Refurb Projects September 2018

Refurb Projects launched in 1987 to cater for the expanding Repair, Maintenance, Improvement and Refurb sectors of the UK Building Industry. This represents a massive market, with refurbishment in the Health, Leisure, Education and Social Housing sectors a mainstay of the industry. Sustainability and the protection of the built environment are essential ingredients of the refurbishment market, and Refurb Projects Journal is a leader in reporting and promoting these ideals.

Refurb Projects launched in 1987 to cater for the expanding Repair, Maintenance, Improvement and Refurb sectors of the UK Building Industry.

This represents a massive market, with refurbishment in the Health, Leisure, Education and Social Housing sectors a mainstay of the industry.

Sustainability and the protection of the built environment are essential ingredients of the refurbishment market, and Refurb Projects Journal is a leader in reporting and promoting these ideals.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

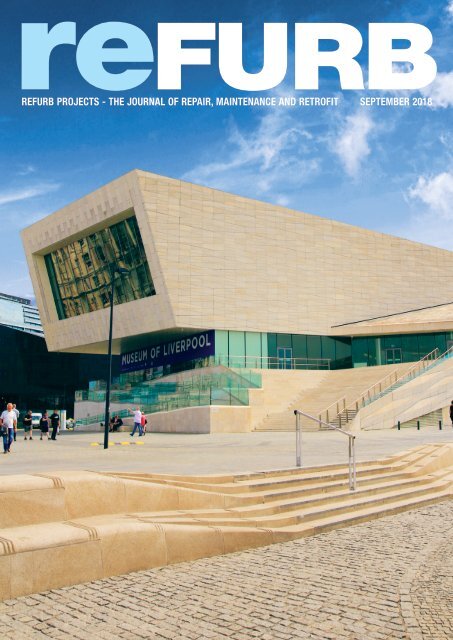

REFURB PROJECTS - THE JOURNAL OF REPAIR, MAINTENANCE AND RETROFIT SEPTEMBER <strong>2018</strong>

All types of projects<br />

deserve Schueco<br />

Unbeatable quality and real value for money make Schueco aluminium façades,<br />

windows and doors the first choice for any project. Offices and shop fronts,<br />

schools and colleges, housing association new-builds and refurbishments will all<br />

benefit from Schueco’s precision engineering. Add in the enhanced comfort and<br />

reduced running costs created by great design, an unrivalled choice of profiles and<br />

excellent thermal and sound insulation and you have a total, cost-effective solution.<br />

For German engineering made in Britain, there’s only one name.<br />

www.schueco.co.uk<br />

2 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS

Contents<br />

Vol. 29 No. 192 <strong>September</strong> <strong>2018</strong><br />

Special Features<br />

5-11 Glass & Glazing<br />

13-14 Roofing<br />

16-17 School Building<br />

18-19 Insulation<br />

20-24 Fire Safety & Security<br />

25-27 Energy & Efficiency<br />

28-38 <strong>Refurb</strong>ishment <strong>Projects</strong><br />

Cover Feature<br />

Kemper System helps create a ‘museum<br />

worthy’ refurbishment on Liverpool’s<br />

waterfront.<br />

For the full story see Page 28<br />

Publisher/ Editor: Carole Titmuss<br />

Editorial Assistant: Sue Watson<br />

Advertising / Marketing: James Kennett<br />

Subscriptions: Kay Knight<br />

Design / Graphics: Ian Purves, Jonathan Milburn<br />

Also in this edition<br />

4 Cladding<br />

6 Waterproofing<br />

8 Fixtures & Fittings<br />

15 Social Housing<br />

This journal includes editorial photographs provided<br />

and paid for by suppliers.<br />

<strong>Refurb</strong>ishment <strong>Projects</strong> incorporating <strong>Refurb</strong>ishment<br />

Products is published by<br />

Sheen Publishing Ltd<br />

50 Queens Road,<br />

Buckhurst Hill,<br />

Photograph by michal-kubalczyk<br />

Essex, IG9 5DD, UK<br />

Tel: 020 8504 1661<br />

Fax: 020 8505 4336<br />

Email: editor@refurbprojects.com<br />

Twitter: @<strong>Refurb</strong><strong>Projects</strong><br />

<strong>Refurb</strong> <strong>Projects</strong> is available on subscription.<br />

