Machinery & Equipment from a Specialty Coating ... - Hilco Industrial

Machinery & Equipment from a Specialty Coating ... - Hilco Industrial

Machinery & Equipment from a Specialty Coating ... - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

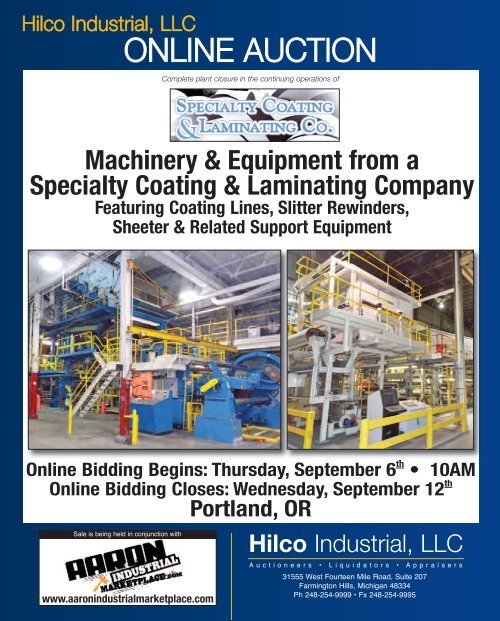

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

OnLIne AuCtIOn<br />

Complete plant closure in the continuing operations of<br />

<strong>Machinery</strong> & <strong>Equipment</strong> <strong>from</strong> a<br />

<strong>Specialty</strong> <strong>Coating</strong> & Laminating Company<br />

Featuring <strong>Coating</strong> Lines, Slitter Rewinders,<br />

Sheeter & Related Support <strong>Equipment</strong><br />

Online Bidding Begins: Thursday, September 6 th • 10AM<br />

Online Bidding Closes: Wednesday, September 12 th<br />

Portland, OR<br />

Sale is being held in conjunction with<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

www.aaronindustrialmarketplace.com<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248-254-9999 • Fx 248-254-9995

2<br />

HILCO IndustrIAL, LLC OnLIne AuCtIOn<br />

Complete plant closure in the continuing operations of<br />

OnLIne BIddIng Opens<br />

tHursdAy, septemBer 6 tH<br />

BegInnIng At 10Am LOCAL tIme<br />

OnLIne BIddIng CLOses<br />

WednesdAy, septemBer 12 tH<br />

please CheCk www.hilCoind.Com for Closing times<br />

prevIeW dAte<br />

tHursdAy, septemBer 6 tH<br />

9:00 Am tO 4:00 pm<br />

Asset LOCAtIOn<br />

12238 n. pOrtLAnd rOAd<br />

pOrtLAnd, Or 97217<br />

dIreCtIOns<br />

FrOm pOrtLAnd InternAtIOnAL AIrpOrt: exIt AIrpOrt And turn rIgHt<br />

OntO ne 82nd WAy. turn rIgHt OntO ne ALderWOOd rd. turn rIgHt OntO<br />

ne COLumBIA BLvd, tHen turn rIgHt OntO ne mArtIn LutHer kIng jr BLvd.<br />

COntInue On tO mArIne drIve W. destInAtIOn WILL Be On tHe LeFt.<br />

FurtHer InFOrmAtIOn<br />

•An 18% Buyer's premIum WILL Be CHArged On ALL Assets. tHe Buyer’s<br />

premIum WILL Be reduCed tO 15% FOr pAyments mAde By CAsH, COmpAny<br />

CHeCk Or WIre trAnsFer. AuCtIOn WILL Be COnduCted In engLIsH, ACCept-<br />

Ing u.s. CurrenCy OnLy.<br />

• REMOVAL DEADLINE IS SEptEMbER 28, WItH HOURS OF REMOVAL bEtWEEN 8AM tO<br />

4pM MONDAY tHRU FRIDAY. bUYERS WItH ItEMS LEFt ON SItE AFtER DEADLINE ARE<br />

SUbjEct tO FINES OF $500 pER DAY.<br />

• FOr FurtHer InFOrmAtIOn On mACHInery & equIpment, pLeAse COntACt<br />

geOrge LAIdLAW At 616.732.1800 Or emAIL gLAIdLAW@HILCOInd.COm<br />

• FOr pAyments pLeAse COntACt LesIA jOsepH At 616.732.1800 x19 Or emAIL<br />

LjOsepH@HILCOInd.COm Or HILCO ACCOunts reCeIvABLe At<br />

HIn_Ar@HILCOInd.COm<br />

• FOr CustOmer servICe, pLeAse COntACt sAndI neeLy At 248.254.9999 x16 Or<br />

emAIL sneeLy@HILCOInd.COm<br />

Information contained herein deemed to be accurate at time of printing and subject to change.<br />

