong>

Contents<br />

1. Dielectric properties<br />

1.1. Partial discharge behavior .................................................................................................... 4<br />

1.2. Withstand capability curves .................................................................................................. 5<br />

1.3. Effect of dissolved water and temperature on dielectric strength ......................................... 7<br />

1.4. Effect of voltage distribution in insulation structure ............................................................... 8<br />

1.5. Effect of temperature on power factor and dielectric constant ............................................. 8<br />

1.6. Creep withstand .................................................................................................................. 10<br />

2. Thermal properties<br />

2.1. Viscosity at low temperatures ............................................................................................. 11<br />

3. Ageing<br />

3.1. Oxidation inhibitors .............................................................................................................. 11<br />

3.2. Transport atmosphere ......................................................................................................... 11<br />

3.3. Long term ageing fluid properties ....................................................................................... 12<br />

3.4. Impact of moisture and dissolved oxygen on ageing .......................................................... 15<br />

3.5. Dissolved oxygen ................................................................................................................ 15<br />

3.6. Causes of dissolved gas ..................................................................................................... 15<br />

3.7. Typical dissolved gas spectra ............................................................................................. 15<br />

3.8. Dissolved gas and ageing ................................................................................................... 16<br />

3.9. Sensitivity to oxygen of immersed material in air ................................................................ 17<br />

3.10. Normal gassing ................................................................................................................... 18<br />

3.11. Effectiveness of gas extraction ........................................................................................... 19<br />

3.12. Interpretation of dissolved gas data .................................................................................... 19<br />

4. General properties<br />

4.1. <strong>Fluid</strong> preservation ................................................................................................................ 19<br />

4.2. Materials compatibility ......................................................................................................... 19<br />

4.3. Water absorption during maintenance and on-site drying .................................................. 20<br />

4.4. Measures to avoid polymerization ...................................................................................... 20<br />

4.5. Traces of other liquids ......................................................................................................... 20<br />

4.6. Aging rate of thermal upgraded paper ................................................................................ 21<br />

4.7. Electrostatic charging and streaming electrification ............................................................ 22<br />

5. Handling / oil processing<br />

2<br />

5.1. Processing rigs .................................................................................................................... 22<br />

5.2. Impregnating solid insulation .............................................................................................. 22<br />

5.3. Influence of other oils and synthetic liquids during degassing ............................................ 22<br />

5.4. Disposal methods ................................................................................................................ 22<br />

5.5. Hydrolytic stability ............................................................................................................... 22

5.6. Processing for water content .............................................................................................. 22<br />

5.7. Vapor phase processing ..................................................................................................... 22<br />

References .......................................................................................................................................... 22<br />

3

1. Dielectric properties<br />

Partial Discharge Inception (kV)<br />

4<br />

1.1 Partial discharge behavior<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid appears to have a higher partial discharge inception voltage compared to<br />

mineral oil.<br />

40<br />

30<br />

20<br />

10<br />

Figure 1 shows results obtained by the<br />

University of New South Wales using<br />

needle to spherical section geometry [1].<br />

Water was added to the fluids for the 4<br />

mm gap tests, resulting in a much smaller<br />

inception voltage for both fluids.<br />

The breakdown voltages of the two fluids<br />

are quite different, however. <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid has a much higher breakdown<br />

voltage compared to mineral oil. This may<br />

be attributed to its higher tolerance of<br />

water.<br />

Figures 2-4 show results from the<br />

University of Hannover [2] using the<br />

IEC 61294 method and a 50mm gap.<br />

The variations of partial discharge<br />

inception with regard to temperature<br />

and relative water content were<br />

explored. At low relative saturations,<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

have similar inception voltages. As the<br />

relative water contents increase,<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid appears to have<br />

higher inception voltages compared to<br />

mineral oil.<br />

IEC 61294, needle-plane, 50mm gap, University of Hanover<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid (50 o C)<br />

mineral oil (60 o C)<br />

0<br />

0 5 10 15 20 25 30 35<br />

Water Content as Relative Saturation (%)<br />

Figure 3. Partial discharge inception voltage versus<br />

water content of mineral oil at 60°C and <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid at 50°C. [2]<br />

Voltage (kV)<br />

20<br />

15<br />

10<br />

5<br />

0<br />

transformer oil <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

inception breakdown inception breakdown inception breakdown<br />

2 mm gap 3 mm gap 4 mm gap + H2O<br />

Partial Discharge (point - semisphere)<br />

Figure 1. Partial discharge inception voltage for<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid. [1]<br />

Partial Discharge Inception (kV)<br />

Partial Discharge Inception (kV)<br />

40<br />

30<br />

20<br />

10<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid: needle-plane<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid: needle-sphere<br />

IEC 61294, 50mm gap, University of Hanover<br />

mineral oil: needle-plane<br />

mineral oil: needle-sphere<br />

0<br />

0 20 40 60 80<br />

Water Content as Relative Saturation at 20 o C (%)<br />

Figure 2. Partial discharge inception voltage versus<br />

water content of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong><br />

fluid at 20°C. [2]<br />

40<br />

30<br />

20<br />

10<br />

IEC 61294, needle-plane, 50mm gap, University of Hanover<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

0<br />

0 2 4 6 8 10 12 14 16 18 20<br />

Water Content as Relative Saturation at 90 o C (%)<br />

Figure 4. Partial discharge inception voltage versus<br />

water content of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

at 90°C. [2]

1.2 Withstand capability curves<br />

Oil gap withstand tests were conducted at three laboratories according to their voltage<br />

capabilities: Cooper Power Systems, Doble Engineering, and <strong>Waukesha</strong> <strong>Electric</strong> Systems. Figure<br />

5 shows the electrode configurations. Withstand capabilities for 60 Hz (Figure 6), full wave<br />

negative and positive impulse (Figure 7), chopped wave negative and positive impulse (Figure 8),<br />

and switching surge negative and positive impulse (Figure 9) are shown.<br />

Sphere-to-sphere full wave negative impulse withstand is shown in Figure 10. The University of<br />

Manchester used the ASTM D3300 test method with a 12.7mm gap.<br />

All of the results demonstrate that the oil gap withstand capabilities of mineral oil and <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid are, for all practical purposes, equivalent.<br />

(a) (b) (c)<br />

Figure 5. Electrode configurations for oil gap tests performed at the Thomas A. Edison Technical Center (a), Doble<br />

Engineering (b), and <strong>Waukesha</strong> <strong>Electric</strong> Systems (c).<br />

60 Hz Breakdown (kV/mm)<br />

100<br />

10<br />

Doble<br />

Engineering<br />

<strong>Waukesha</strong><br />

<strong>Electric</strong> Systems<br />

Thomas A. Edison<br />

Technical Center<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

Oil Gap (mm)<br />

Figure 6. AC withstand for mineral oil and <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid.<br />