Annual rate: UK £28. Europe: £36 Overseas: £40.<br />

Single Copies: UK: £5 Overseas: £10<br />

ISSN 1475-1135<br />

Printed by Manson Group<br />

www.refurbprojects.com<br />

reFURB PROJECTS / SEPTEMBER <strong>2018</strong> 3

CLADDING<br />

Shackerley Façades complete Office-to-Resi<br />

transformation in Bristol<br />

Developers have been<br />

permitted to convert office<br />

space to residential use<br />

without needing full<br />

planning permission since 2013,<br />

creating a number of development<br />

hot spots.<br />

Amongst these is Bristol, where a<br />

six-storey office block has been<br />

converted into The Milliners; a<br />

development of 109 apartments by<br />

principal contractor Headoffice3.<br />

The refurbishment project<br />

needed to offer high end<br />

accommodation while remaining in<br />

keeping with the surrounding<br />

commercial and heritage buildings,<br />

so Shackerley’s SureClad® ventilated<br />

façade system was specified with<br />

creamy-beige coloured ceramic<br />

granite panels to reference the<br />

surrounding Bath Stone buildings.<br />

Detailed Specification<br />

HeadOffice3 delivered the<br />

project as a fully-designed and<br />

specified scheme with a mix of<br />

studio, one-bed and two-bed<br />

apartments and penthouses. All twobed<br />

apartments have allocated<br />

parking and roof terraces, which<br />

contributed to the detailing<br />

requirements for the cladding<br />

system.<br />

Explains Ian Blakemore from Task<br />

Contract Services, the cladding subcontractor<br />

on the project: “The<br />

upgrades and modifications<br />

introduced as part of the conversion<br />

created some significant detailing<br />

challenges.<br />

“We needed bespoke detailing to<br />

accommodate both the protruding<br />

balconies to the rear of the building<br />

and the windows, which are flush to<br />

the façade, so it was vital that<br />

Shackerley prefabricated every<br />

façade panel to our exact<br />

dimensions and delivered each item<br />

to site aligned to the programme.”<br />

RE-IMAGINING THE FAÇADE<br />

The existing 1970s building was a<br />

concrete frame structure with a<br />

façade of brown brick. Although the<br />

existing brick façades were in a good<br />

state of repair, they were<br />

significantly out of line and it was<br />

not possible to overclad them on the<br />

confined city centre site without<br />

increasing the external area of the<br />

building. Instead, the programme<br />

required the building to be stripped<br />

back to the concrete frame, with a<br />

completely new wall build up.<br />

New structural infill panels were<br />

inserted between the concrete frame<br />

slabs with insulation fixed to the<br />

new external wall surface. The<br />

SureClad® ventilated façade system<br />

was then installed using Shackerley’s<br />

Queen’s Award winning SureClad®<br />

Access installation system.<br />

Explains Ian Blakemore: “The<br />

ceramic granite panels were all<br />

prefabricated off-site under qualitycontrolled<br />

conditions in Shackerley’s<br />

ISO 9001 accredited factory. Each<br />

panel was cut, drilled and fitted<br />

with SureClad® Access fixing straps,<br />

which were secured to the rear with<br />

special undercut anchors.<br />

“Shackerley prefabricated the<br />

façade system to our precise<br />

requirements and delivered<br />

everything to site in an installationready<br />

format to fit our schedule.<br />

Shackerley fabricated more than<br />

960m2 of façade cladding for the<br />

project, delivering items on a justin-time<br />

basis due to the lack of<br />

storage space at the city centre site.<br />

INSPIRING AESTHETICS<br />

The majority of the ceramic granite<br />

cladding was specified in a creamy<br />

‘Travertine’ colourway with a natural<br />

honed finish, creating a high-end<br />

aesthetic that mimics the look and<br />

texture of Bath Stone. A second<br />

colourway, beige Volcado, in the<br />

same natural honed finish, has been<br />

used to complement the ‘Travertine’.<br />

Façade panels were specified in a<br />

combination of 1200 x 600mm and<br />

1200 x 300mm formats to allow the<br />

installation team to deliver a visually<br />

interesting offset façade design with<br />

feature banding.<br />

David Smith from HeadOffice3<br />

explains: “Shackerley’s SureClad®<br />

ceramic granite panels provided the<br />

appearance of Bath Stone with a<br />

much slimmer, more durable,<br />

lightweight panel.<br />

“They also offer the advantage of<br />

being impermeable, ensuring freezethaw<br />

resistance by preventing<br />

moisture penetration, and they are<br />

resistant to algae, graffiti and U/V,<br />

so the robust new façade will retain<br />

its high-end aesthetic over time.”<br />

All Shackerley façade systems are<br />

also non-combustible to Class A1 or<br />

Class A2 in accordance with BS EN<br />

13501-1.<br />

01257 273114<br />

www.shackerley.com<br />

4 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS

GLASS & GLAZING<br />

Added security with<br />

Selectaglaze secondary glazing<br />

By Appointment to<br />

Her Majesty The Queen<br />

Manufacturer and Supplier<br />

of Secondary Glazing<br />

Selectaglaze Ltd.<br />

St Albans<br />

Hearing about break-ins or<br />

threats of terrorism has<br />

become a regular<br />

occurrence, which can be<br />

unsettling. Selectaglaze secondary<br />

glazing can provide an unseen level of<br />

security to any property. It creates a<br />

second barrier of protection from the<br />

inside that can prevent the most<br />

determined thief or protect the<br />

occupants from the effects of bomb<br />

blast.<br />

Securing the contents of a<br />

building is essential; be it physical<br />

high value objects, highly sensitive<br />

data or the people within. If this is the<br />

case, secondary glazing could provide<br />

the solution.<br />

Physical attack - Under physical<br />

attack secondary glazing works by<br />

providing a second barrier to entry. At<br />

lower risk levels it must prevent<br />

manipulation of the locks and catches<br />

or removal of the glass or glazed<br />

panels. As the performance increases<br />

it must resist levering or use of<br />

cutting tools including penetration of<br />

the glazing, which at higher risk levels<br />

will be a sophisticated combination of<br />

glass, resin and polycarbonate.<br />

Blast mitigation - Secondary<br />

glazing can protect occupants and<br />

contents from the effects of an<br />

explosion by containing the flying<br />

shards of glass from the breakup of<br />

the primary window under the blast<br />

load. The front layers of glass are<br />

designed to shatter, thereby absorbing<br />

the initial impact energy, subsequent<br />

glass and interlayers absorb the lower<br />

level shock waves. Lighter, thinner<br />

bullet resistant glass can be produced<br />

by the use of polycarbonate in the<br />

lamination<br />

Ballistic - Protection from firearm<br />

attack is achieved by several layers of<br />

glass of various thicknesses laminated<br />

together. The front layers of glass are<br />

designed to shatter, thereby absorbing<br />

the initial impact energy, subsequent<br />

glass and interlayers absorb the lower<br />

level shock waves.<br />

Fire - Fire resistant glazing<br />

provides a protected escape route for<br />

occupants. Specialist glass, together<br />

with fire and intumescent seals set<br />

within appropriate framing, resists the<br />

intense heat of a fire. This provides<br />

"integrity" which prevents breach of<br />

flames and gases, and where required<br />

"insulation" to reduce the transfer of<br />

heat.<br />

Banqueting House, London was<br />

treated with Selectaglaze blast units<br />

to provide sufficient levels of security<br />

to protect the Rubens ceiling painting,<br />

historic architectural features and<br />

those who visit/use the Royal Palace.<br />

Established in 1966, granted a<br />

Royal Warrant in 2004 and working to<br />

a certified ISO 9001 quality system,<br />

Selectaglaze is the UK’s leading<br />

secondary glazing specialist.<br />

Selectaglaze will be exhibiting on<br />

Stand N82 at the International<br />

Security Expo at Olympia on the 28th<br />

and 29th of November.<br />

For further information,<br />

please contact Selectaglaze<br />

Tel: 01727 837271<br />

e mail:<br />

enquiries@selectaglaze.co.uk or<br />

visit: www.selectaglaze.co.uk<br />

Clapham Common - Residential<br />

Seamless integration giving you the added<br />

benefit of:<br />

Warmer<br />

Secondary glazing blast test<br />

• Reversible adaptation for Listed and heritage<br />

buildings<br />

• Exemplary thermal retention and draught<br />

insulation<br />

• Most effective method of sound proofing<br />

• Secured By Design accredited<br />

• Blast mitigation<br />

Quieter<br />

• Second barried to entry<br />

• Maintains a normalised environment<br />

T: 01727 837271<br />

E: enquiries@selectaglaze.co.uk<br />

www.selectaglaze.co.uk<br />

Safer<br />

@selectaglaze<br />

REFURBISHMENT PROJECTS, SEPTEMBER <strong>2018</strong> 5

WATERPROOFING<br />

Tuff Waterproofing showcase new product at<br />

UK Construction Week<br />

Tuff Waterproofing, one of the<br />

UK’s leading suppliers of<br />

heavy-duty waterproof flat<br />

roofing, will showcase its<br />

latest product developments at UK<br />

Construction Week (UKCW) taking<br />

place at the NEC in Birmingham<br />