For updated information, please visit our website at www.hilcoind.com for any<br />

date, sale process, terms and conditions and list of available assets.<br />

COATING & LAMINATION LINES<br />

1 – BLACK CLAWSON WEB FED SOLVENT/AQUEOUS PAPER COATING LINE, (1965), With 34" to 73" Web Width, 75 to 1,600 FPM, Contra, Solvent Blade, Dahlgren Roll,<br />

Reverse Gravure, Direct Gravure, Doctor Blade, Trailing Blade & Slot Die <strong>Coating</strong> Methods, Black Clawson 42-220 Dual Shaft Turret Unwind, S/N 299A149367, 50" Max<br />

Diameter Unwind, Hydraulic Arm Roll Lift, In Floor Manual Roll Transport System, Automatic Splicer, Dancer Roll, Pit Web Roll, Belt Driven Idler Rolls, Nip Pull Rolls, Black<br />

Clawson Cartridge Coater (#1), Tracer Lab/Panther Non-Contact Nuclear Thickness Measuring System with Dual Tracerlab SNP7B Gamma Detectors and Panther Interface<br />

System, (2007), Black Clawson 3-Zone Gas-Fired Felted Dryer, 30', Chill Roll, Turn Bar, Pit Web Path, Belt Driven Idler Rolls, Gastech Safetnet 410 Gas/O2 Monitor, Fife Web<br />

Guide, Tracerlab/Panther Non-Contact Nuclear Thickness Measuring System with Dual Tracerlab SNP7B Gamma Detectors and Panther Interface System, (2007), Nip Pull<br />

Rolls, Black Clawson Cartridge Coater (#2), Black Clawson 3-Zone Gas-Fired Felted Dryer, 30', Chill Roll, Turn Bar, Pit Web Path, Belt Driven Idler Rolls, Fife Web Guide, Nip<br />

Pull Rolls, BTC <strong>Coating</strong> Systems Dahlgren-Type Roll Coater/Moisturizer, Tracerlab/Panther Non-Contact Nuclear Thickness Measuring System with Dual Tracerlab SNP7B<br />

Gamma Detectors and Panther Interface System, (2007), Chill Roll, Cognex Video Web Defect Detection System, Fife Web Guide, Tidland Shear Slitter, (2003), S-Wrap Unit,<br />

Rewinder Dancer Roll, Black Clawson Automatic Splicer, Black Clawson Dual Shaft Turret Rewind, 50" Max Diameter, Automatic Handling Hydraulic Roll Lift, Automatic<br />

Handling Power In Floor Roll Transport System, Motors, Pumps, Controls, Catwalks, CO2 Fire Suppression System, (5) Crane Systems<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

COAtIng & LAmInAtIOn LInes • sLItter-reWInders<br />

COATING & LAMINATION LINES, CONT.<br />

1 – BLACK CLAWSON WEB FED 2-PLY SOLVENT/AQUEOUS<br />

PAPER LAMINATING COATING LINE, (1967), With 34" to 76"<br />

Web Width, 75 to 1,100 FPM, Contra, Solvent Blade, Dahlgren<br />

Roll, Reverse Gravure, Direct Gravure, Offset Gravure, Doctor<br />

Blade, Trailing Blade, Slot Die & Bill Blade <strong>Coating</strong> Methods,<br />