Full Wave Negative Impulse (kV/mm)<br />

Full Wave Positive Impulse (kV/mm)<br />

100<br />

10<br />

Doble<br />

Engineering<br />

<strong>Waukesha</strong><br />

<strong>Electric</strong> Systems<br />

Thomas A. Edison<br />

Technical Center<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

100<br />

10<br />

Doble<br />

Engineering<br />

<strong>Waukesha</strong><br />

<strong>Electric</strong> Systems<br />

Thomas A. Edison<br />

Technical Center<br />

Oil Gap (mm)<br />

(a)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

Oil Gap (mm)<br />

Figure 7. Negative (a) and positive (b) full wave<br />

impulse withstand for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong><br />

fluid.<br />

(b)<br />

5

Chopped Wave Negative Impulse (kV/mm)<br />

Chopped Wave Positive Impulse (kV/mm)<br />

100<br />

10<br />

Doble<br />

Engineering<br />

Thomas A. Edison<br />

Technical Center<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

Oil Gap (mm)<br />

Figure 8. Chopped wave negative (a) and positive (b)<br />

impulse withstand for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong><br />

fluid.<br />

Full Wave Negative Impulse (kV/mm)<br />

100<br />

20<br />

15<br />

10<br />

5<br />

0<br />

10<br />

Doble<br />

Engineering<br />

Thomas A. Edison<br />

Technical Center<br />

(a)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

Oil Gap (mm)<br />

(b)<br />

ASTM D3300, sphere-sphere, 12.7mm gap, University of Manchester<br />

Absolute Water Content (mg/kg)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

0 100 200 300 400<br />

Switching Surge Negative Impulse (kV/mm)<br />

Switching Surge Positive Impulse (kV/mm)<br />

100<br />

10<br />

Doble<br />

Engineering<br />

<strong>Waukesha</strong><br />

<strong>Electric</strong> Systems<br />

Thomas A. Edison<br />

Technical Center<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

100<br />

10<br />

Doble<br />

Engineering<br />

<strong>Waukesha</strong><br />

<strong>Electric</strong> Systems<br />

Thomas A. Edison<br />

Technical Center<br />

Oil Gap (mm)<br />

(a)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

Oil Gap (mm)<br />

(b)<br />

Figure 9. Switching surge negative (a) and positive (b)<br />

impulse withstand for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong><br />

fluid.<br />

0<br />

0 10 20 30 40<br />

Relative Water Content (% 20 o C saturation)<br />

(a) (b)<br />

Figure 10. Full wave negative impulse strength versus absolute water content (a) and relative water content (b) of<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid. [2]<br />

6<br />

Full Wave Negative Impulse (kV/mm)<br />

20<br />

15<br />

10<br />

5<br />

ASTM D3300, sphere-sphere, 12.7mm gap, University of Manchester<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid

D1816 Dielectric Breakdown Strength (kV)<br />

D1816 Dielectric Breakdown Strength (kV)<br />

1.3 Effect of dissolved water and temperature on dielectric strength<br />

The dependence of dielectric breakdown strength on water content is shown in Figures 11-13.<br />

Variation of ASTM D1816 (VDE electrodes) dielectric breakdown strength in term of both absolute<br />

and relative water contents are shown for 2mm gap (Figure 11) and 1mm gap (Figure 12). The<br />

ASTM D877 (disk electrodes) dependence on absolute water content is shown in Figure 13.<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Dielectric breakdown strength variation with temperature is given in Figure 14.<br />

0<br />

0 100 200 300 400 500 600 700<br />

Water Content (mg/kg)<br />

(a)<br />

(b)<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

Figure 11. Dielectric breakdown strength versus water<br />

content for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

D 877 Dielectric Breakdown (kV)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Water Content (% of 20 o C saturation)<br />

Water Content (ppm)<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

<strong>FR3</strong> production history<br />

conventional transformer oil<br />

0<br />

0 100 200 300 400 500 600<br />

Figure 13. Dielectric breakdown strength versus water<br />

content for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Dielectric Breakdown Strength (kV)<br />

Dielectric Breakdown Strength (kV)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

50<br />

40<br />

30<br />

20<br />

10<br />

ASTM D1816, 1mm gap, University of Manchester<br />

0 100 200 300 400<br />

Absolute Water Content (mg/kg)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

(a)<br />

(b)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

ASTM D1816, 1mm gap, University of Manchester<br />

0<br />

0 10 20 30 40<br />

Relative Water Content (% 20 o C saturation)<br />

Figure 12. Dielectric breakdown strength versus water<br />

content for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid. [3]<br />

D1816 Dielectric Breakdown Strength (kV)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

-40 -20 0 20 40 60<br />

Temperature ( o C)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

Figure 14. Dielectric breakdown strength versus<br />

temperature for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

7

Relative Permittivity<br />

8<br />

1.4 Effect of voltage distribution in insulation structure<br />

“The dielectric strength of solid insulation (in this case Kraft insulation impregnated with dielectric<br />

fluid) is close to an order of magnitude higher than the fluid itself. Thus the weak material in the<br />

insulation structure is the fluid. By bringing the permittivity of the liquid and solid insulation closer<br />

together more of the dielectric stress will be distributed in the solid material. This will reduce the<br />

stress in the fluid, which typically sets the design clearance.” T. Prevost, presentation of [4]<br />

An example is given in Figure<br />

28.<br />

ε1=permittivity fluid<br />

mineral oil ≅ 2 <strong>FR3</strong> fluid ≅ 3<br />

ε2=permittivity solid insulation<br />

solid insulation ≅ 4<br />

Z=(d1/ε1) + (d2/ε2)<br />

Let d1 = d2 = 5mm<br />

E1= U/(ε1 * Z)<br />

E2= U/(ε2 * Z)<br />

U= Applied Voltage<br />

Let U = 100 kV<br />

E1= Stress fluid<br />

E2= Stress in solid insulation<br />

Mineral oil:<br />

E1= 13.33 kV/mm<br />

E2= 6.67 kV/mm<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid:<br />

E1= 11.43 kV/mm<br />

E2= 8.57 kV/mm<br />

Figure 28. Dielectric breakdown strength versus temperature for mineral<br />

oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid. from T.A. Prevost presentation of [4]<br />

1.5 Effect of temperature on power factor and dielectric constant<br />

The dielectric constants of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid as a function of temperature are<br />

shown in Figure 14. The University of Hannover [2] values are the average dielectric constant for<br />

a range of water contents. The error bars represent the maximum and minimum dielectric<br />

constants. <strong>Envirotemp</strong> <strong>FR3</strong> fluid was tested at water contents of 30, 50, 200, and 500 mg/kg;<br />

mineral oil was tested at 11, 20, and 40 mg/kg. Figures 15-17 show the dielectric constants of<br />

impregnated solid insulation versus temperature.<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

EHV Weidmann Thomas A. Edison Technical Center University of Hannover<br />

mineral oil mineral oil<br />

mineral oil<br />

<strong>FR3</strong> fluid <strong>FR3</strong> fluid<br />

-20 0 20 40 60 80 100 120<br />

Temperature ( o C)<br />

<strong>FR3</strong> fluid<br />

Figure 14. Relative permittivity versus temperature of<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Diamond Pattern Paper<br />

Relative Permittivity<br />

5.5<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

20 40 60 80 100 120<br />

Temperature ( o C)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

Figure 15. Relative permittivity versus temperature of<br />

Kraft paper impregnated with mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.