from 9-11 October.<br />

The UK’s largest built<br />

environment event, UKCW brings<br />

together 35,000 construction<br />

professionals and over 650<br />

exhibitors with nine shows across<br />

three days, including Grand Designs<br />

Live and the Build Show. Tuff<br />

Waterproofing’s stand (B480) will<br />

feature Tuff Tech Pro VP/UV, a new<br />

seamless and waterproof<br />

polyurethane membrane which the<br />

company has launched primarily for<br />

the commercial market. Providing an<br />

advanced fast-curing formulation<br />

which significantly reduces time and<br />

labour on site, the product is a costeffective<br />

solution for new or<br />

existing flat roofs, walkways,<br />

balconies and gutters.<br />

Also on show will be Tuff<br />

Waterproofing’s flagship product,<br />

TuffStuff GRP roofing, which uses<br />

the latest liquid polyester resins,<br />

glass fibre mat reinforcement and<br />

flexible edge trims to create a<br />

waterproof seamless finish which is<br />

fully integrated and ideal for new<br />

OSB timber boards and overlay<br />

systems.<br />

Greg Gimenez, Managing<br />

Director of Tuff Waterproofing,<br />

commented:<br />

“Tuff Waterproofing enjoyed a<br />

very successful appearance at last<br />

year’s UK Construction Week and we<br />

are excited to be returning to the<br />

NEC for this stand-out event in the<br />

industry calendar. Product<br />

Cembrit Plank brings life to a painted bungalow<br />

development is a major part of Tuff<br />

Waterproofing’s business strategy<br />

and UK Construction Week<br />

represents the ideal platform to<br />

introduce new innovations to<br />

stakeholders across every facet of<br />

design and build.<br />

www.tuffstuff.co.uk<br />

Water leaks are a distant<br />

memory for the owners<br />

of a bungalow in the<br />

Isle of Wight after<br />

Cembrit Plank was installed on the<br />

property to provide a new<br />

watertight cladding system.<br />

Ryde-based roofing contractor, L<br />

J Teal Roofing Service was<br />

approached by the homeowners who<br />

were looking for a solution to fix a<br />

water ingress issue. The concrete<br />

blocks and render finish had become<br />

porous and water was penetrating<br />

through. Having heard about the<br />

recently launched Cembrit Plank, the<br />

contractor was confident that this<br />

weatherboard could provide a good<br />

cladding solution for the customer.<br />

“We pitched the idea of<br />

installing a weatherboard cladding<br />

option to Mr and Mrs Morrison, and<br />

they agreed that it would be a good<br />

way forward” commented Liam Teal<br />

of L J Teal Roofing Service. “We<br />

supplied Cembrit Plank in Ivory via<br />

Roofstore and the project began in<br />

February <strong>2018</strong>.”<br />

L J Teal Roofing Service started<br />

the project by chipping off the paint<br />

and render, stabilising the wall with<br />

bonding agents and installing a<br />

two-coat render system. Due to the<br />

block work having an uneven finish,<br />

the contractor fitted 38mm x 50<br />

mm counter battens required<br />

individual attention to create a<br />

uniform structure onto which<br />

Cembrit Plank could be installed.<br />

Ventilated starter profiles ensured<br />

the correct air flow behind the<br />

weatherboard. The original roof<br />

overhang presented a problem, as<br />

the gable roof ends did not extend<br />

out far enough to accommodate the<br />

cladding underneath. This resulted in<br />

the contractor altering the roof and<br />

installing new PVC fascia being<br />

fitted at the gable ends.<br />

Once the breathable membrane<br />

was installed on top of the counter<br />

battens, L J Teal Roofing Service<br />

then turned their attention to the<br />

cladding. The contractor started by<br />

levelling the first board around the<br />

whole building and worked their<br />

way up the property fixing Cembrit<br />

Plank horizontally. Work continued<br />

rapidly with the help of Gecko<br />

gauges which meant after the first<br />

plank was laid level, the successive<br />

planks were quickly placed and<br />

fixed. Extremely easy to install, the<br />

project was completed by April<br />

<strong>2018</strong>. The owners are delighted with<br />

their brand-new exterior, which has<br />

a natural aesthetic, and is<br />

watertight, non-combustible and<br />

low in maintenance.<br />

Fibre cement Cembrit Plank is<br />

low in maintenance, rot, rust, warp,<br />

crack, sun, heat, rain resistant, is<br />

non-combustible, providing a<br />

superior alternative to timber and<br />

plastic based alternatives. The<br />

overlapping plank is designed to<br />

look like painted timber but will<br />

retain its attractive appearance long<br />

after alternatives have started to<br />

age. Furthermore, Cembrit Plank<br />

does not require toxic preservative<br />

treatments in the way timber<br />

weatherboarding does.<br />

Offering a 15-year warranty,<br />

Cembrit Plank is available in 15<br />

different colours. A range of white<br />

and dark grey shades match<br />

traditional building styles, while the<br />

addition of reds, pale browns and<br />

pastel green offer a more<br />

contemporary choice. In addition,<br />

the range includes a ready primed<br />

option for clients wishing to add<br />

their own choice of colour. For large<br />

enough orders, Cembrit can arrange<br />

customised colours. The range<br />

includes a comprehensive set of<br />

colour matched accessories,<br />

including the roofline trims needed<br />

for a neat finish where façade meets<br />

the roof.<br />

Tel: 020 3372 2300<br />

sales@cembrit.co.uk<br />

www.cembrit.co.uk<br />

6 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS

9-11 OCTOBER | NEC | BIRMINGHAM<br />

THE UK’S LARGEST<br />

BUILT ENVIRONMENT EVENT<br />

9 SHOWS<br />

UNDER ONE ROOF<br />

<strong>2018</strong><br />

EVENT HIGHLIGHTS INCLUDE<br />

The ‘Future of<br />

Construction’ is UKCW’s<br />

<strong>2018</strong> theme, exploring the<br />

latest innovative ideas,<br />

products and systems<br />

100+ product<br />

launches and creative<br />

ideas that will<br />

inspire construction<br />

professionals<br />

10,000+ innovative<br />

products and services<br />

will be showcased<br />

by 650+ exhibiting<br />

companies<br />

300+ content hours<br />

via CPD Hubs, Offsite<br />

Theatre, UKCW Stage,<br />

Regeneration Hub &<br />

Digital Construction Hub<br />

ukconstructionweek.com<br />

EXHIBITORS INCLUDE<br />

BUILD SHOW<br />

HEADLINE SPONSOR<br />

REGISTRATION<br />

SPONSOR<br />

#UKCW<strong>2018</strong> @UK_CW<br />

HEALTH AND<br />

SAFETY SPONSOR<br />

BEER FESTIVAL<br />

SPONSOR<br />

REGISTER<br />

FREE

FIXTURES & FITTINGS<br />

Hidden talents: Astra and concealed hinges<br />

prove perfect match<br />

Astra 3003<br />

concealed door closers<br />

CE-Marked<br />

have proved to be the<br />

perfect partner for concealed hinges<br />

recent tests, making them the<br />

seamless choice for high<br />

performance and fire doors wherever<br />

clean, refined design lines are called<br />

for.<br />

Modern concealed hinges paired<br />

with the CE-Marked Astra 3003<br />

closer – both designed to be<br />

unobtrusive in situ – have<br />

successfully completed nearly three<br />

quarter of a million cycles on Astra’s<br />

in-house test-rig. This is well in<br />

excess of the 200,000 cycles<br />

required by the<br />

European standard (BS EN1154)<br />

and marks a huge success for Astra’s<br />

best-selling concealed closer.<br />

With so many concealed hinges<br />

on the market, made from different<br />

materials and with different pivot<br />

points, it is vital that they are tested<br />

successfully with the closer to<br />

ensure optimum performance. Astra<br />

3000 Series closers are increasingly<br />

being specified with concealed<br />

hinges by architects, designers and<br />

architectural ironmongers on<br />

projects where clean design lines<br />

and elegant aesthetics are the<br />

priority. Specifiers now have the<br />

peace of mind of ‘guaranteed<br />

performance’ along with the<br />

pleasing design of concealed<br />

hardware.<br />

Concealed closers are the<br />

obvious choice in settings where<br />

visual appeal is paramount since<br />

they are not visible when the door is<br />

closed, avoiding the somewhat<br />

institutional and ungainly<br />

appearance of overhead closers.<br />

Designers select Astra 3000 series<br />

closers because, with full<br />

adjustability, they are powerful<br />

enough to handle doors of almost<br />

any weight and width. Unlike other<br />

concealed closers on the market<br />

Astra 3003 size three closers are CE-<br />

Marked for use on fire doors.<br />

Astra is well known for its door<br />

closer range and the Lancashirebased<br />

company can demonstrate<br />

many years’ experience in the sector<br />

and carries out all its own R&D inhouse.<br />

It exports its British door closers<br />

across the globe via a network of<br />

distributors and partner companies.<br />

Tel: 01772 796901<br />

info@astradoorcontrols.com<br />

Karndean Designflooring announces new designs as part<br />

of Art Select wood collection<br />

The UK’s market leader in<br />

luxury vinyl flooring Karndean<br />

Designflooring is extending its<br />

sophisticated Art Select wood<br />

collection with 14 new designs<br />

including French oak, hickory and<br />