Black Clawson 21-429 Dual Shaft Primary Unwind, S/N<br />

299E186754, 52" Max Diameter, 3", 6", & 10" Core Diameter,<br />

Black Clawson 412 Automatic Splicer, S/N 323R184448, In<br />

Floor Hydraulic Loft, Black Clawson 40 Dual Shaftless<br />

Secondary Unwind, S/N 299E277509, 52" Max Diameter, 3", 6",<br />

10" Core Diameter, Automatic Splicer, In Floor Hydraulic Lift,<br />

Fife Web Guide, In Floor Roll Transport Systems, Accuray<br />

U-7/S-11 Non-Contact Nuclear Thickness Measuring System,<br />

S/N K-1116-A, Vacuum Pull Roll, Inventing Group BL2100 Bill<br />

Blade Coater, S/N 65/1979, Kruger Pit-Mounted 4-Zone Gas<br />

Fired Infrared Dryer, Sweat Roll, Non-Contact Nuclear<br />

Thickness Measuring System, Black Clawson Cartridge Coater,<br />

Pit Mounted Aqueous Sump, Recirculating Pump, Gastech<br />

Safetnet 410 Gas/O2 Monitor, Vacuum Pull Roll, Sweat Roll,<br />

Non-Contact Nuclear Thickness Measuring System, Idler Roll,<br />

TEC Systems 2-Zone Gas-Fired Floatation Dryer, 36", Chill<br />

Roll, Turn Bar, Process Sensor Moisture Gauge, Idler Roll, Non-<br />

Contact Nuclear Thickness Measuring System, Vacuum Pull<br />

Roll, Black Clawson Cartridge Coater, Solvent Enclosure,<br />

Combustion Technology/Valsala LFL & Temperature/Humidity<br />

Sensors, Vacuum Pull Roll, Black Clawson 3-Zone Gas-Fired<br />

Felted Dryer, 60', Combustion Technology LFL Monitors, Chill<br />

Roll, Non-Contact Nuclear Thickness Measuring System,<br />

Dahlgren LAS72CZ Stainless Steel <strong>Coating</strong> Tank, 400-Gallon,<br />

Gravity Feed, Black Clawson 13015250 Gas-Fired Floatation<br />

Dryer, S/N 376912, (1999), 10', Single Zone, Idler Roll, Chill<br />

Roll, Black Clawson Fluidex Web Moisturizer/Steam Foil,<br />

(1999), Chill Roll, Fife Web Guide, Non-Contact Nuclear<br />

Thickness Measuring System, Tidland Shear Slitter, Zink<br />

Automatic Lay-On Roll Splicer, S/N 78-278, (1999), Black<br />

Clawson 21-429 Dual Shaftless Turret Rewind, S/N<br />

303E185770, 52" Max Diameter, 60" Cores, In Floor Roll<br />

Transport System, Motors, Pumps, Controls, Catwalks, CO2<br />

Fire Suppression System, (8) Crane Systems<br />

SLITTER-REWINDERS<br />

1 – GOEBEL MODEL H3 60" SLITTER REWINDER, S/N 7702, (1974), With<br />

60" Max Web, 58" Max Diameter Unwind, 8" Max Diameter Rewind, 1,000<br />

FPM, (1) Pacific Machine & Development Shaftless Unwind, Air Brakes,<br />

Hydraulic Roll Pick Up, Fife Edge Guide, UV Inspection Lamp, In Floor<br />

Hydraulic Scissor Lift, Vacuum Trim Removal System, Custom Shaftless<br />

Rewind, Custom Finished Roll Delivery Conveyor, Custom Pneumatic Finished<br />

Roll Delivery Table, PLC Controls<br />

1 – GOEBEL MODEL PRACTICA4/H4 54" SLITTER REWINDER, S/N 8522,<br />

(1984), With 54" Max Web, 60" Max Diameter Unwind, 16" Max Diameter<br />

Rewind, 1,200 FPM, Shaftless Unwind, Water-Cooled Air Brakes, In Floor<br />

Hydraulic Roll Lift, Fife Web Guide, (2) UV Inspection Lamps, In Floor Hydraulic<br />

Scissor Lift, Vacuum Trim Removal System, Single Shaft Rewind, Finished Roll<br />

Delivery Conveyor, Pneumatic Finished Roll Delivery Table, PLC Controls<br />

1 – GOEBEL MODEL PRACTICA4/H4 50" SLITTER REWINDER, S/N 8465,<br />

(1983), With 50" Max Web, 50" Max Diameter Unwind, 16" Max Diameter<br />

Rewind, 1,200 FPM, Single Shaftless Unwind, Water-Cooled Air Brakes,<br />

Hydraulic Roll Lift, Fife Web Guide, (2) UV Inspection Lamps, In Floor Hydraulic<br />

Scissor Lift, Vacuum Trim Removal System, Single Shaft Rewind, Finished Roll<br />