Medium Density Pressboard<br />

Relative Permittivity<br />

Dielectric <strong>Fluid</strong><br />

Dissipation Factor (%)<br />

Medium Density Pressboard<br />

Dissipation Factor (%)<br />

5.5<br />

5.0<br />

4.5<br />

4.0<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

3.5<br />

20 40 60 80 100 120<br />

Temperature ( o C)<br />

Figure 16. Relative permittivity versus temperature of<br />

T-IV pressboard impregnated with mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

10<br />

1<br />

0.1<br />

0.01<br />

0.001<br />

High Density Pressboard<br />

Relative Permittivity<br />

5.5<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

20 40 60 80 100 120<br />

Temperature ( o C)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

Figure 17. Relative permittivity versus temperature of<br />

Hi-Val pressboard impregnated with mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Dissipation factors of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid as a function of temperature are shown<br />

in Figure 18. Again, the University of Hannover [2] values are the average dielectric constant for a<br />

range of water contents, and the error bars represent the maximum and minimum values. Figures<br />

19-21 show the dissipation factors of impregnated solid insulation versus temperature.<br />

University of Hannover<br />

mineral oil<br />

<strong>FR3</strong> fluid<br />

EHV Weidmann<br />

mineral oil<br />

<strong>FR3</strong> fluid<br />

0 20 40 60 80 100 120<br />

Temperature ( o C)<br />

Thomas A. Edison Technical Center<br />

mineral oil<br />

<strong>FR3</strong> fluid<br />

Figure 18. Dissipation factor versus temperature of<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

10<br />

1<br />

0.1<br />

0.01<br />

Temperature ( o C)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

0.001<br />

20 40 60 80 100 120<br />

Figure 20. Dissipation factor versus temperature of T-IV<br />

pressboard impregnated with mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Diamond Pattern Paper<br />

Dissipation Factor (%)<br />

10<br />

1<br />

0.1<br />

0.01<br />

0.001<br />

20 40 60 80 100 120<br />

Temperature ( o C)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

Figure 19. Dissipation factor versus temperature of<br />

Kraft paper impregnated with mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

High Density Pressboard<br />

Dissipation Factor (%)<br />

10<br />

1<br />

0.1<br />

0.01<br />

0.001<br />

20 40 60 80 100 120<br />

Temperature ( o C)<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

Figure 21. Dissipation factor versus temperature of<br />

Hi-Val pressboard impregnated with mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

9

60 Hz Creep Breakdown Stress (kV/mm)<br />

60 Hz Creep Breakdown Stress<br />

Weibull 1% Probability (kV/mm)<br />

10<br />

1.6 Creep Withstand Capabilities<br />

AC and impulse creep withstand tests were performed by EHV Weidmann [4]. Their electrode<br />

configuration is shown in Figure 27. The geometry gives a non-uniform field with the highest<br />

stress along the pressboard-fluid interface. The electrode and test specimen are designed to<br />

minimize the effect of oil wedges.<br />

100<br />

10<br />

(a) (b)<br />

Figure 27. EHV Weidmann creep electrode design (a) and photo of creep<br />

breakdown (b). [4]<br />

1<br />

1 10 100<br />

100<br />

10<br />

EHV Weidmann<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

EHV Weidmann<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

Creep Distance (mm)<br />

(a)<br />

Weidmann design curve<br />

1<br />

1 10 100<br />

Creep Distance (mm)<br />

(b)<br />

Figure 22. 60 Hz creep strength of mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid: (a) shows test values and (b)<br />

shows the calculated Weibull 1% probability.<br />

Full Wave Negative Creep<br />

Breakdown Stress (kV/mm)<br />

Full Wave Negative Creep<br />

Weibull 1% Probability (kV/mm)<br />

100<br />

10<br />

EHV Weidmann<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

100<br />

10<br />

EHV Weidmann<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

mineral oil<br />

Weidmann design curve<br />

Creep Distance (mm)<br />

(a)<br />

1<br />

1 10 100<br />

Creep Distance (mm)<br />

(b)<br />

Figure 23. Full wave negative creep strength of<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid: (a) shows test<br />

values and (b) shows the calculated Weibull 1%<br />

probability.

Full Wave Positive Creep<br />

Breakdown Stress ( kV/mm)<br />

100<br />

10<br />

For AC creep withstand (Figure 22) and negative full wave impulse creep withstand (Figure 23),<br />

the Weibull 1% probability is calculated and compared to the published Weidmann creep curve.<br />

Figure 24 shows the results to date for positive full wave impulse creep withstand. Tests<br />

completed to date demonstrate that the creep strengths of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

are, for all practical purposes, equivalent.<br />

EHV Weidmann<br />

mineral oil<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

1<br />

1 10 100<br />

Creep Distance (mm)<br />

Figure 24. Full wave positive impulse creep withstand<br />

of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

2. Thermal properties<br />

1000<br />

100<br />

10<br />

Kinematic Viscosity (cSt) 10000<br />

2<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

7-day hold<br />

conventional transformer oil<br />

-20 0 20 40 60 80 100 120 140<br />

Temperature ( o C)<br />

Figure 25. Viscosity versus temperature for mineral oil<br />

and <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

2.1 Viscosity at low temperatures<br />

Many variables affect the low temperature flow characteristics of <strong>Envirotemp</strong> <strong>FR3</strong> fluid. The low<br />

temperature viscosity depends not only on the temperature, but also time at temperature, the rate<br />

of cooling, and the fluid volume. Figure 25 shows the viscosity versus temperature curves for<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid. Comparing the 7-day hold values to the standard viscosity<br />

shows the time at temperature effect.<br />

3. Ageing<br />

(Another Cooper Power Systems’ product, R-Temp fluid, has a pour point similar to that of<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid, but its viscosity is considerably higher. R-Temp fluid had the same cold flow<br />

concerns, but has had no field issues in 30+ years of cold climate applications.)<br />

3.1 Oxidation inhibitors<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid contains an additive package that includes a proprietary oxidation inhibitor<br />

at 0.4 wt%. The ASTM D4768 gas chromatography method for determining the inhibitor content in<br />

insulating liquids can be used to determine the inhibitor content in <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

3.2 Transport atmosphere<br />

Tests using transformer power factor<br />

models are currently underway to evaluate<br />

the effects of dry air transport of<br />

transformers using <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

The pressboard models, impregnated with<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid,<br />

emulate the geometry of power transformer<br />

coils on a small scale (Figure 26).<br />

Figure 26. Example of power factor model used in<br />

tests to evaluate dry air transport of <strong>Envirotemp</strong> <strong>FR3</strong><br />

11

D1816 Dielectric Strength, 2mm gap (kV)<br />

DC Resistivity (Ω-cm)<br />

12<br />

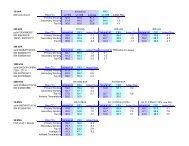

3.3 Long term ageing fluid properties<br />

A number of side-by-side accelerated aging tests have been conducted using <strong>Envirotemp</strong> <strong>FR3</strong><br />

fluid and mineral oil. One series of tests used transformer construction materials in the proper<br />

proportions to evaluate material compatibility. The tests, run at multiple temperatures and times,<br />

show the changes in fluid properties over 4 IEEE “normal” lifetimes, the rough equivalent of 86<br />

years of operation at rated load (Figures 27-34).<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

130 o C<br />

150 o C<br />

170 o C<br />

0<br />

0 1 2 3 4<br />

Equivalent "Normal" Lifetimes<br />

mineral<br />

oil<br />

130 o C<br />

150 o C<br />

170 o C<br />

Figure 27. Dielectric breakdown strength versus time<br />

for mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

1e+16<br />

1e+15<br />

1e+14<br />

1e+13<br />

1e+12<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

130 o C<br />

150 o C<br />

170 o C<br />

1e+11<br />

0 1 2 3 4<br />

Equivalent Lifetimes<br />

mineral<br />

oil<br />

130 o C<br />

150 o C<br />

170 o C<br />

Figure 29. Resistivity versus time for mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Dissipation Factor, 25 o C (%)<br />