American chestnut.<br />

Designed to accommodate a<br />

growing desire for highly realistic<br />

flooring, Karndean’s latest Art Select<br />

wood designs feature intricate<br />

patterns for impressive variation<br />

across the floor, with a preferred<br />

3.0mm thickness, 0.7mm wear layer<br />

and enhanced R10/R11 slip<br />

resistance ratings.<br />

The new designs offer beautiful<br />

and inspiring natural wood effects<br />

with realistic cross-sawn and handscraped<br />

embosses to produce an<br />

authentic look of traditional crafted<br />

planks that is perfect for a wide<br />

variety of commercial settings.<br />

Four brand new oak designs -<br />

Prairie Oak, Glacier Oak, Mountain<br />

Oak and Savannah Oak - offer an<br />

extended colour range to include<br />

gentle beige, cool grey and warm<br />

honey tones. Available in a choice of<br />

extra-large planks (56 x 9”) and<br />

parquet format (18 x 3”) the new<br />

oak designs are suitable for different<br />

laying patterns, such as herringbone<br />

or laying at 45 degrees, bringing a<br />

sense of grandeur to any interior.<br />

Joining Karndean’s Art Select<br />

hickory range are four brand new<br />

designs – Natural Hickory,<br />

Weathered Hickory, Vintage Hickory<br />

and Classic Hickory – offering<br />

unique and elegant contrasts in<br />

colour between the<br />

deeper heartwood of<br />

the plank and the<br />

bright outer sapwood.<br />

A new and exclusive<br />

emboss enhances the<br />

characteristic saw<br />

marks of the original<br />

wood flooring,<br />

authentically<br />

replicating the<br />

appearance and texture<br />

of unfinished timber.<br />

A new Reclaimed<br />

Chestnut design<br />

faithfully replicates the<br />

rustic feel and rich<br />

warm tones of traditionally crafted<br />

wood planks found in historic barns<br />

and factories of North America.<br />

Featuring the subtle matte finish of<br />

unfinished boards, the new design<br />

offers an eclectic, rustic appearance.<br />

Now scarce in its natural form,<br />

reclaimed American chestnut floors<br />

are often collated from many<br />

sources and feature a mix and<br />

match pattern of planks, so for<br />

additional realism, Karndean’s<br />

Reclaimed Chestnut design is also<br />

available in a random plank option.<br />

“We are delighted to bring these<br />

new designs to the market,<br />

accurately replicating the features<br />

and characteristics of real wood<br />

with new finishes and embosses for<br />

a more authentic look.” explains<br />

Fleur Carson, commercial sales<br />

director at Karndean Designflooring.<br />

“In a range of shades from light<br />

and airy to rich and warm, and in a<br />

choice of plank formats, the new Art<br />

Select wood designs offer specifiers<br />

flexibility to create highly individual<br />

looks within a range of commercial<br />

spaces. They’ll bring the natural<br />

beauty and style of real wood to life<br />

in settings from retail and<br />

hospitality to education spaces and<br />

workplaces.”<br />

Available from October <strong>2018</strong>,<br />

Karndean’s updated and extended<br />

Art Select collection now features a<br />

total of 33 wood designs and 21<br />

stone designs.<br />

For more information visit<br />

www.karndean.com<br />

8 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS

THE DESOWOOD REPAIR SYSTEM<br />

A DURABLE<br />

ALTERNATIVE TO<br />

LINSEED OIL PUTTY<br />

DESOWOOD DAP<br />

ELASTIC GLAZING<br />

SEALANT<br />

l A Product with an established record for performance.<br />

l A Product with over 20 year’s history in use.<br />

l Ideal for windows affected by break down of linseed oil putty.<br />

l Ideal for sash and casement windows.<br />

l For use on existing or new bead glazed windows.<br />

l Ideal for fixing single or double glazed sealed units on puttied or<br />

bead glazed windows.<br />

l For fixing laminated / safety glass.<br />

l Can be used on softwood, hardwood and metal windows.<br />

l Ideal for sealing plywood or pre-finished ‘in-fil’ panels.<br />

l Ideal replacement for ‘Back putties’ on windows affected by<br />

condensation on internally bead glazed windows.<br />

l Improves paint durability and contributes towards the prevention<br />

of wood decay<br />

l Can be painted with an opaque paint finish or translucent wood<br />

stain.<br />

l Excellent adhesion to timber, metal, concrete, brick and glass.<br />

Tel: 01767 682446 E:sales@desofil-uk.com<br />

Web-site: www.desofil-uk.com<br />

THE DESOWOOD REPAIR SYSTEM

GLASS & GLAZING<br />

Kawneer launches a super-robust and super-thermal<br />

commercial entrance door<br />

Manufacturer introduces the AA®190 TB door to its portfolio.<br />

An entrance door with classleading<br />

thermal<br />

performance that is so<br />

robust it is offered with a<br />

lifetime guarantee has been<br />

launched by Kawneer, the leading<br />

UK manufacturer of architectural<br />

glazing systems.<br />

Kawneer’s AA®190 TB door<br />

features welded corner construction<br />

– the strongest aluminium door<br />

construction available, with each<br />

corner having four separate weld<br />

points, each of which has a ‘lifetime<br />

guarantee’. Rigorous testing has<br />

verified its exceptional strength and<br />

durability, making it suitable for use<br />

in severe-duty applications as<br />

defined in BS 6375-2: 2009.<br />

With regards to weather<br />

performance, the system has Class 2<br />

(300 Pa) air permeability, Class 3A<br />

(100 Pa) watertightness and Class C2<br />

(800 Pa) wind resistance, results that<br />

are based on an open-in double<br />

door with butt hinges and rebated<br />

threshold.<br />

An all-purpose door for use in<br />

high-traffic areas and automatic<br />

entrances, it is as suitable for<br />

internal as it is external applications,<br />

for refurbishment as well as newbuild,<br />

and for all sectors, particularly<br />

education, healthcare, commercial,<br />

and leisure and retail. With security<br />

hardware it meets Secured by Design<br />

criteria.<br />

The door is designed to accept<br />

glass units up to 43mm thick, with a<br />

maximum leaf weight of 120kg with<br />

an overhead closer and a maximum<br />

of 200kg using the floor closer, all<br />

with leaf sizes up to 1320mm wide<br />

and 3000mm high.<br />

As well as its high strength and<br />

robust properties, the AA®190 TB<br />

door also provides improved thermal<br />

performance. A whole-door thermal<br />

transmittance of Uw = 1.7 W/m2K<br />

can be achieved with a glass centre<br />

pane of Ug = 1.0 W/m2K.<br />

The AA®190 TB door is offered<br />

with a finger guard pivot stile as<br />

standard, providing child-friendly<br />

reassurance, safeguarding against<br />

injury to fingers that might be<br />

accidentally caught between the<br />

hinge stile and frame.<br />

Independently tested to PAS 24:<br />

2016 for the enhanced security<br />

performance of single and doubleleaf<br />

external doors, the enhanced<br />

security is available for both pivot<br />

and butt hung doors which can<br />

feature panic hardware.<br />

A range of multi-point lock<br />

options provides security solutions<br />

for all applications including panic<br />

doors and electronic access control.<br />

There is also a range of thresholds<br />

including drained low thresholds<br />

compliant with the Equality Act 2010.<br />

For ultimate design flexibility the<br />

AA®190 TB door is available as<br />

single-leaf and double-leaf in openin,<br />

open-out and dual-action swing<br />

doors suitable for automatic<br />

powered operation. Additionally, the<br />

AA®190 TB door can be used with<br />

automatic sliding or bi-parting<br />

entrance systems.<br />

Naturally, the door is available<br />

with its own thermally broken<br />

framing system – 451PT, which<br />

suites with other Kawneer<br />

fenestration solutions.<br />

All door options are available in<br />

an extensive range of single or dualcolour<br />

finishes.<br />

The AA®190 TB door is extruded<br />

and thermal breaks added before<br />

painting and in-house fabrication –<br />

all in the Kawneer factory at<br />

Runcorn.<br />

Kawneer’s new AA®190 TB doors<br />

have already been specified by<br />

architects Foster + Partners at<br />

Central Square in Cardiff, including<br />

on BBC Cymru’s HQ.<br />

Tel: +44 (0) 1928 502500<br />

www.kawneer.com<br />

Schueco Jansen renovation window is the preferred solution<br />

Janisol Arte 2.0, the secondgeneration<br />

renovation window<br />

from steel systems specialist<br />

Schueco Jansen, is proving<br />

popular with architects because of<br />

its enhanced specification, improved<br />

performance characteristics and<br />

ability to satisfy the aesthetic<br />

concerns of local authority planners<br />

and conservation officers.<br />

Now being seen as the preferred<br />

solution for many refurbishment<br />

projects, especially those involving a<br />

listed building, elegantly ‘retro’<br />

Janisol Arte 2.0 offers an enlarged<br />

range of profiles with slim sightlines<br />

from 25 mm. A wider choice of<br />

glazing bead shapes – right-angled,<br />

bevelled, scotia and flat – makes it<br />

even easier to find an exact match<br />

for the steel windows being<br />

replaced.<br />

Furthermore, since laser-welded<br />

profiles can now be added to<br />

standard Arte profiles, mullion spans<br />

can be significantly increased, so<br />

