You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Schwerpunkte<br />

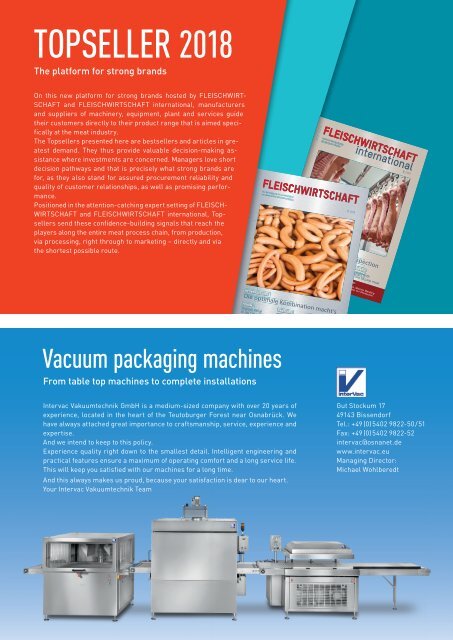

<strong>TOPSELLER</strong> <strong>2018</strong><br />

The platform for strong brands<br />

On this new platform for strong brands hosted by FLEISCHWIRT-<br />

SCHAFT and FLEISCHWIRTSCHAFT international, manufacturers<br />

and suppliers of machinery, equipment, plant and services guide<br />

their customers directly to their product range that is aimed specifically<br />

at the meat industry.<br />

The Topsellers presented here are bestsellers and articles in greatest<br />

demand. They thus provide valuable decision-making assistance<br />

where investments are concerned. Managers love short<br />

decision pathways and that is precisely what strong brands are<br />

for, as they also stand for assured procurement reliability and<br />

quality of customer relationships, as well as promising performance.<br />

Positioned in the attention-catching expert setting of FLEISCH-<br />

WIRTSCHAFT and FLEISCHWIRTSCHAFT international, Topsellers<br />

send these confidence-building signals that reach the<br />

players along the entire meat process chain, from production,<br />

via processing, right through to marketing – directly and via<br />

the shortest possible route.<br />

<strong>2018</strong><br />

7<br />

**FONT**<br />

98. Jahrgang _ D2867E<br />

Von der Erzeugung bis zur Vermarktung<br />

von Lebensmitteln tierischen Ursprungs<br />

<strong>2018</strong><br />

2<br />

international<br />

Animal Welfare<br />

Volume 33 _ D 42804 F<br />

Journal for meat production,<br />

processing and research international<br />

Modernization of meat inspection<br />

Processing<br />

Reducing fat for<br />

improving health<br />

Food Safety<br />

7_<strong>2018</strong><br />

2_<strong>2018</strong><br />

FLEISCHWIRTSCHAFT<br />

Identification of<br />

meatborne germs<br />

inspection<br />

Research<br />

Sausages with<br />

addition of carp meat<br />

Topics<br />

Mixing,<br />

Mixing, Mincing, Blending<br />

Hygiene and Disinfection<br />

Hydrokolloide<br />

Die optimale Kombination macht‘s<br />

Forum<br />

Digitale Reise<br />

in die Datenwolke<br />

Prozesse<br />

Walgen statt<br />

Tumbeln<br />

Forschung<br />

Pilze als alternative<br />

Proteinquelle<br />

Vacuum packaging machines<br />

From table top machines to complete installations<br />

Schneidtechnik<br />

Kühl und Transportlogistik<br />

Intervac Vakuumtechnik GmbH is a medium-sized company with over 20 years of<br />

experience, located in the heart of the Teutoburger Forest near Osnabrück. We<br />

have always attached great importance to craftsmanship, service, experience and<br />

expertise.<br />

And we intend to keep to this policy.<br />

Experience quality right down to the smallest detail. Intelligent engineering and<br />

practical features ensure a maximum of operating comfort and a long service life.<br />

This will keep you satisfied with our machines for a long time.<br />

And this always makes us proud, because your satisfaction is dear to our heart.<br />

Your Intervac Vakuumtechnik Team<br />

Gut Stockum 17<br />

49143 Bissendorf<br />

Tel.: +49 (0) 5402 9822-50 / 51<br />

Fax: +49 (0) 5402 9822-52<br />

intervac@osnanet.de<br />

www.intervac.eu<br />

Managing Director:<br />

Michael Wohlberedt

Clean and hygienic processing of up to<br />

22 tons of fresh meat per hour<br />

Industrial meat processing in particular requires exceptionally powerful solutions which<br />

can continuously and effortlessly produce high output coupled with excellent quality. The<br />

AW K 280 automatic grinder by K + G Wetter, specially designed for stringent industry<br />

requirements, delivers peak performance day after day. With a hopper volume of<br />

635 litres, the robust and silent grinder easily processes up to 22 tons of fresh meat<br />

per hour or frozen meat. For standard blocks (60 x 40 x 25 cm) it has a capacity of<br />

3.5 to 8 t/h depending on end-hole plate size and product, and for pre-cut frozen<br />

meat up to 16 t/h. The result is a clean and clear cut without smearing.<br />

The industrial grinder also scores points with additional details that make<br />

the job significantly easier. One innovation is the optimised counter<br />

bearing of the feeder worm of the machine, which is now attached to<br />

the body of the machine with hinges. Instead of having to remove the<br />

counter bearing, it can be opened easily without tools. It only takes<br />

a few simple steps to move the feeder worm forward and clean it.<br />

What’s more, a special flushing connector means that the area<br />

behind the worm’s drive socket can be cleaned quickly and<br />

thoroughly. Thus, when it comes to hygiene, the machine<br />

also guarantees absolute safety.<br />

www.kgwetter.de/en<br />

K+G Wetter GmbH<br />

Goldbergstraße 21, 35216 Biedenkopf-Breidenstein<br />

As one of the world’s largest suppliers of processing lines for the<br />

fast food/convenience industry, Alco-food-machines GmbH & Co. KG<br />

places great emphasis on state-of-the-art technology to ensure<br />

quality products. Function and quality are their top priorities, but<br />

consistent and practical research has also made alco successful<br />

both locally and abroad.<br />

Their machine portfolio ranges from the schnitzel flattening<br />

machines to the blenders, from mincers to various techniques for<br />

cutting, steaking and breading. From cooking, roasting, frying to<br />

freezing and other thermal processes.<br />

It’s not just the highest technical quality and constant expansion of<br />

the machine portfolio that guarantees the company’s success, the<br />

family structures, which turn out to be a competitive advantage,<br />

also play a major role.<br />

Individual customer requests are often considered when planning<br />

production lines and implemented during production. The Bad Iburg<br />

company‘s strength is highly regarded by well-known customers<br />

at home and abroad.<br />

Alco-food-machines GmbH & Co. KG<br />

Kreienbrink 3 + 5<br />

49186 Bad Iburg<br />

Germany<br />

Telefon +49 (0) 5403 79 33-0<br />

Telefax +49 (0) 5403 79 33-33<br />

info@alco-food.com<br />

www.alco-food.com<br />

grinding<br />

mixing<br />

predusting<br />

frying<br />

forming<br />

Convenience-Line<br />

breading<br />

cooking<br />

cooling