Delivery Conveyor, Pneumatic Finished Roll Delivery Table, PLC Controls<br />

2 – DUSENBERY MODEL 614AB 48" SLITTER REWINDERS, S/Ns 58732,<br />

58722, (1987), With 48" Max Web, 50" Max Diameter Unwind, 7-1/2" Max<br />

Diameter Rewind, 1,500 FPM, Dusenbery Single Shaftless Unwind, Water-<br />

Cooled Air Brakes, Hydraulic Roll Lift, Splice Detector, Automatic Tail Tucking<br />

System, (2) UV Inspection Lamps, In Floor Hydraulic Scissor Lift, Vacuum Trim<br />

Removal System, Shaftless Rewind, Finished Roll Delivery Conveyor,<br />

Pneumatic Dual-Station Finished Roll Delivery Table, Bishamon On Floor<br />

Pneumatic Pallet Lift Turntable, PLC Controls<br />

For more information, please visit us on the web at www.hilcoind.com 3

4<br />

sHeAr sLItter-reWInders • sHeeter • suppOrt & LAB equIpment<br />

SHEAR SLITTER-REWINDERS<br />

1 – DUSENBERY MODEL 800XJ 78" DUPLEX CENTER SURFACE SHEAR SLITTER/REWINDER,<br />

S/N 57161 (1974), With 78" Max Web, 52" Max Diameter Unwind & Rewind, 1,500 FPM, Dusenbery<br />

Shaftless Unwind, Water-Cooled Air Brakes, In Floor Hydraulic Roll Table, Fife Edge Guide, (2) UV<br />

Inspection Lamps, Vacuum Trim Removal System, Dual Shaft Rewinds, Dual Bridge Crane System,<br />

PLC Controls<br />

1 – ARROW CONVERTING MODEL 2000 78" SIMPLEX CENTER SURFACE SHEAR<br />

SLITTER/REWINDER, S/N 18920 (1986), With 78" Max Web, 50" Max Diameter Unwind & Rewind,<br />

2,500 FPM, Arrow 452-38-1 Shaftless Unwind, Water-Cooled Air Brakes, Hydraulic Roll Lift, Fife<br />

Edge, Arrow S-Wrap Tension Control, UV Inspection Lamp, Vacuum Trim Removal System, Arrow<br />

Single Shaft Rewind, Track-Mounted Hydraulic Roll Lift, Arrow Shaft Extractor, PLC Controls<br />

1 – DUSENBERY MODEL 613 GM 72" SLITTER REWINDER, S/N 59210 (1993), With Shafted<br />

Unwind, Dusenbery 620TA Tension Control, Scissor Lift Table, Fife Web Guide, Vacuum Trim<br />

Removal System, Single Shaft Rewind, Finished Roll Delivery Conveyor & Table, Positech<br />

Freestanding Jib Crane, Oregon Crane Vacuum Hoist, PLC Controls<br />

SHEETER<br />

1 – BIELOMATIK MODEL P2000 26-3/4" MODULAR SHEETER, S/N P2000/16 (1997), With 26-3/4"<br />

Max Web, 3-Pocket, 700 FPM, Monomatic UMDZ.127 Dual Shaft Unwind, S/N 1323, 50" Max<br />

Diameter, Track Mounted, Manual Splicer, Black Clawson Fluidex Single Side Steam Foil, (1999),<br />

Chill Roll, Web Guide, Cross Cut Slitting, Cross Scoring, Inline Flexo Printing, Magnetic Punch<br />

Module, 11" Repeats, Cross Cut Slitting, Stacker Counter, Power Belt Delivery Conveyor, 30" x 35',<br />

PLC Controls<br />

PROCESS SUPPORT EQUIPMENT<br />

5 – MOREHOUSE-COWLES TANK MOUNTED DISPERSERS, 25-50-HP, 600-700-Gallon<br />

4 – HOLDING TANKS, 750 to 1500-Gallon Capacity<br />

1 – FRYMA MODEL VEIII STAINLESS STEEL DEAERATOR, S/N M13387 (1988), With Vacuum Pump<br />

2 – MOYNO MULTI-STAGE PROGRESSIVE CAVITY PUMPS<br />

3 – 3,000 GALLON BULK CHEMICAL STORAGE TANKS<br />

LABORATORY EQUIPMENT<br />

1 – ELLIOT WILLIAMS ENVIRONMENTAL CHAMBER, With 12' x 12' x 7' H, (4) Chrome Wire Shelf<br />