enabling the Janisol Arte 2.0<br />

window to accommodate much<br />

larger areas of fenestration.<br />

Available in all the opening types<br />

commonly encountered in both preand<br />

post-war industrial buildings,<br />

maximum vent weights have<br />

increased to 150 kg thanks to the<br />

introduction of state-of-the-art, 3D<br />

adjustable stainless steel hinges.<br />

Another benefit is that simpler<br />

fabrication techniques reduce<br />

manufacturing time by up to 85%,<br />

meaning that six and a half Janisol<br />

Arte 2.0 vents can be produced in<br />

the time it took to make a single<br />

vent in the previous system.<br />

Special new foam profiles<br />

located between the glass and the<br />

frame mean that the insulation in<br />

the Janisol Arte 2.0 window has<br />

been significantly enhanced and<br />

following the introduction of insert<br />

profiles – which also speed up<br />

fabrication times – results in<br />

drainage that is even more reliable.<br />

In addition, because all Janisol<br />

Arte 2.0 profiles now go through the<br />

latest ZF 100 galvannealed hot-dip<br />

process, corrosion resistance has<br />

been improved and processing<br />

weldability enhanced.<br />

Finally, as well as standard,<br />

premium-quality steel profiles, clients<br />

can opt for Janisol Arte 2.0 profiles in<br />

high-grade austenitic 1.4401 stainless<br />

steel or Corten steel, completing a<br />

specification that is thought to be<br />

unmatched by any other renovation<br />

window on the market.<br />

mkinfobox@schueco.com<br />

www.schueco.co.uk<br />

10 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS

GLASS & GLAZING<br />

Schueco slimline façade system offers unrivalled<br />

elegance and performance<br />

The compelling combination of<br />

extreme visual elegance and<br />

excellent thermal performance<br />

makes the ultra-slimline FWS<br />

35 PD panorama design façade from<br />

Schueco UK the ideal system<br />

solution for low-rise, high-end<br />

residential and commercial projects.<br />

A particularly attractive feature<br />

is the frameless glass-to-glass corner<br />

option that eliminates the need for<br />

an intrusive corner profile by<br />

transferring the glass load directly<br />

onto the adjacent mullions. The<br />

result is wider unobstructed views<br />

from the inside and a sleek<br />

contemporary look from the outside.<br />

The FWS 35 PD façade is offered<br />

with a choice of two levels of<br />

insulation – .HI (highly insulated) or<br />

.SI (super-insulated) – the latter<br />

being officially certified by the<br />

Passive House Institute with a Ucw<br />

value of 0.79 W/m2K. It can<br />

accommodate double- and tripleglazed<br />

units from 22 mm to 50 mm<br />

in thickness, with weights up to 250<br />

kg per transom.<br />

The versatility of the system is<br />

further enhanced by a heavy-duty<br />

version that can carry up to 400 kg<br />

The EMKA PROflex aluminium<br />

window system enables users<br />

to fabricate what they want,<br />

when they want it, off the<br />

and the inclusion of a single glazed<br />

option that is perfect for use in<br />

high-end display windows and<br />

internal applications.<br />

Importantly, where ventilation is<br />

required, the Schueco FWS 35 PD<br />

façade can incorporate Schueco<br />

AWS 114 opening window units;<br />

operated either manually or<br />

mechatronically with a concealed<br />

Schueco TipTronic actuator, these<br />

are an attractive and practical<br />

method of ventilation and can be<br />

specified with either top-hung or<br />

parallel-opening types.<br />

A further option is to insert<br />

Schueco’s new concept window, the<br />

AWS 75 PD.SI turn-tilt window, into<br />

the façade. This advanced, ultra-slim<br />

system is expected to become<br />

generally available in the UK later<br />

this year.<br />

Despite the slimness of its<br />

profiles, the Schueco FWS 35 PD<br />

façade can be fitted with a variety<br />

of solar shading and may be<br />

specified with three levels of<br />

security – standard or resistance<br />

classes 2 and 3 of EN 1627, the<br />

latter incorporating P4A and P6B<br />

security glass. Because the<br />

components that help to achieve<br />

this are fully concealed, the<br />

appearance of the façade is<br />

unaffected.<br />

EMKA Aluminium PROflex window<br />

kits for quicker self-assembly<br />

shelf for use as windows or<br />

mounting panels with or without<br />

depth frame for clearance of door<br />

mounted instrumentation.<br />

The DIY approach enables panels<br />

to be outsourced in non-standard<br />

materials to non-standard sizes. It<br />

also allows for standard sizes to be<br />

For full details of Schueco's FWS<br />

35 PD panorama design façade<br />

system, please email<br />

mkinfobox@schueco.com<br />

adapted or modified to suit custom<br />

requirements at short notice.<br />

The PROflex window system can<br />

be configured as a low profile<br />

window or as a protection for<br />

indicators/buttons/switches that<br />

protrude from the door panel. The<br />

system incorporates an integral<br />

cylinder lock mechanism or multiple<br />

locks on longer sizes.<br />

Further information on EMKA<br />

products can be found on the<br />

EMKA website - www.emka.com.<br />

Readers can find the latest<br />

information and news on the<br />

EMKA blog – www.emkablog.co.uk<br />

or follow them on twitter -<br />

http://twitter.com/emkauk.<br />

REFURBISHMENT PROJECTS, SEPTEMBER <strong>2018</strong> 11

DON’T RIP IT,<br />

WRAP IT!<br />

Transform any surface with 3M TM DI-NOC<br />

self-adhesive lms - the alternative choice<br />

for refurbishments.<br />

BEFORE<br />

Did you know projects using 3M DI-NOC can signicantly reduce costs<br />

compared to traditional remodelling? Current xtures and ttings don’t<br />

need to become landll, simply wrap existing surfaces to completely<br />

redesign commercial environments .<br />

With less noise, mess and minimal downtime or inconvenience to your<br />

customers meaning there’s no need to close business during application.<br />

Looking to become an installer?<br />

Full training courses now available.<br />

Contact us for further information...<br />

CALL 01833 694707<br />

www.architextural.co.uk<br />

AFTER

ROOFING<br />

Safesite provides Roehampton Leisure Centre<br />

with a roof safety solution<br />

Safesite, a supplier of fall<br />

protection solutions, has<br />

provided Roehampton Sports<br />

and Fitness Centre with a<br />

collective roof edge protection<br />

system that ensures optimum roof<br />

top safety for maintenance and<br />

inspection teams.<br />

Roehampton Sports and Fitness<br />

Centre is managed by Places for<br />

People Leisure on behalf of<br />

Wandsworth Council. The building<br />

previously had no roof safety<br />

measures in place, with maintenance<br />

teams having to assess the flat roof<br />

via portable ladders to carry out<br />

inspection work. It therefore became<br />

necessary for the building to have a<br />

safety upgrade comprising a<br />

complete roof protection system<br />

that enables safe access.<br />

Due to previous experience with<br />

Safesite on another leisure centre<br />

within the borough, Wandsworth<br />

Council contacted the company<br />

directly. The brief was to conduct a<br />

site evaluation, provide a full design<br />

package, and install the specified<br />

system. Safesite recommended the<br />

installation of Kee Walk®,<br />

KeeGuard®, KeeGuard® Topfix,<br />

Wireanka®, and an access ladder. The<br />

combination of these products has<br />

provided the very best roof top<br />

safety solution.<br />

“We are extremely satisfied with<br />

the end result,” says Lukasz Plaska,<br />

Project Officer, Design Service<br />

serving Richmond and Wandsworth<br />

Councils. “The safety solutions<br />

installed by Safesite provide the<br />

perfect safe access solution and are<br />

a vast improvement to the previous<br />

existing unsafe access methods.”<br />

Kee Walk® is a permanent roof<br />

top walkway solution for use on<br />

composite, trapezoidal metal profiles<br />

and standing seam roofs. The<br />

system provides a demarcated<br />

walking surface protecting the roof’s<br />

surface from unnecessary foot<br />

traffic and potential damage. As an<br />

off-the-shelf, modular system which<br />

can be easily adapted to a wide<br />

range of different roof, pitches and<br />

configurations, Kee Walk® is easy to<br />

install and cost-effective on either<br />

flat, barrel or sloping surfaces.<br />

Compatible with a range of roof<br />

membranes, including concrete,<br />

asphalt, PVC membrane, metal and<br />

felt, KeeGuard® offers a freestanding<br />

roof edge protection<br />

system capable of keeping workers<br />

on the roof safe without<br />

endangering the roof membrane<br />

itself. It does not penetrate the roof<br />

surface and can be used on flat<br />

roofs up to 10° slope. Employing a<br />

proven counterweight system,<br />

KeeGuard® combines a non-slip<br />

secure base with galvanised fittings<br />

and tube arranged in a modular<br />

configuration. Fully modular and<br />

versatile enough to adapt to most<br />

roof edge profiles and level changes,<br />

sections can be easily taken down<br />

and re-erected as necessary.<br />

KeeGuard® Topfix provides a<br />

simple solution when collective<br />

protection is the preferred safety<br />