10<br />

1<br />

0.1<br />

0.01<br />

0.001<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

130 o C<br />

150 o C<br />

170 o C<br />

0 1 2 3 4<br />

Equivalent "Normal" Lifetimes<br />

mineral<br />

oil<br />

130 o C<br />

150 o C<br />

170 o C<br />

Figure 28. Dissipation factor versus temperature for<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Acid Number (mg KOH/g)<br />

10<br />

1<br />

0.1<br />

0.01<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

0.001<br />

0 1 2 3 4<br />

Equivalent "Normal" Lifetimes<br />

130 mineral<br />

oil<br />

o C<br />

130 o C<br />

150 o C 150 o C<br />

170 o C 170 o C<br />

Figure 30. Acid number versus temperature for<br />

mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Interfacial Tension (dyne/cm)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

0<br />

0 1 2 3 4<br />

Equivalent "Normal" Lifetimes<br />

130 mineral<br />

oil<br />

o C 130 o C<br />

150 o C 150 o C<br />

170 o C 170 o C<br />

Figure 31. Interfacial tension versus time for mineral<br />

oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.

Water Content (mg/kg)<br />

Water Content (% 25 o C saturation)<br />

Fire Point (oC)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

0<br />

0 1 2 3 4<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Equivalent "Normal" Lifetimes<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

(a)<br />

Equivalent "Normal" Lifetimes<br />

130 mineral<br />

oil<br />

o C 130 o C<br />

150 o C 150 o C<br />

170 o C 170 o C<br />

130 mineral<br />

oil<br />

o C 130 o C<br />

150 o C 150 o C<br />

170 o C 170 o C<br />

0<br />

0 1 2 3 4<br />

(b)<br />

Figure 32. Water content versus time as (a) absolute<br />

water content and (b) relative water content of mineral<br />

oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

360<br />

350<br />

340<br />

330<br />

180<br />

170<br />

160<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

Equivalent "Normal" Lifetimes<br />

130 mineral<br />

oil<br />

o C 130 o 150<br />

C<br />

o C<br />

150 o C<br />

170 o C<br />

170 o C<br />

150<br />

0 1 2 3 4<br />

Viscosity at 100 o C (mm 2 /s)<br />

Viscosity at 40 o C (mm 2 /s)<br />

10<br />

8<br />

6<br />

4<br />

2<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

130 o C<br />

150 o C<br />

170 o C<br />

0<br />

0 1 2 3 4<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Equivalent "Normal" Lifetimes<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

(a)<br />

130 o C<br />

150 o C<br />

170 o C<br />

Equivalent "Normal" Lifetimes<br />

mineral<br />

oil<br />

mineral<br />

oil<br />

130 o C<br />

150 o C<br />

170 o C<br />

130 o C<br />

150 o C<br />

170 o C<br />

0<br />

0 1 2 3 4<br />

(b)<br />

Figure 33. Kinematic viscosity versus time at (a)<br />

100°C and (b) 40°C of mineral oil and <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid.<br />

Flash Point ( o C)<br />

340<br />

320<br />

300<br />

280<br />

170<br />

160<br />

150<br />

<strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid<br />

0 1 2 3 4<br />

Equivalent Lifetimes<br />

(a) (b)<br />

Figure 34. Flash point (a) and fire point (b) versus time of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

130 o C<br />

130 o 150<br />

C<br />

o C<br />

150 o C<br />

170 o C 170 o mineral<br />

oil<br />

C<br />

13

Temperature ( o C)<br />

Dielectric Breakdown Voltage (kV)<br />

14<br />

360<br />

340<br />

320<br />

300<br />

Figure 35 shows the dielectric breakdown<br />

strength versus dissipation factor at 25°C<br />

for <strong>Envirotemp</strong> <strong>FR3</strong> fluid. The fairly small<br />

decrease in dielectric strength indicates the<br />

high dissipation factor is due to larger polar<br />

molecules resulting from <strong>Envirotemp</strong> <strong>FR3</strong><br />

fluid thermal degradation instead of<br />

conductive particulate contaminants.<br />

D1816 Dielectric Breakdown Strength (kV)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

110 o C<br />

150 o C<br />

130 o C 170 o C<br />

210 o C (Nomex)<br />

10-3 10-2 10-1 100 101 102 0<br />

Dissipation Factor, 25 o C (%)<br />

Figure 35. Dielectric breakdown strength versus<br />

dissipation factor <strong>Envirotemp</strong> <strong>FR3</strong> fluid 2mm gap.<br />

The transformers having the longest continuous service are installed at a Cooper Power Systems<br />

factory in <strong>Waukesha</strong>, Wisconsin. These transformers, both 225 kVA 3P and installed in 1996,<br />

have been constantly loaded at about 90% of nameplate rating and periodically monitored. The<br />

fluid properties are shown in Figures 36-42. Several laboratories have tested the fluid samples<br />

over the years, accounting for some of the variations seen. Except for resistivity (Figure 40), which<br />

shows a moderate decrease over time, the properties remain essentially unchanged. Of note is<br />

the viscosity (Figure 37). Viscosity is the definitive indicator of oxidation in <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

The unchanging viscosity demonstrates absence of fluid oxidation in the transformers.<br />

Fire Point:<br />

Flash Point:<br />

IEC 61203 continued service fire point minimum<br />

ASTM D6871 new fluid fire point minimum<br />

S/N 1429 S/N 1430<br />

S/N 1429 S/N 1430<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 36. Flash and fire points over time of new<br />

transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

100<br />

80<br />

60<br />

40<br />

20<br />

S/N 1429: S/N 1430:<br />

D1816, 2mm gap D1816, 2mm gap<br />

D877<br />

D877<br />

0<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 38. Dielectric breakdown strength over time of<br />

new transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Kinematic Viscosity (cSt)<br />

Dissipation Factor at 25 o C (%)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

ASTM D6871 40 o C new fluid maximum<br />

40 o C:<br />

100 o C:<br />

ASTM D6871 100 o C new fluid maximum<br />

S/N 1429 S/N 1430<br />

S/N 1429 S/N 1430<br />

0<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 37. Kinematic viscosity over time of new<br />

transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

ASTM D6871 new fluid maximum<br />

IEC 1203 continued service maximum (60 Hz)<br />

S/N 1429<br />

S/N 1430<br />

0.0<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 39. Dissipation factor over time for new<br />

transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.