Units, Air Lock Entry, Ransco 30000 Series Digital Control Panel, S/N 5586, Honeywell 2-Pen<br />

Round Chart Recorder<br />

1 – DATA AIRE MODEL DAP II LABORATORY ROOM TEMPERATURE/HUMIDITY CONTROL SYSTEM<br />

1 – LABORATORY COUNTER, With Sinks, Fume Hoods, Approx. 100'<br />

1 – ATLAS MODEL HPUV INDOOR ACTINIC EXPOSURE SYSTEM<br />

1 – VWR MODEL 1630 BENCH-TOP LABORATORY OVEN<br />

Quantity of Test <strong>Equipment</strong> Including: Moisture & Solids Analyzer, Electronic Balances, PH Meter,<br />

Viscometer, Moisture Tester, Microscope, Resistance Tester, Tearing Tester, Monitor/Slip & Friction<br />

Tester, Opacimeter, Electronic Precision Micrometer, Smoothness Tester With Accessories, Grazing<br />

Light, Megohmeter, Hand-Held Digital Spectrodensitometers, More<br />

PALLET WRAPPING<br />

1 – LANTECH MODEL LAN-WRAPPER AUTOMATIC PALLET WRAPPING SYSTEM, With 73" Max<br />

Roll, Automatic Handling 6,000-Lbs. Hydraulic Roll Upender, GSE 455 Electronic Weigh System,<br />

Liver Roller Conveyor Transfer Table, Turntable & Delivery Table, Photoelectric Eye, PLC Controls<br />

1 – INFRAPAK MODEL SIDEWINDER PALLET WRAPPER, S/N 282H98P (1998), With 4' x 4; Turn<br />

Table, First Weigh DH2 Electric Platform Scale, 5' x 7'<br />

1 – SHANKLIN SHRINK WRAP SYSTEM, With QC Industries Belt Conveyor, 18" x 10', (2) Willett<br />

430/460Si Ink Jet Coders, Shuttleworth Live Roller Infeed Conveyor, 16" x 10', Shanklin F-5A Shrink<br />

Wrapper, S/N F9744 (1997), Tearstrip Systems F5 Tear Strip Applicator, S/N 1753, Shanklin T-72<br />

Shrink Tunnel, S/N T-97138, (1997), PFC/FLO-Turn FT4018-90 Right-Angle Power Belt Conveyor,<br />

Gravity Roller Conveyor, 18" x 10', Loveshaw Little David LD19B Portable Carton Sealer, S/N<br />

18918319B, Interpack USA2024BB Portable Carton Sealer, S/N NCO0M045-004, Gravity Roller<br />

Conveyor, 18" x 5', PLC Control<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

mACHIne sHOp • mAterIAL HAndLIng • suppOrt equIpment<br />

SCRAP HANDLING SYSTEM<br />

1 – KILKOM MODEL K5-60 HYDRAULIC HORIZONTAL BALER, S/N 980182<br />

1 – ECONOMY MODEL 54A36 HYDRAULIC HORIZONTAL BALER, S/N 61321<br />

2 – MANUAL WIRE TYING<br />

1 – ROOF MOUNTED CYCLONE SEPARATOR<br />

BOILER<br />

1 – CLEAVER BROOKS MODEL CB-200-400 150 PSI PACKAGED BOILER, S/N L-66764<br />

(1979), With 16,738,000 BTU/Hr Input, Natural Gas & Oil Fired<br />

REGENERATIVE THERMAL OXIDIZER<br />

1 – DURR 41,000 CFM REGENERATIVE THERMAL OXIDIZER, S/N 22261 (1999), With<br />

1,500° to 2,000°F Combustion Chamber Temperature, 209°F Max Exhaust Temp, NY Blower<br />

491A Blower, S/N T-9031-100<br />

LATHES<br />

1 – LEBLOND MODEL REGAL 24" x 11' ENGINE LATHE, S/N 3H838 (1965), With Curtis Kelsey<br />

RG2BTF Abrasive Belt Grinding Attachment, S/N 9312331, US Turbine Supervac Vacuum<br />