option for metal profile and<br />

standing seam roofs up to 45° pitch.<br />

The specially designed powder<br />

coated base plate, which<br />

incorporates multiple fixing centres,<br />

allows installation to a wide range<br />

Building Innovation unveils new website<br />

of popular roofs. Being an ‘off the<br />

shelf’ product, specification is simple<br />

and it also removes the need to<br />

fabricate a different solution for<br />

each site, minimising site visits and<br />

down time.<br />

Wireanka® is a system of<br />

deadweight anchor devices designed<br />

to support Class `C’ horizontal,<br />

flexible safety lines to BS EN 795. It<br />

is intended for use on flat roofs, in<br />

temporary situations, or where it is<br />

preferable the penetration of the<br />

roof surface be avoided.<br />

Tel: +44 (0)1293 851115<br />

www.safesite.co.uk<br />

Leading tapered insulation<br />

experts, Building Innovation,<br />

has launched its new website<br />

showcasing its extensive range<br />

of roofing systems backed by its<br />

specialist design service —<br />

www.building-innovation.co.uk.<br />

Since it was established in 2004,<br />

Building Innovation has designed<br />

and supplied schemes for thousands<br />

of projects across the country,<br />

including warm roofs, terraces,<br />

access ramps and car parks. Its team<br />

of highly-trained experts carefully<br />

tailor each system specification to<br />

the project’s unique requirements —<br />

whether it be enhanced thermal<br />

performance, outstanding acoustics<br />

or maximising cost efficiency.<br />

The easily navigable site allows<br />

users to explore the company’s full<br />

range of roofing products and<br />

systems, such as the hybrid ASPIRE<br />

and ACOUSTIC Solutions and the<br />

Inno range of PIR solutions. Each<br />

product listing is supported with<br />

detailed technical information and a<br />

downloadable data sheet covering<br />

the different design possibilities for<br />

the product. The revised enquiry<br />

form also makes it simpler than ever<br />

to submit a design request directly<br />

from the website, considering the<br />

roof area, desired U-value and the<br />

required fall.<br />

In addition, an all-new<br />

Knowledge Base provides a clear<br />

overview of what to look for in a<br />

tapered system and what the current<br />

Building Regulation requirements<br />

are across the different regions of<br />

the UK.<br />

Tel: +44 (0) 1926 888808<br />

info@building-innovation.co.uk<br />

www.building-innovation.co.uk<br />

REFURBISHMENT PROJECTS, SEPTEMBER <strong>2018</strong> 13

ROOFING<br />

Funding secured to refurbish Woodlands<br />

Academy in Scarborough<br />

Woodlands Academy is a<br />

special educational<br />

needs (SEN) school in<br />

Scarborough for pupils<br />

aged 2-16. The two-storey building<br />

on campus had previously been<br />

refurbished using Sika Liquid<br />

Plastics’ Decothane Ultra 25-year<br />

cold-applied liquid roofing system.<br />

With an additional four buildings on<br />

site in need of roof refurbishment as<br />

the existing roof surfaces reached<br />

the end of their service life, the<br />

school worked with Sika Liquid<br />

Plastics’ and building surveyor<br />

partner, Make Consulting, to secure<br />

government funding for a new roof<br />

refurbishment project.<br />

PROJECT REQUIREMENT<br />

The roofs of two classroom blocks,<br />

the kitchen and the hall on the<br />

campus had reached the end of their<br />

service life with the existing felt<br />

surface leaking in several places.<br />

While some of the works could<br />

be carried out during the summer<br />

holiday period, there was a need to<br />

complete the project during term<br />

time. Working in a live school<br />

environment always involves specific<br />

health and safety and safeguarding<br />

challenges. Consequently, it was vital<br />

to avoid the use of hot works and<br />

heavy equipment during the project<br />

to minimise health and safety risk<br />

and noise, the use of virtuallyodourless<br />

Decothane Ultra avoided<br />

any nuisance odours on site.<br />

SIKA LIQUID PLASTICS SOLUTION<br />

Following a site audit and roof<br />

condition survey carried out as part<br />

of the funding bid process, Sika<br />

Liquid Plastics’ Area Technical<br />

Manager developed a full technical<br />

specification and Quality Assured<br />

(QA) contractor, Surface Protection<br />

Coatings Ltd, was appointed to carry<br />

out the project.<br />

The Surface Protection Coatings<br />

team prepared the roof surface and<br />

carried out spot repairs before<br />

undertaking the roof refurbishment<br />

as an overlay.<br />

The buildings were brought up to<br />

current building regulations<br />

standards with 130mm Decotherm<br />

insulation board, adhered to the<br />

existing roof surface using Decostik<br />

adhesive. The Decotherm was also<br />

used to create new gutters to reduce<br />

the risk of ponding water on the<br />

new roof surface.<br />

On the classroom block and<br />

kitchen roofs more than 50 roof<br />

lights were replaced using the<br />

existing apertures and customfabricated<br />

Decolight triple-glazed<br />

fittings.<br />

“The school had been so pleased<br />

with the Decothane system on their<br />

previous roof refurbishment that<br />

they were keen to use the same<br />

system again on these four<br />

buildings”.<br />

Martin Eyre, Commercial Director<br />

Surface Protection Coatings.<br />

Woodlands Academy before (above) and after (below) the refurbishment.<br />

Video of the refurbishment can be viewed at https://bit.ly/2LUryTB<br />

For more information on Academy Funding please visit:<br />

http://gbr.liquidplastics.sika.com/en/group/service/AcademyFunding.html<br />

Project Participants<br />

Contractor: Surface Protection Coatings<br />

Roofing Client: Woodlands Academy<br />

Size: 2,500m2<br />

Products:<br />

Decothane Ultra<br />

Decotherm<br />

Decostik<br />

S-Vap 5000<br />

Decotrim<br />

Decolights

SOCIAL HOUSING<br />

How to cut the costs and increase the impact<br />

of positive input ventilation<br />

Positive Input Ventilation (PIV)<br />

may have been regarded as<br />

the most effective way to<br />

manage condensation for<br />

some time but running costs<br />

associated with warming the cold air<br />

entering a property have been<br />

known to cause problems for<br />

housing providers and tenants alike.<br />

Paul Harrington, Head of Residential<br />

Sales at Elta Group Building Services,<br />

explains how emerging technologies<br />

can make ventilation costs more<br />

affordable.<br />

For many years, social housing<br />

providers have turned to Positive<br />

Input Ventilation (PIV) as the go-to<br />

method of ventilation for dealing<br />

with condensation dampness in<br />

homes. While there are numerous<br />

benefits to PIV systems, one of the<br />

challenges is the problem of<br />

delivering cold air into the home<br />

during the winter months, while<br />

maintaining a high level of tenant<br />

acceptability.<br />

To address this issue, many PIV<br />

systems now feature an electric<br />

heater designed to increase the<br />

incoming air temperature. While this<br />

may solve the problem of cold air<br />

entering the home, the actual cost<br />

of using the heater can create its<br />

own issues. We should be<br />

encouraging end users to avoid an<br />

over-reliance on the heater and to<br />

make use of the existing heating<br />

system a little more.<br />

Thankfully, technology is now<br />

available to give housing providers a<br />

more flexible and energy efficient<br />

way to manage the risk of<br />

condensation. Thanks to modulating<br />

technology, such as the Eco-LoFlo<br />

mode offered by Elta Fans’ SANO<br />

Intelligent PIV system, air flow can<br />

be automatically adjusted according<br />

to the temperature and moisture<br />

content of the incoming air. This<br />

ensures optimum airflow and<br />

provides the most efficient<br />

ventilation rates for the conditions,<br />

reducing running costs.<br />

Paul Harrinton,<br />

Head of Residential Sales Elta Fans.<br />

are only able to deliver either 20 or<br />

30. This results in homes that are<br />

either under-ventilated, and<br />

therefore less able to deal with<br />

condensation related dampness, or<br />

over-ventilated, which leads to<br />

greater demands on in-built heaters<br />

and heating systems in winter<br />

months. To tackle this Elta Fans’<br />

latest SANO Intelligent PIV system<br />

has up to eight settings, which<br />

closely match Building Regulations.<br />

REGULATIONS VERSES<br />

REGULATED FAN SPEEDS<br />

Part F of the Building Regulations<br />

fails to acknowledge the quality of<br />

the air provided to a home via the<br />

ventilation process. Consequently,<br />

the amount of air provided into the<br />

home is the same all year round. By<br />

using a system which measures the<br />

temperature and moisture content<br />

of the air delivered into the home,<br />

the fan speed can be regulated to<br />

ensure the best levels of ventilation<br />

effectiveness are achieved in the<br />

most energy efficient way. Social<br />

housing providers and residents are<br />

able to avoid the excessive heating<br />

costs and discomfort reported by<br />

users of conventional PIV systems.<br />

Thanks to new developments,<br />

housing providers can now tackle<br />