DC Resisitvity (ohm-cm)<br />

1e+15<br />

1e+14<br />

1e+13<br />

1e+12<br />

(IEC 61203 continued service minimum)<br />

S/N 1429<br />

S/N 1430<br />

1e+11<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 40. Resistivity over time of new transformers<br />

filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Interfacial Tension (dyne/cm)<br />

50<br />

40<br />

30<br />

20<br />

S/N 1429<br />

S/N 1430<br />

10<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 42. Interfacial tension over time of new<br />

transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Acid Number (mg KOH/g)<br />

10<br />

1<br />

0.1<br />

IEC 61203 continued service maximum<br />

ASTM D6871 new fluid maximum<br />

S/N 1429<br />

S/N 1430<br />

0.01<br />

1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Figure 41. Acid number over time of new transformers<br />

filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Water Content in Paper (wt%)<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

540<br />

672<br />

824<br />

0 o C<br />

10 o C<br />

996<br />

20 o C<br />

30 o C<br />

1189<br />

Solubility Limit (mg/kg)<br />

40 o C<br />

50 o C<br />

1403<br />

70 o C<br />

60 o C<br />

90 o C<br />

0<br />

0 200 400 600 800 1000<br />

1640<br />

1898<br />

80 o C<br />

Water Content in <strong>Envirotemp</strong> <strong>FR3</strong> <strong>Fluid</strong> (mg/kg)<br />

110 o C<br />

100 o C<br />

2179<br />

2481<br />

2806<br />

3151<br />

3519<br />

Figure 43. Water content in <strong>Envirotemp</strong> <strong>FR3</strong> fluid in<br />

equilibrium with water content in thermally upgraded<br />

Kraft paper based on vapor pressure of water (“Piper”<br />

chart).<br />

3.4 Impact of moisture and dissolved oxygen on ageing<br />

Increasing water content in the solid insulation increases its aging rate (thermo-hydrolytic<br />

degradation). The solubility of water in <strong>Envirotemp</strong> <strong>FR3</strong> fluid is higher than that of mineral oil,<br />

shifting the equilibrium and causing water to migrate from the paper into the fluid. Figure 43 shows<br />

the effect of the equilibrium shift and its drying effect on the solid insulation. The influence of the<br />

water shift is discussed in [10,11].<br />

3.5 Dissolved oxygen<br />

Dissolved oxygen in and of itself is not a problem. The amount of oxygen that can be dissolved<br />

into <strong>Envirotemp</strong> <strong>FR3</strong> from the headspace or as a result of small leaks is insignificant in terms of<br />

fluid stability. The concern instead is long-term (years) free access to oxygen. Cooper Power<br />

Systems does not recommend applying <strong>Envirotemp</strong> <strong>FR3</strong> fluid in free-breathing equipment.<br />

Transformers using conservators fitted with bags or membranes, nitrogen preservation systems,<br />

and sealed designs in general are suitable applications of <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

3.6 Causes of dissolved gas<br />

Just as with mineral oil, gases in <strong>Envirotemp</strong> <strong>FR3</strong> fluid are formed during normal aging processes,<br />

thermal breakdown, operation of fuses or switches, by electrical defects, or during abnormal<br />

events. The <strong>Envirotemp</strong> <strong>FR3</strong> dissolved gas guide [16] contains analysis recommendations and<br />

examples of normally operating and faulted transformers.<br />

15

Dissolved Gas (ppm)<br />

Dissolved Gas (ppm)<br />

16<br />

10,000<br />

1,000<br />

100<br />

10<br />

1<br />

0<br />

10,000<br />

1,000<br />

100<br />

10<br />

1<br />

0<br />

hydrogen H2 carbon<br />

monoxide CO<br />

hydrogen H2 carbon<br />

monoxide CO<br />

methane CH4 ethane C2H6 ethylene C2H4 acetylene C2H2 Total<br />

Combustible<br />

Gases<br />

(a)<br />

methane CH4 ethane C2H6 ethylene C2H4 acetylene C2H2 Total<br />

Combustible<br />

Gases<br />

(b)<br />

carbon dioxide<br />

CO2<br />

carbon dioxide<br />

CO2<br />

after fill<br />

Sept `96<br />

Dec `96<br />

Jan `97<br />

May `97<br />

March `98<br />

Feb `99<br />

July `99<br />

July `00<br />

July `01<br />

July `02<br />

July `03<br />

May `04<br />

Sept '05<br />

after fill<br />

Oct `96<br />

Nov `96<br />

Jan `97<br />

Jan `97<br />

March `98<br />

July `99<br />

July `00<br />

July `01<br />

July `02<br />

July `03<br />

May `04<br />

Sept '05<br />

Figure 44. Dissolved gases over time of new 225 kVA distribution transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid:<br />

(a) S/N 1429, (b) S/N 1430. Note the fairly high initial gas content. <strong>Fluid</strong> for power transformers is typically more<br />

thoroughly processed.<br />

3.7 Typical dissolved gas spectra<br />

Dissolved gases over time for the two transformers described in 3.3 are shown in Figure 44. Both<br />

have a higher proportion of ethane than is typical for a normally operating mineral oil transformer<br />

– a signature of <strong>Envirotemp</strong> <strong>FR3</strong> fluid [16].<br />

3.8 Dissolved gas and ageing<br />

To help develop an understanding of the gases dissolved in <strong>Envirotemp</strong> <strong>FR3</strong> fluid as transformers<br />

age, two sets of transformers were aged at 137°C, one set filled with mineral oil and the other with<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid for the equivalent of 36 “normal” years. At 137°C, one IEEE "normal" year is<br />

equivalent to 672 hours. <strong>Fluid</strong> samples for dissolved gas analysis were periodically taken. The gas<br />

results are shown in Figure 45.<br />

The gas generation rates as well as the quantities and proportions of gases in the mineral oil and<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid are strikingly similar. Other than the characteristically higher proportion of<br />

ethane in the <strong>Envirotemp</strong> <strong>FR3</strong> fluid compared to mineral oil, the gases over time are comparable.

Dissolved Gas (ppm)<br />

Dissolved Gas (ppm)<br />

1,000,000<br />

100,000<br />

10,000<br />

1,000<br />

100<br />

1,000,000<br />

100,000<br />

10,000<br />

1,000<br />

100<br />

10<br />

10<br />

1<br />

0<br />

1<br />

0<br />

hydrogen H2 carbon<br />

monoxide<br />

CO<br />

methane<br />

CH4<br />

ethane C2H6 ethylene<br />

C2H4<br />

(a)<br />

hydrogen H2 carbon methane CH4 ethane C2H6 ethylene<br />

monoxide CO<br />

C2H4<br />

(b)<br />

acetylene<br />

C2H2<br />

acetylene<br />

C2H2<br />

Total<br />

Combustible<br />

Gases<br />

Total<br />

Combustible<br />

Gases<br />

carbon<br />

dioxide CO2<br />

carbon<br />

dioxide CO2<br />

Figure 45. Dissolved gas versus time. Test transformers filled with (a) mineral oil and (b) <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

were run at an hottest spot temperature of 137°C using the IEEE C57.100 method. One IEEE "normal" year of<br />