Dust Collector<br />

1 – TURNOW MODEL TUJ50M 25" x 14' GAP BED ENGINE LATHE, S/N 0065241J44, With<br />

Digital Readout<br />

1 – VICTOR MODEL 1630 16" x 30" ENGINE LATHE, S/N 451073<br />

VERTICAL MILLING MACHINE<br />

1 – SHARP 3-HP VERTICAL MILLING MACHINE, S/N 70601107, With 9" x 42" Power Feed<br />

Table, 3-Axis Digital Readout<br />

MACHINE SHOP EQUIPMENT<br />

Quantity of Machine Shop & Support <strong>Equipment</strong> Including: Saws, Drill Presses, Fume<br />

Collector, Presses, Threaders, Grinders, Welders, More<br />

SHOP EQUIPMENT<br />

1 – RITE-HITE AUTOMATIC HIGH-SPEED ROLL-UP DOOR, S/N 1069260, (2002), With Electric Eyes<br />

Quantity Of Support <strong>Equipment</strong> Including: (200) Sections Of Pallet Storage Racks, Stock<br />

Racks, Work Benches, Vises, Carts, Platform Trucks, Flammable Liquid Storage Cabinets, Parts<br />

Bins, Hand Tools, Oxy-Fuel Torch Sets, Fans, Ladders, Shop Desks, Chemical Spill Containment<br />

Pallets, Drum Pumps, Shop Vacuums, Granite Surface Plates, Pallet Jacks, Platform Scales, Glue<br />

Guns, Hand Trucks, Core Cutter, Roll/Cylinder Storage Racks, Hoists<br />

AIR COMPRESSORS<br />

1 – QUINCY QNW740-D 150-HP ROTARY SCREW AIR COMPRESSOR, S/N 930704, (1993)<br />

1 – VERTICAL AIR RECEIVING TANK, 3' X 8'<br />

1 – PNEUMATIC EE-750 750 SCFM HEAT REACTIVATED REGENERATIVE AIR DRYER,<br />

S/N 9311-S225545-57931<br />

1 – DEW POINT DEMAND RETROFIT<br />

MATERIAL HANDLING<br />

2 – HYSTER S120XLS 7700-LB. LPG FORK LIFT TRUCKS, S/Ns D004D03016T,<br />

D004V05934N (1996 & 1992), With 182" Lift, 3-Stage Mast, Cushion Tires, Overhead Guard,<br />

Cascade Roll Clamp<br />

1 – HYSTER S65XM 6400-LB. LPG FORK LIFT TRUCK, S/N D167V06835U (1997), With 181"<br />

Lift, 3-Stage Mast, Cushion Tires, Overhead Guard, Roll Clamp<br />

1 – HYSTER S80E 5500-LB. LPG FORK LIFT TRUCK, S/N C004D07562F (1985), With 192" Lift,<br />

3-Stage Mast, Cushion Tires, Overhead Guard, Rotating Forks<br />

2 – HYSTER S55XM 5300-LB. LPG FORK LIFT TRUCKS, S/Ns D187V13025W, D187V12622V (1999<br />

& 1998), With 181”-189" Lift, 3-Stage Mast, Cushion Tires, Overhead Guard, Side Shift Attachment<br />

1 – YALE NR040ACN 4000-LB. STAND UP RIDER-TYPE ELECTRIC LIFT TRUCK,<br />

S/N A815N02555S, With Pole Attachment<br />

1 – PRIME MOVER RR34B 3800-LB. ELECTRIC STAND-ON LIFT TRUCK, S/N RR340208994<br />

(1981), With 192" Lift, 2-Stage Mast, Overhead Guard, Roll Prong, Side Shift Attachment,<br />

Battery Charger<br />

1 – YALE MS040MAN12CS077 3800-LB. ELECTRIC WALK-BEHIND STRADDLE TYPE LIFT<br />

TRUCK, S/N 373868 (1981), With 113" Lift, 2-Stage Mast, Overhead Guard, Battery Charger<br />

1 – YALE ESC30G4S083 3800-LB. ELECTRIC STAND-ON LIFT TRUCK, S/N S270997 (1975),<br />

With 113" Lift, 2-Stage Mast, Overhead Guard, Battery Charger<br />

1 – YALE ESC030G4T083 3000-LB. ELECTRIC STAND-ON LIFT TRUCK, S/N 375887 (1982),<br />

With 192" Lift, 3-Stage Mast, Overhead Guard, Side Shift Attachment, Battery Charger<br />