the issue of condensation dampness,<br />

without it leading to complaints<br />

about reduced thermal comfort and<br />

increased heating costs. PIV need no<br />

longer be considered a catch 22, but<br />

a win-win for both providers and<br />

residents.<br />

For more information on Elta Fans’<br />

SANO Intelligent PIV Unit, visit<br />

www.eltafans.com.<br />

BUILDING REGULATIONS AND PIV<br />

AN UNEASY MATCH<br />

With PIV systems having remained<br />

largely unchanged for decades, their<br />

ability to meet building regulation<br />

requirements is often clumsy at best.<br />

While Part F of the Building<br />

Regulations increases in increments<br />

of 4 litres per second, many PIV<br />

systems come with as few as three<br />

speed settings. Part F requires the<br />

ventilation system to deliver a<br />

minimum of 25 litres per second, yet<br />

even some of the leading PIV units<br />

REFURBISHMENT PROJECTS, SEPTEMBER <strong>2018</strong> 15

SCHOOL BUILDING<br />

Grundfos know the questions to Aske<br />

The Haberdashers’ Aske School<br />

in Elstree is a leading<br />

independent school for girls of<br />

4-18. Originally established in<br />

1875, it is a well-respected name<br />

within the education sector. Their<br />

aim is to help each pupil attain their<br />

individual potential.<br />

This forward-thinking attitude<br />

seeps into many other aspects<br />

relating to the school and can for<br />

example be seen following through<br />

into recent building improvement<br />

works. F G Alden, Building Services<br />

Engineers from Oxford were tasked<br />

with delivering a new project and<br />

turned to Grundfos Pumps to help<br />

them to deliver the best pump<br />

solution.<br />

With energy efficiency a key<br />

driver in the school’s overall<br />

ambitions, both parties focussed on<br />

this aspect to deliver the best M&E<br />

result. The outcome was a complete,<br />

integrated state-of-the-art HVAC<br />

and water boosting pump package.<br />

This included the most advanced<br />

pump technological solutions<br />

available to the market such as the<br />

Grundfos MAGNA3 commercial<br />

circulators and TPE2 single stage inline<br />

pumps, as well as the Hydro<br />

MPC-E booster set.<br />

Maintaining a leading-edge<br />

position, regardless of the sector you<br />

operate in, can be difficult, however,<br />

by linking up with people with the<br />

right expertise, the results can be<br />

exceptional.<br />

For more information of this and<br />

many other solutions visit<br />

www.grundfos.co.uk<br />

Armstrong Ceilings set to debut virtual reality education experience<br />

The leading UK manufacturer<br />

will debut a virtual reality<br />

ceiling installation in a<br />

classroom at the Education<br />

Estates exhibition at Manchester<br />

Central from October 16th to 17th<br />

(stand G11) and at the Education<br />

Buildings exhibition at Edinburgh<br />

International Conference Centre<br />

from November 21st to 22nd (stand<br />

B9).<br />

On the Armstrong stand, users of<br />

the new VR experience will find<br />

themselves transported to a typical<br />

classroom setting which has not<br />

been acoustically treated. Amidst the<br />

students, they will hear for<br />

themselves how typical classroom<br />

noise and clatter effects<br />

intelligibility and acoustic comfort.<br />

Finally, the user will personally<br />

experience the acoustical<br />

transformation of the learning<br />

environment through the<br />

installation of a typical classroom<br />

ceiling system solution, using<br />

Ultima+ acoustic tiles (the first<br />

mineral ceiling tile range in Europe<br />

to win Cradle to Cradle<br />

certification), Blind Boxes, Axiom<br />

transitions, and Prelude 24 TLS<br />

suspension system .<br />

It makes it easy to see why 65%<br />

of teachers in a London South Bank<br />

University survey reported voice<br />

problems during their career – a<br />

point the VR experience also makes<br />

as well as the fact that up to 30%<br />

of what is said in classrooms is<br />

missed due to extraneous noise. The<br />

presentation also shows that a high<br />

light-reflecting ceiling can also help<br />

with eye strain and fatigue.<br />

Designed for specifiers to<br />

experience for themselves how to<br />

create a better and more sustainable<br />

learning environment, whether it is<br />

new-build or refurbishment, the VR<br />

experience will be joined on stand<br />

by the new education brochure and<br />

demonstrations of Armstrong’s<br />

online selector tool. This advises<br />

specifiers on the well-being<br />

requirements for a variety of school<br />

rooms including auditoriums,<br />

classrooms, gyms, cafes, lobbies and<br />

corridors.<br />

Case studies on the use of<br />

Armstrong solutions at UK schools<br />

including Ystalyfera Welsh Medium<br />

Comprehensive School in South<br />

Wales, Royal Holloway University of<br />

London and Parsons Tower at<br />

Newcastle College, will also be<br />

featured.<br />

More information is accessible via<br />

the Armstrong Ceilings website<br />

https://www.armstrongceilings.com<br />

/commercial/en-gb/.<br />

16 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS

Students to move to refurbished rooms<br />

following work by J Tomlinson<br />

SCHOOL BUILDING<br />

JTomlinson is undertaking £4m<br />

of refurbishment work on<br />

student accommodation blocks<br />

at the University of Warwick.<br />

The scheme is the second<br />

completed for the university by the<br />

Nottingham-based firm and follows<br />

a £1m refurbishment project at the<br />

Avon building on the Westwood<br />

Campus.<br />

In addition, the company has<br />

also won a £900,000 contract to<br />

replace windows at the university’s<br />

conference centre, Scarman, which<br />

began at the beginning of August.<br />

The latest project involves the<br />

full redecoration of around 250<br />

bedrooms and bathrooms, along<br />

with communal and circulation<br />

spaces, at two of the Arthur Vick<br />

accommodation blocks on the<br />

university’s main campus in<br />

Coventry. This scheme will see major<br />

improvement works undertaken<br />

within the halls of residence,<br />

including the installation of new<br />

aluminum windows and en-suite<br />

shower rooms, full rewiring of<br />

lighting, and new floor coverings<br />

throughout each block.<br />

It will also include the<br />

replacement of sanitary ware, new<br />

plumbing and extractor fans to ensuites,<br />

fire stopping works, small<br />

power, data cabling, sub-mains<br />

cabling and fire alarm works, along<br />

with a new heat exchanger and<br />

ancillary works to the mechanical<br />

plant.<br />

Work got under way in July and<br />

is expected to be completed ready<br />

for the start of the new term in<br />

early <strong>September</strong>, in accordance with<br />

a 10-week fast-track programme.<br />

The contract, which was won<br />

following a tender, is being delivered<br />

by J Tomlinson’s commercial<br />

refurbishment and regeneration<br />

teams.<br />

J Tomlinson’s construction<br />

director, Pete Woods, who heads the<br />

refurbishment team, said: “This is<br />

our second refurbishment project for<br />

the University of Warwick, and<br />

follows an earlier scheme at the<br />

Westwood Campus.<br />

“It is always a ringing<br />

endorsement of the standard of<br />

work achieved when a client<br />

appoints a second and subsequent<br />

contract, and J Tomlinson is<br />

delighted to once again be<br />

supporting the University of<br />

Warwick as it invests in and<br />

improves its facilities for students.”<br />

J Tomlinson, which also has a<br />

West Midlands office in Canwell,<br />

completed the refurbishment of the<br />

Avon building for the university in<br />

February this year. It included<br />

revamping a café and the Centre for<br />

Lifelong Learning, and creating an<br />

editing suite, a drama room, green<br />

room, family room, and toilets.<br />

www.jtomlinson.co.uk.<br />

Green light for Canon Green Campus development<br />

Amajor redevelopment project<br />

that will bring more than<br />

100 affordable homes to<br />

Salford has been given the<br />

green light. Salford Council has today<br />

(Thursday, <strong>September</strong> 6) approved<br />

plans for the multi-million pound<br />

Canon Green Campus development<br />

on Canon Green Drive in Trinity.<br />

The £22.5m project by Salford<br />

housing association Salix Homes will<br />

see ageing tower block Canon Green<br />

Court completely transformed and<br />

modernised, along with neighbouring<br />

apartment block Westminster House,<br />

which will undergo an external<br />

facelift.<br />

As part of the development, a<br />

brand new 11-storey apartment block<br />

will be built within the grounds of<br />

the expansive site, comprising of 108<br />

one and two-bedroom affordable<br />

apartments.<br />

Lee Sugden, chief executive at<br />

Salix Homes, said: ‘We are delighted<br />

that Salford Council has given the<br />

green light for our Canon Green<br />

Campus development – this is a<br />

proud moment for Salix Homes.<br />

‘At the time of a national housing<br />

crisis, this project will not only<br />

refurbish and modernise the homes<br />

of the existing residents, but it will<br />

Artist’s impressions of how the new Canon Green Campus development will look.<br />