21.54 years is represented by 672 hrs at 137°C represents.<br />

3.9 Sensitivity to oxygen of immersed material in air<br />

Although <strong>Envirotemp</strong> <strong>FR3</strong> fluid in bulk is relatively immune to oxidation due to air exposure, thin<br />

films of the fluid can oxidize to form a polymer coating. It is the metal surfaces coated with thin<br />

films that are prone to polymerization. A metal surface with a thin coating of <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

exposed to shop air may become tacky in a matter of days. Porous surfaces, such as paper and<br />

pressboard, impregnated with <strong>Envirotemp</strong> <strong>FR3</strong> fluid can be exposed for months without becoming<br />

tacky. They will, of course, absorb water from the atmosphere.<br />

Following a sequence of tests, a large test tank filled with <strong>Envirotemp</strong> <strong>FR3</strong> was put into a<br />

warehouse without a cover, and was promptly forgotten. After several years, it was discovered<br />

and the fluid tested. Aside from elevated dissipation factor and water content values, the fluid was<br />

still in good condition. No film was seen on the surface of the fluid. There was no change in<br />

viscosity, the definitive indicator of oxidation in <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Ongoing experiments use the power factor models described in 3.2 to assess the effects of hot air<br />

drying on impregnated surfaces.<br />

initial<br />

1 yrs<br />

2 yrs<br />

3 yrs<br />

6 yrs<br />

9 yrs<br />

12 yrs<br />

15 yrs<br />

18 yrs<br />

21 yrs<br />

24 yrs<br />

27 yrs<br />

30 yrs<br />

33 yrs<br />

36 yrs<br />

initial<br />

1 yrs<br />

2 yrs<br />

3 yrs<br />

6 yrs<br />

9 yrs<br />

12 yrs<br />

15 yrs<br />

18 yrs<br />

21 yrs<br />

24 yrs<br />

27 yrs<br />

30 yrs<br />

33 yrs<br />

36 yrs<br />

17

18<br />

An effect of hot air oven processing of <strong>Envirotemp</strong> <strong>FR3</strong> fluid-impregnated coils was inadvertently<br />

determined for us. Two transformers manufactured using <strong>Envirotemp</strong> <strong>FR3</strong> fluid were tested for<br />

power factor. The power factors of both transformers were higher than typically found in mineral<br />

oil transformers. The power factor specification limit for mineral oil, 0.5%, was used as the limit for<br />

these units. Because the dissipation factor of <strong>Envirotemp</strong> <strong>FR3</strong> fluid is higher than that of mineral<br />

oil, the power factor of the transformer also increases. Assuming a problem existed, the<br />

transformers were reworked as if they were impregnated with mineral oil. The coils were ovendried<br />

and the transformer retested. The power factor of the transformers went up due to the<br />

increase in dissipation factor of the <strong>Envirotemp</strong> <strong>FR3</strong> fluid as some oxidation occurred, instead of<br />

down as expected. This process is used to dry mineral oil coils to lower the transformer power<br />

factor. It also dried the <strong>Envirotemp</strong> <strong>FR3</strong> fluid coils, but the increase in power factor due to<br />

increased dissipation factor was larger than the reduction in power factor due to drier insulation.<br />

3.10 Normal gassing<br />

Dissolved gas levels in normally operating transformers filled with <strong>Envirotemp</strong> <strong>FR3</strong> fluid are similar<br />

to those found in equivalent mineral oil transformers. A feature unique to <strong>Envirotemp</strong> <strong>FR3</strong> fluid is<br />

its higher proportion of ethane compared to that found in normally operating mineral oil<br />

transformers [16].<br />

Dissolved Gas (ppm)<br />

Dissolved Gas (ppm)<br />

10,000<br />

1,000<br />

100<br />

10<br />

1<br />

0<br />

100,000<br />

10,000<br />

1,000<br />

100<br />

10<br />

1<br />

0<br />

hydrogen H2 carbon methane CH4 ethane C2H6 ethylene<br />

monoxide CO<br />

C2H4<br />

(a)<br />

acetylene<br />

C2H2<br />

hydrogen H2 carbon methane CH4 ethane C2H6 ethylene C2H4 acetylene<br />

monoxide CO<br />

C2H2<br />

(b)<br />

Total<br />

Combustible<br />

Gases<br />

Total<br />

Combustible<br />

Gases<br />

carbon<br />

dioxide CO2<br />

carbon dioxide<br />

CO2<br />

mineral oil<br />

<strong>FR3</strong> fluid<br />

mineral oil control<br />

<strong>FR3</strong> fluid control<br />

mineral oil<br />

<strong>FR3</strong> fluid<br />

mineral oil + Cu<br />

<strong>FR3</strong> fluid + Cu<br />

Figure 46. Mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid subjected to (a) partial discharge and (b) thermal stress [12]

3.11 Effectiveness of gas extraction<br />

Degassing <strong>Envirotemp</strong> <strong>FR3</strong> fluid is done in the same way using the same equipment as used for<br />

mineral oil. In order to keep the mineral oil flow rate through the processor and the same<br />

transformer set time after filling, <strong>Envirotemp</strong> <strong>FR3</strong> fluid should be heated to 80-85°C, compared to<br />

60°C temperature typically used for mineral oil processing. If higher temperature is not feasible,<br />

lower pressure in the degasser or slower flow rate can be used.<br />

3.12 Interpretation of dissolved gas data<br />

In general, the same basic interpretations of gas content used for mineral oil are used for<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid [16]. The IEC “Duval” method has been the most reliable fault identification<br />

method for <strong>Envirotemp</strong> <strong>FR3</strong> fluid. Combinations of combustible gas generation rate and gas<br />

proportions, along with the Duval method, are recommended. Applications of these methods are<br />

given in the examples of [16].<br />

Figure 46 shows the results of subjecting mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid to partial discharge<br />

and thermal stress [12].<br />

4. General properties<br />

4.1 <strong>Fluid</strong> preservation<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid is not suitable for long-term use in true free-breathing equipment. A<br />

transformer equipped with a nitrogen preservation system or a conservator fitted with a bag or<br />

membrane is suitable, as are sealed tank designs in general.<br />

4.2 Materials compatibility<br />

CPS has run multiple compatibility studies and found that <strong>Envirotemp</strong> <strong>FR3</strong> fluid, relative to mineral<br />

oil, has similar compatibility with materials used in the manufacture of transformers.<br />