1 – YALE ESC030S4T083 3000-LB. ELECTRIC STAND-ON LIFT TRUCK, S/N N400607 (1984),<br />

With 192" Lift, 3-Stage Mast, Cushion Tires, Overhead Guard, Battery Charger<br />

1 – YALE ESC030G4T083 3000-LB. ELECTRIC STAND-ON LIFT TRUCK, S/N N348630 (1979),<br />

With 216" Lift, 3-Stage Mast, Overhead Guard, Battery Charger<br />

4 – MODIFIED ELECTRIC PALLET TRUCKS FOR CYLINDER/ROLL MOVING<br />

2 – US CRANE & HOIST 2-TON SINGLE-GIRDER OVERHEAD BRIDGE CRANES, With<br />

30' Span, 55' Runway<br />

WIDE FORMAT PRINTERS & PRINTERS<br />

3 – WIDE FORMAT INK JET PRINTERS Including: Epson Novajet 700 72", 4-Color, Epson Stylus<br />

Pro 4000 24", 8-Color, HP Designjet 1050c 36", 4-Color, With Duplex Capability<br />

1 – HP DESIGNJET 5000 42" INK JET PRINTER, 6-Color<br />

OFFICE EQUIPMENT<br />

ATT Merlin Legend Key Telephone System, Burle CCTV Security System, Office Furniture, Desks,<br />

Chairs, Tables, Modular Offices, Cubicles, Machine Stands, Storage Cabinets, File Cabinets<br />

For more information, please visit us on the web at www.hilcoind.com 5

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong (Greater China) •<br />

Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Forwarding Service Requested<br />

HILCO OnLIne AuCtIOn<br />

Complete plant closure in the continuing operations of<br />

<strong>Machinery</strong> & <strong>Equipment</strong> <strong>from</strong> a<br />

<strong>Specialty</strong> <strong>Coating</strong> & Laminating Company<br />

Featuring <strong>Coating</strong> Lines, Slitter Rewinders,<br />

Sheeter & Related Support <strong>Equipment</strong><br />

Online Bidding Begins: Thursday, September 6 th • 10AM<br />

Online Bidding Closes: Wednesday, September 12 th<br />

Portland, OR<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters 5 revere drive, ste. 206 • northbrook, IL 60062 • All rights reserved<br />

printed in usA • Int0180 • IL License #444.000215 • please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 2655<br />

Terms of Sale<br />

An 18% buyer's premium will be charged on all assets. the<br />

buyer’s premium will be reduced to 15% for payments<br />

made by cash, company check or wire transfer. Everything<br />

will be sold online to the highest bidder for cash, in accordance<br />

with the Auctioneer’s customary “terms of Sale”,<br />

copies of which will be posted online. All items will be sold<br />

“as is, where-is” without any warranties, expressed or<br />

implied. Although obtained <strong>from</strong> sources deemed reliable,<br />

the Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained. bidders are<br />

encouraged to thoroughly inspect the items on which they<br />

intend to bid prior to sale. Absolutely no items will be<br />

removed until the day after the conclusion of the sale and<br />

payment is made in full. Subject to additions, deletions and<br />

prior sale. For updated information, please visit our website<br />

at www.hilcoind.com for any date, sale process, terms and<br />

conditions and list of available assets.<br />

Payment: ALL pURcHASES MUSt bE pAID IN FULL ON<br />

tHE DAY OF tHE AUctION. If you intend to pay by wire<br />

transfer, we will accept payment the day after the sale<br />

ONLY IF a deposit of 25% of total purchases is made on<br />

the day of the sale. contact our office for wire transfer<br />

instructions. Only cash, wire transfer or certified check,<br />

payable to <strong>Hilco</strong> <strong>Industrial</strong>, LLc will be accepted. company<br />

checks payable to <strong>Hilco</strong> <strong>Industrial</strong>, LLc will be accepted<br />

only if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales tax.<br />

purchasers claiming exemptions <strong>from</strong> taxes must provide<br />

proof satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(bank Name) unconditionally guarantees payment to<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLc <strong>from</strong> (company Name). this<br />

guarantee will be valid for purchases made at the<br />

Auction of a <strong>Specialty</strong> coating & Laminating<br />

company on September 6-12, 2012.<br />

Follow<br />

Us on: