You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Tech<br />

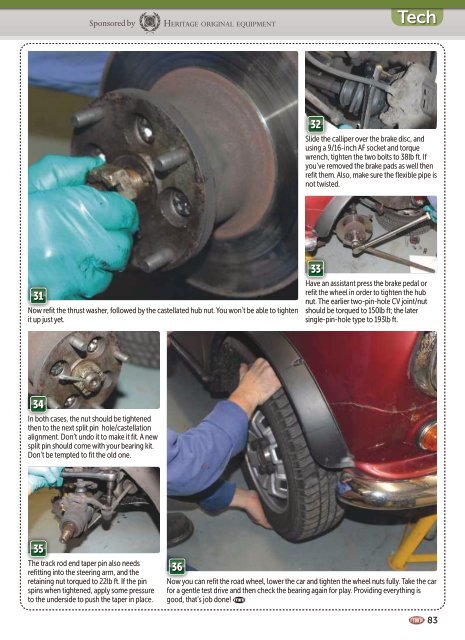

32<br />

Slide the calliper over the brake disc, and<br />

using a 9/16-inch AF socket and torque<br />

wrench, tighten the two bolts to 38lb ft. If<br />

you’ve removed the brake pads as well then<br />

refit them. Also, make sure the flexible pipe is<br />

not twisted.<br />

31<br />

Now refit the thrust washer, followed by the castellated hub nut. You won’t be able to tighten<br />

it up just yet.<br />

33<br />

Have an assistant press the brake pedal or<br />

refit the wheel in order to tighten the hub<br />

nut. The earlier two-pin-hole CV joint/nut<br />

should be torqued to 150lb ft; the later<br />

single-pin-hole type to 193lb ft.<br />

34<br />

In both cases, the nut should be tightened<br />

then to the next split pin hole/castellation<br />

alignment. Don’t undo it to make it fit. A new<br />

split pin should come with your bearing kit.<br />

Don’t be tempted to fit the old one.<br />

35<br />

The track rod end taper pin also needs<br />

refitting into the steering arm, and the<br />

retaining nut torqued to 22lb ft. If the pin<br />

spins when tightened, apply some pressure<br />

to the underside to push the taper in place.<br />

36<br />

Now you can refit the road wheel, lower the car and tighten the wheel nuts fully. Take the car<br />

for a gentle test drive and then check the bearing again for play. Providing everything is<br />

good, that’s job done!<br />

83