Core & Coil Materials<br />

core steel<br />

bare copper<br />

bare aluminum<br />

polyvinyl Formvar<br />

copper magnet wire<br />

aluminum magnet wire<br />

conical mandrel<br />

Kraft paper<br />

pressboard<br />

diamond paper<br />

plain paper<br />

tubing<br />

crepe tubing<br />

vulcanized fiber sheet<br />

polyamide bias tape w/o<br />

epoxy<br />

polyvinyl acetate adhesive<br />

Group A Materials<br />

thermo set epoxy<br />

Rynite 530 (PET)<br />

high temperature Nylon<br />

Rostone thermoset<br />

polyester<br />

fiberglass/epoxy<br />

GPO3 polyester/glass<br />

laminate<br />

Amodel 1133<br />

polyphthalimide<br />

Mylar film (PET)<br />

Masonite<br />

porcelain - radio glaze<br />

Nylon tie wrap<br />

Carri-strap<br />

Group B Materials<br />

Rosite 3250<br />

PVC wire jacket<br />

Storm Trapper epoxy<br />

coating & wires<br />

pine block<br />

Switchgear Components<br />

tin-plated bus bar<br />

silver-plated bus bar<br />

Nylon tie wraps<br />

fiberglass string<br />

fiberglass string<br />

bottle bushing<br />

CT protector<br />

cover gasket – wide<br />

cover gasket – narrow<br />

bushing gasket<br />

GPO-3 polyester<br />

semaphore window<br />

auxiliary switches<br />

shaft seal o-ring<br />

semaphore gasket<br />

bottle disc<br />

tank connector<br />

tank connector gasket<br />

CT with wire leads<br />

Elastomers<br />

Buna-N<br />

Nitrile NBR<br />

Nitrile HNBR<br />

Epichlorohydrin<br />

Viton<br />

Neoprene (used)<br />

Cork/neoprene (used)<br />

Sealants<br />

Locktite PST592 pipe sealant<br />

Locktite Vibra-Seal<br />

Permatex 51D pipe joint<br />

compound<br />

Core Banding<br />

Glass / Polyester<br />

Dacron / Epoxy<br />

Green Polyester Bands<br />

Black Nylon Bands<br />

Adhesives<br />

PVA<br />

Casein<br />

Epoxy<br />

Cyanoacrylate<br />

Anaerobic (Thread lockers)<br />

Acrylics (Tapes)<br />

Tapes<br />

polyester/glass with<br />

thermo set rubber adhesive<br />

thermosetting acrylic adhesive<br />

Kraft paper w/ wheat gum adhesive<br />

Miscellaneous<br />

polyethylene naphthalate (PEN)<br />

Rynite 350<br />

HTN primary bushing<br />

tap changer<br />

bayonet fuse<br />

Epoxy Paint (Two Part)<br />

Core Epoxy<br />

Phenolic (DETC)<br />

Heat Shrink (Polyester)<br />

Laminated Wood<br />

TX Block Material<br />

Nylon (6/6) Ty-wraps, Banding<br />

Yoke Band Insulation<br />

CTC (Bonded)<br />

Epoxy Paint (Two Part)<br />

Core Epoxy<br />

19

Absolute Water Content (mg/kg)<br />

4.3 Water absorption during maintenance and on-site drying<br />

Water absorption from the atmosphere is shown in Figure 47. In terms of absolute water content,<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid absorbs water at a faster rate than does mineral oil. In terms of relative<br />

water content, mineral oil absorbs water at a faster rate. The same precautions taken to minimize<br />

water absorption by mineral oil during maintenance should be taken for <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

0 500 1000 1500 2000 2500 3000<br />

Exposure Time (hrs)<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

transformer oil<br />

Relative Water Content<br />

(% room temperature saturation)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 500 1000 1500 2000 2500 3000<br />

Exposure Time (hrs)<br />

(a) (b)<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

transformer oil<br />

Figure 47. Water absorption from laboratory ambient atmosphere of mineral oil and <strong>Envirotemp</strong> <strong>FR3</strong> fluid as (a)<br />

absolute water content and (b) relative water content.<br />

20<br />

4.4 Measures to avoid polymerization<br />

Water uptake is almost always more of a concern than oxidation. Polymerization (oxidation leads<br />

to the formation of oligomers, which eventually form polymers) is most likely to occur when thin<br />

films of <strong>Envirotemp</strong> <strong>FR3</strong> fluid on metal surfaces are exposed to air and sunlight (UV radiation). In<br />

transformers, a free-breathing system will take years to show an increase in viscosity, the<br />

definitive indication that oxidation is occurring. Long before the viscosity increases, the dissipation<br />

factor will increase greatly, so ample warning is given in transformers routinely sampled.<br />

Maintenance and repair tasks are most likely to expose thin films of <strong>Envirotemp</strong> <strong>FR3</strong> fluid to the<br />

atmosphere. Ideally, components impregnated with <strong>Envirotemp</strong> <strong>FR3</strong> fluid or having thin films on<br />

the surface will be immersed in <strong>Envirotemp</strong> <strong>FR3</strong> fluid or mineral oil. The components could be<br />

rinsed with mineral oil or stored in plastic bags of low oxygen permeability. Do not dry components<br />

in hot air ovens.<br />

4.5 Traces of other liquids<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid is compatible with most dielectric fluids except silicone. The two do not mix,<br />

and when put together separate into two phases. Silicone oil, even in low concentrations, may<br />

cause foaming during the degassing process. Changes in <strong>Envirotemp</strong> <strong>FR3</strong> fluid properties with<br />

mineral oil content are shown in Figures 48-50.

Temperature ( o C)<br />

350<br />

300<br />

250<br />

200<br />

150<br />

0 2 4 6 8 10 20 40 60 80 100<br />

Mineral Oil Content (%)<br />

fire point<br />

flash point<br />

Figure 48. Flash and fire points versus mineral oil<br />

content in <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Kinematic Viscosity (mm 2 /s)<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 10 20 30 40 50 60 70 80 90 100<br />

Mineral Oil Content (%)<br />

viscosity at 40 o C<br />

viscosity at 100 o C<br />

Figure 49. Kinematic viscosity versus mineral oil<br />

content in <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

Interfacial Tension (dynes/cm)<br />

50<br />

40<br />

30<br />

20<br />

0 10 20 30 40 50 60 70 80 90 100<br />

Mineral Oil Content (%)<br />

Figure 50. Interfacial tension versus mineral oil<br />

content in <strong>Envirotemp</strong> <strong>FR3</strong> fluid.<br />

4.6 Aging rate of thermal upgraded paper<br />

Significant reductions in the aging rates of plain Kraft, cotton/Kraft, and thermally upgraded Kraft<br />

are seen. Full-scale transformer accelerated aging tests, using the IEEE C57.100 method, are<br />

described in [5]. These tests qualified the <strong>Envirotemp</strong> <strong>FR3</strong> fluid/thermally upgraded Kraft paper<br />

insulation system for 65°C average winding rise applications. Extending the tests qualified the<br />

insulation system as a 75°C average winding rise system.<br />

The results obtained in the full-scale tests led to an in-depth study of <strong>Envirotemp</strong> <strong>FR3</strong> fluid<br />

interactions. Sealed tube studies using the IEEE C57.100 method showed a much slower aging<br />

rate of the thermally upgraded Kraft paper in <strong>Envirotemp</strong> <strong>FR3</strong> fluid [6]. Plain (not thermally<br />

upgraded) Kraft also show a significant decrease in aging [7], as did cotton/Kraft paper [8]. The<br />

previous studies focused on new paper. Retrofill simulations were conducted showing a change<br />

from the aging rate of paper/mineral oil to the aging rate of paper/<strong>Envirotemp</strong> <strong>FR3</strong> fluid after the<br />

retrofill [9]. The mechanisms responsible for the reduced aging rates are proposed in [10,11].<br />

The thermally upgraded Kraft paper/<strong>Envirotemp</strong> <strong>FR3</strong> fluid aging rates are applied to ANSI<br />

standard transformer designs [13,15] using the aging equation derived from the sealed tube<br />

studies [14].<br />

21

4.7 Electrostatic charging and streaming electrification<br />

The higher dissipation factor and lower resisitivity of <strong>Envirotemp</strong> <strong>FR3</strong> fluid compared to those of<br />

mineral oil should reduce the electrostatic charging and streaming electrification tendencies.<br />

Cooper Power Systems is planning experiments to verify this.<br />

5. Handling / oil processing<br />

5.1 Processing rigs<br />

Standard mineral oil processing rigs are commonly used with good results to process <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid. The rig should be drained of mineral oil and flushed with <strong>Envirotemp</strong> <strong>FR3</strong> fluid. It is then<br />

ready for <strong>Envirotemp</strong> <strong>FR3</strong> fluid processing. When finished, drain the <strong>Envirotemp</strong> <strong>FR3</strong> fluid and<br />

flush with mineral oil to return the rig to mineral oil use. Mineral oil is typically processed at about<br />

60°C. To keep the same mineral oil flow rate through the processor and set time for the filled<br />

transformer, the <strong>Envirotemp</strong> <strong>FR3</strong> fluid should be processed around 80-85°C. The fluid degasses<br />

easily at that temperature. If higher temperature operation of the rig is not possible, a reduced flow<br />

rate may be needed.<br />

5.2 Impregnating solid insulation<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid penetrates solid insulation more slowly than does mineral oil. Allow double<br />

the mineral oil impregnation time for <strong>Envirotemp</strong> <strong>FR3</strong> fluid at the same temperature. Impregnation<br />

times of laminated TX-2 is given in [17].<br />

5.3 Influence of other oils and synthetic liquids during degassing<br />

Avoid contamination with silicone oil. Most other dielectric fluids are compatible with <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid and will degas normally.<br />

5.4 Disposal methods<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid is suitable as base stock used for biodiesel fuel production. Local lubrication<br />

oil recyclers, restaurant grease recyclers, or fat rendering operations may also be possible.<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid can be burned for heat recovery only if diluted to 10% or less in mineral oil.<br />

It is not a hazardous waste for landfill disposal. If contaminated with hazardous materials, it must<br />

be treated as such.<br />

5.5 Hydrolytic stability<br />

<strong>Envirotemp</strong> <strong>FR3</strong> fluid, like other esters, can undergo hydrolysis. The hydrolysis reaction gives free<br />

fatty acids. These acids typically are present in <strong>Envirotemp</strong> <strong>FR3</strong> fluid and result in acid numbers<br />

higher than those seen in mineral oil. The acid number quantifies the amount of acid but does not<br />

advise its reactivity. Long chain fatty acids are less reactive than the shorter chain organic acids<br />

found in mineral oil. A discussion of hydrolysis in Enirotemp <strong>FR3</strong> fluid is given in [11].<br />

5.6 Processing for water content<br />

The water content of <strong>Envirotemp</strong> <strong>FR3</strong> fluid is reduced in the same way as in mineral oil. Water<br />

contents below 50 mg/kg are easily achieved. See 5.1.<br />

5.7 Vapor phase processing<br />

Cooper Power Systems has not had the opportunity to use vapor phase processing of <strong>Envirotemp</strong><br />

<strong>FR3</strong> fluid coils. <strong>Envirotemp</strong> <strong>FR3</strong> fluid is compatible with the kerosene type oils used in vapor<br />

phase. Consult the manufacturer of the vapor phase equipment for recommendations.<br />

References<br />

[1] T.C. Wei, T.R. Blackburn, “A Report of the Partial Discharge Test Conducted on <strong>Envirotemp</strong> <strong>FR3</strong> <strong>Fluid</strong> for<br />

Cooper Power Systems”, School of <strong>Electric</strong>al Engineering and Telecommunications, University of New South<br />

Wales, June 2004<br />

[2] E. Gockenbach, H. Borsi, B. Dolata, “Research project on the comparison of electric and dielectric properties<br />

of natural Ester fluid with a synthetic Ester and a Mineral based transformer oil: Report No. 2 (Partial<br />

22

discharge behaviour, permittivity and dissipation factor tan d)”, Institute of <strong>Electric</strong> Power Systems, Division of<br />

High Voltage Engineering, Schering-Institute, University of Hanover, Germany, Sept.-Nov. 2005<br />

[3] D. Martin and Z.D. Wang, “A Comparative Study of the Impact of Moisture on the Dielectric Capability of<br />

Esters for Large Power Transformers”, IEEE/DEIS Conf. on <strong>Electric</strong>al Insulation and Dielectric Phenomena,<br />

Oct. 15-18, 2007, Kansas City, USA<br />

[4] T.A. Prevost, “Dielectric Properties of Natural Esters and their Influence on Transformer Insulation System<br />

Design and Performance”, IEEE/PES Transmission and Distribution Conf., May 21-26, Dallas USA<br />

[5] C. P. McShane, G.A. Gauger, and J. Luksich, “Fire Resistant Natural Ester Dielectric <strong>Fluid</strong> and Novel<br />

Insulation System for Its Use”, IEEE/PES Transmission & Distribution Conf., April 12-16, 1999, New Orleans,<br />

USA<br />

[6] C.P. McShane, K.J. Rapp, J.L. Corkran, G. A. Gauger, and J. Luksich, “Aging of Paper Insulation in Natural<br />

Ester Dielectric <strong>Fluid</strong>”, IEEE/PES Transmission & Distribution Conf, Oct. 28 - Nov. 2, 2001, Atlanta, USA<br />

[7] C.P. McShane, K.J. Rapp, J.L. Corkran, G. A. Gauger, and J. Luksich, “Aging of plain Kraft paper in natural<br />

ester dielectric fluid”, IEEE/DEIS 14th International Conf. on Dielectric Liquids, July 7-12, 2002, Graz, Austria<br />

[8] C.P. McShane, K.J. Rapp, J.L. Corkran, and J. Luksich, “Aging of cotton/Kraft blend insulation paper in natural<br />

ester dielectric fluid”, TJ|H2b TechCon Asia-Pacific Condition Based Maintenance & Diagnostic Conf., May 7-9,<br />

2003, Sidney, Australia<br />

[9] C.P. McShane, J.L. Corkran, K.J. Rapp, and J. Luksich, “Aging of paper insulation retrofilled with natural ester<br />

dielectric fluid”, IEEE/DEIS International Conf. on <strong>Electric</strong>al Insulation and Dielectric Phenomena, Oct. 19-22,<br />

2003, Albuquerque, USA<br />

[10] K.J. Rapp, C.P. McShane, and J. Luksich, “Interaction Mechanisms of Natural Ester Dielectric <strong>Fluid</strong> and Kraft<br />

Paper”, IEEE/DEIS 15th International Conf. on Dielectric Liquids, June 26 - July 1, 2005, Coimbra, Portugal<br />

[11] A.W. Lemm, K.J. Rapp, and J. Luksich, “Effect of Natural Ester (Vegetable Oil) Dielectric <strong>Fluid</strong> on the Water<br />

Content of Aged Paper Insulation”, EIA/IEEE 10th Insucon International <strong>Electric</strong>al Insulation Conf., May 24-26,<br />

2006, Birmingham, UK<br />

[12] L. Lewand, “Laboratory evaluation of several synthetic and agricultural-based dielectric liquids”, Doble<br />

International Client Conference, 5E, 2001, Boston, MA USA<br />

[13] S. Durian, “Dielectric <strong>Fluid</strong> Relative Thermal Performance”, Engineering Development Report TP03-DR-006,<br />

Cooper Power Systems, May 21, 2003<br />

[14] J. Luksich, “IEEE Loading Guide A and B Factors for <strong>Envirotemp</strong> <strong>FR3</strong> <strong>Fluid</strong> and Thermally Upgraded Kraft<br />

Insulation”, Engineering Development Report TP03-DR-009, Rev. 1, Cooper Power Systems, June 12, 2003<br />

[15] S. Durian, “Comparative Loading, Thermal, and Aging Performance of Thermally Upgraded Paper in Mineral<br />

and <strong>Envirotemp</strong> <strong>FR3</strong> <strong>Fluid</strong>”, Engineering Development Report TP03-DR-017, Cooper Power Systems, July 14,<br />

2003<br />

[16] “<strong>Envirotemp</strong> <strong>FR3</strong> <strong>Fluid</strong> Dissolved Gas Guide”, R900-20-19, Cooper Power Systems, August 17, 2006<br />

[17] T. Prevost, “Oil Impregnation Rate of Cooper <strong>FR3</strong> Oil”, Wicor International Technical Report 3206, EHV<br />

Weidmann, February 6, 2006<br />

23