also deliver desperately-needed new<br />

and affordable housing in Salford.<br />

‘We have worked incredibly<br />

closely with the existing residents to<br />

develop these proposals and we are<br />

confident our plans will deliver the<br />

essential improvement work they<br />

have been calling for and help create,<br />

safe and modern homes we can all be<br />

proud of for generations to come.’<br />

The refurbishment at Canon<br />

Green Court, which was built during<br />

the 1960s, includes new kitchens,<br />

bathrooms, heating systems, sprinkler<br />

systems and exterior re-facing and<br />

insulation.<br />

alix Homes, which owns more<br />

than 8,000 homes across Salford, will<br />

now appoint a contractor to carry<br />

out the project and it’s hoped that<br />

work will start on site later this year.<br />

www.salixhomes.org<br />

Canon Green Court as it is now.<br />

REFURBISHMENT PROJECTS, SEPTEMBER <strong>2018</strong> 17

INSULATION<br />

Flat Out performance<br />

by Adrian Pargeter, Head of Technical and Product Development, Kingspan Insulation Limited<br />

As we head into the wetter<br />

winter months, the nation’s<br />

roofs are once again set to be<br />

put to the test. This can<br />

prove to be a particularly challenging<br />

time for buildings with flat roofs, with<br />

water ponding occurring either<br />

because the existing surface has<br />

become damaged or an insufficient<br />

fall was introduced when the building<br />

was first constructed. When<br />

refurbishing these surfaces,<br />

contractors should not only look to<br />

address drainage issues but also to<br />

consider whether improvements can<br />

be made to the thermal performance<br />

of the element. One of the simplest<br />

ways to achieve both of these aims is<br />

by installing a tapered insulation<br />

system. The latest systems now<br />

incorporate phenolic insulation,<br />

allowing the desired U-value to be<br />

met with a slimmer build-up.<br />

<strong>Refurb</strong>ishment Requirements<br />

Flat roofs are defined in BS 6229:<br />

2003 as “having a pitch less than 10o<br />

to the horizontal”, although some<br />

within the industry extend this<br />

definition to pitches of up to 15o.<br />

The British Standard recommends<br />

that flat roofs should have a design<br />

fall of 1:40 and a minimum “as-built”<br />

fall of 1:80. These falls are crucial as<br />

failure to effectively channel<br />

rainwater run-off can result in water<br />

ponding. If untreated, this can lead to<br />

a number of further issues including<br />

alkaline formation and mould growth.<br />

The additional roof loading can cause<br />

further deflection, aggravating the<br />

issue and potentially reducing the<br />

design life of the roof.<br />

Poorly insulated flat roofs can also<br />

act as a significant source of heat loss<br />

from a property, so it makes sense to<br />

raise the thermal performance of<br />

these surfaces as part of any work.<br />

Typically, this can<br />

either be achieved<br />

with a warm roof<br />

construction,<br />

where the<br />

insulation layer is<br />

installed above the<br />

deck, or a cold<br />

roof construction,<br />

where insulation is<br />

installed between<br />

and below the roof<br />

rafters with a<br />

minimum air gap<br />

of 50mm between<br />

the insulation and<br />

the deck.<br />

Recently, a<br />

trend has emerged<br />

where installers fit<br />

a hybrid solution<br />

with a thin layer<br />

of insulation above<br />

the deck and the<br />

rest below. Whilst<br />

in principle this may seem like a<br />

sensible way to reduce the above-deck<br />

construction depth whilst eliminating<br />

the need for a below deck ventilation<br />

gap, it can lead to significant longterm<br />

issues.<br />

In a warm roof, condensation is<br />

prevented by keeping the deck at a<br />

warm temperature, therefore there is<br />

no cold surface for the condensation<br />

to form on. In a cold roof,<br />

condensation is prevented as the<br />

ventilation current takes away the<br />

moisture vapour before it can form as<br />

condensation.<br />

With the hybrid solution, however,<br />

the above-deck insulation layer often<br />

offers insufficient performance to<br />

keep the deck warm and as the<br />

ventilation void is absent there is no<br />

way to remove the moisture before it<br />

forms condensation. This construction<br />

should only be considered if a full<br />

condensation risk analysis is carried<br />

out and even then, it will rely on an<br />

almost perfect level of workmanship.<br />

Kingspan Thermataper TT44-K and TT47-K incorporate phenolic<br />

packer boards, allowing the desired drainage and thermal<br />

performance to be achieved with a reduced system thickness<br />

compared with PIR only solutions.<br />

Tapered insulation systems can<br />

provide a better<br />

alternative,<br />

delivering<br />

excellent drainage<br />

and thermal<br />

performance in a<br />

single solution.<br />

Insulated Fall<br />

Tapered<br />

systems typically<br />

comprise sloped<br />

tapered boards, hip<br />

and valley boards<br />

and flat packer<br />

boards. They can<br />

be installed above<br />

concrete and<br />

metal decks either<br />

with standard waterproofing or as<br />

part of a green roof system.<br />

The systems offer a number of<br />

practical benefits for contractors.<br />

Unlike screed to fall solutions, tapered<br />

insulation systems can be fitted with a<br />

dry installation process, meaning no<br />

time is lost waiting for the surface to<br />

dry. In many cases, these systems can<br />

be fitted above the existing roof<br />

surface, further streamlining project<br />

time scales. They can also weigh as<br />

little as 1.5% that of a screed to fall<br />

system – removing structural loading<br />

concerns.<br />

Tapered systems are typically<br />

manufactured from rigid insulation<br />

such as EPS (expanded polystyrene),<br />

XPS (extruded polystyrene) or<br />

Polyisocyanurate (PIR). For enhanced<br />

thermal performance, systems are<br />

now available which combine PIR<br />

sloped, hip and valley boards with<br />

Phenolic insulation packer boards with<br />

thermal conductivities as low as 0.018<br />

W/m·K. This enhanced level of thermal<br />

performance can allow desired U-<br />

values to be met with thickness<br />

savings of 20 – 40 mm, depending on<br />

the individual scheme and build-up,<br />

when compared with a full PIR<br />

system.<br />

Kingspan Insulation provide a tapered roofing design<br />

service to ensure the most cost-effective solution is<br />

identified.<br />

Some suppliers also provide a<br />

tapered roofing design service to<br />

support installers. The system boards<br />

are provided with a clear layout<br />

tailored to the specific design of the<br />

roof. This allows a simple installation<br />

and ensures the desired level of<br />

rainwater run-off and insulation<br />

performance to be achieved with a<br />

minimal construction depth. Some<br />

also include a full condensation risk<br />

analysis as part of this process.<br />

Designed to Last<br />

As with any refurbishment work,<br />

improvements to flat roofs should<br />

provide a lasting resolution to the<br />

underlying issue, not a quick patch<br />

which allow it to reoccur at a later<br />

date. Combined PIR and Phenolic<br />

tapered insulation systems can be<br />

quickly and easily installed whilst also<br />

delivering lasting improvements to<br />

roof drainage and the overall energy<br />

performance of the building.<br />

Kingspan Thermataper systems combine insulation and drainage in a<br />

single, lightweight solution allowing simple, fast-track installations.<br />